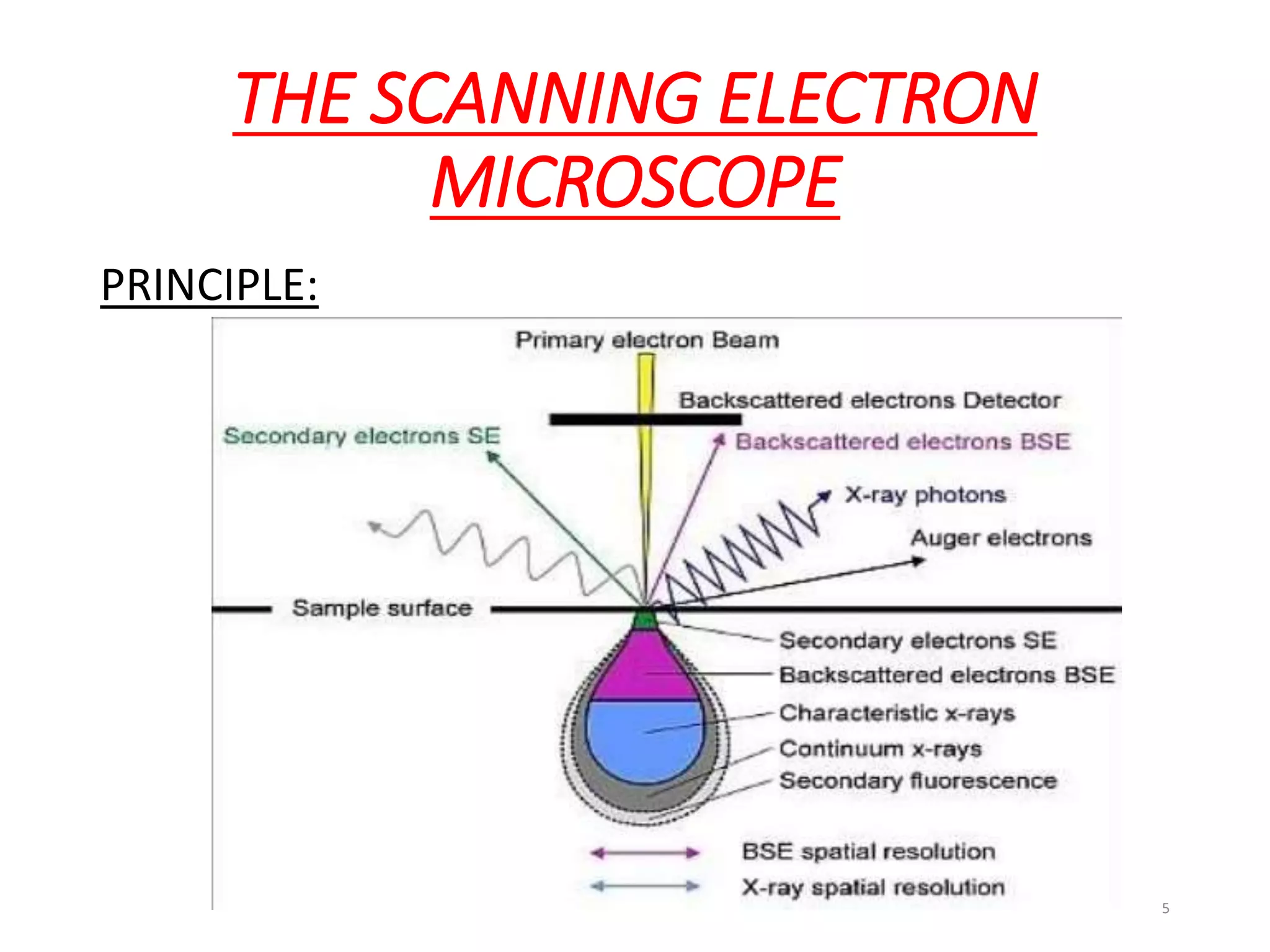

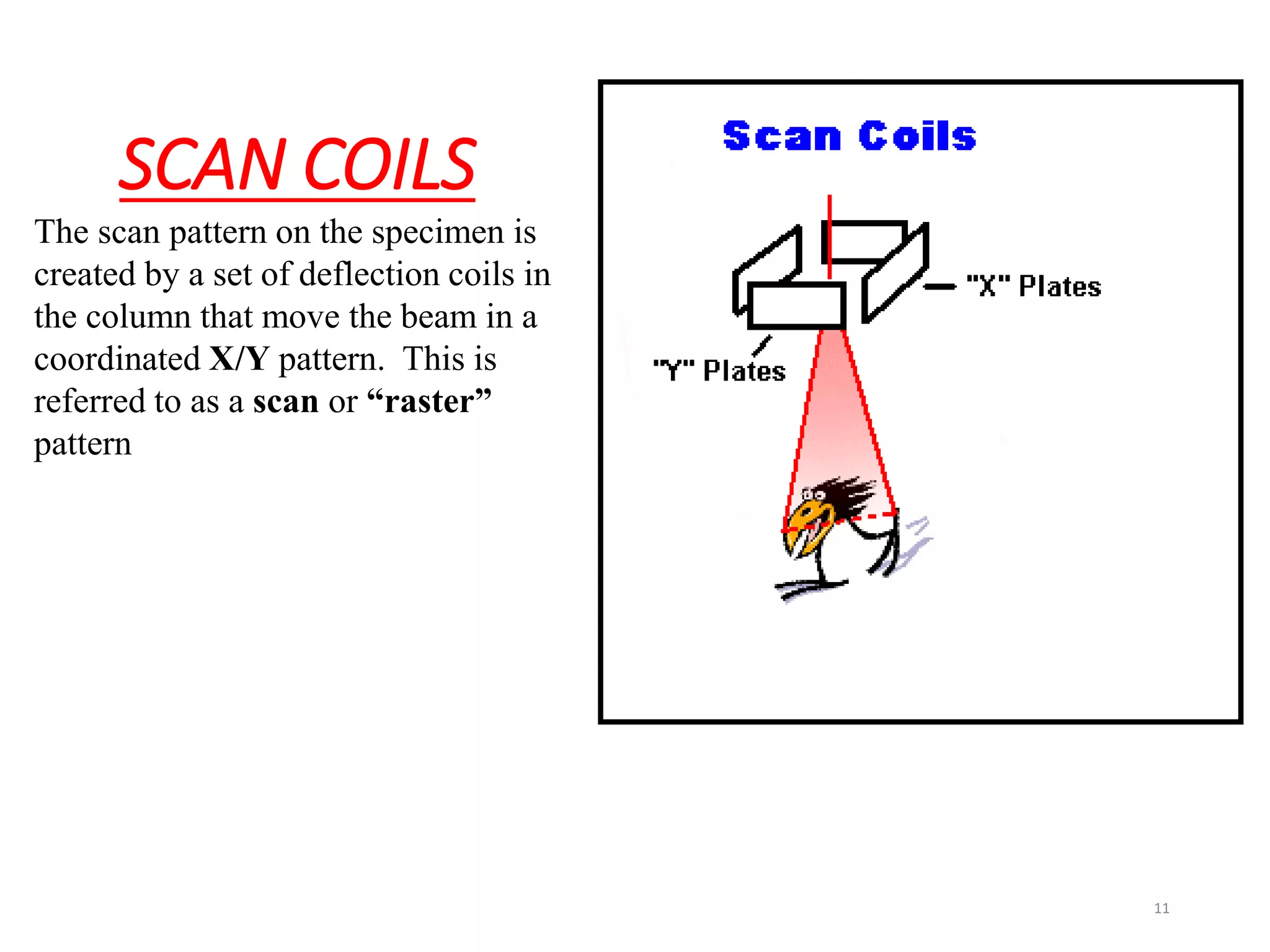

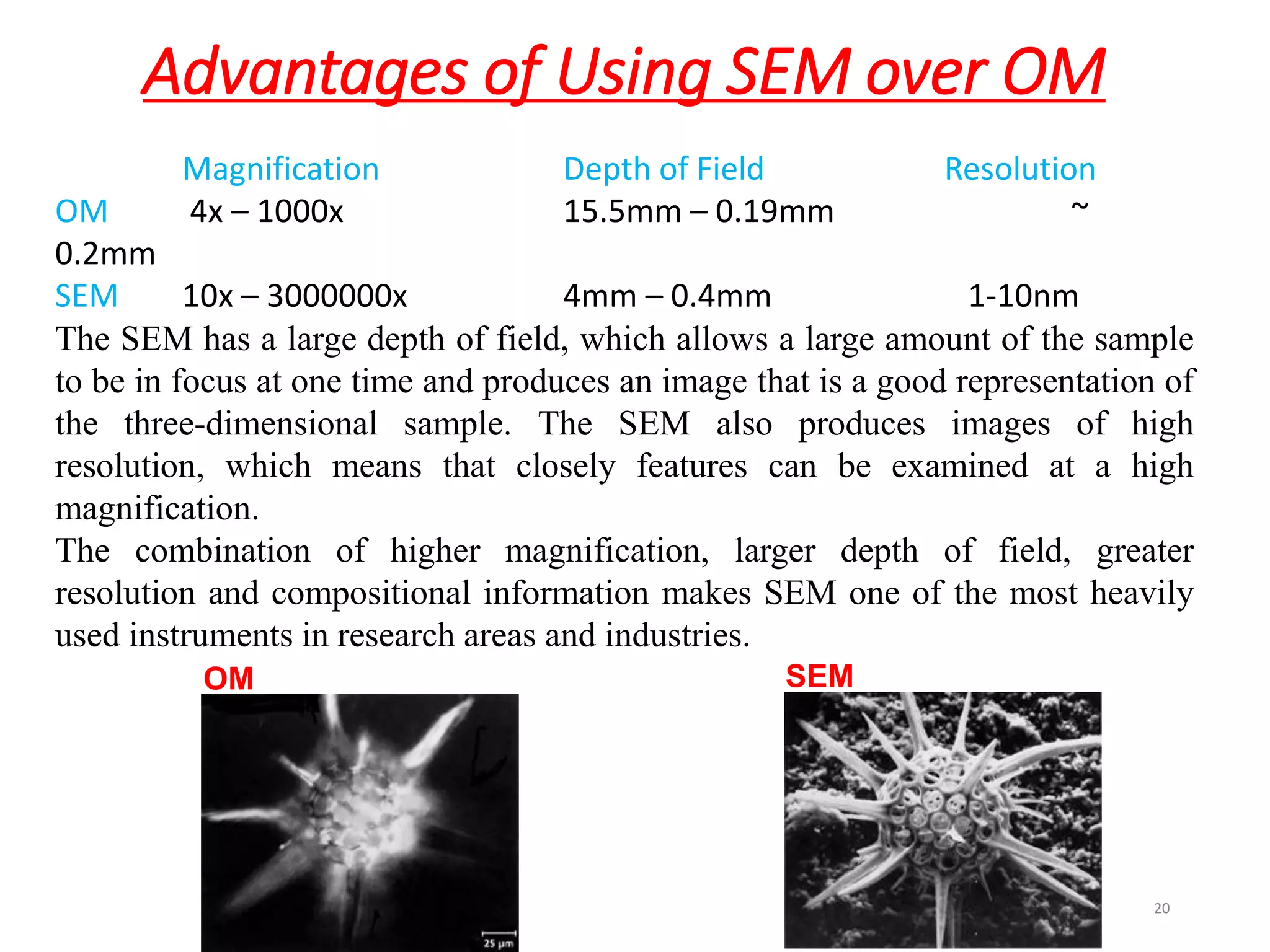

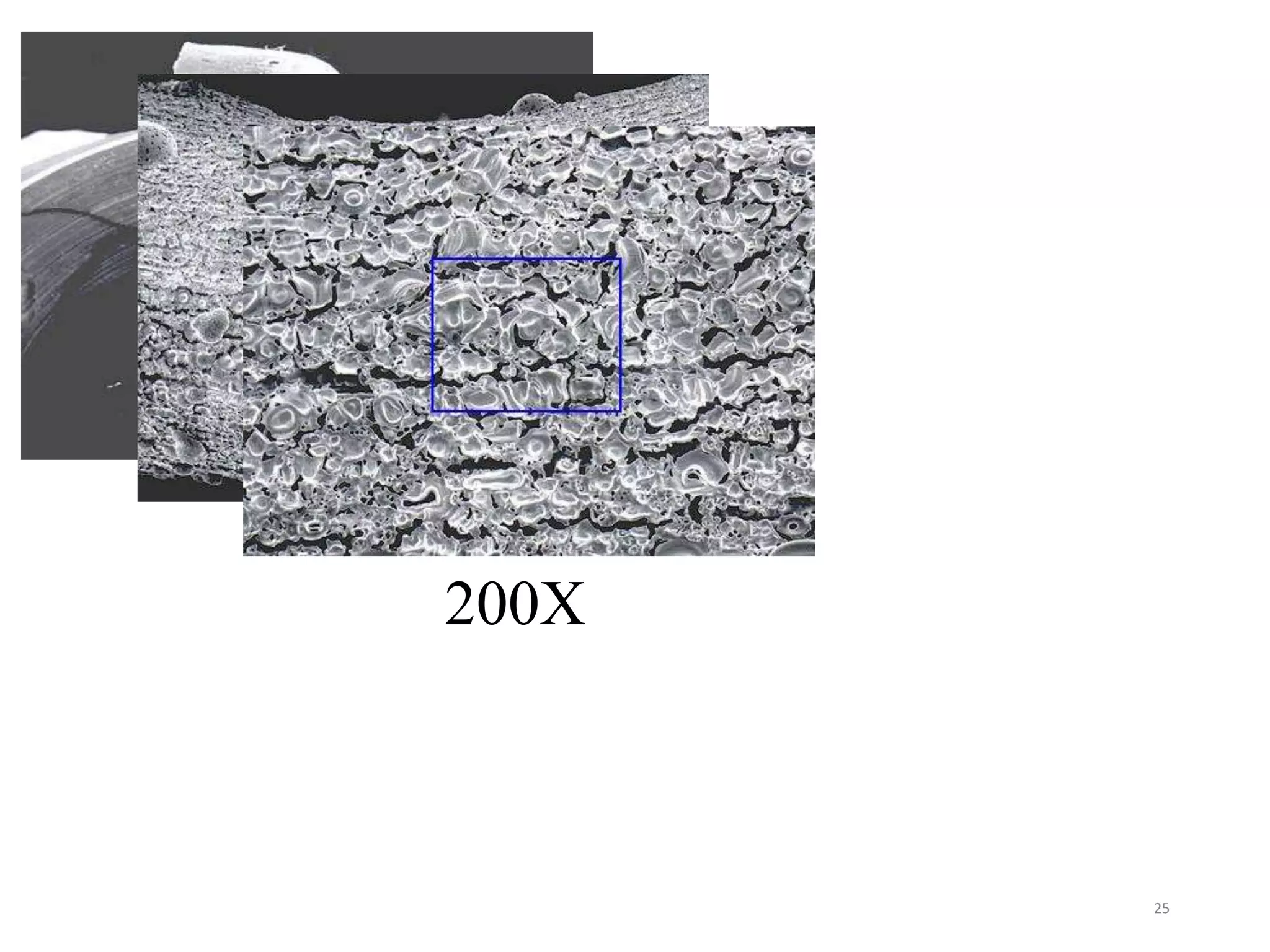

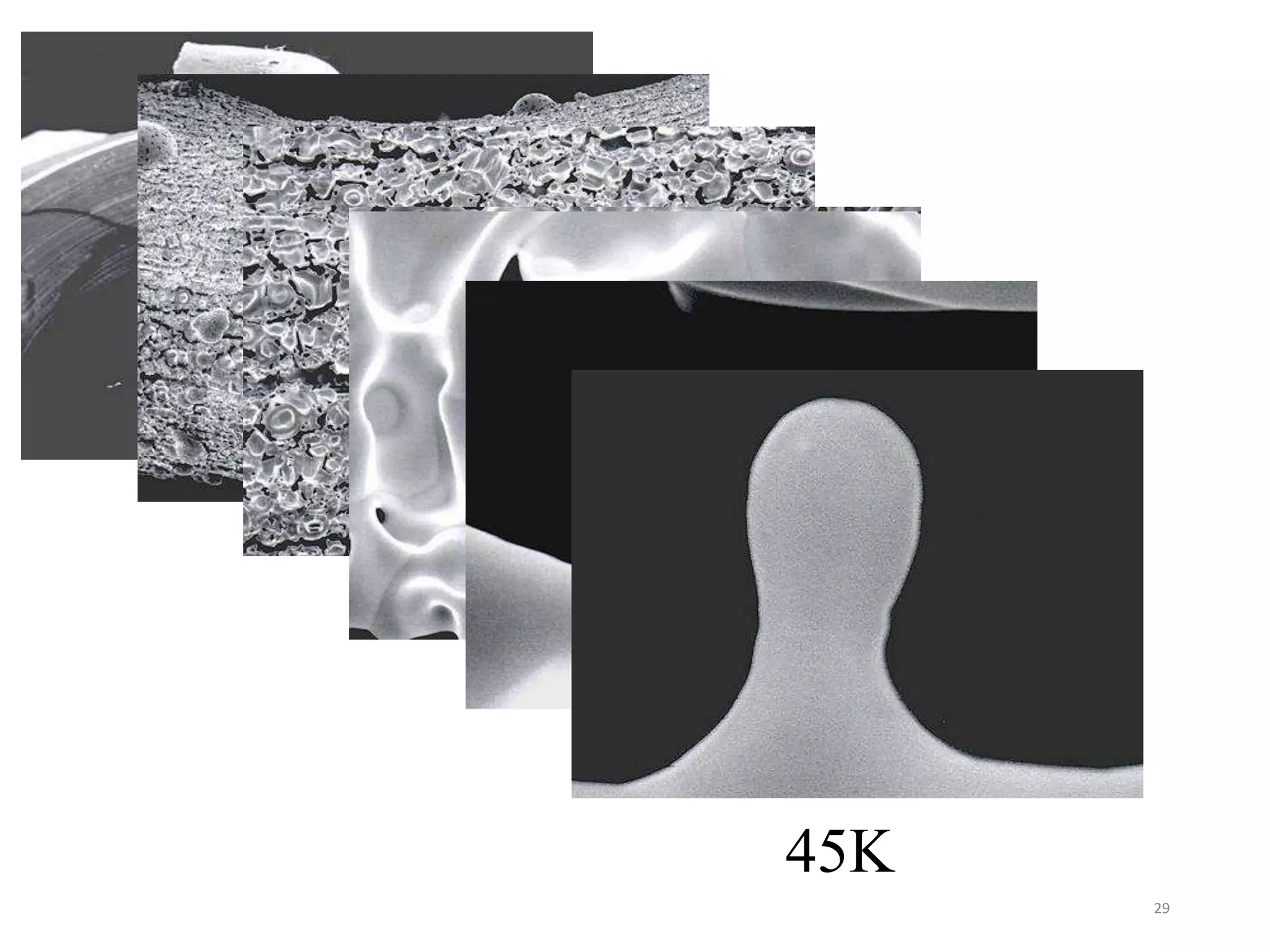

This presentation summarizes scanning electron microscopy (SEM). It begins with an introduction to SEM and then covers the basic components and working principle. The main components discussed are the electron gun, condenser lenses, scan coils, vacuum chamber, and detectors. It describes how an electron beam is focused on and scans the sample, emitting signals that are detected and used to form images. The presentation highlights the advantages of SEM such as high magnification and resolution images of surface topography and ability to determine composition. It also notes some disadvantages like high cost and sample requirements. Finally, it outlines several applications of SEM in science, industry, and technology.