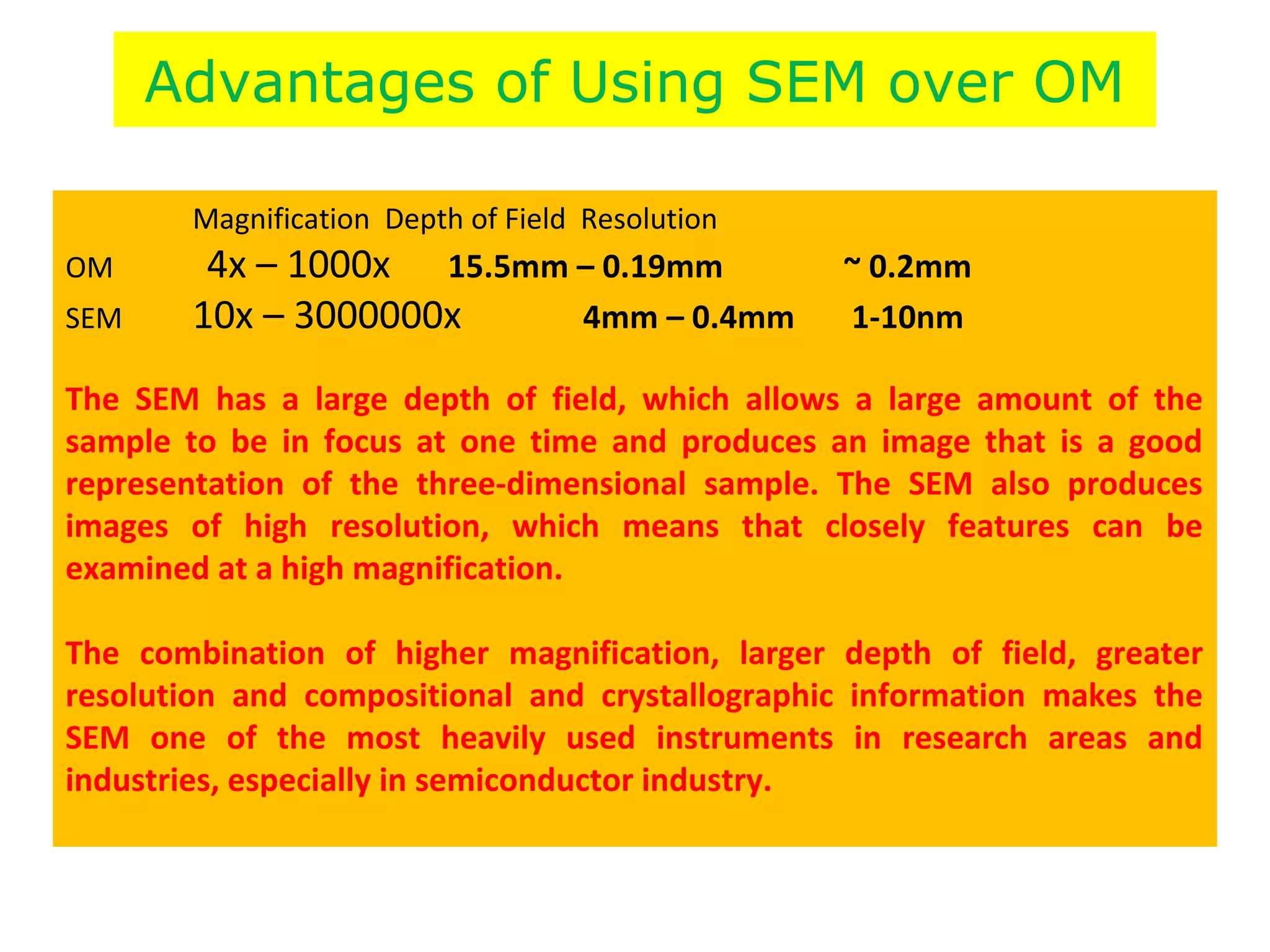

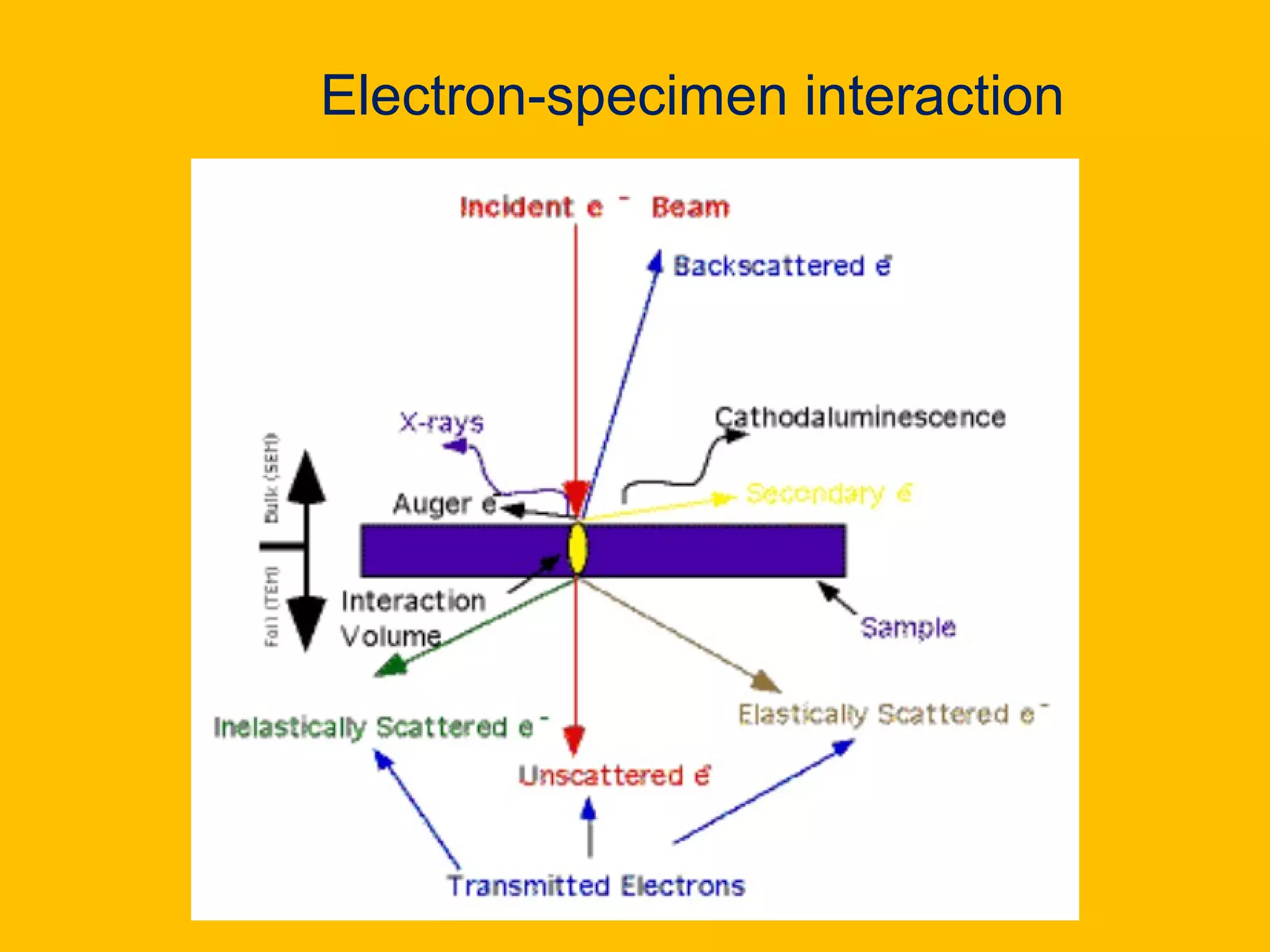

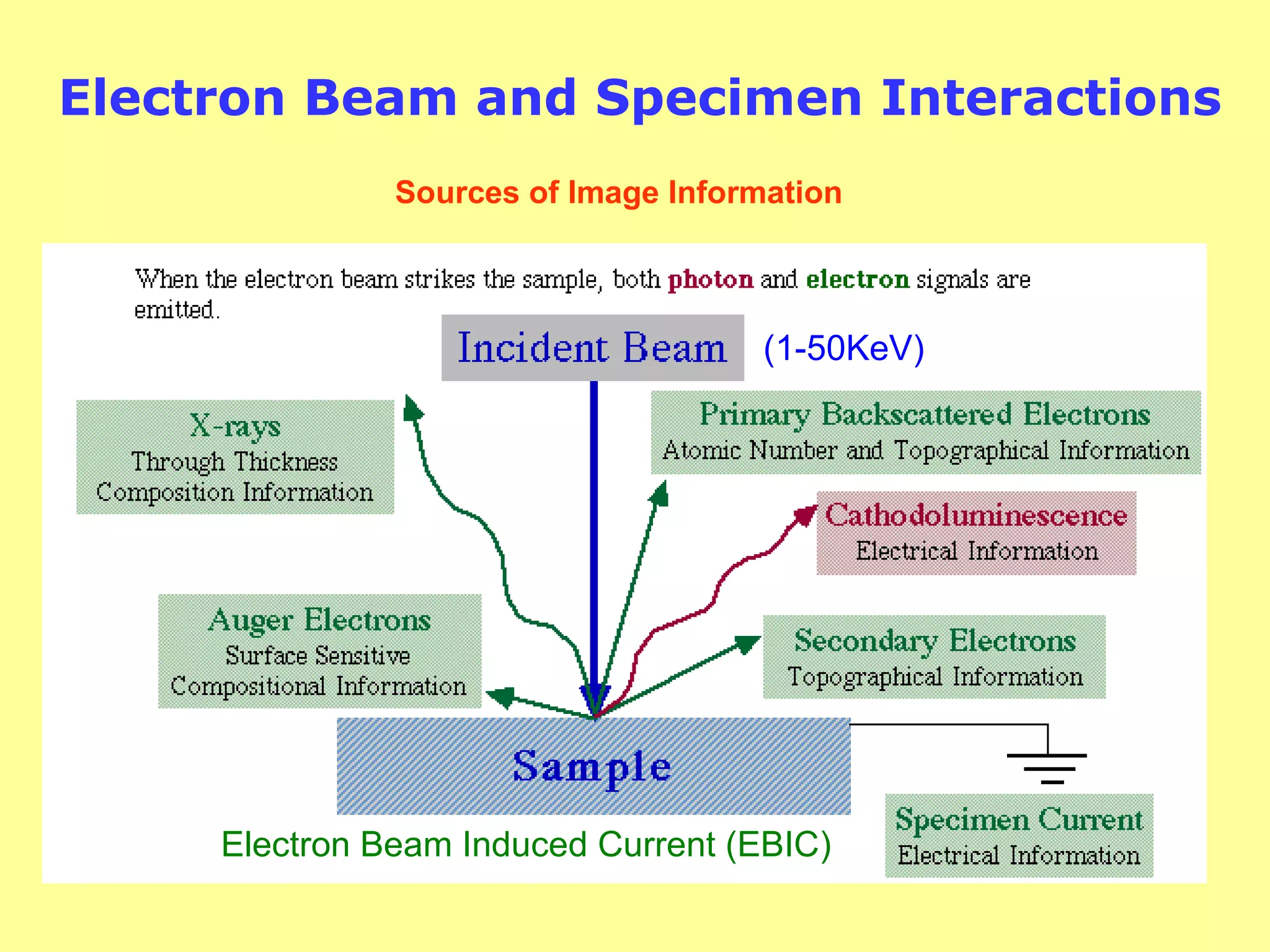

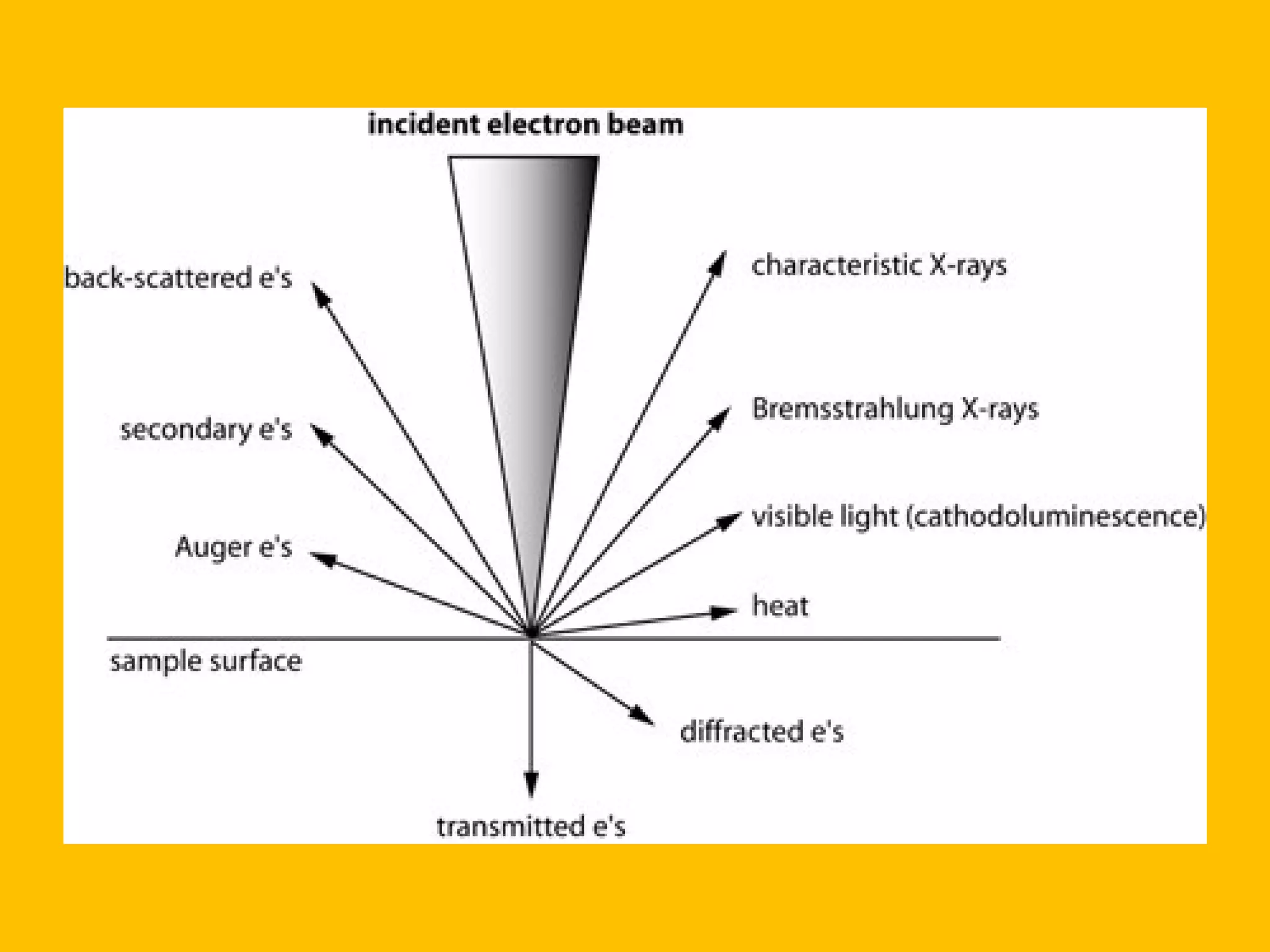

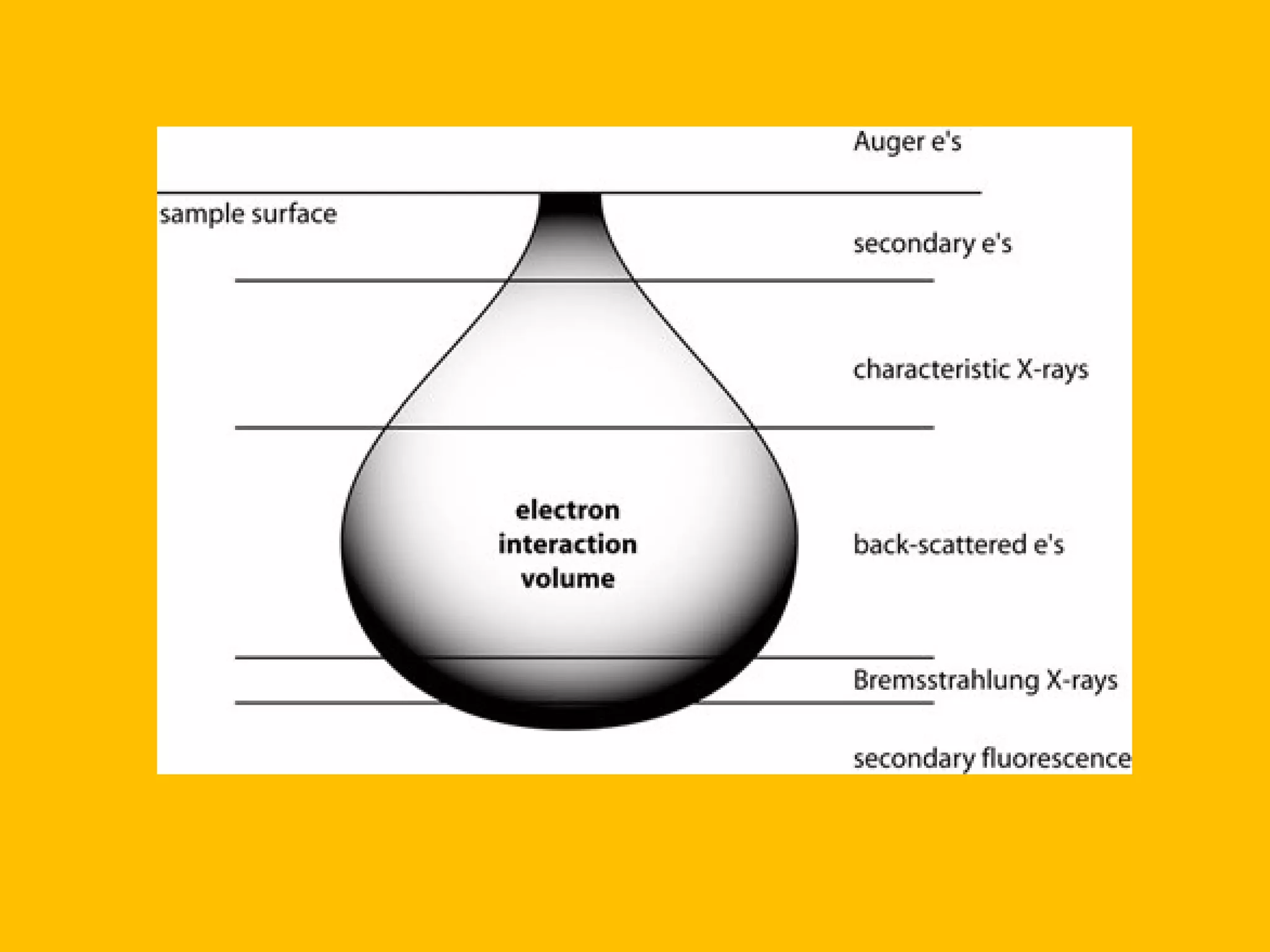

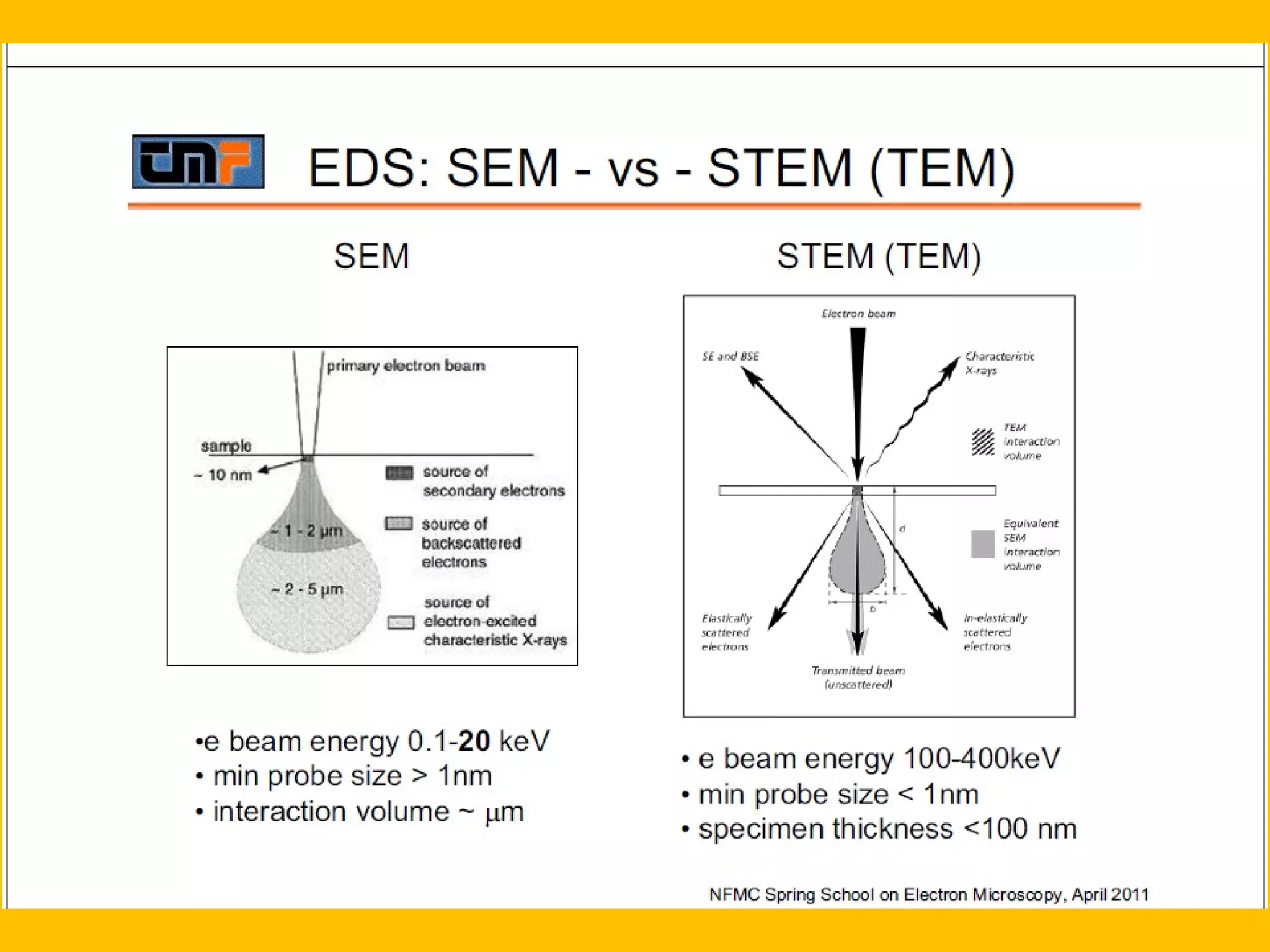

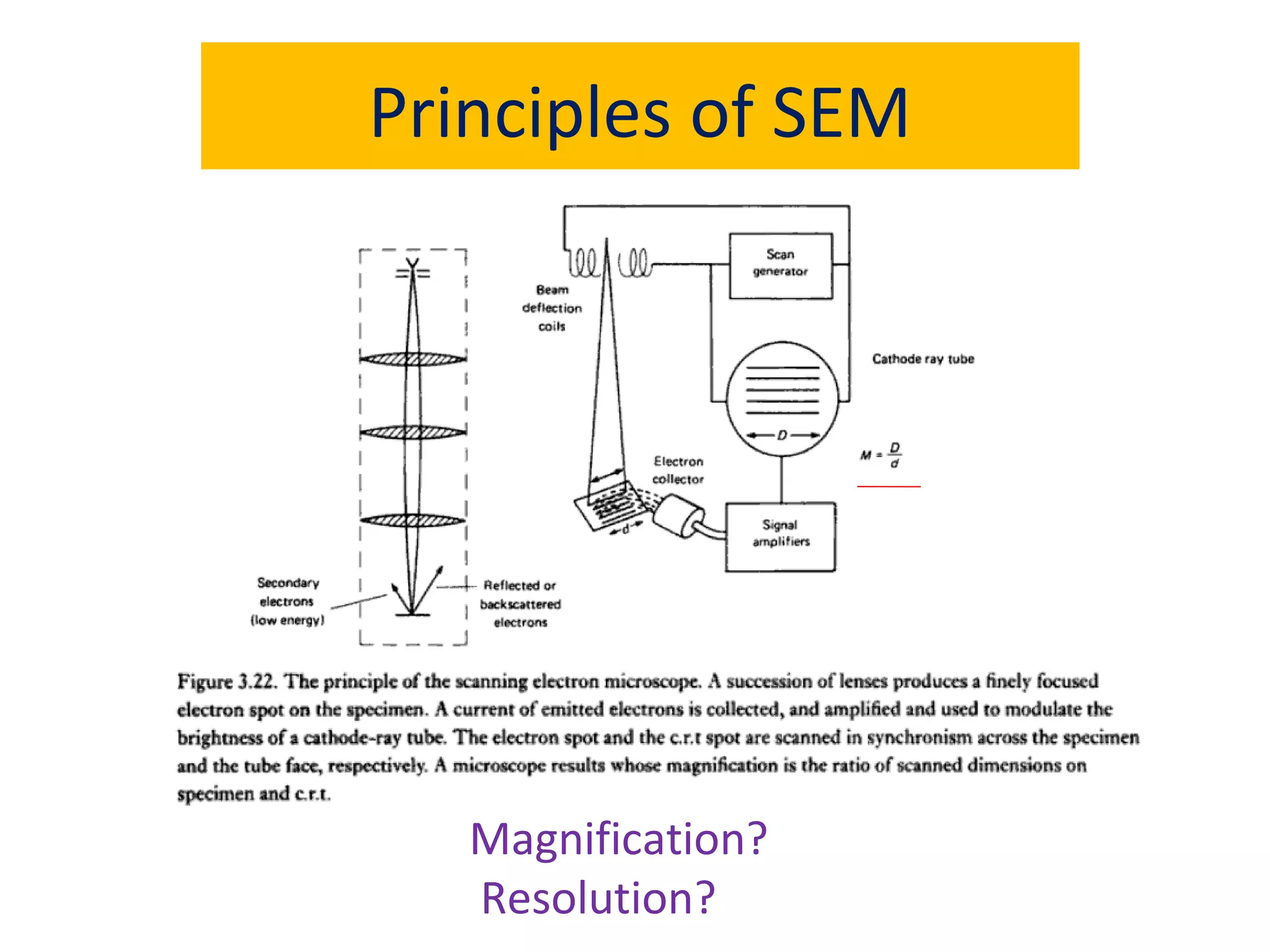

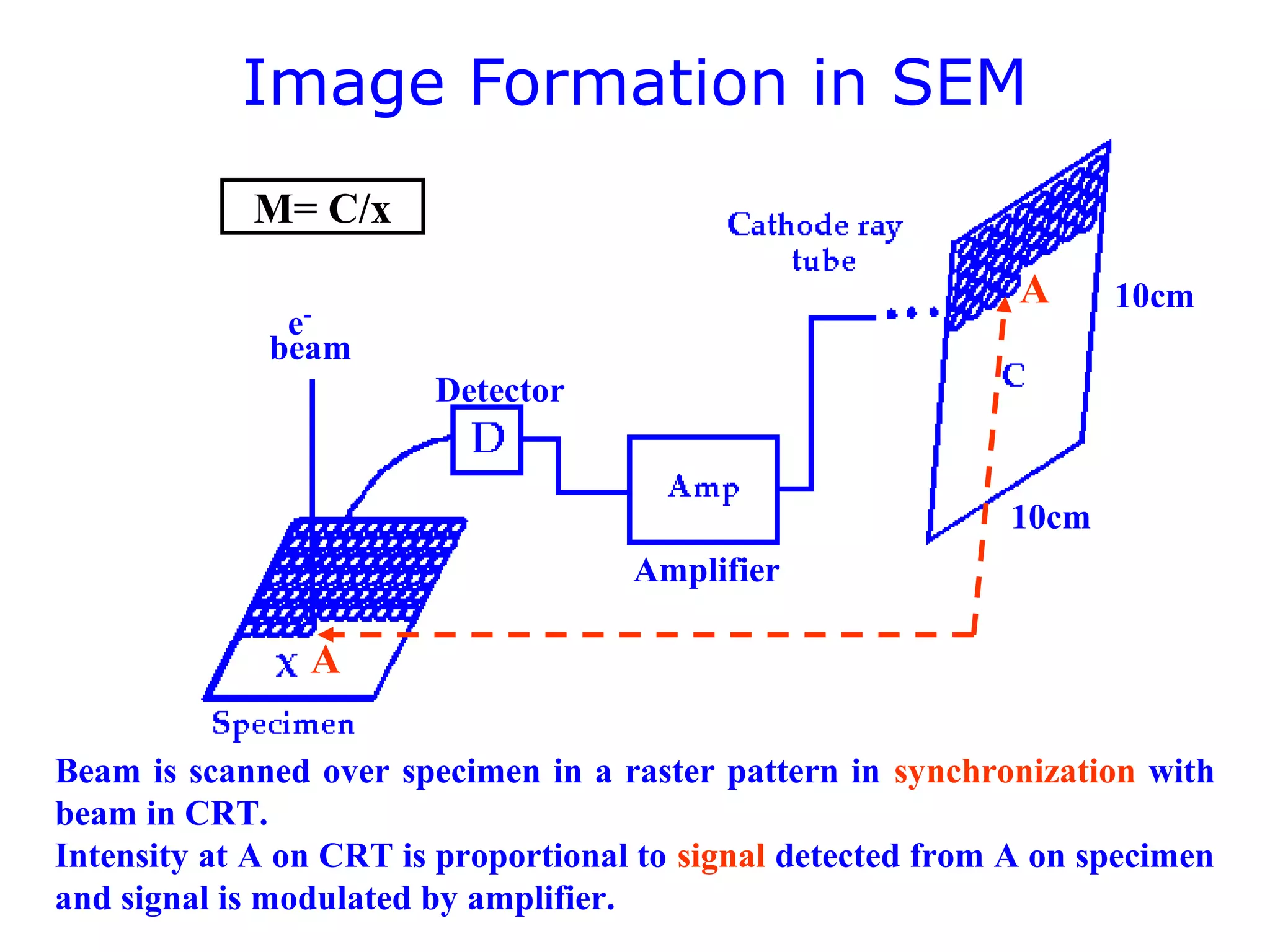

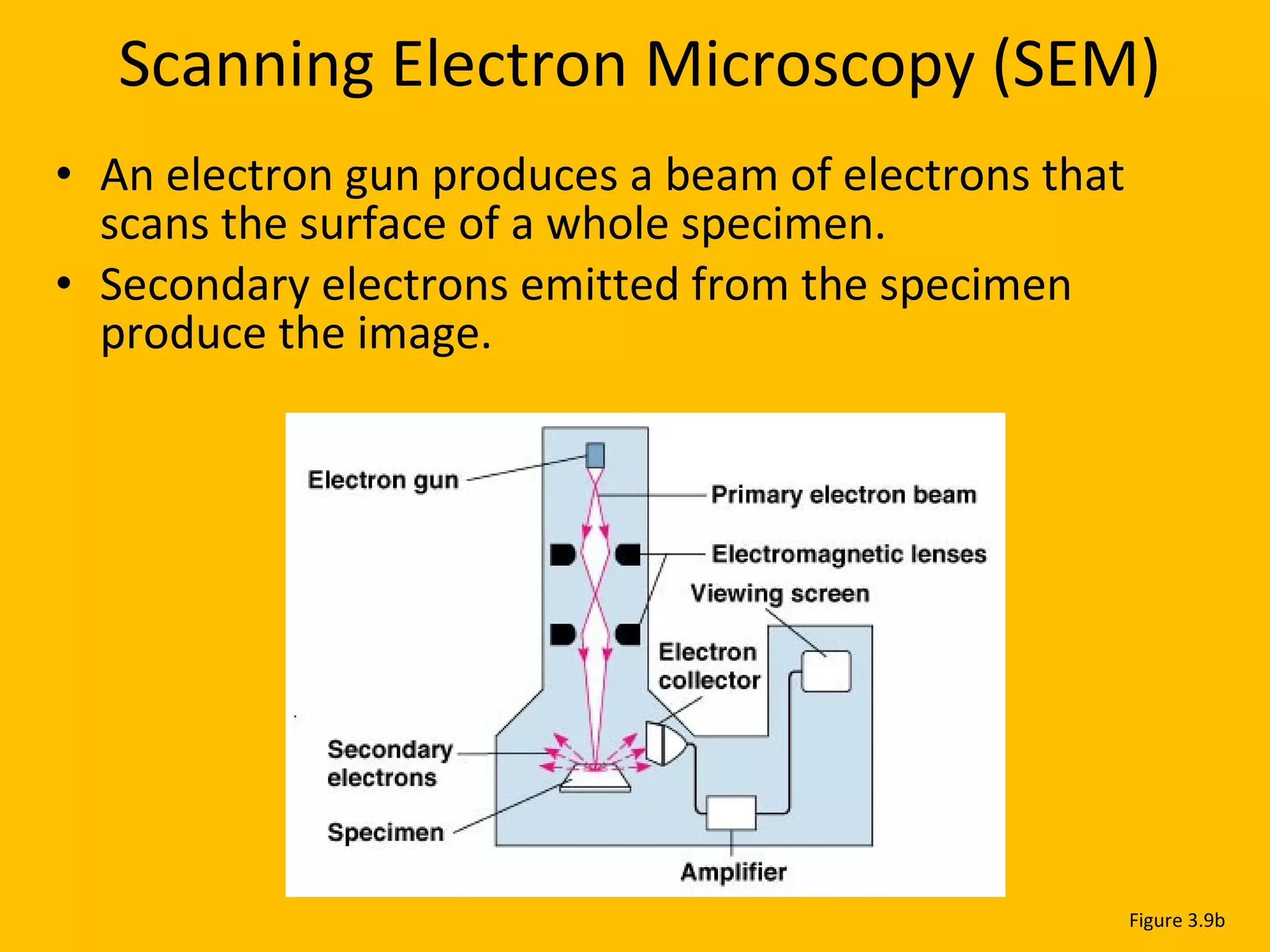

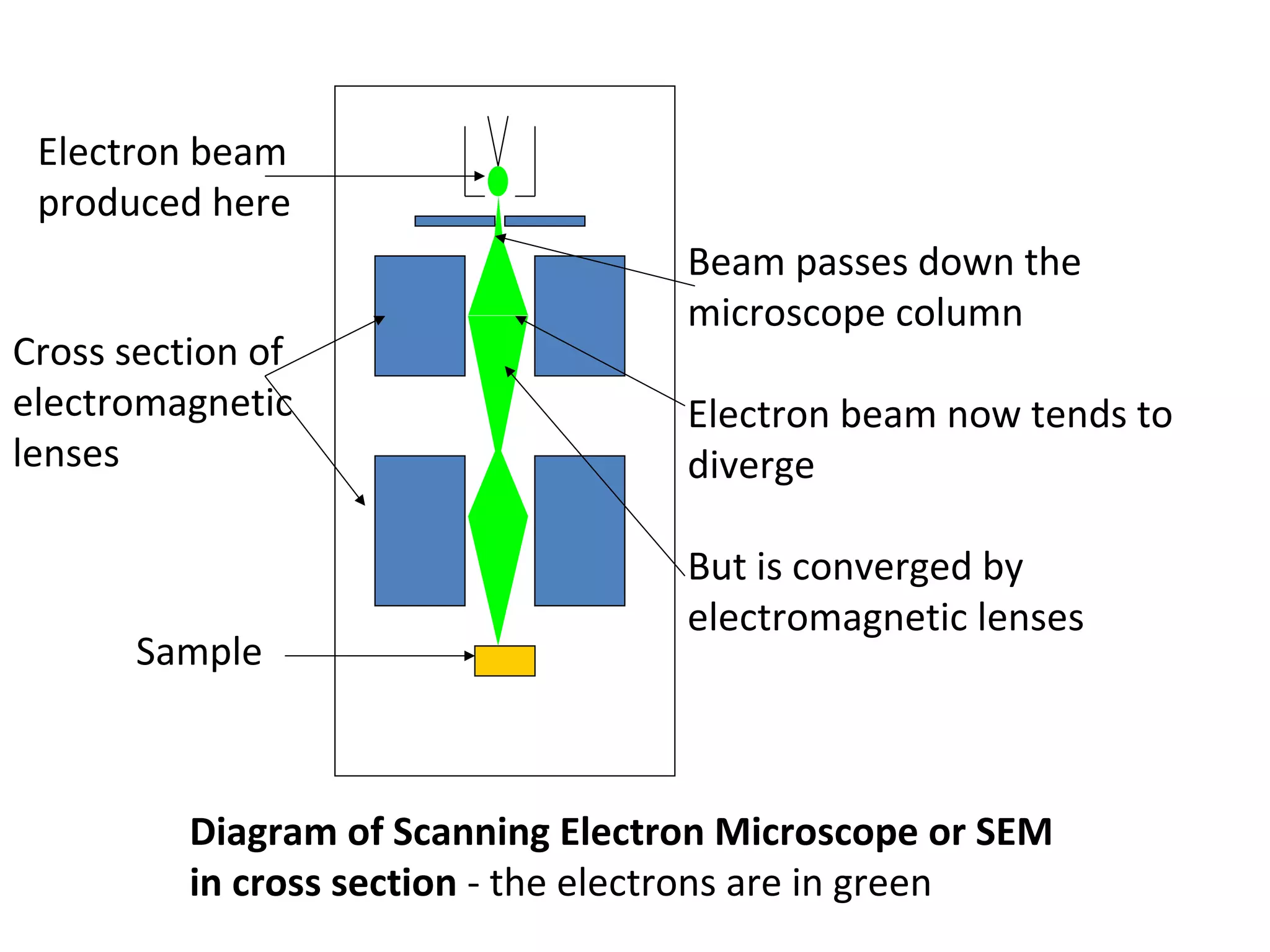

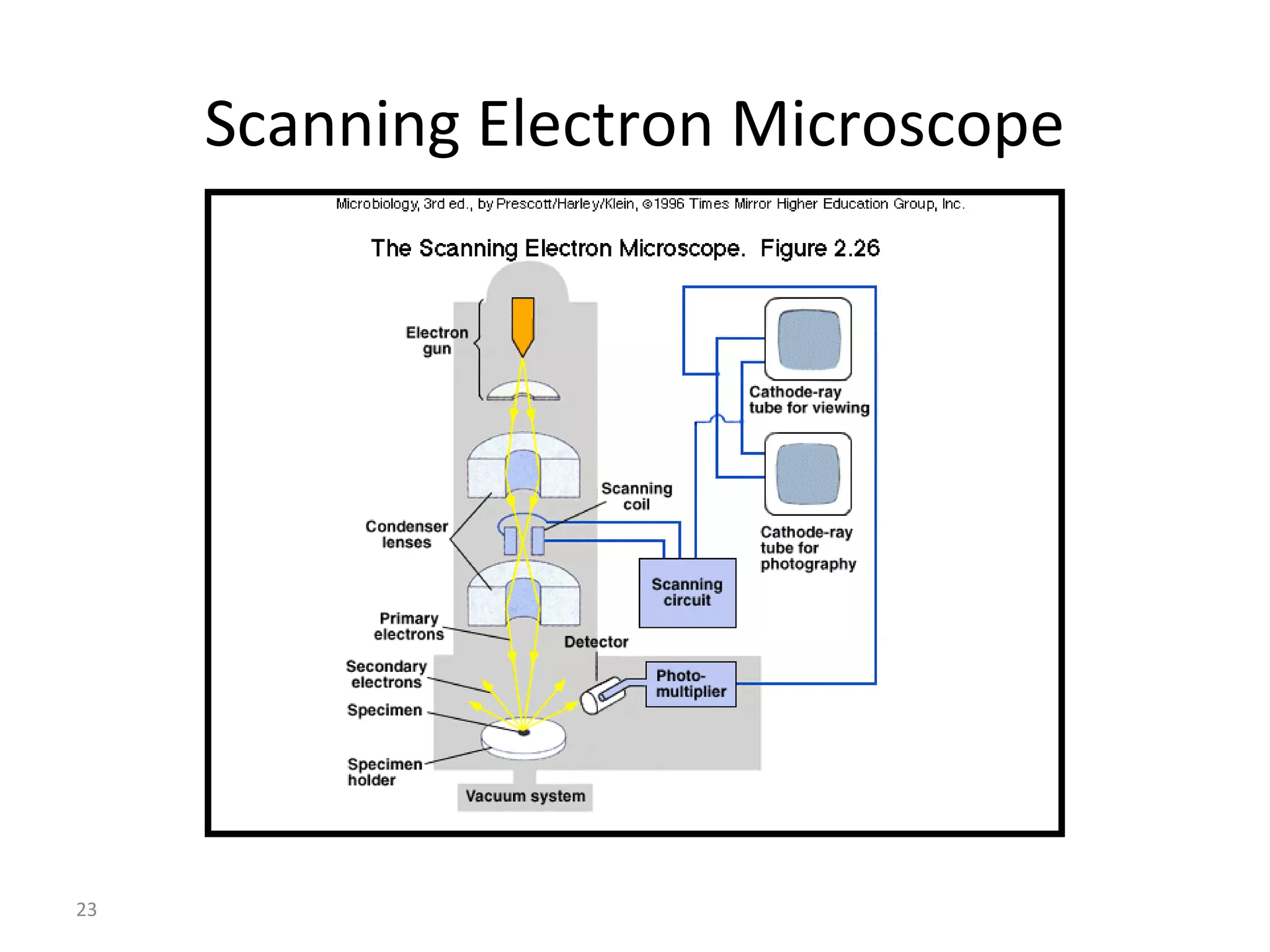

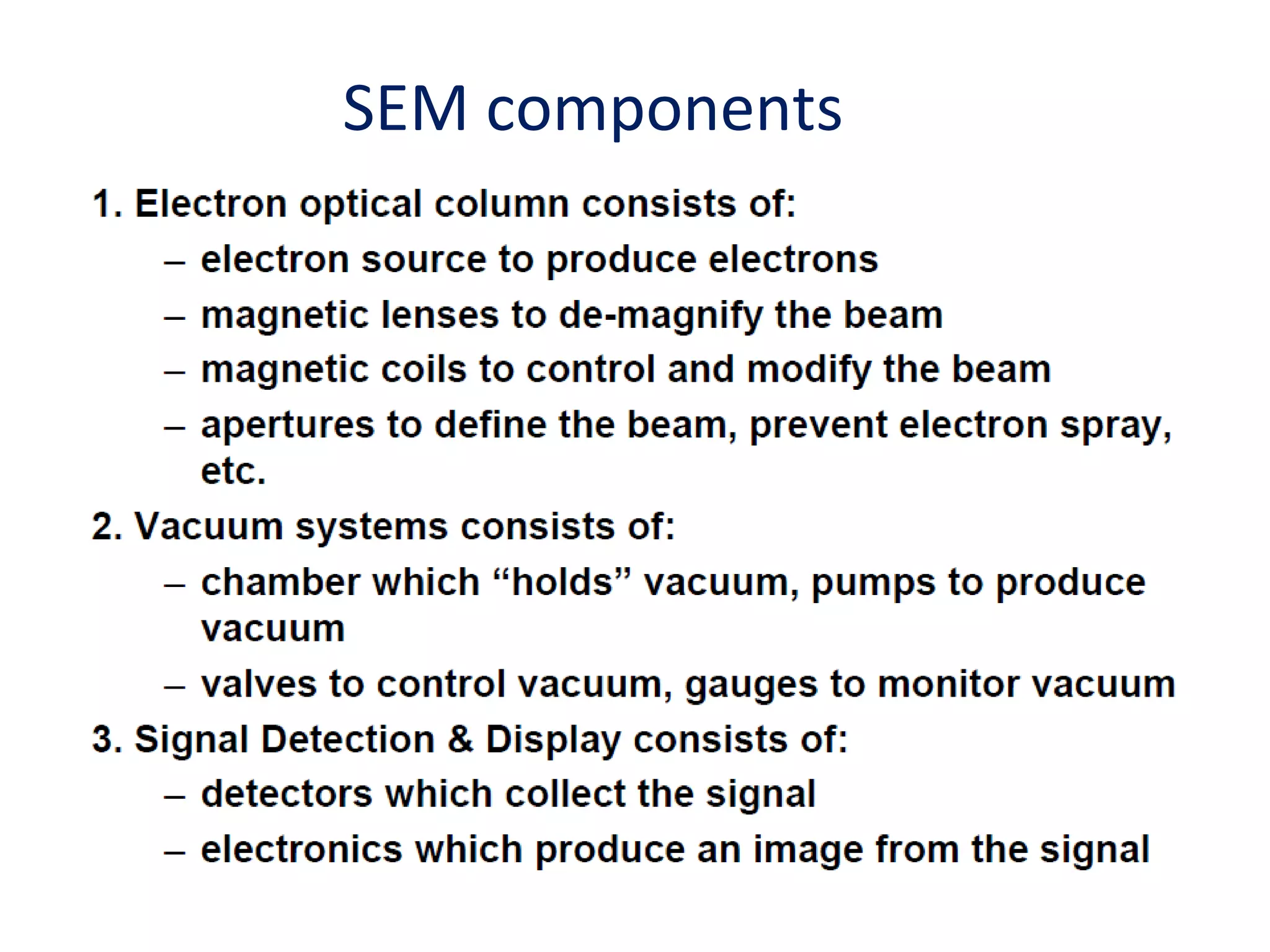

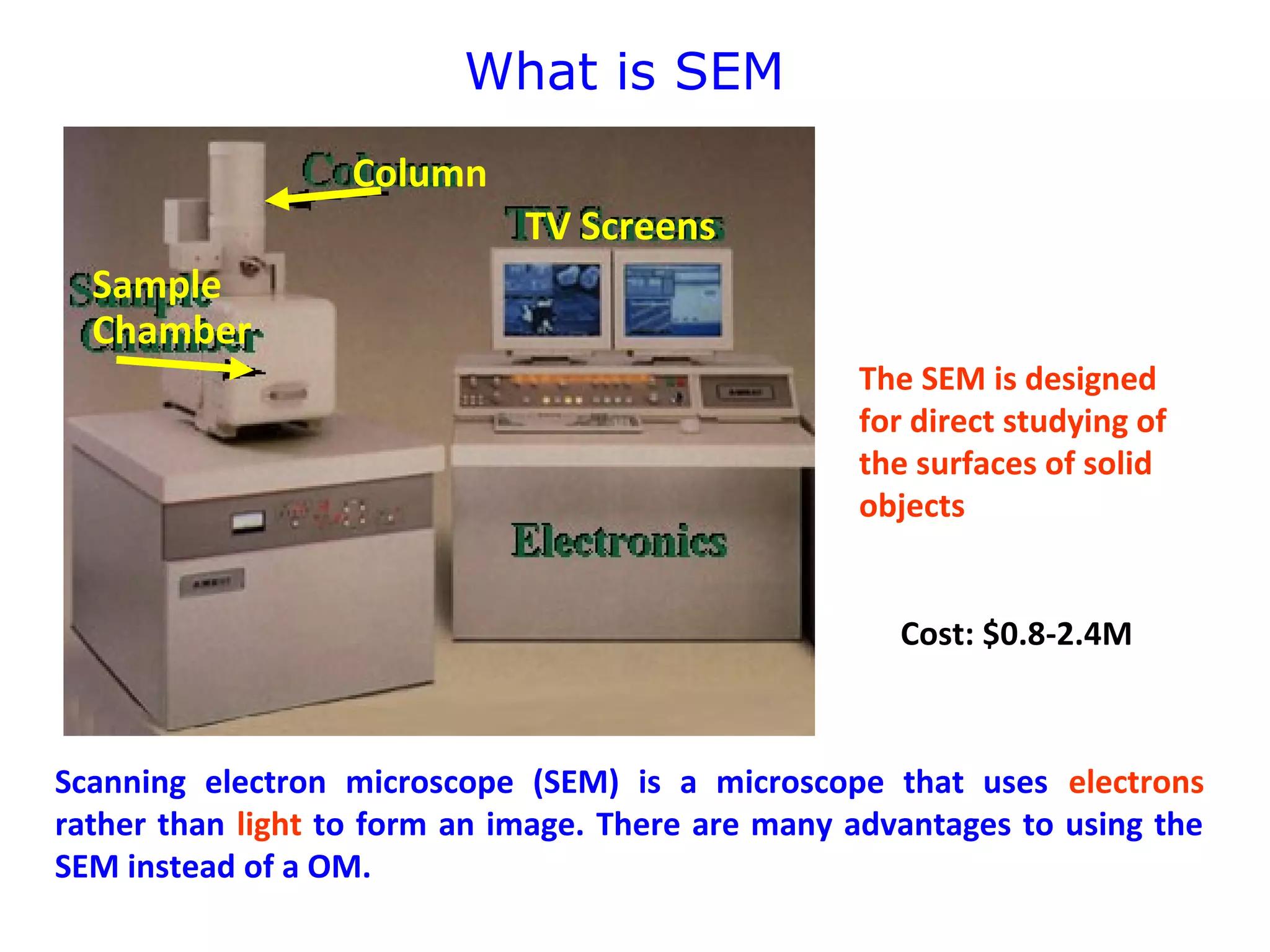

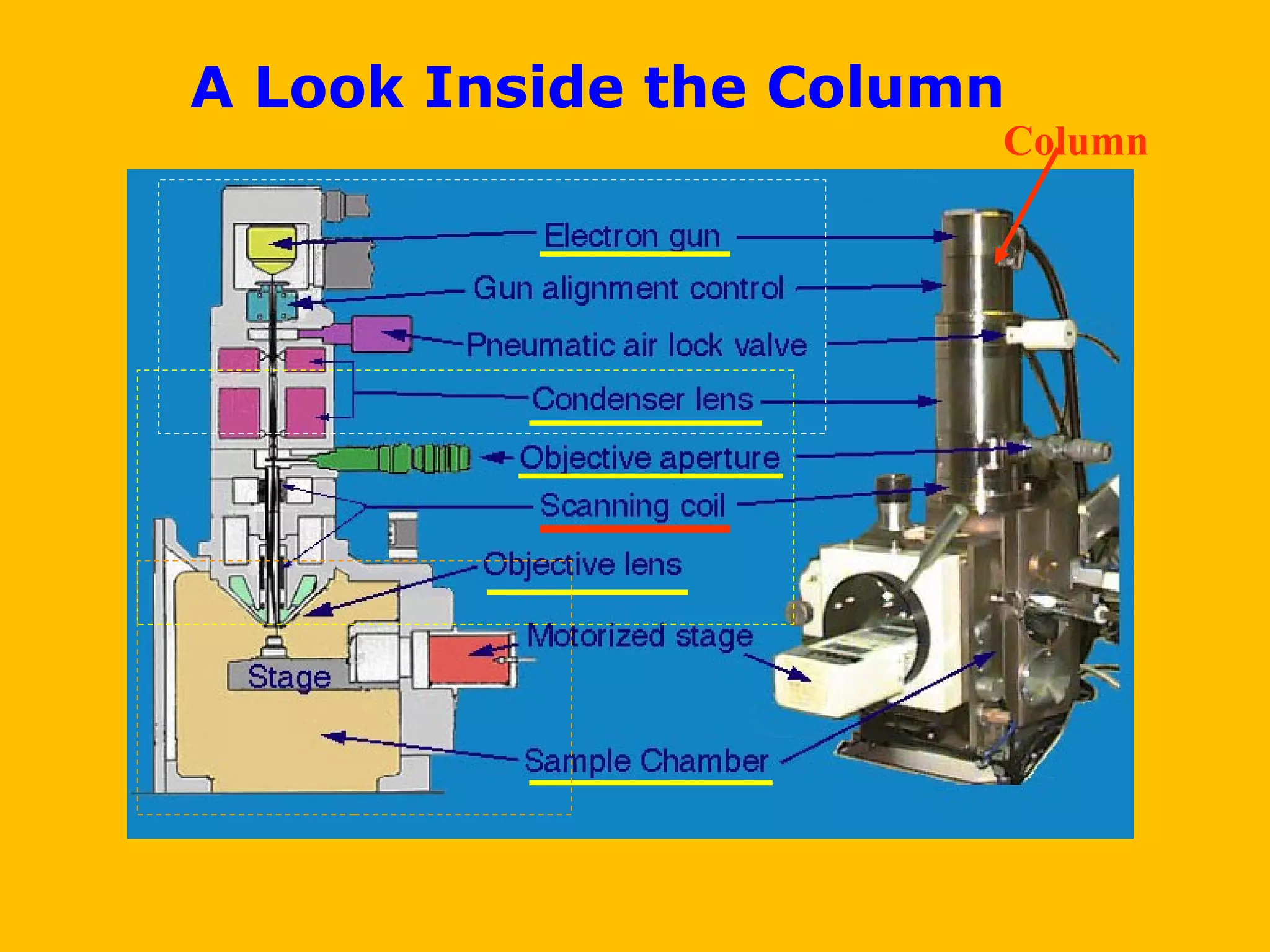

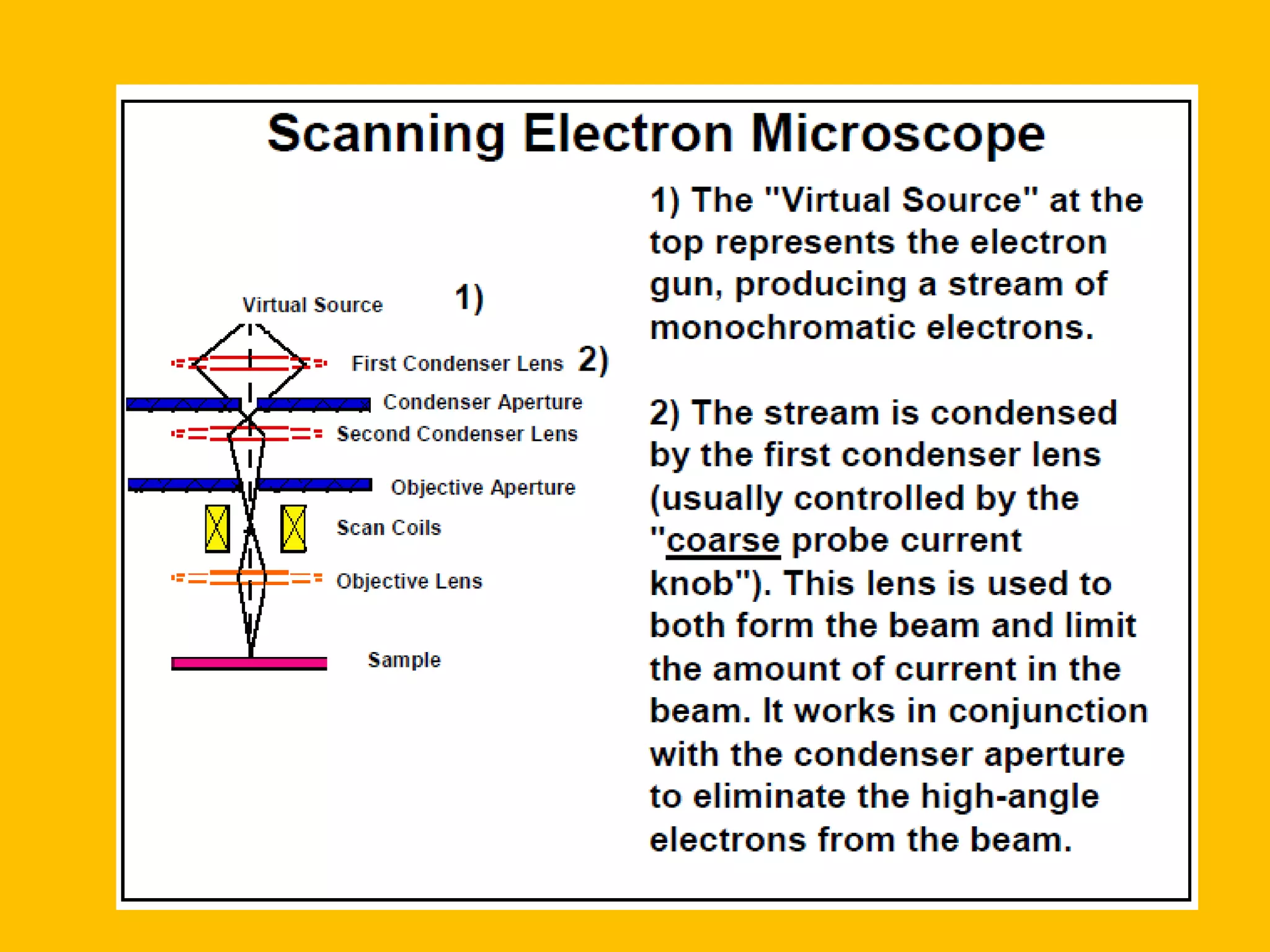

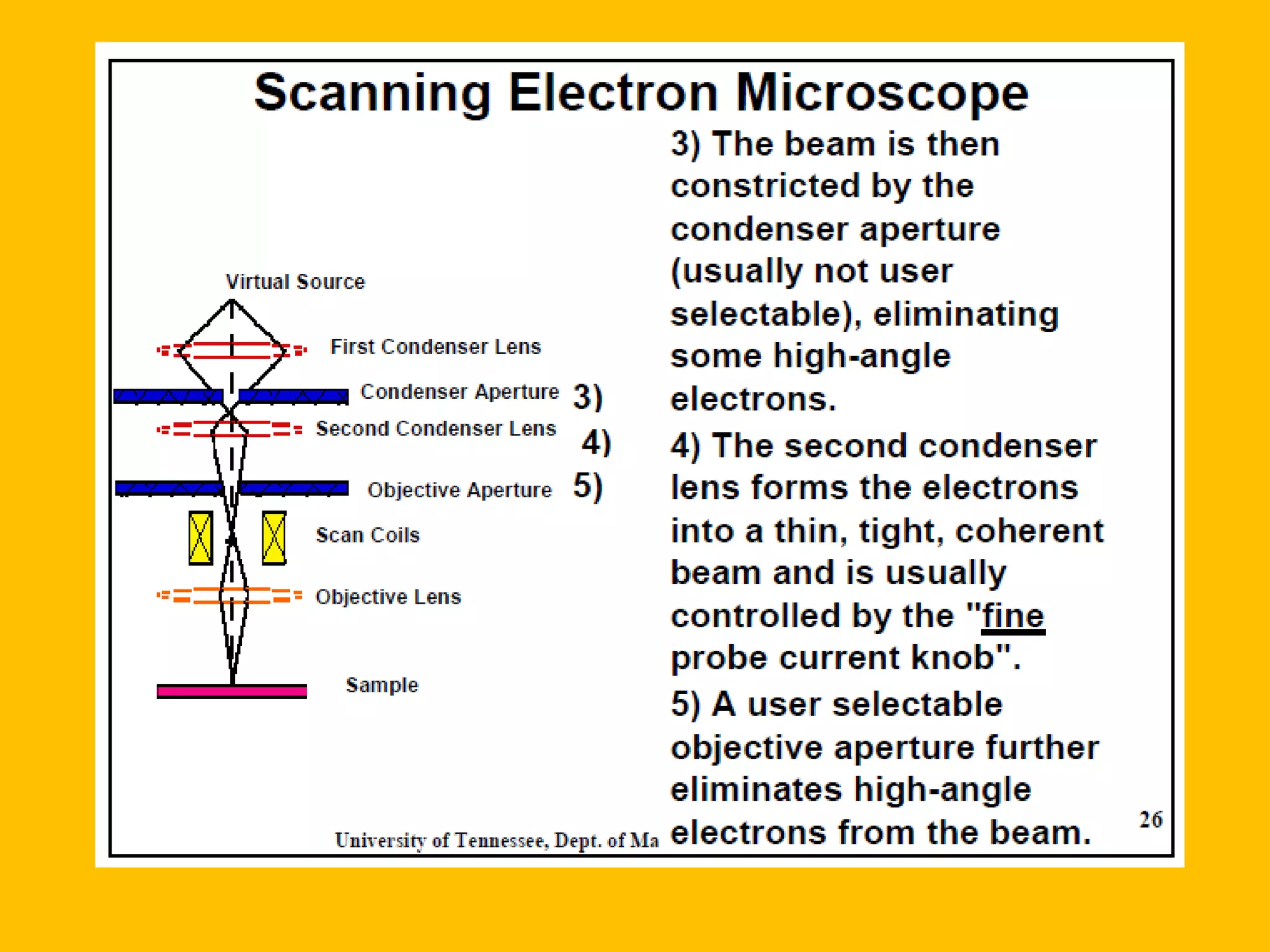

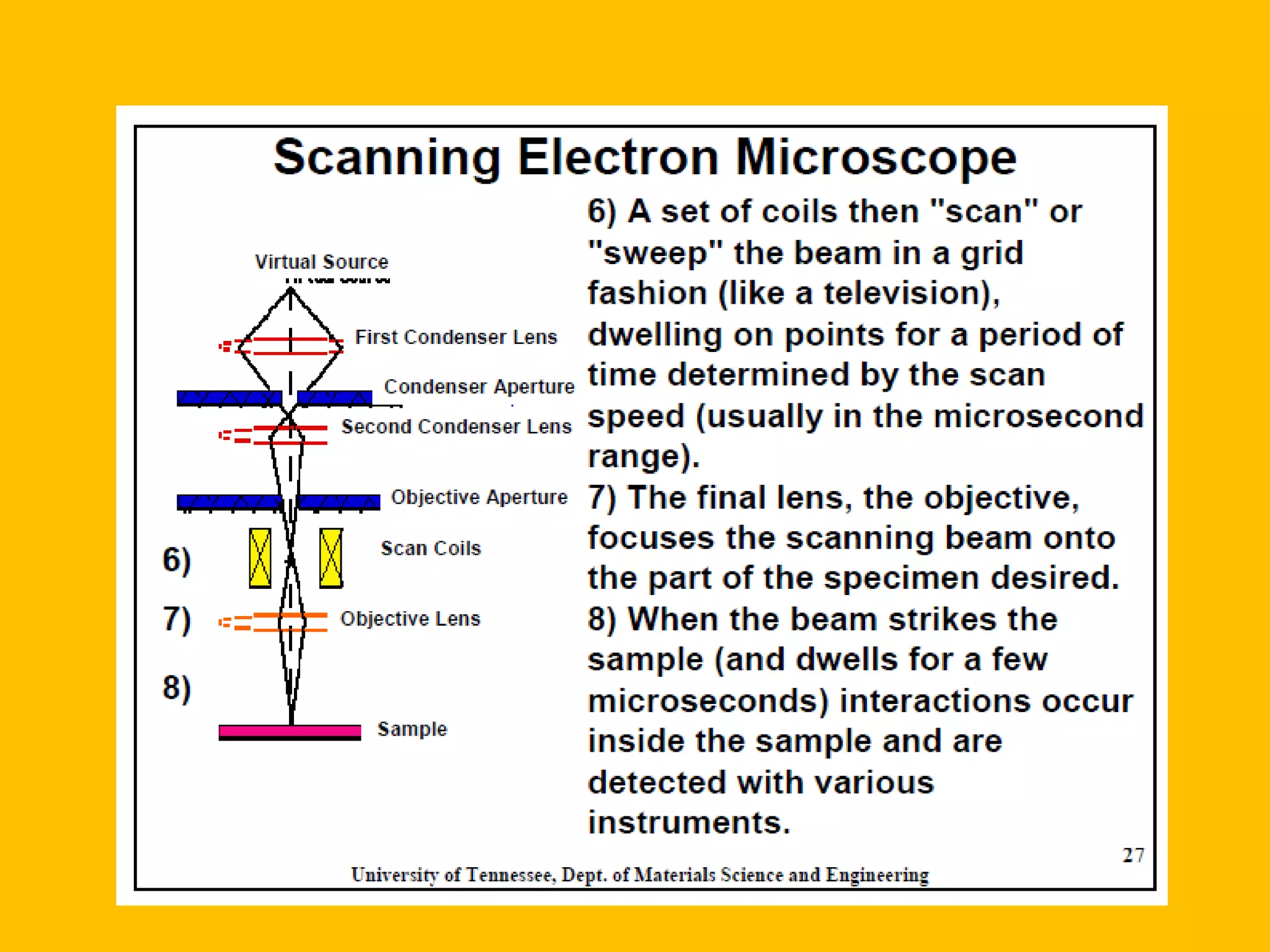

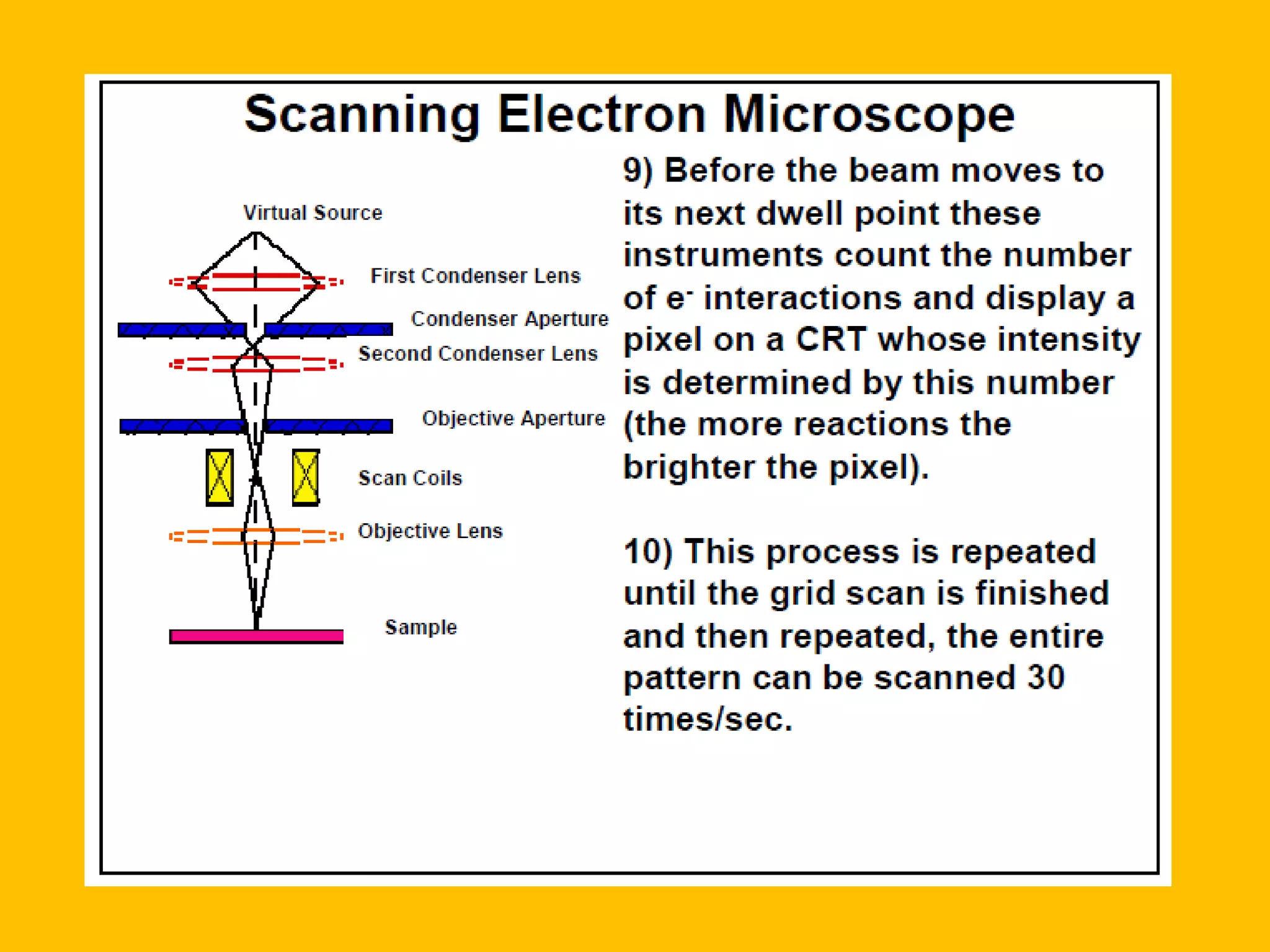

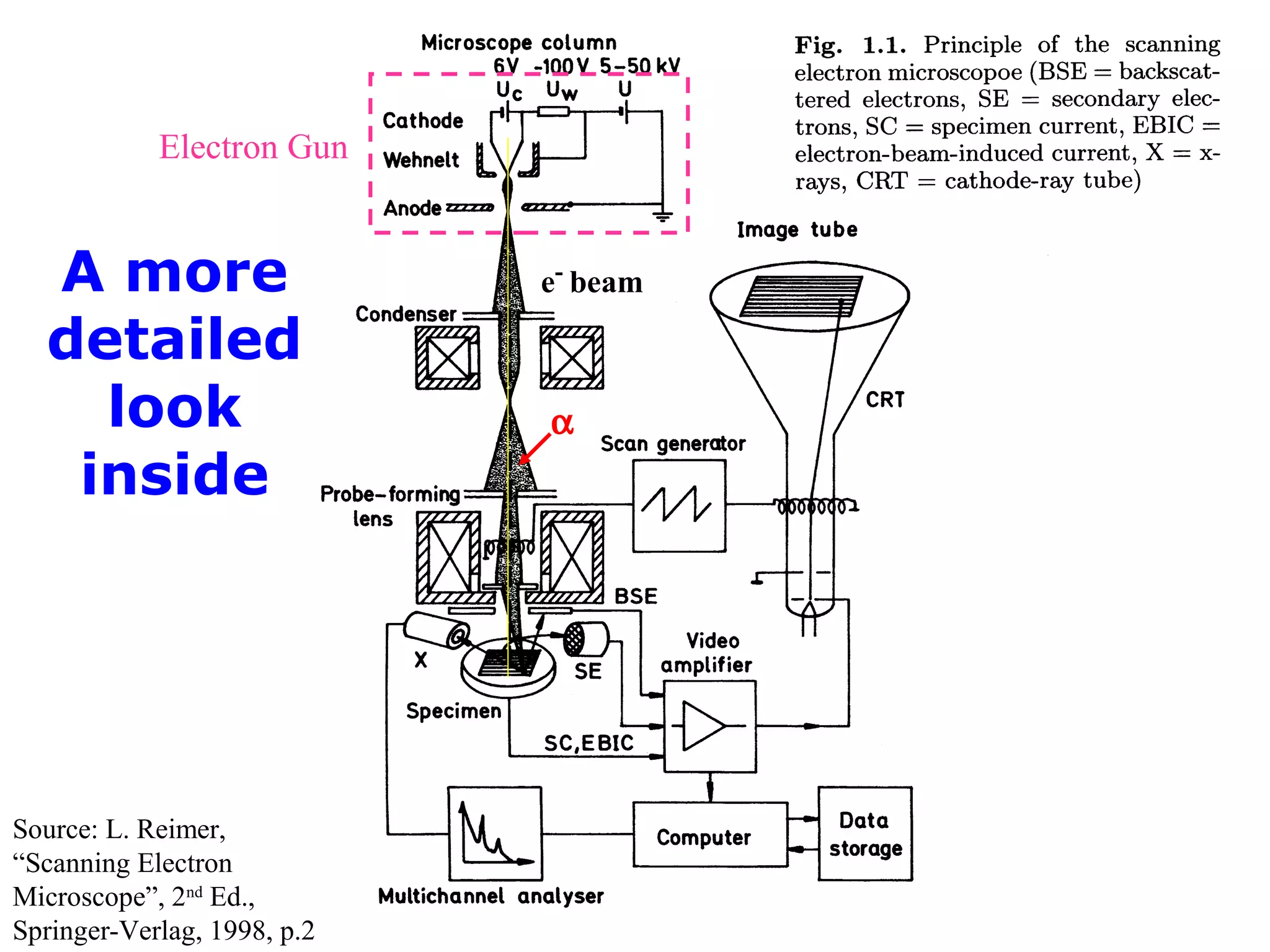

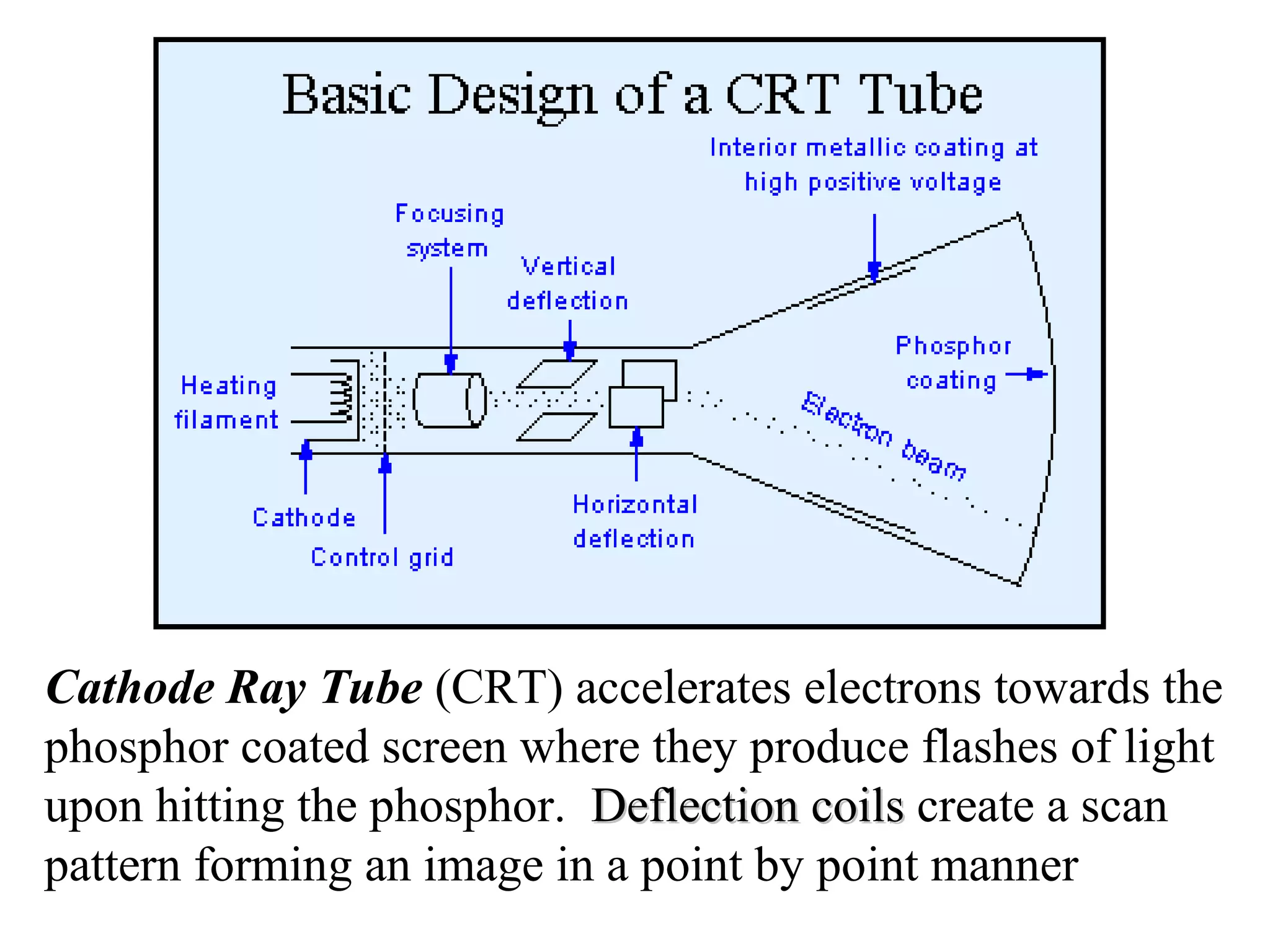

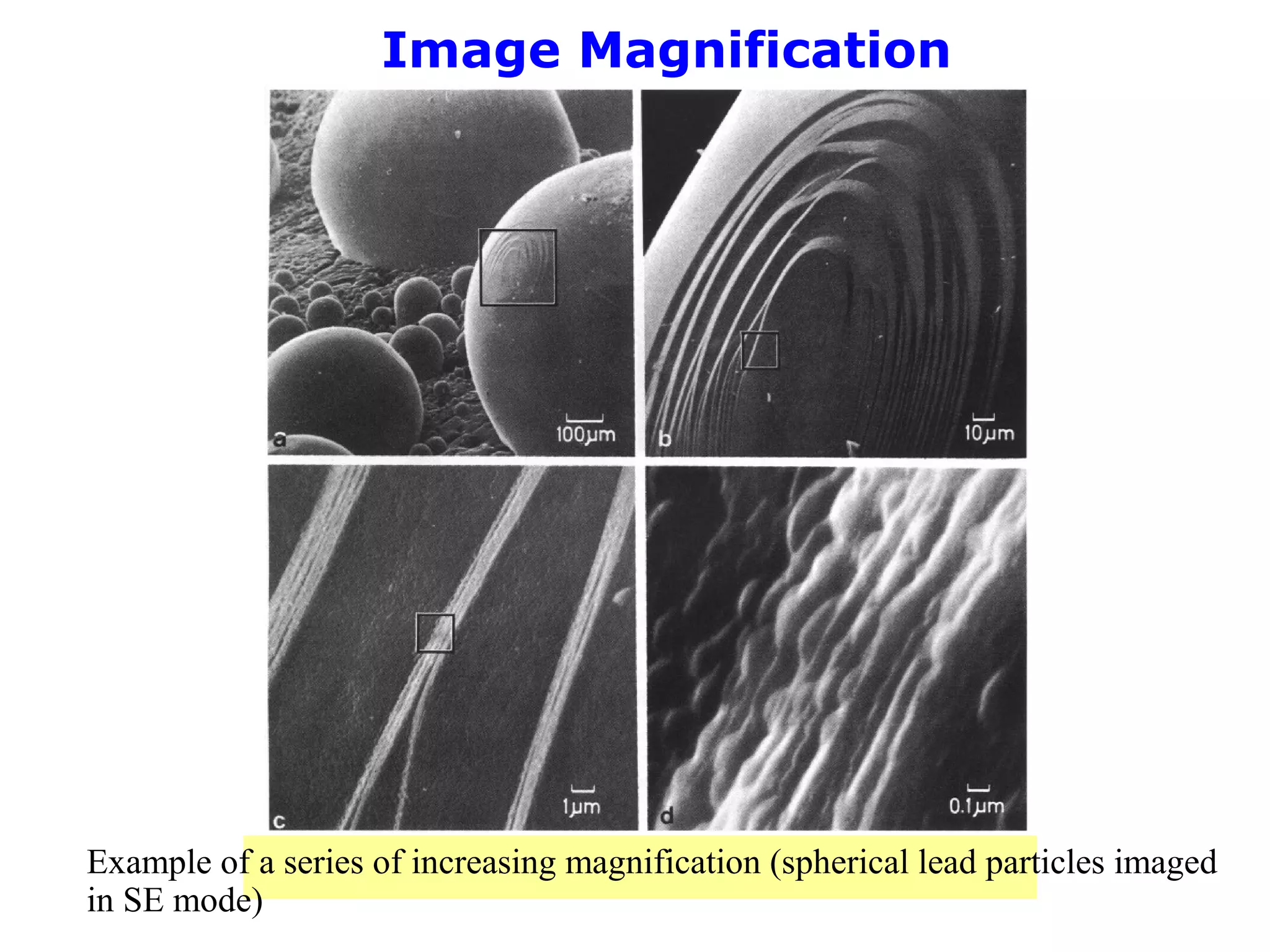

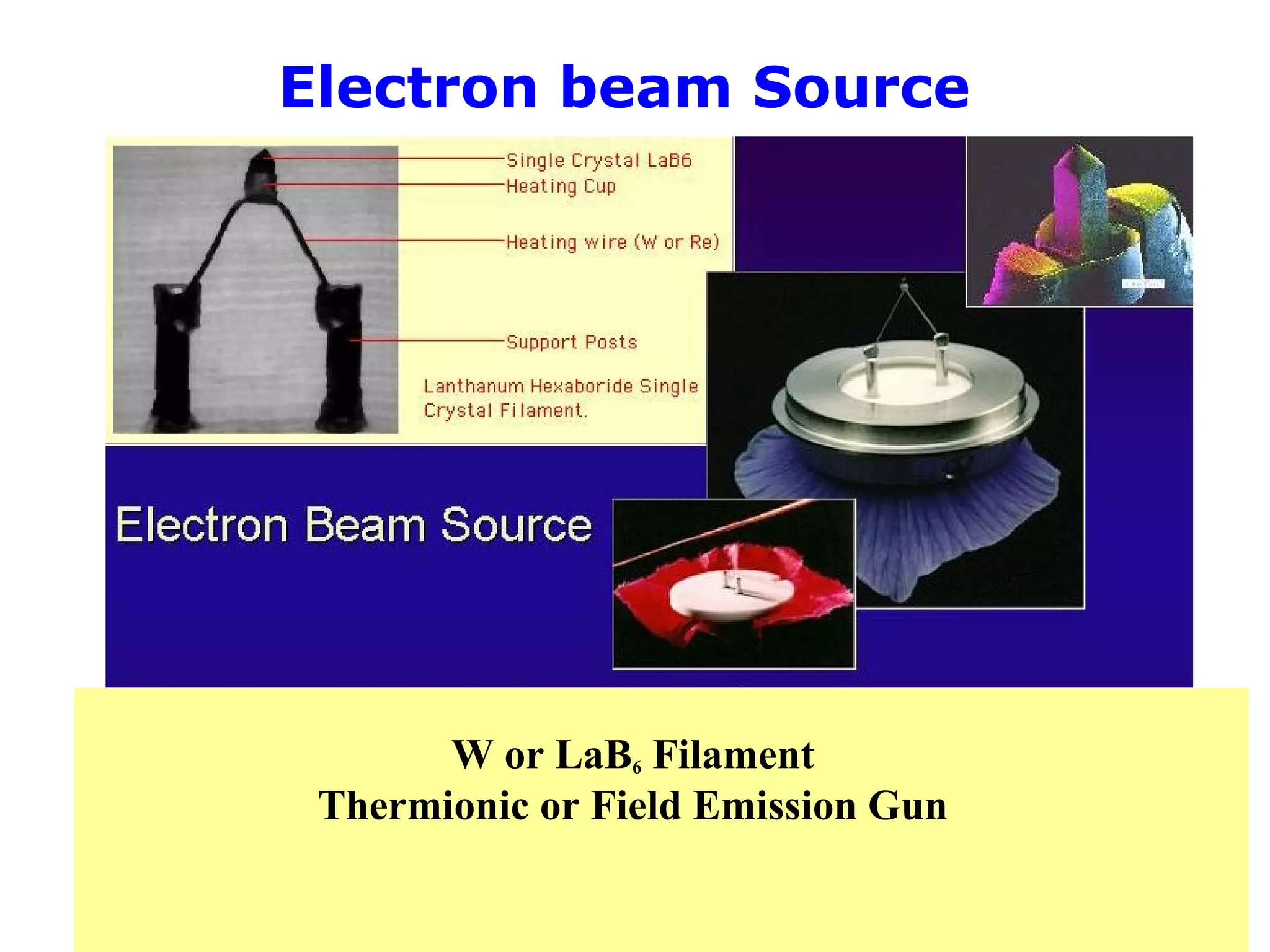

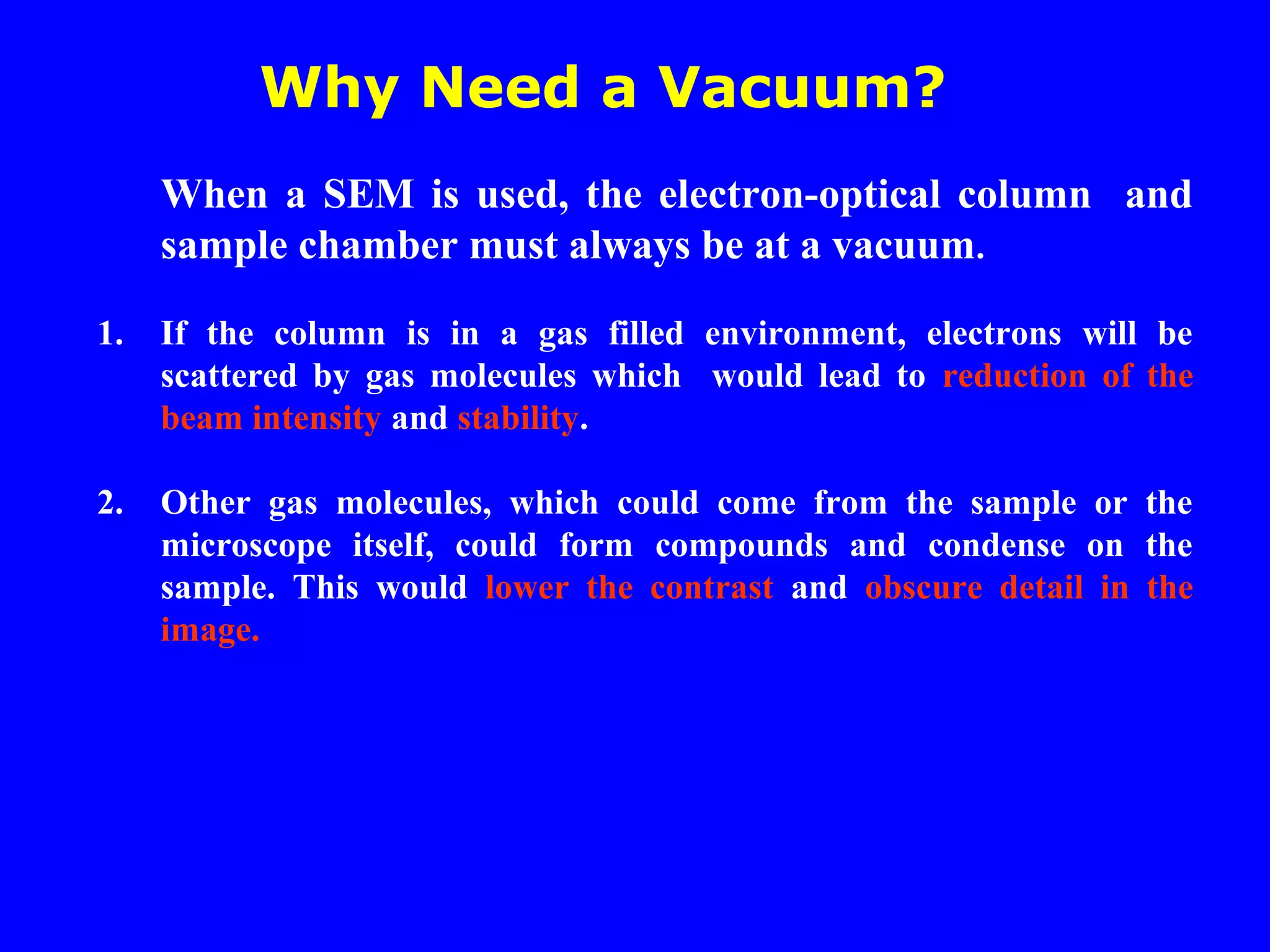

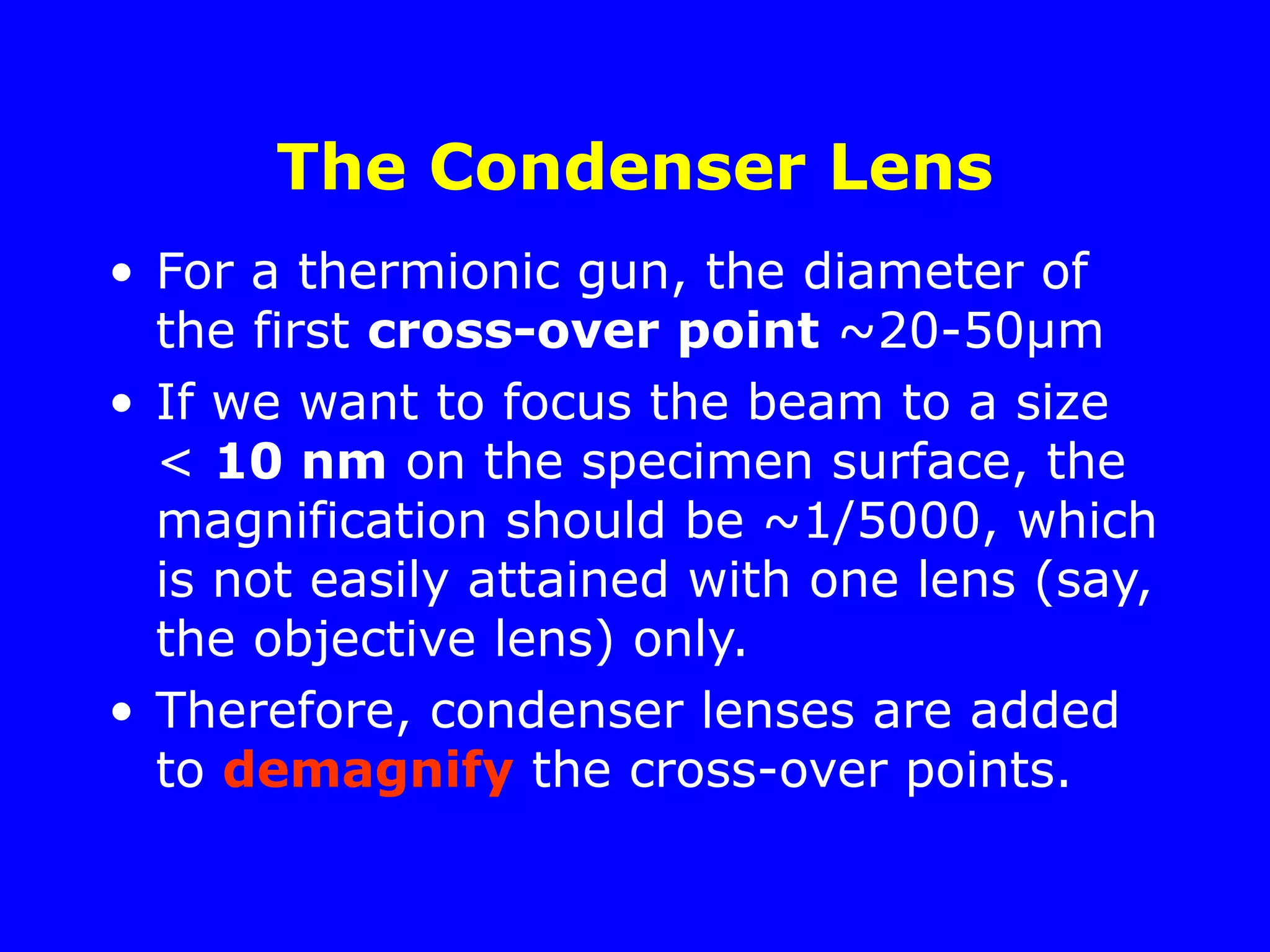

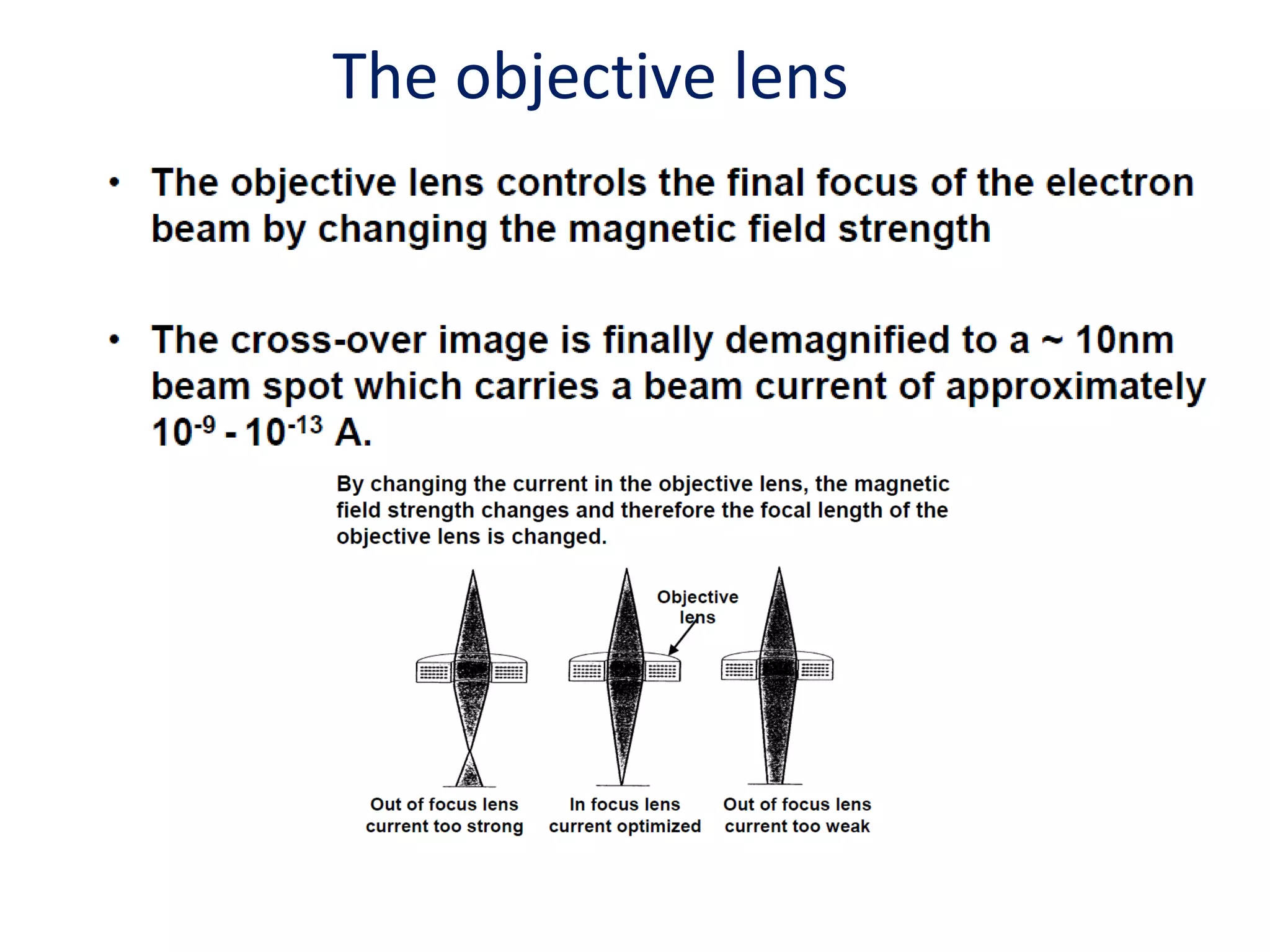

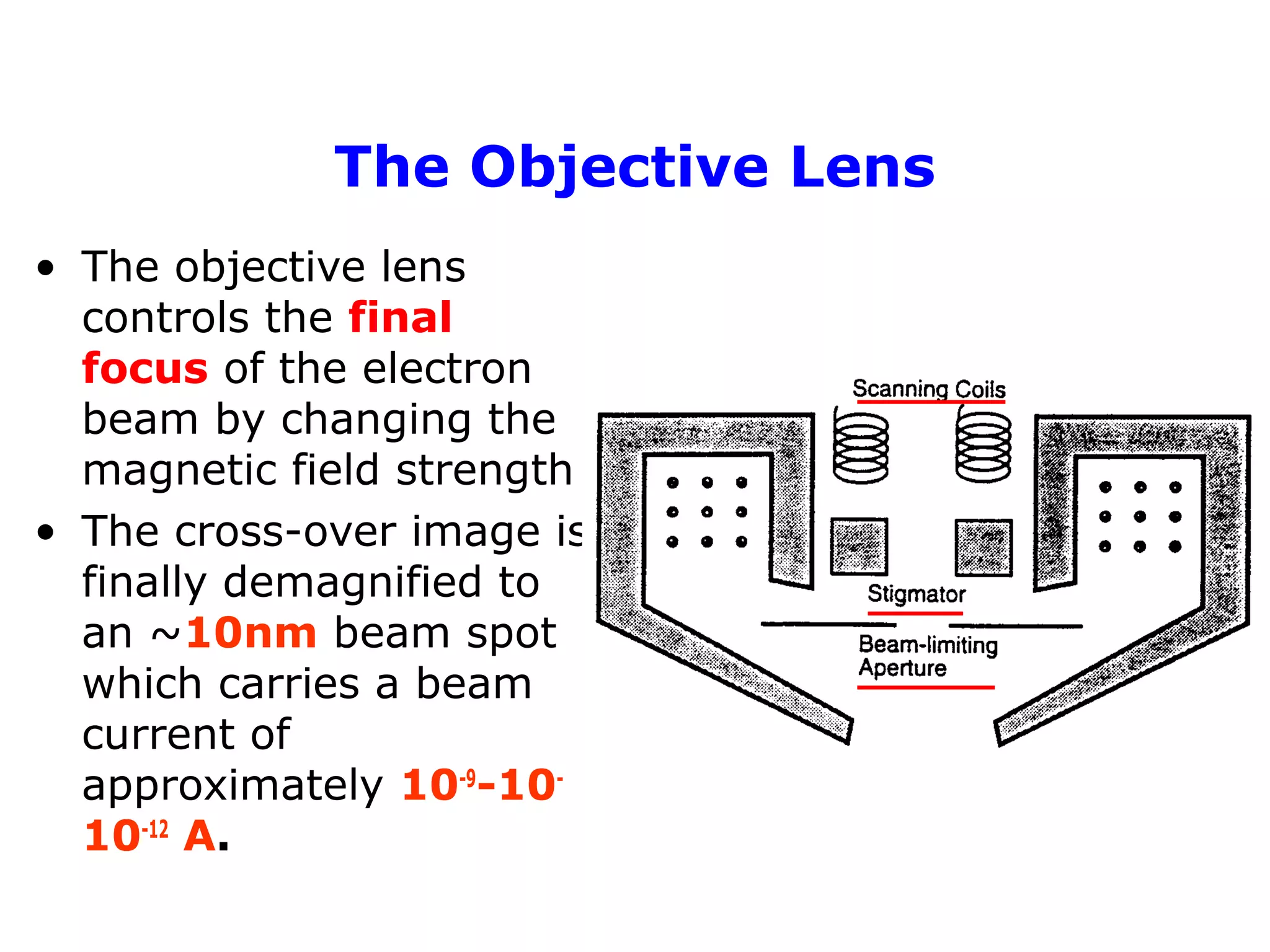

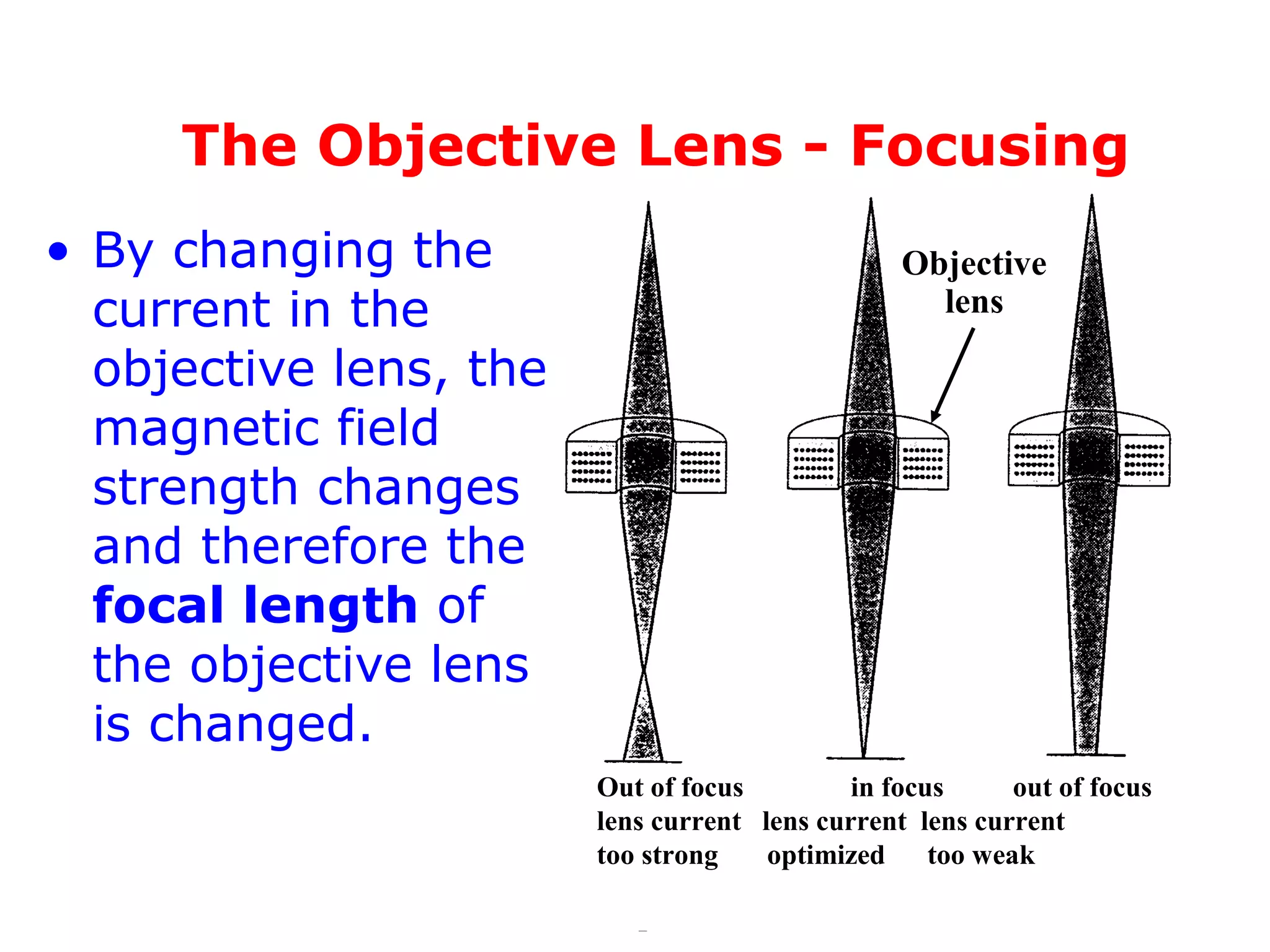

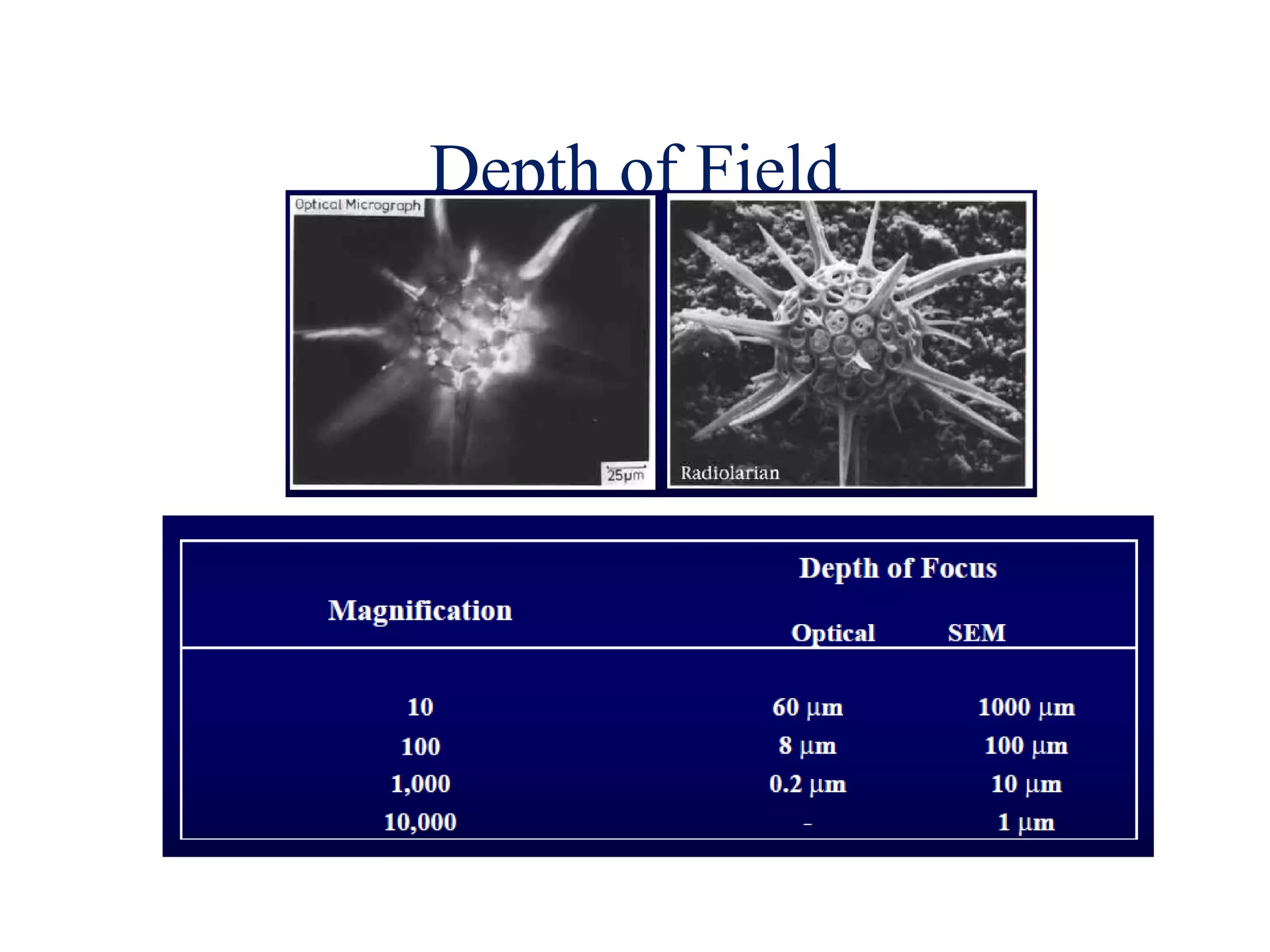

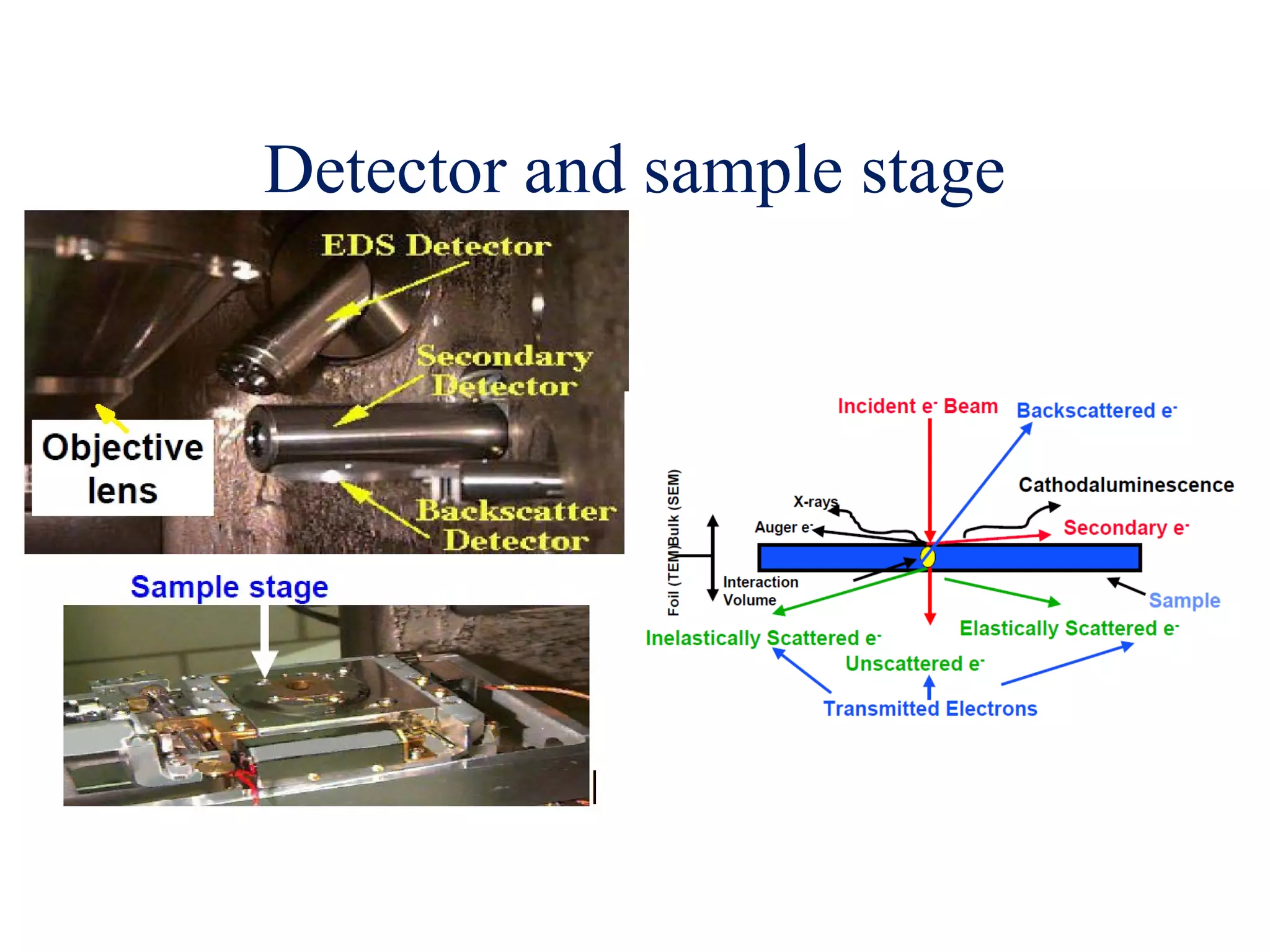

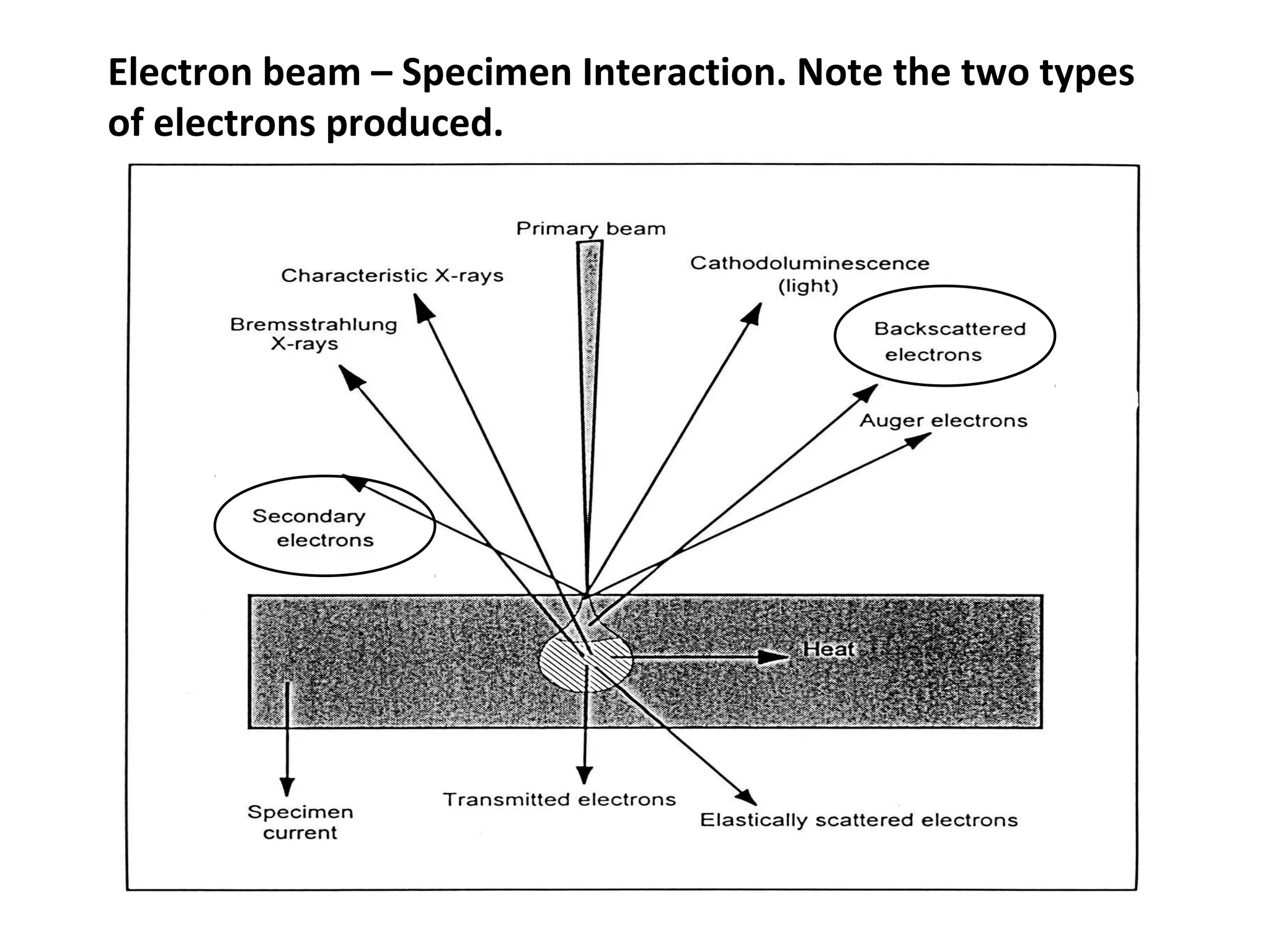

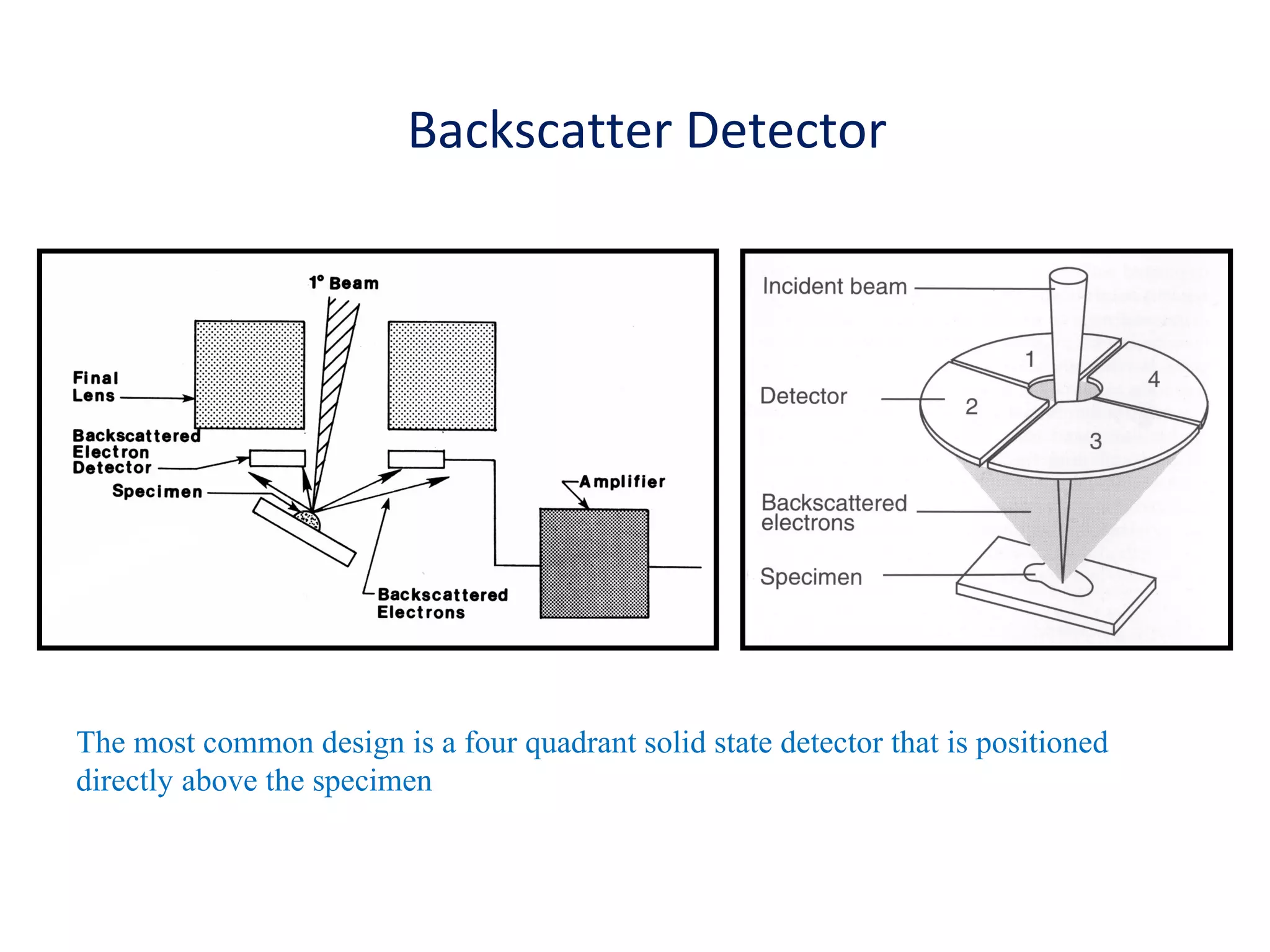

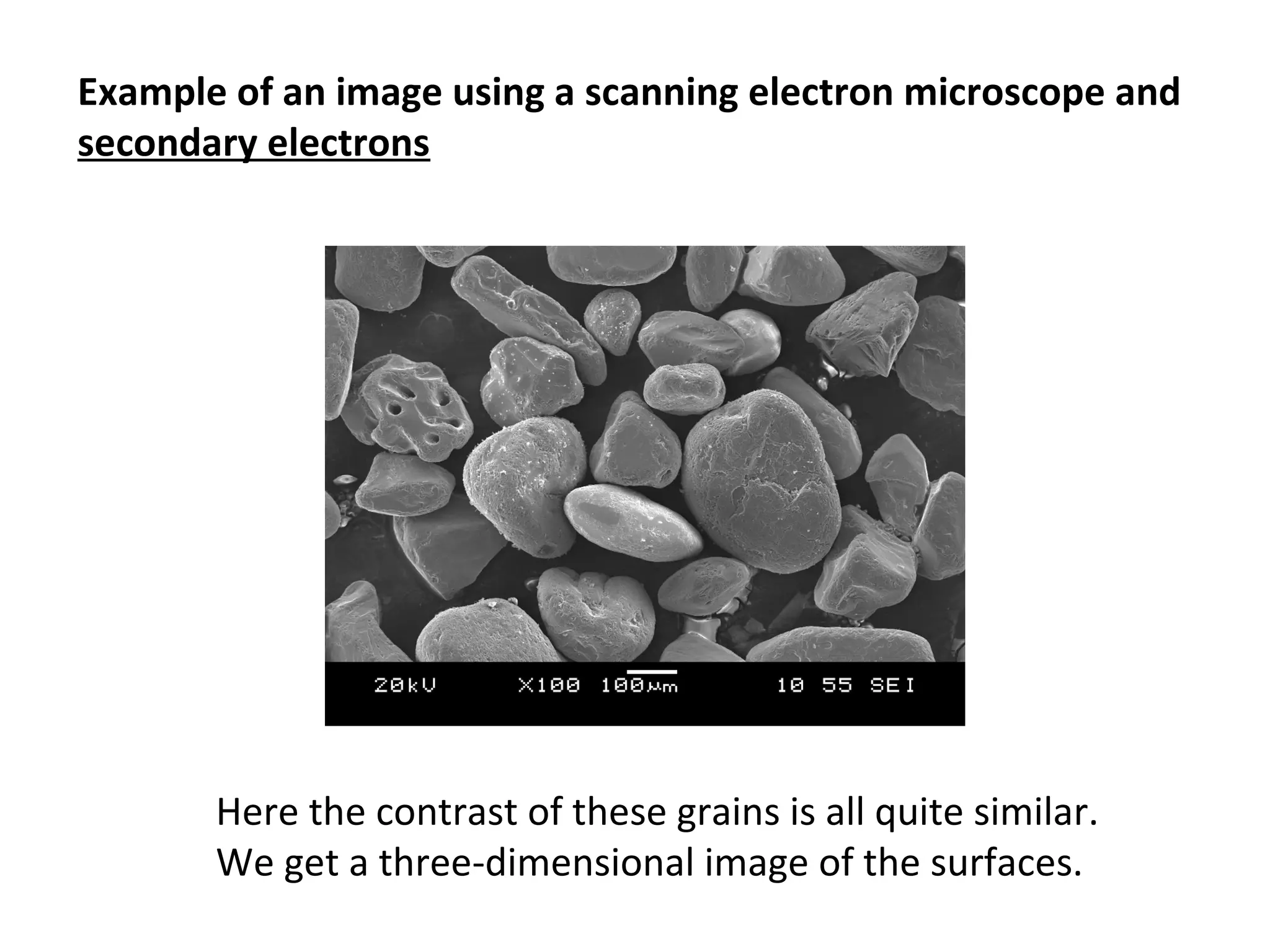

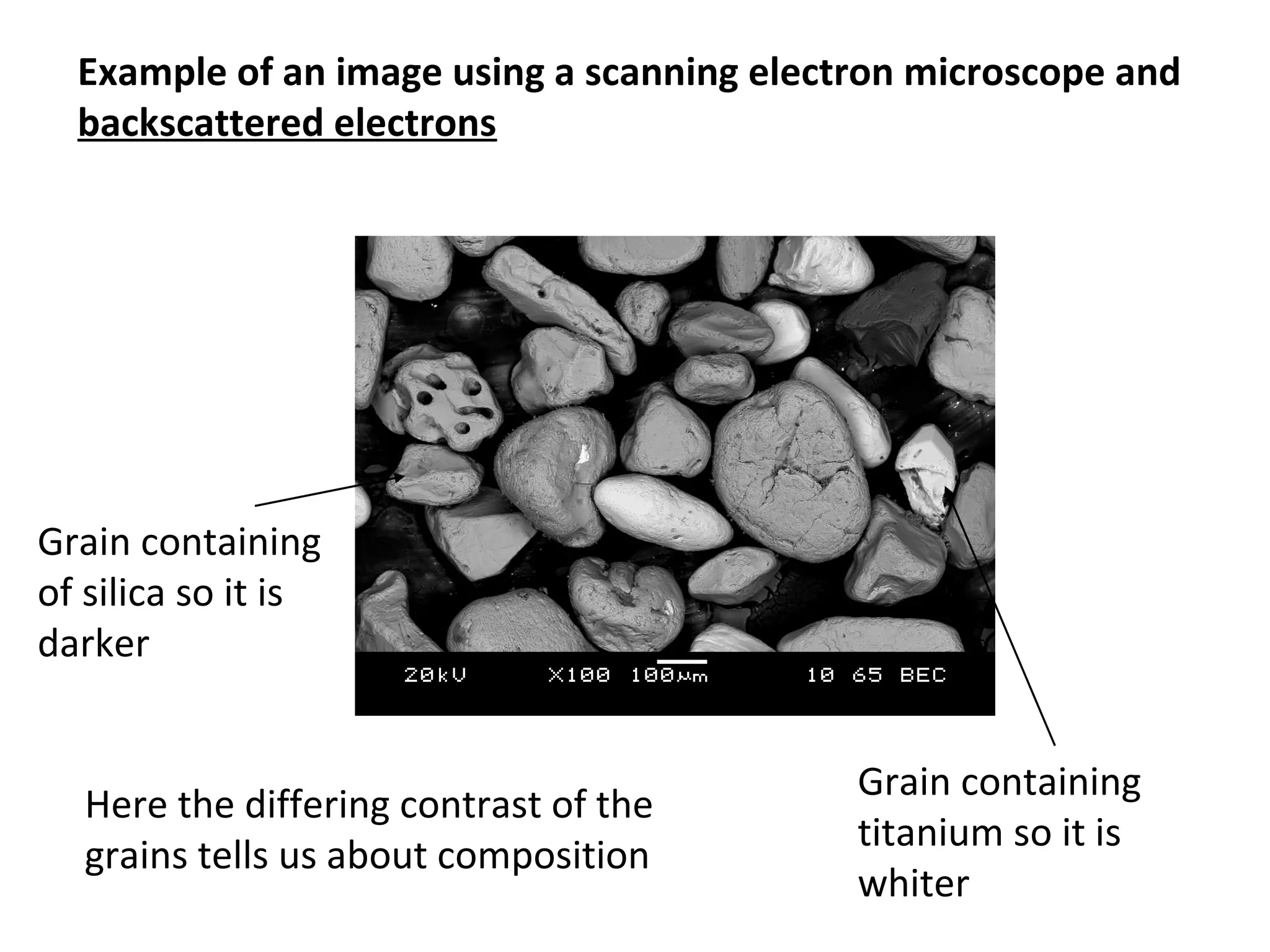

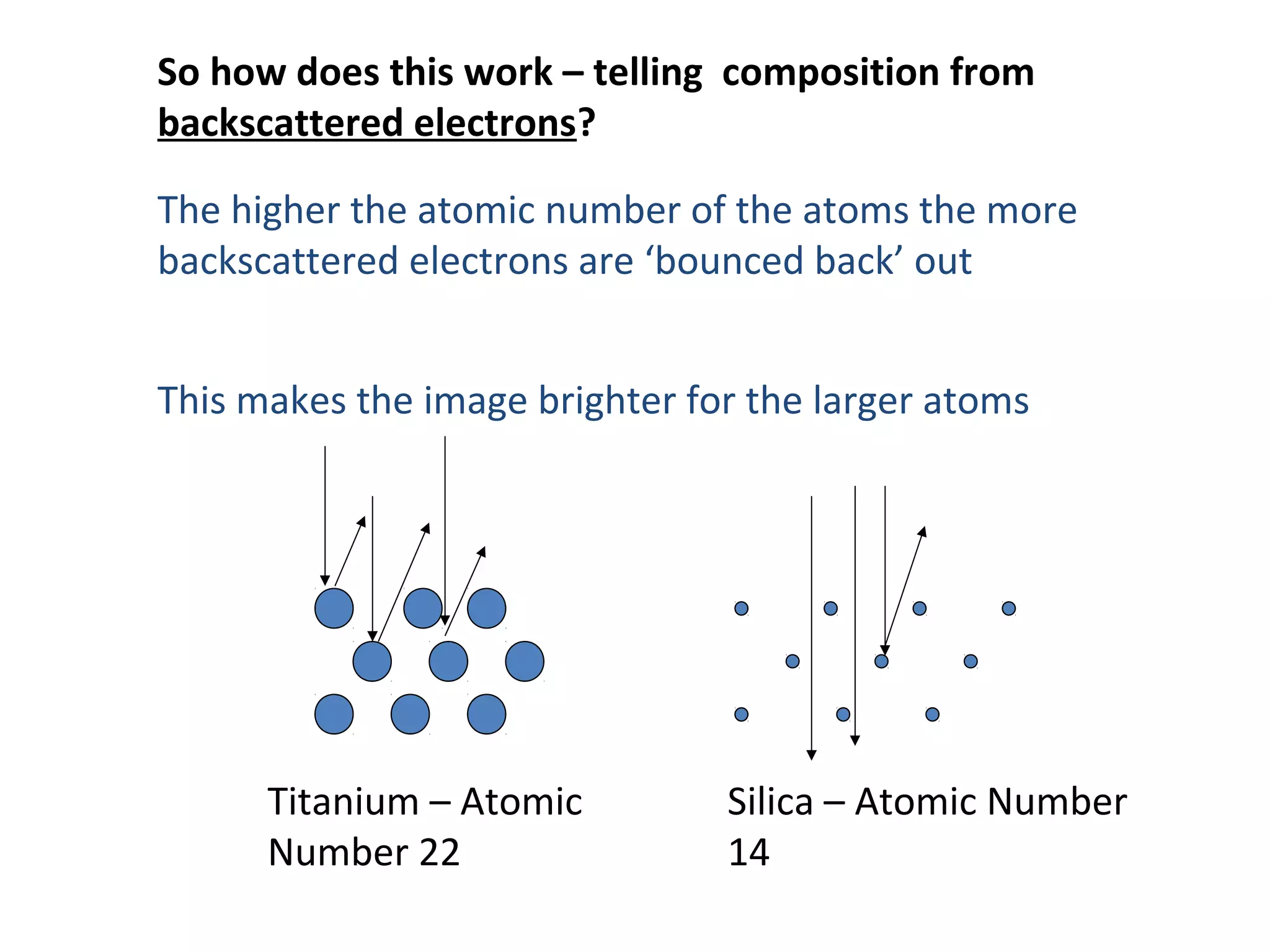

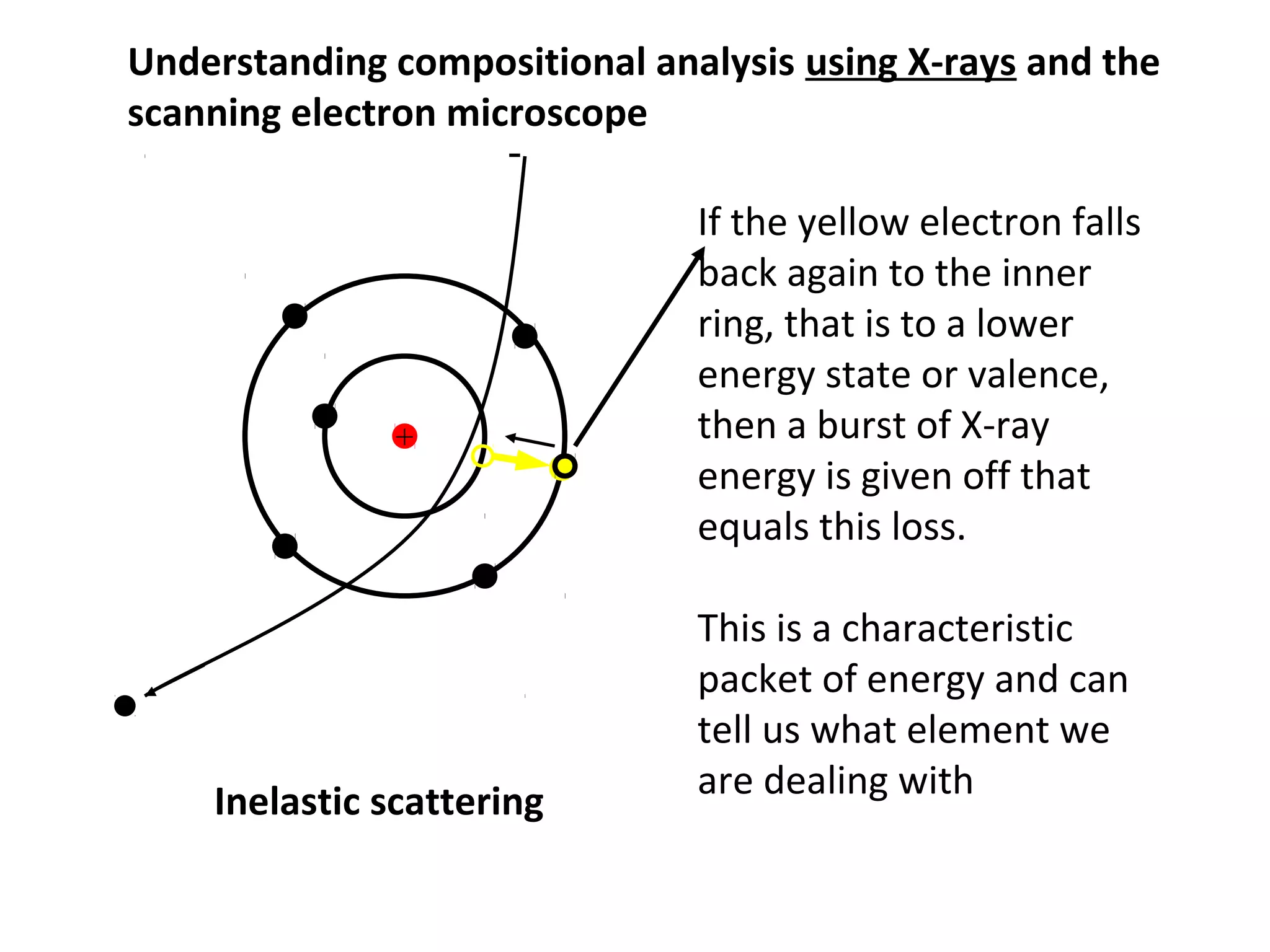

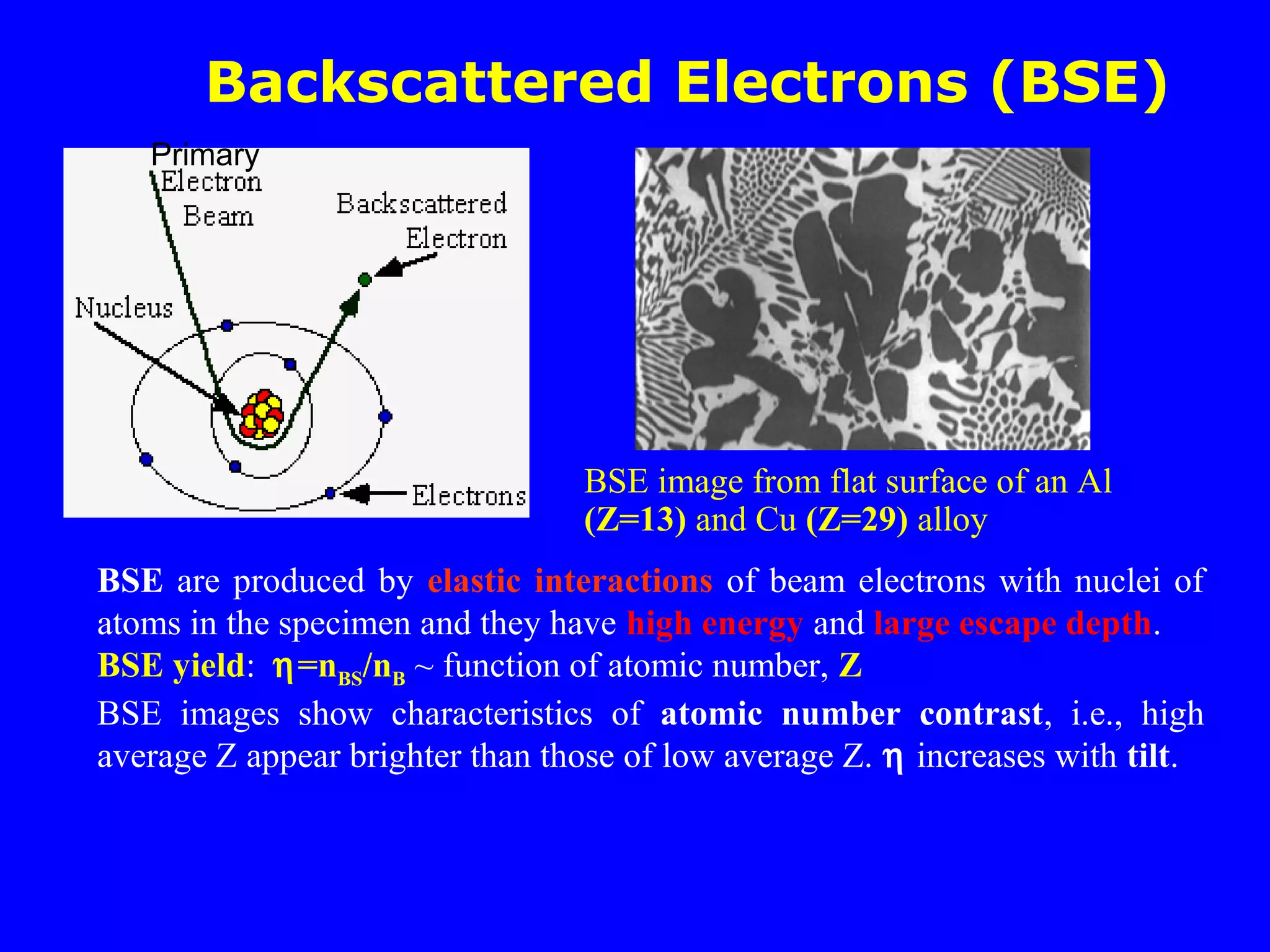

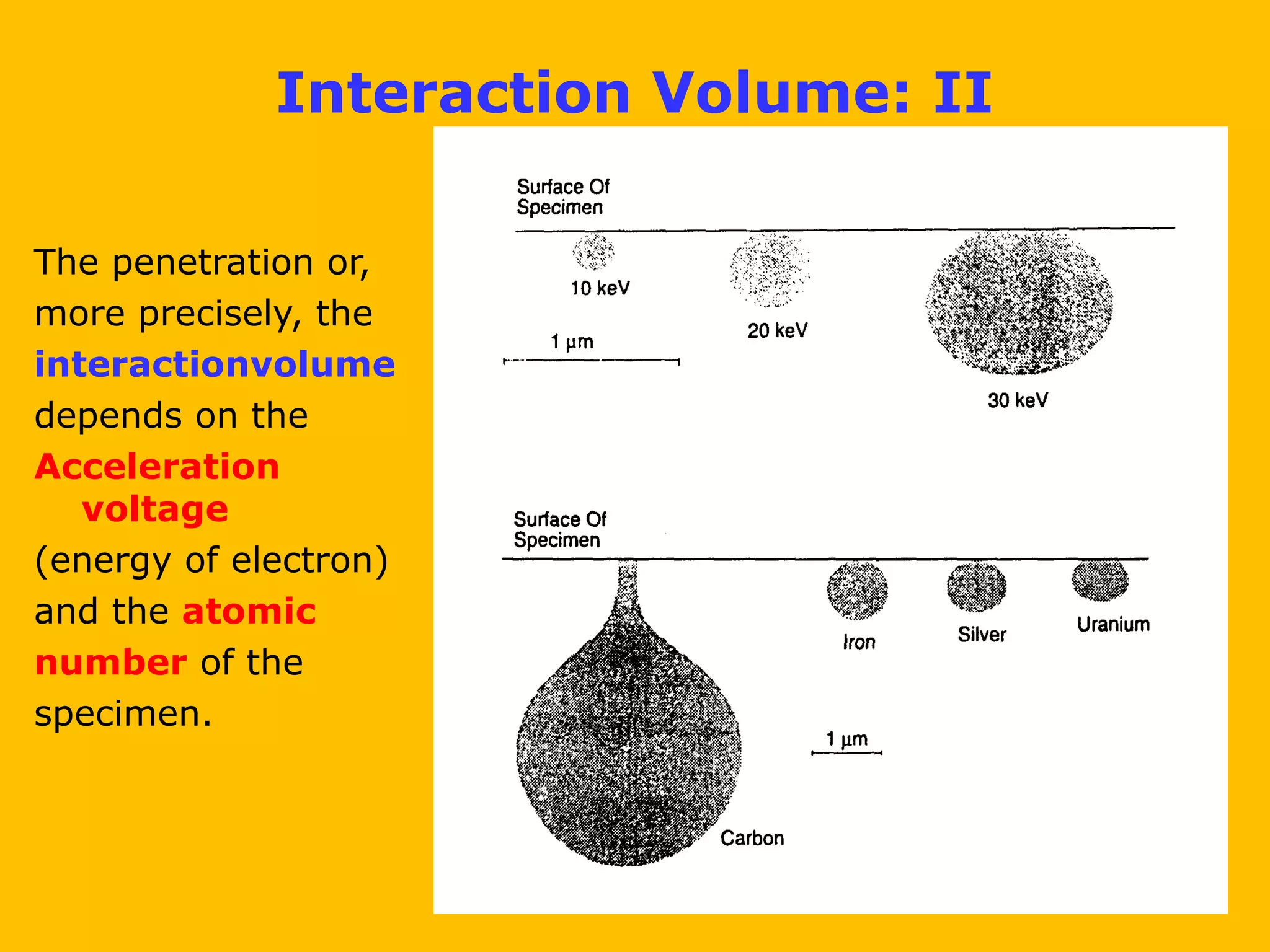

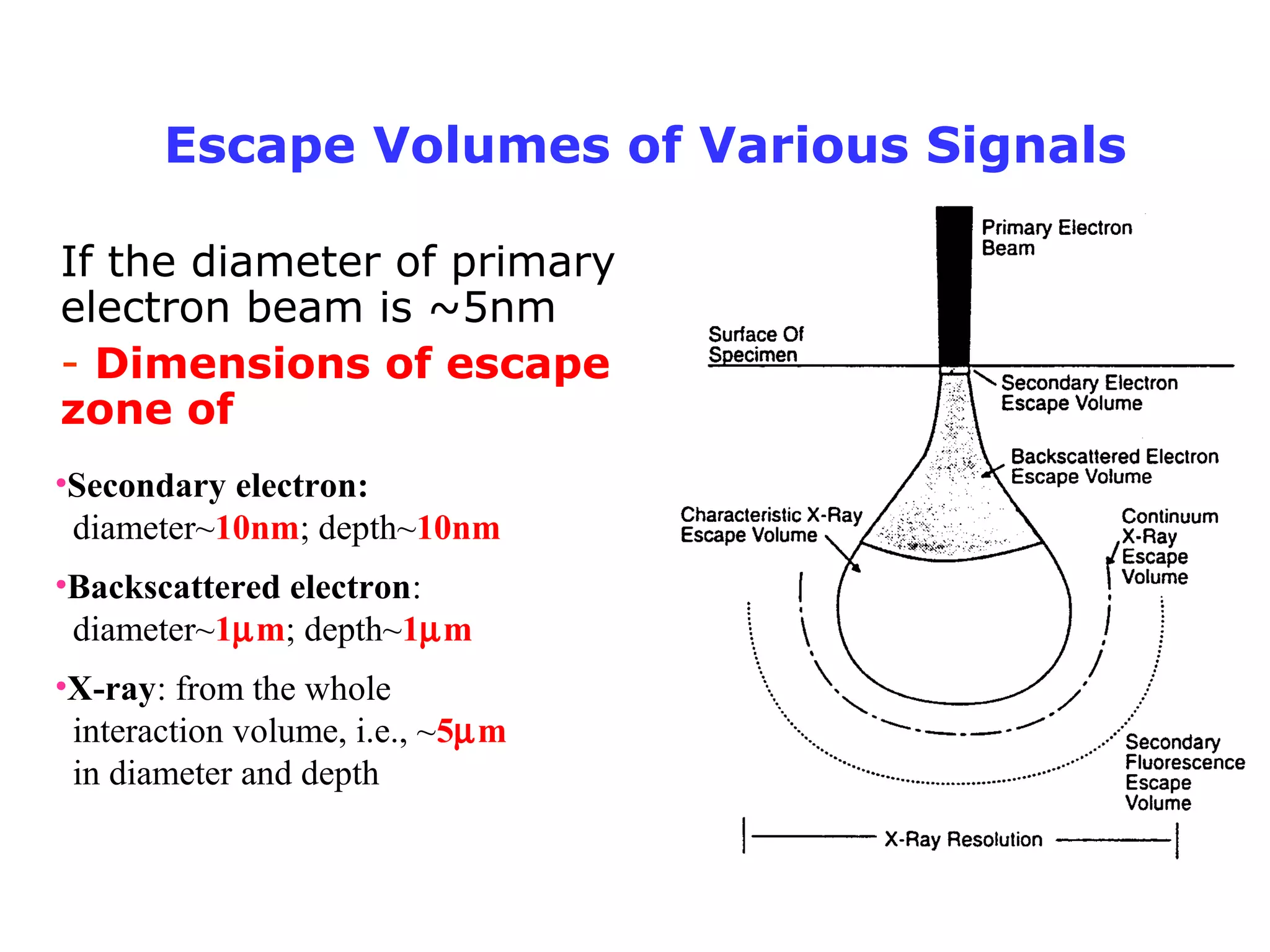

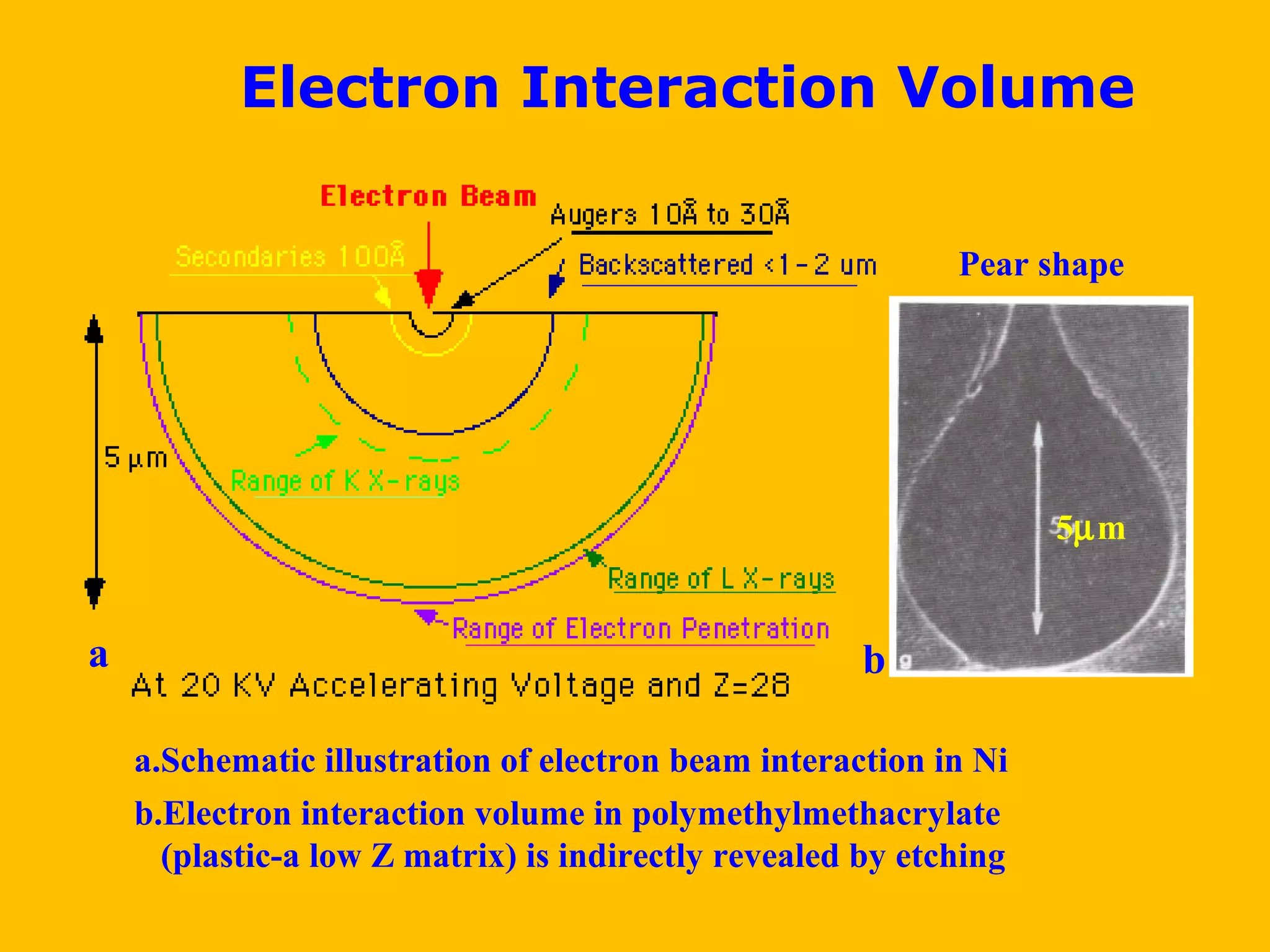

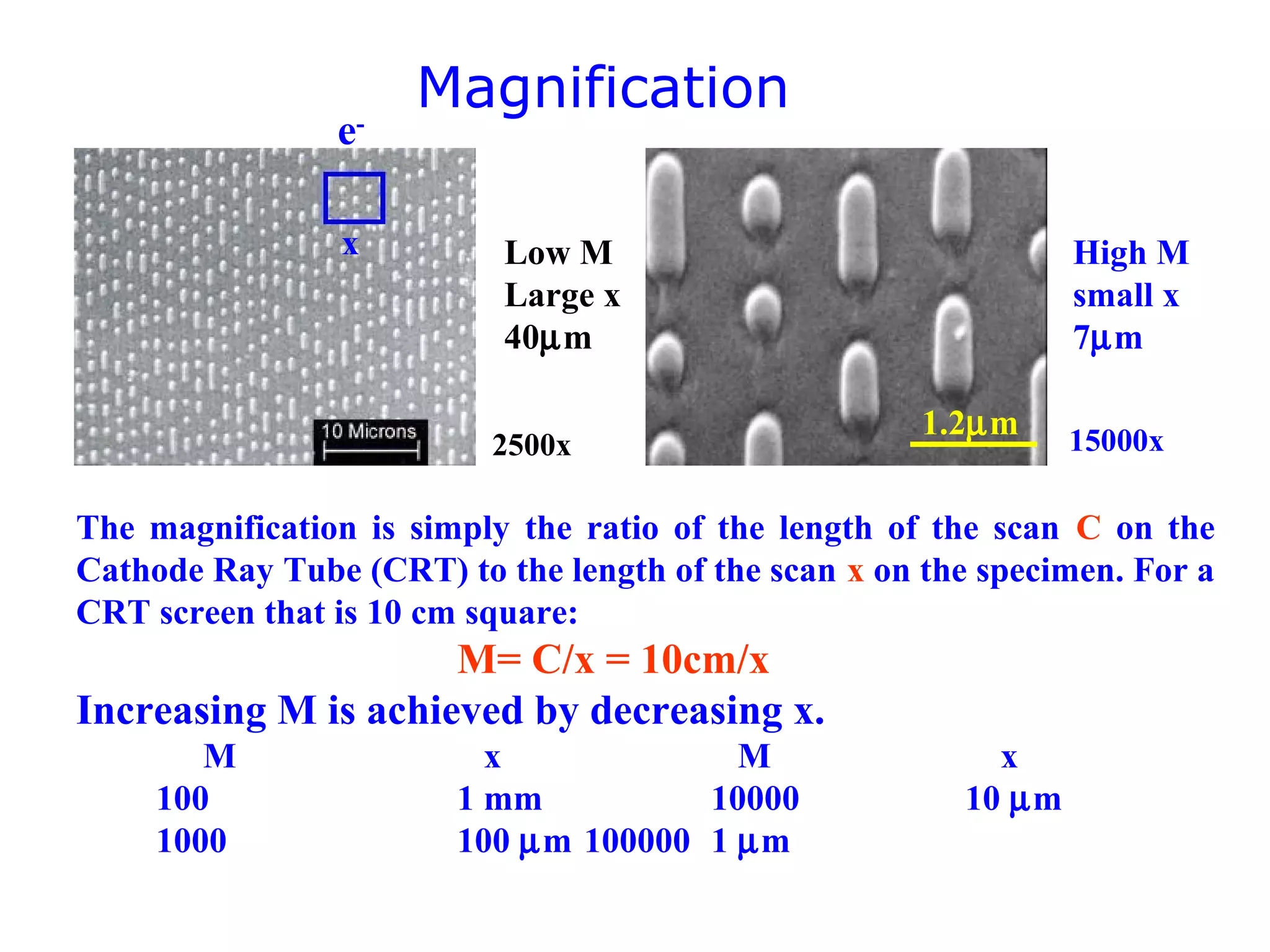

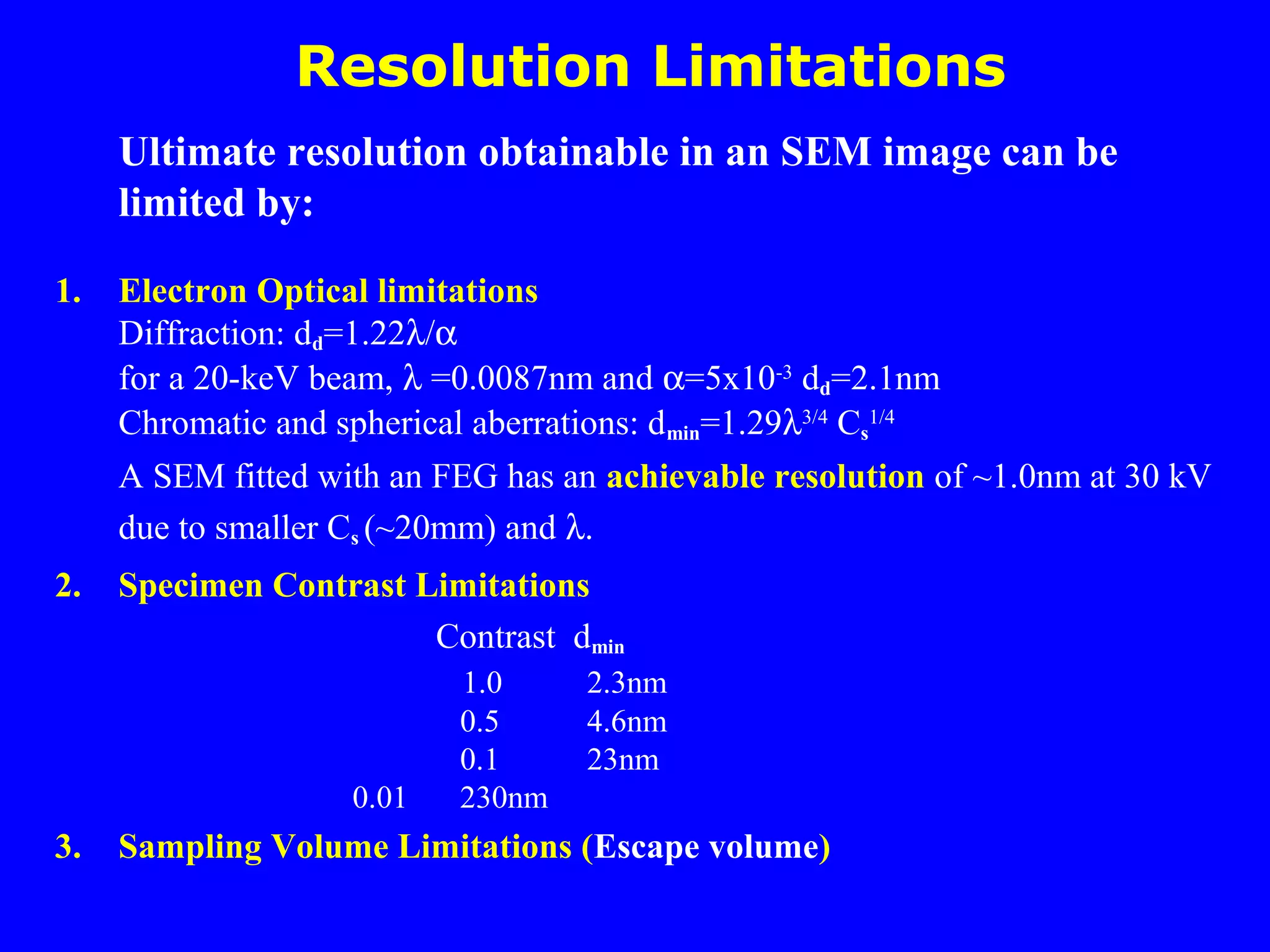

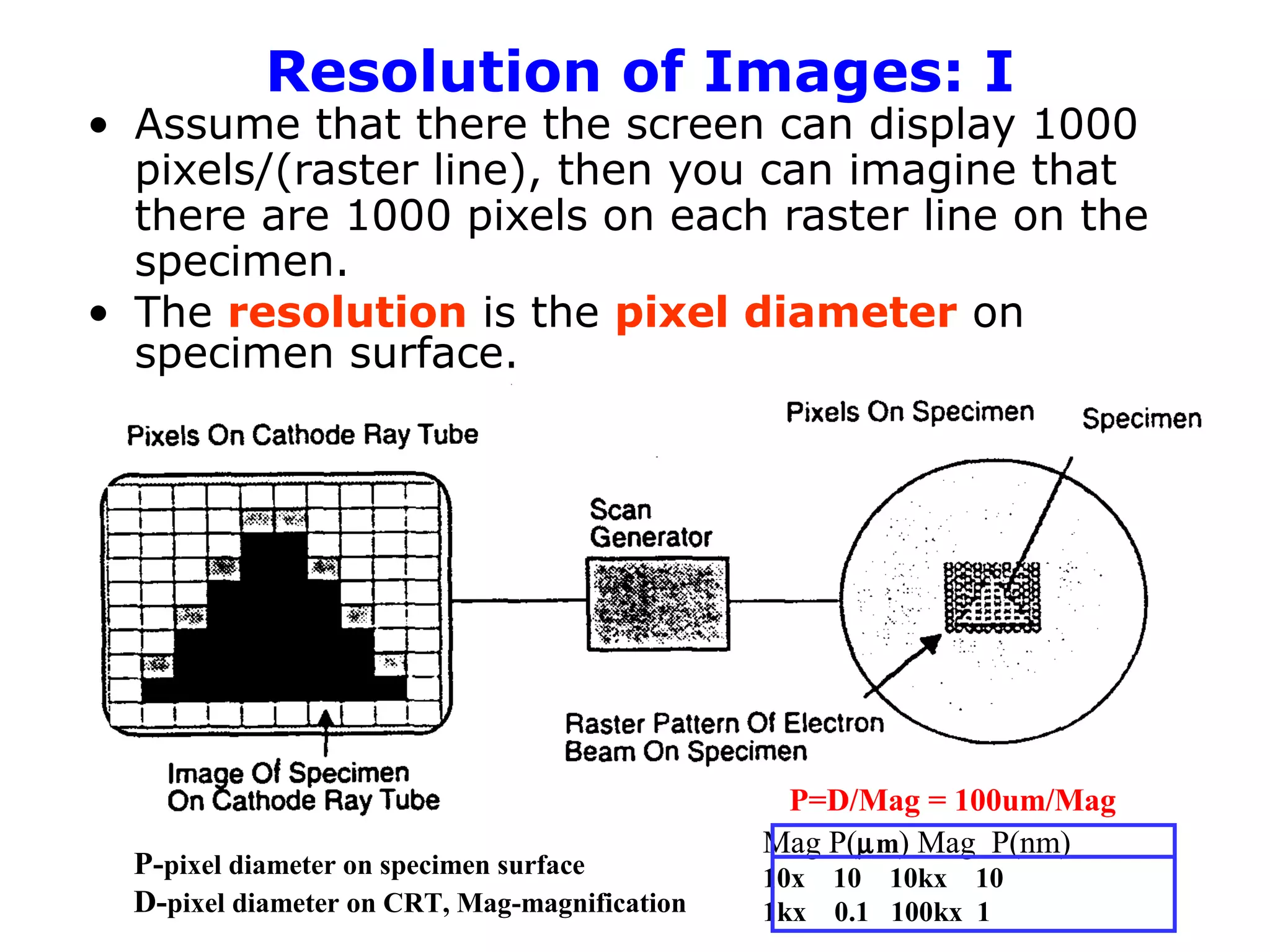

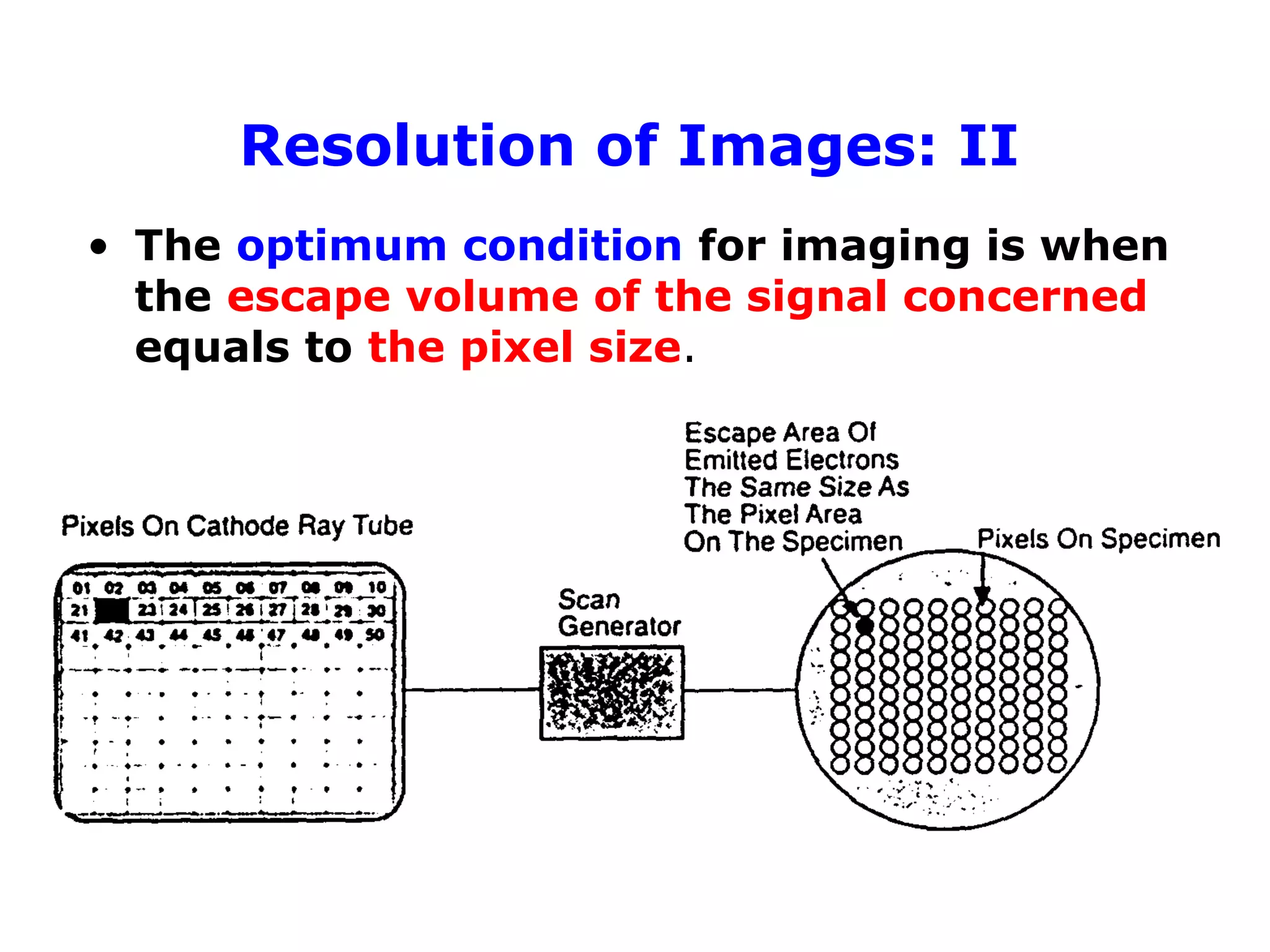

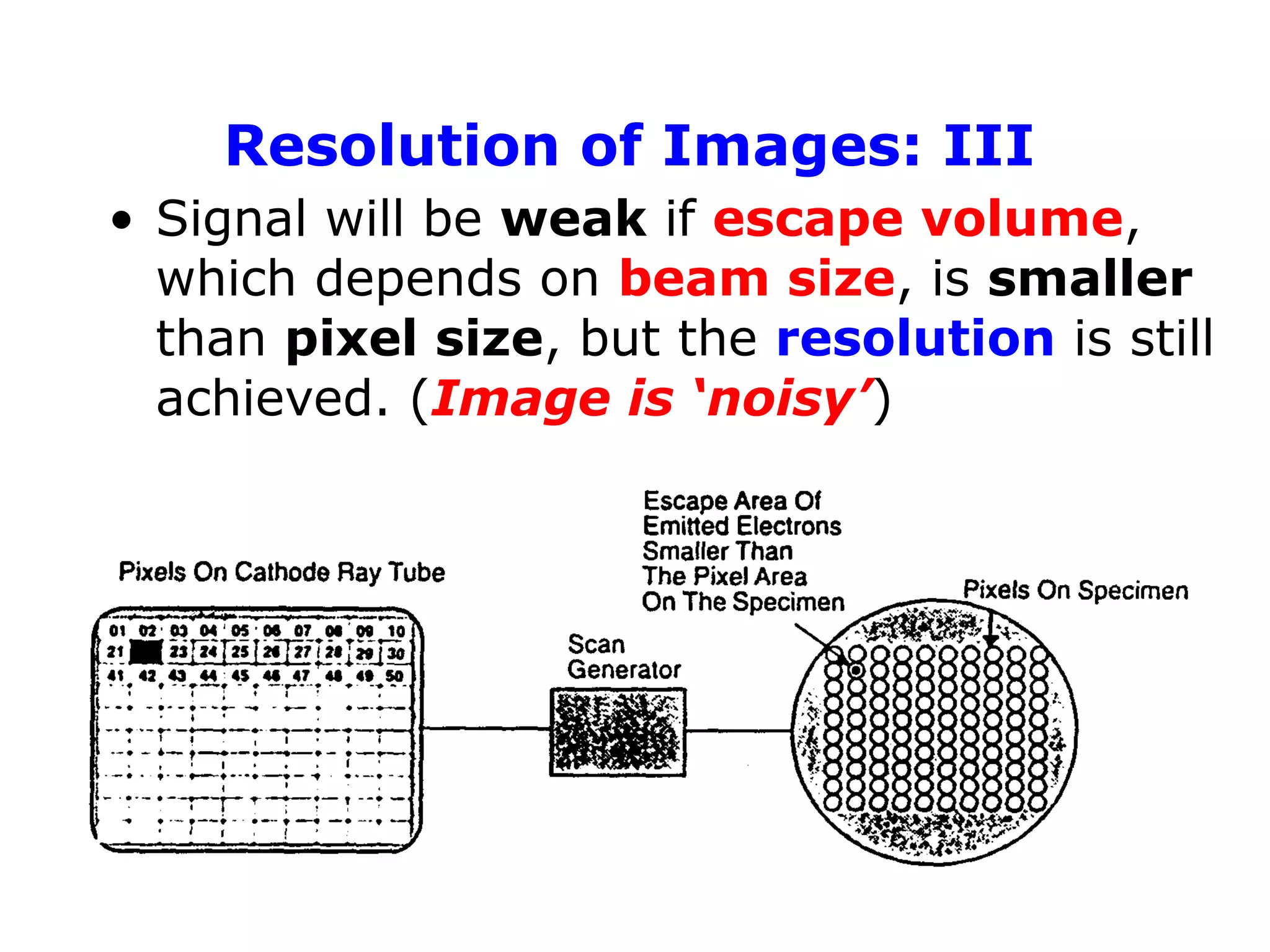

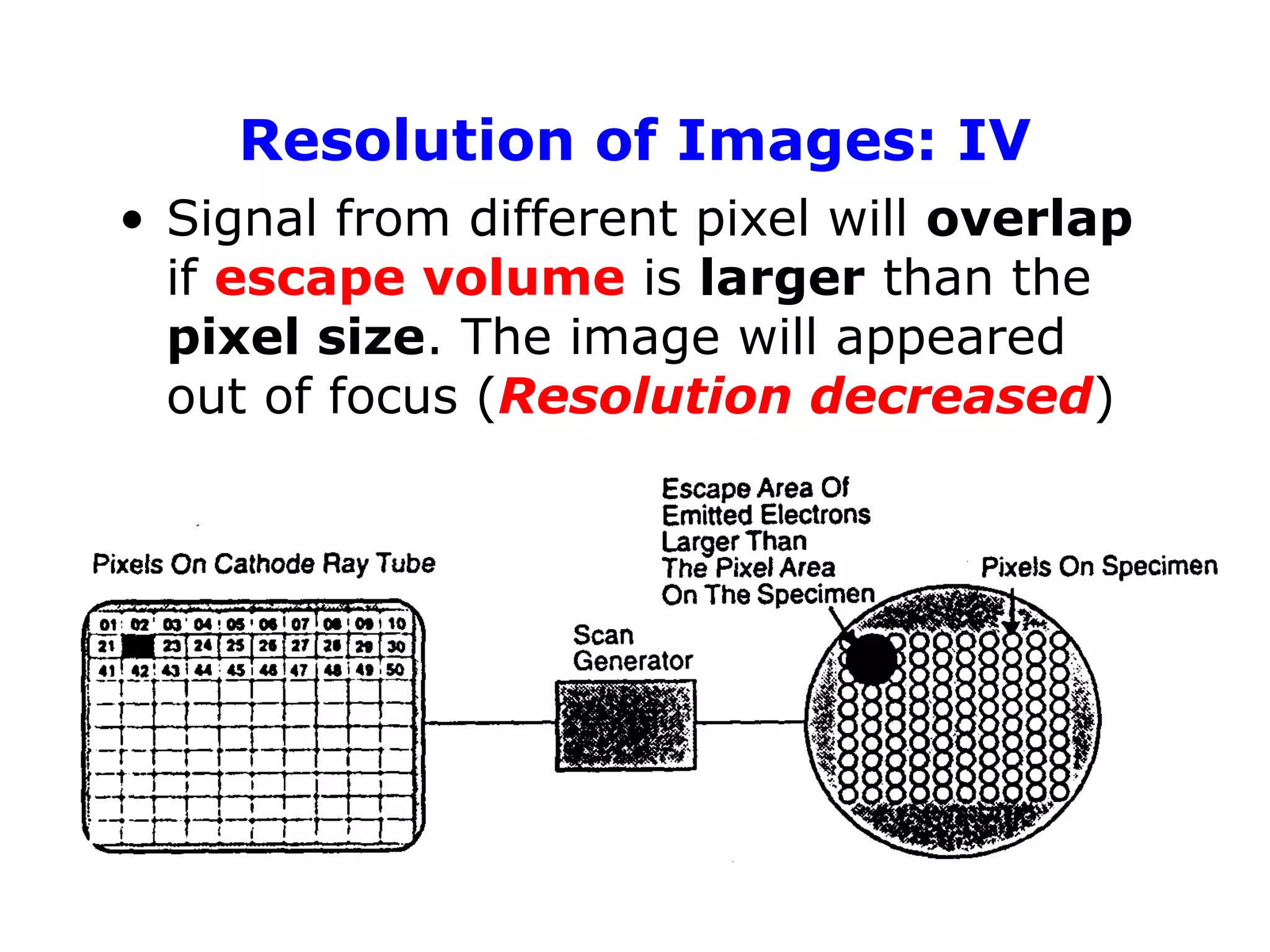

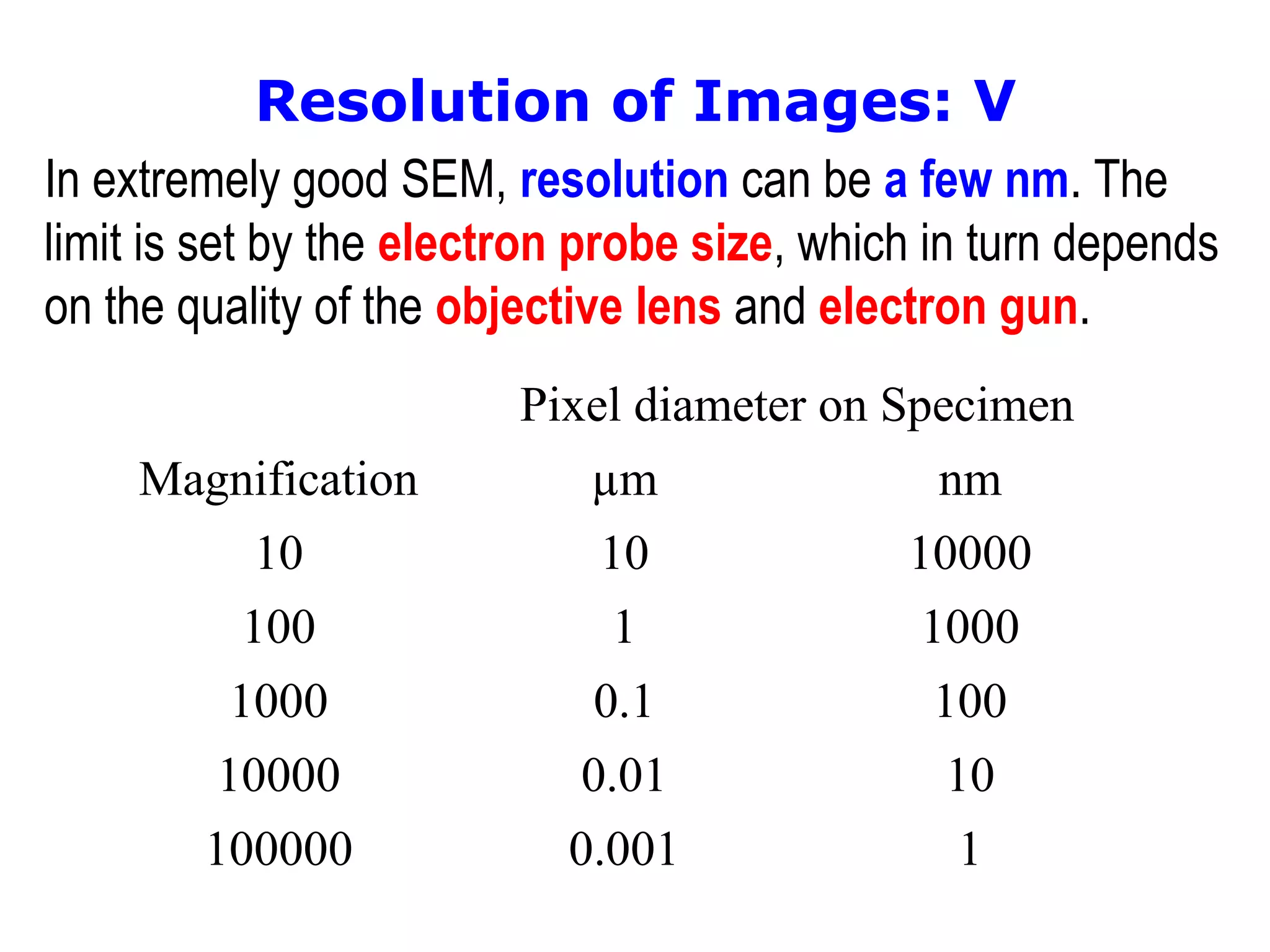

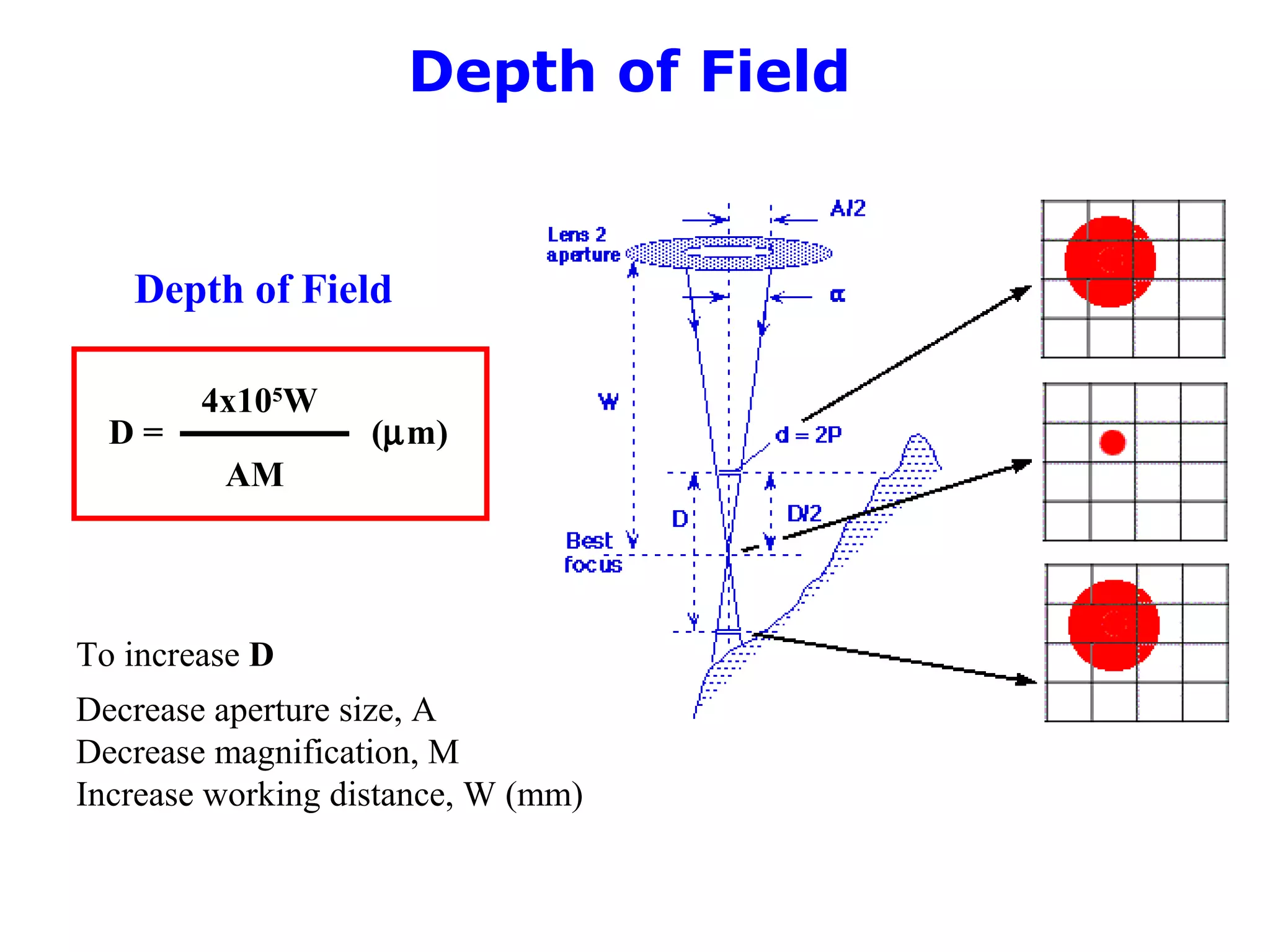

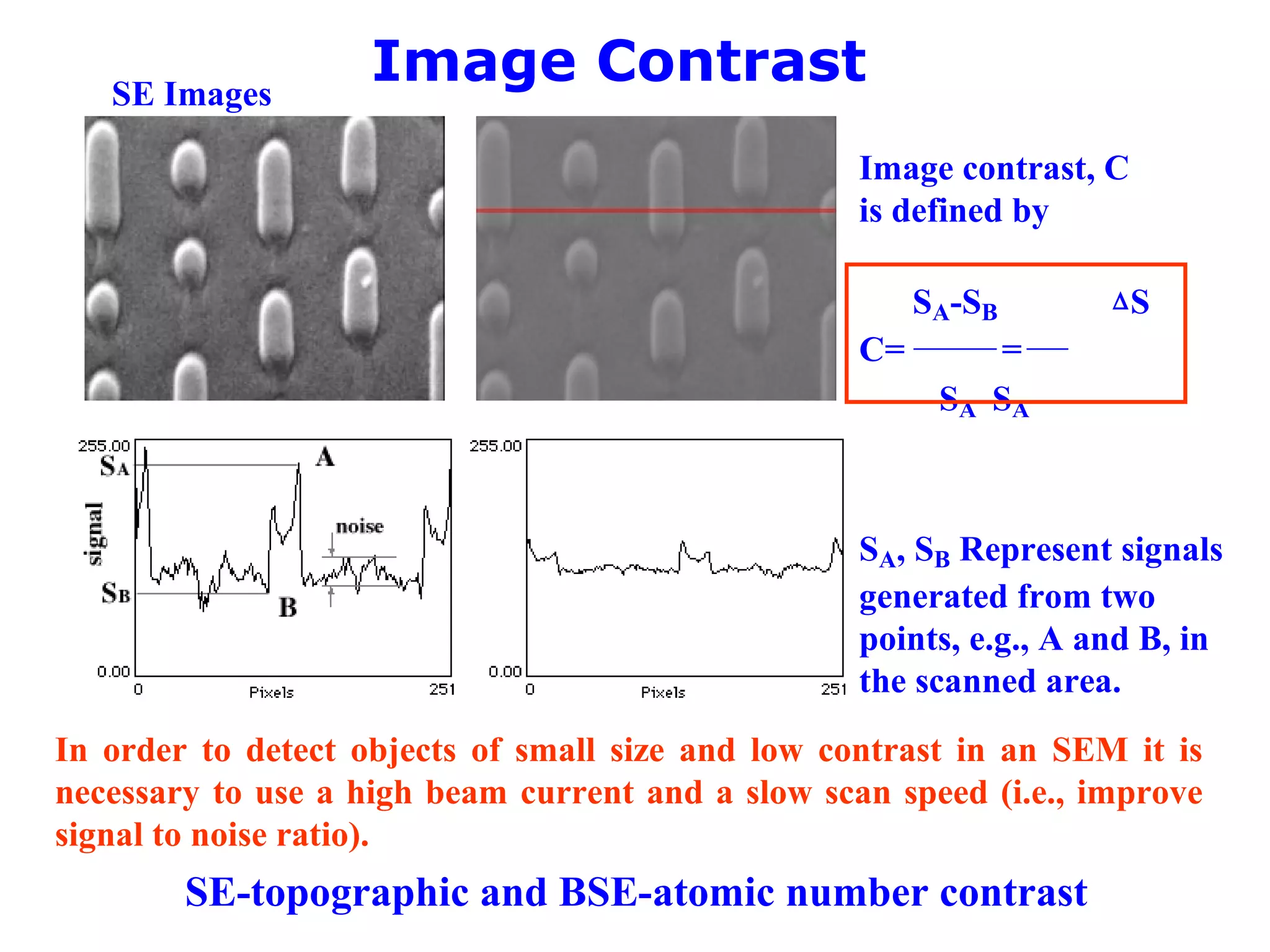

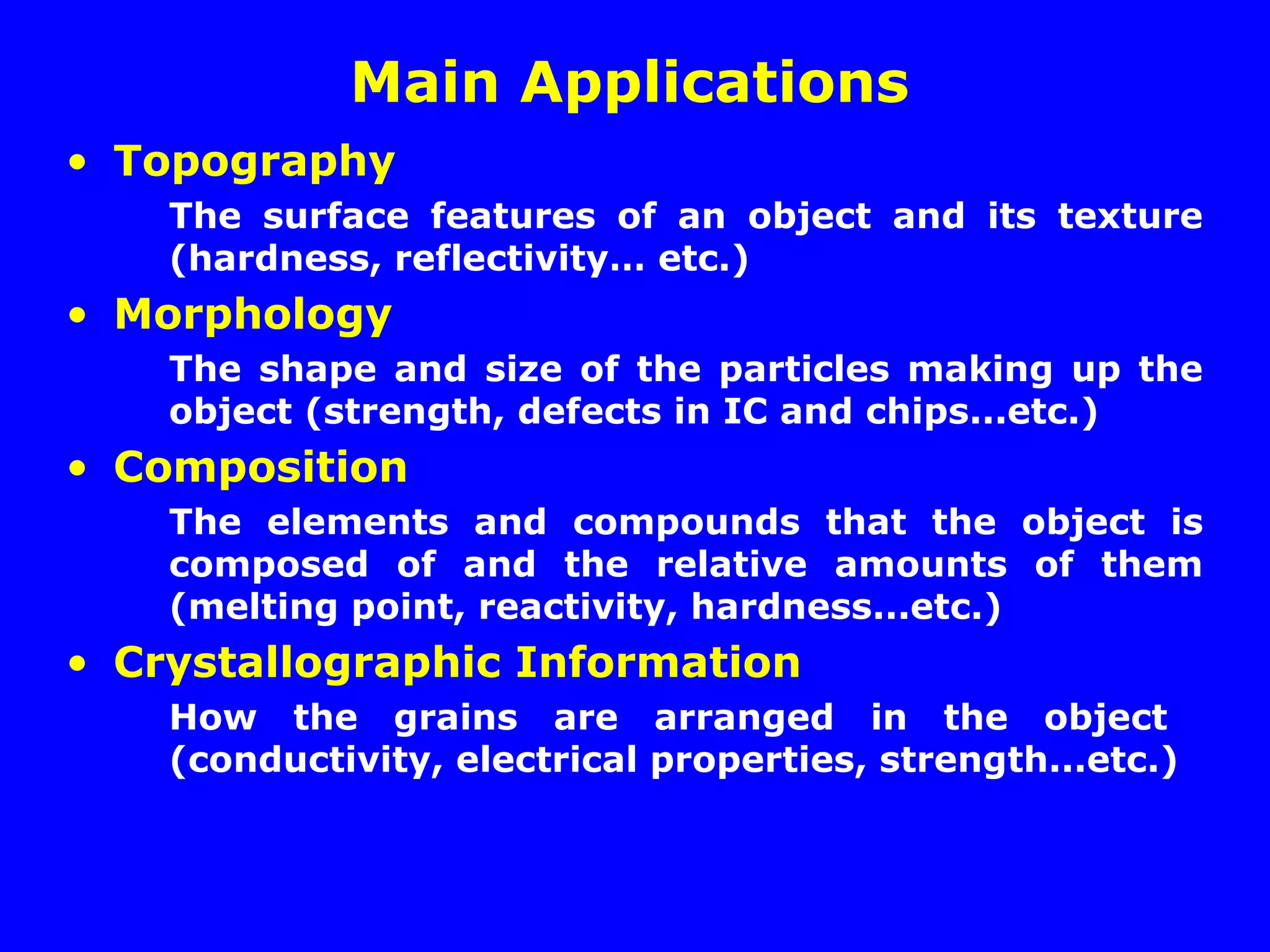

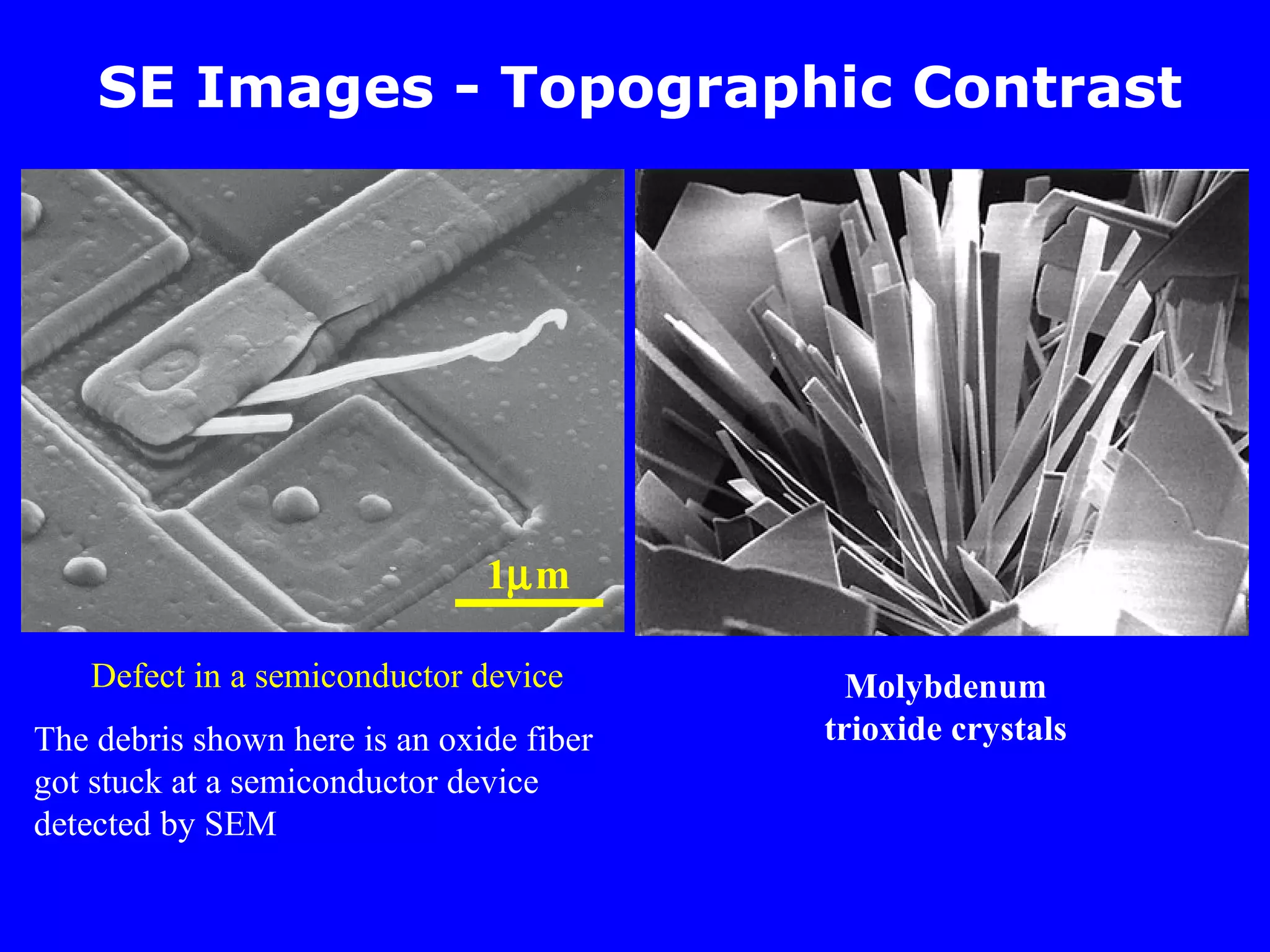

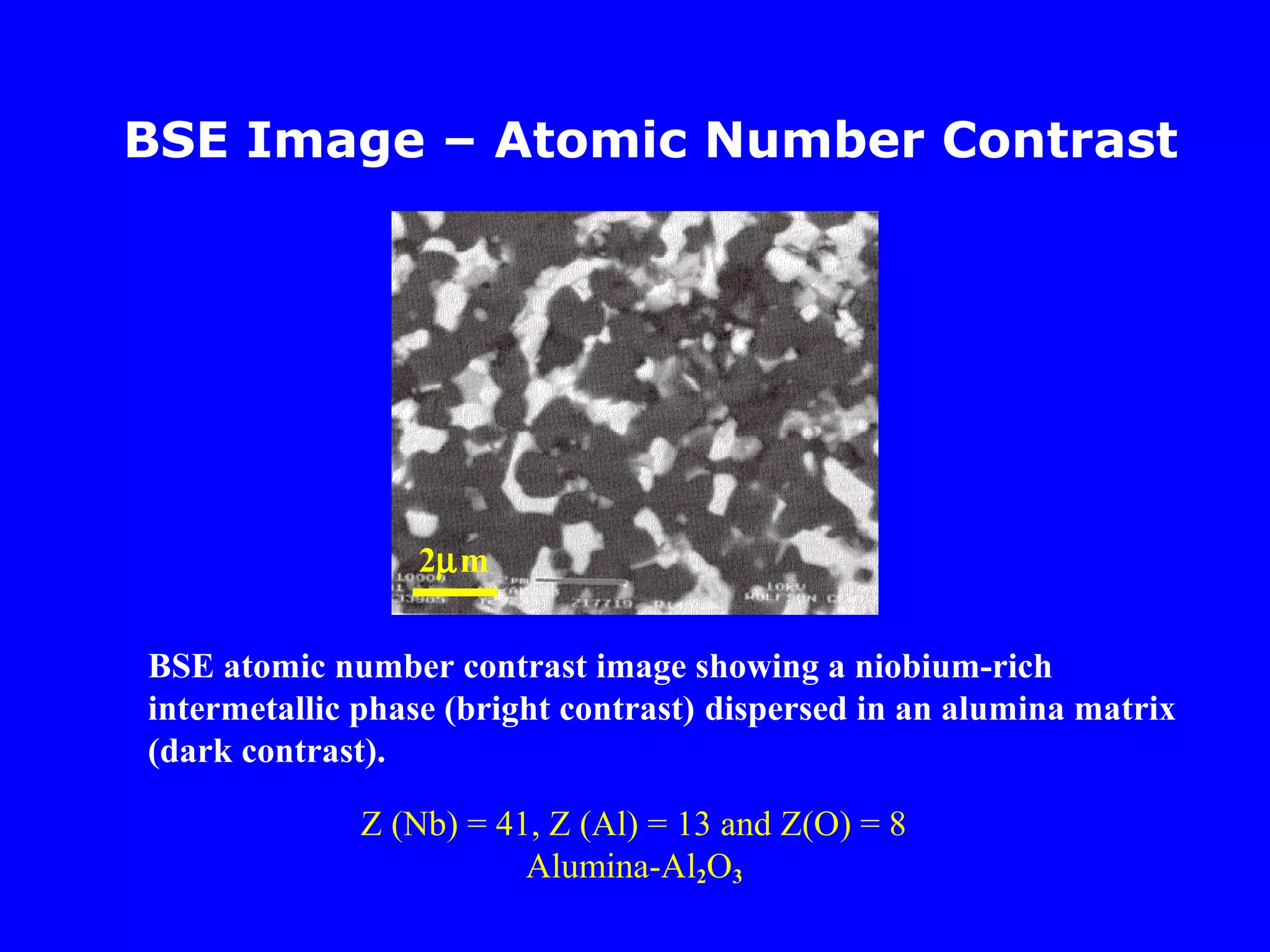

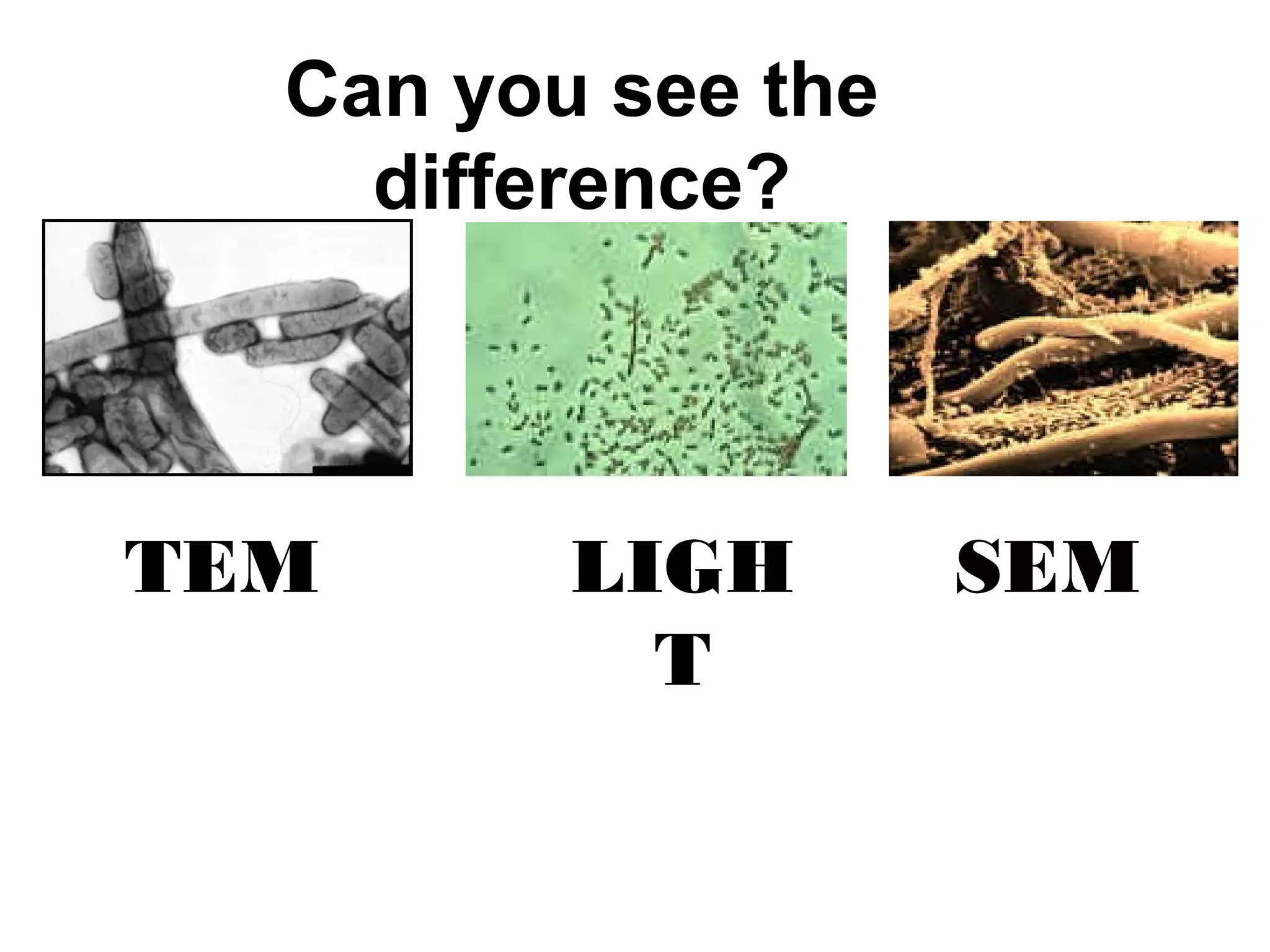

The document provides an overview of Scanning Electron Microscopy (SEM), focusing on its principles, instrumentation, and applications. SEM produces high-resolution, three-dimensional images of sample surfaces using a high-energy electron beam, and it is particularly valuable in semiconductor research and defect analysis. The document also details the electron-specimen interactions and the advantages of SEM over optical microscopy, including greater magnification and depth of field.