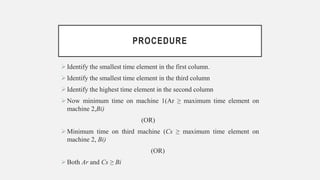

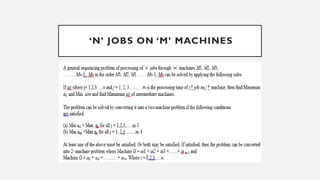

The document discusses sequencing models for production processes involving multiple jobs and machines. It defines sequencing as finding the optimal order of jobs to minimize total processing time. The objective is to determine the best sequence of jobs across machines. It provides assumptions of the models and describes different types of sequencing problems involving various numbers of jobs and machines. Solution methods discussed include Gantt charts and converting problems with more than two machines into equivalent two-machine problems.