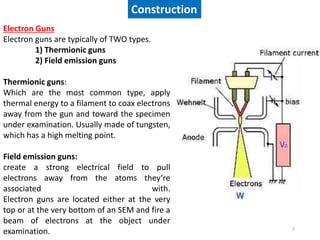

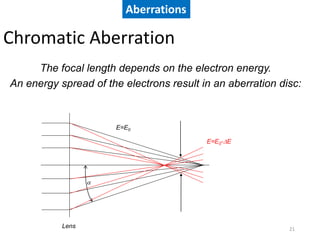

The document provides information about scanning electron microscopes (SEMs). It describes that SEMs produce images of samples by scanning them with a focused beam of electrons, and electrons interact with atoms in the sample providing information about surface topography and composition. Key components of SEMs are electron guns, condenser lenses, objective apertures, scan coils, detectors, and vacuum chambers. SEMs have various applications in science and industry for examining surface features, fractures, and compositions at high magnifications.