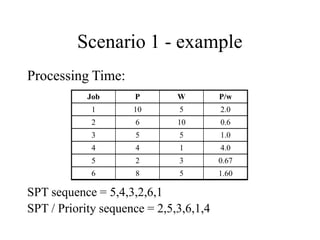

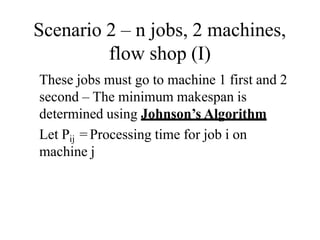

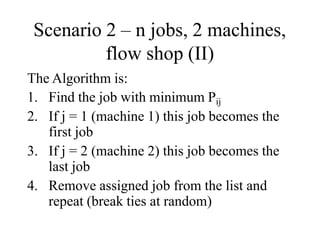

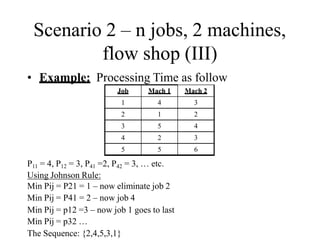

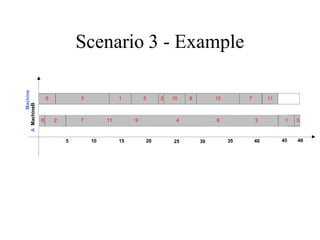

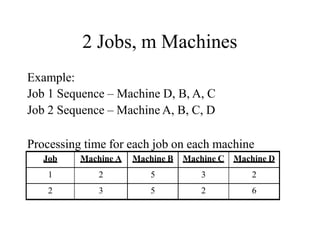

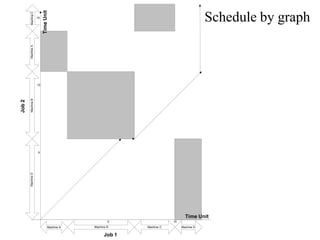

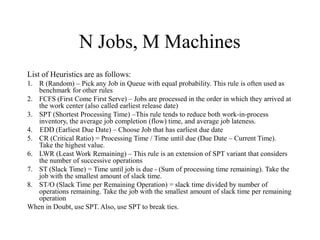

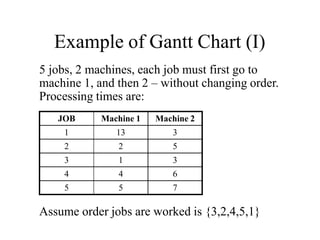

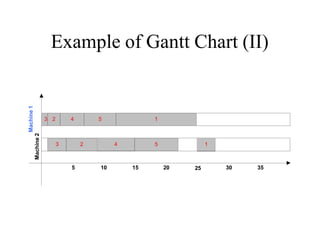

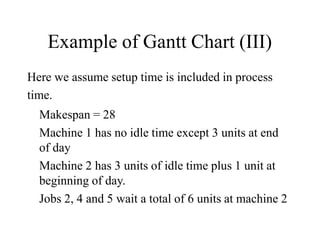

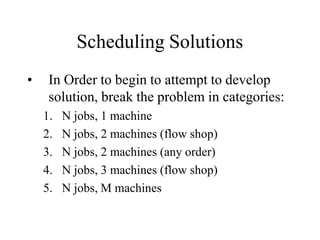

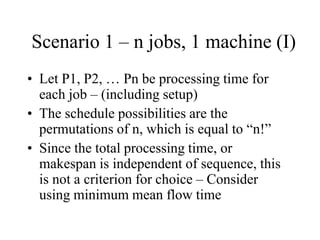

This document discusses job shop scheduling, which involves scheduling jobs at general purpose work stations. It describes factors like arrival patterns, number of machines, work sequences, and performance criteria. Two common arrival patterns are static and dynamic. Work sequences can be fixed or random. Performance is often evaluated based on makespan (total time) and machine utilization. Gantt charts are used to graphically display schedules. Several scenarios for job shop scheduling are presented, including strategies for 1 machine, flow shops with 2 machines, and systems with multiple jobs and machines. Heuristics like shortest processing time are commonly used to generate schedules.

![Scenario 1 – n jobs, 1 machine (II)

Mean flow time for n jobs:

k

Flow time for job in kth position is:

F[k] P[i]

i1

n n

n n k

F k1

k1 i1

F[k] P[i]

n

(n i 1)Pi

F i1

n](https://image.slidesharecdn.com/jobshopscheduling-230830082059-1f699722/85/Job-Shop-Scheduling-pptx-13-320.jpg)

![Scenario 1 – n jobs, 1 machine (III)

It can be proven that F is minimized by

taking jobs in order of shortest processing

time [SPT]

That is order by increasing P, so that

P[1] P[2] P[3] ... P[n]](https://image.slidesharecdn.com/jobshopscheduling-230830082059-1f699722/85/Job-Shop-Scheduling-pptx-14-320.jpg)

![Scenario 1 – n jobs, 1 machine (IV)

Provide numerical weighting to jobs by

priority

(w) – higher w, more important then

and jobs are sequenced by:

n

n

wi F[i]

i1

w

F

w[n]

...

P[n]

P[1]

P[2]

P[3]

w[1] w[2] w[3]](https://image.slidesharecdn.com/jobshopscheduling-230830082059-1f699722/85/Job-Shop-Scheduling-pptx-15-320.jpg)