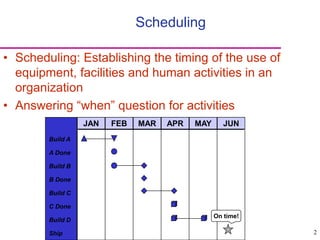

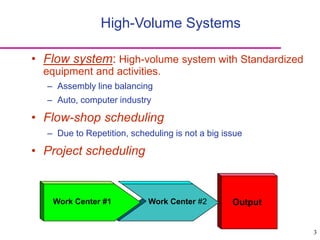

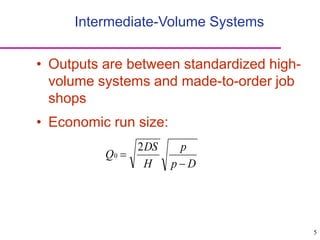

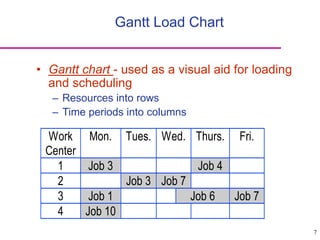

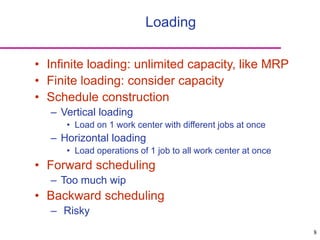

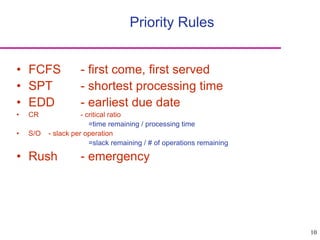

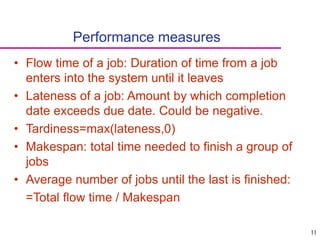

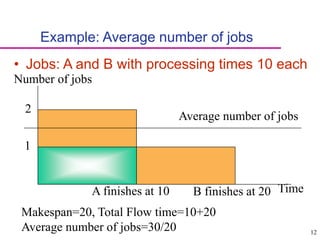

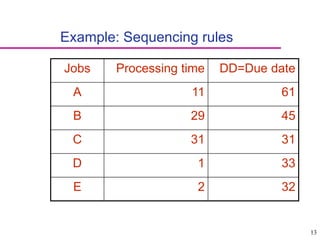

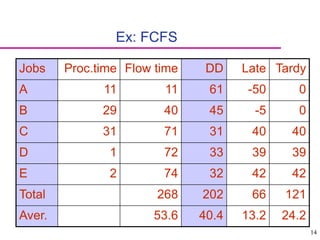

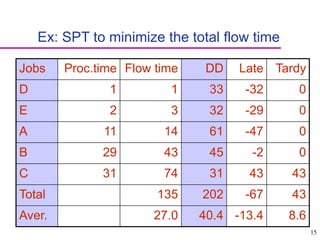

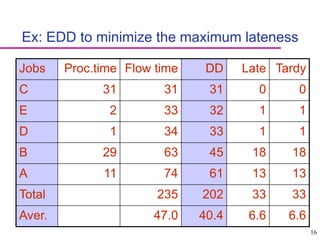

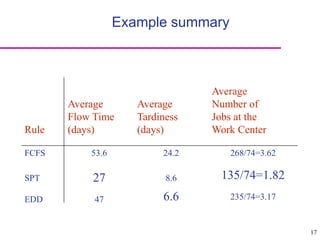

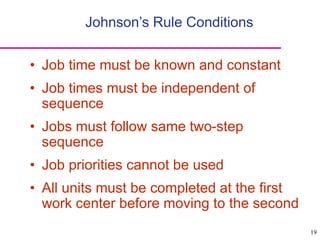

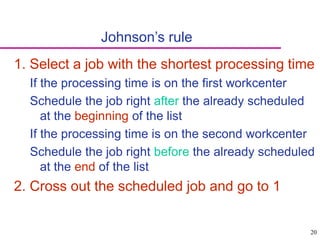

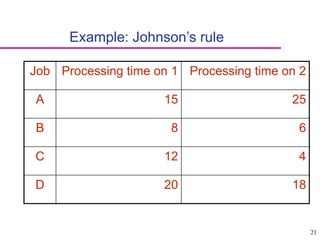

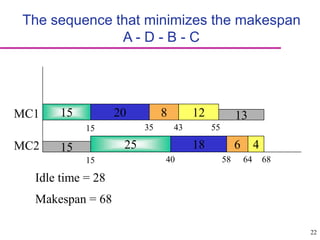

This document discusses various scheduling concepts and techniques. It begins by defining scheduling as establishing the timing of activities and answering the "when" question. It then covers scheduling approaches for high, intermediate, and low volume production systems. Key concepts covered include flow shop scheduling, project scheduling, priority rules, performance measures, and sequencing techniques like Johnson's rule. The document provides examples to illustrate different scheduling methods and how they impact metrics like flow time, tardiness, and makespan.