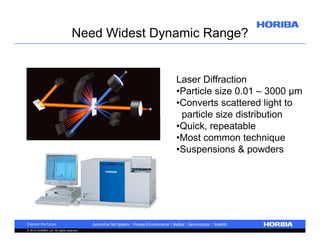

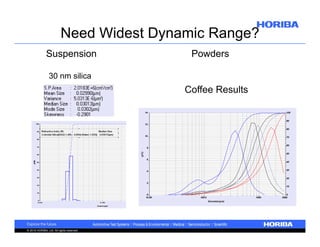

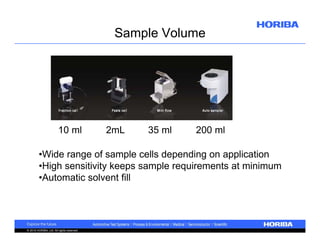

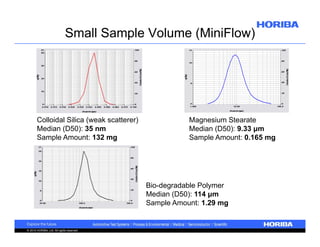

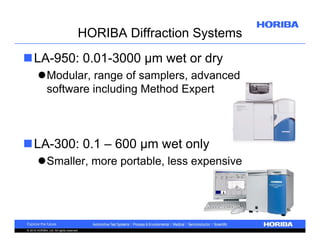

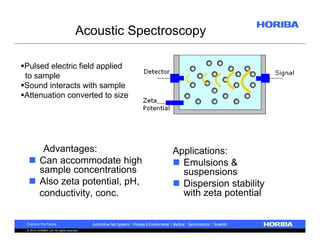

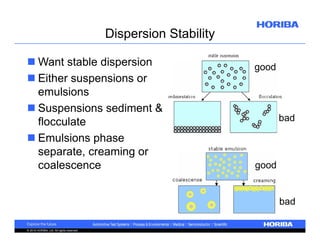

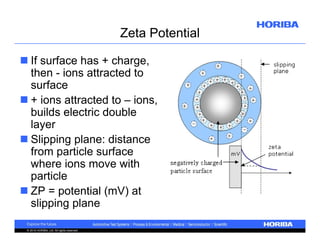

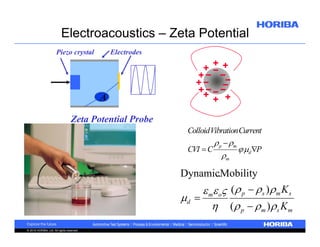

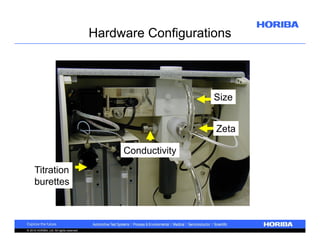

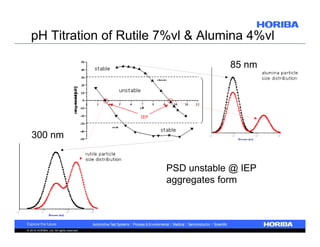

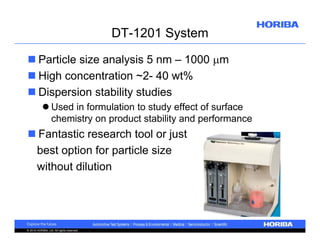

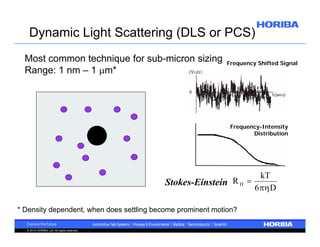

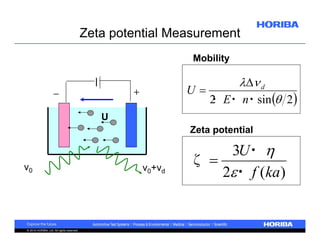

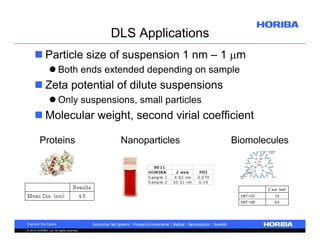

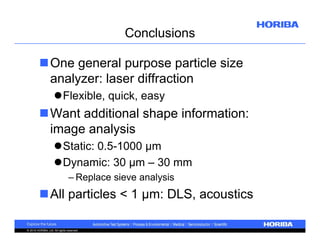

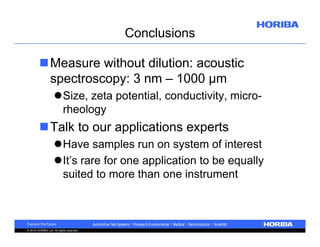

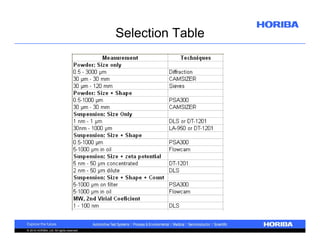

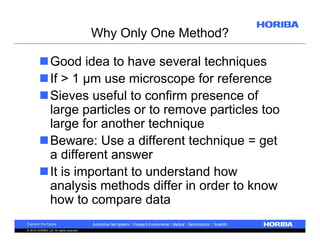

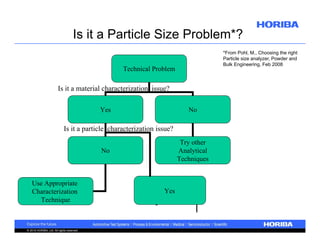

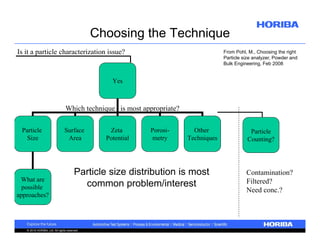

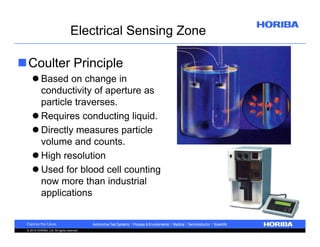

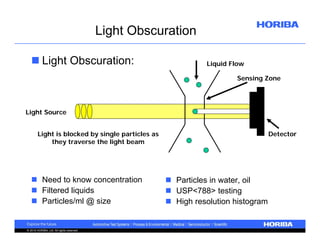

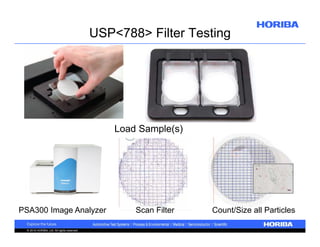

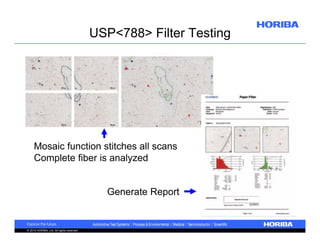

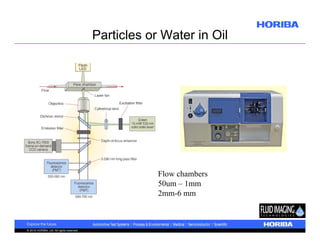

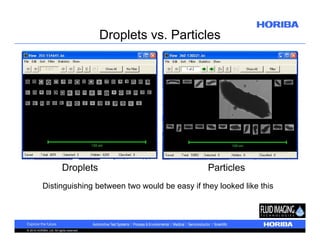

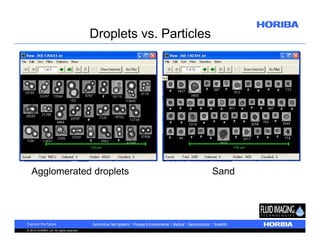

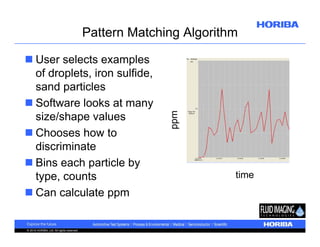

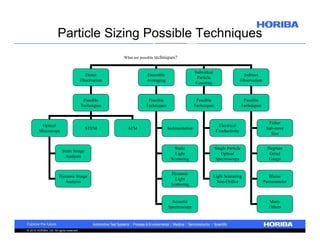

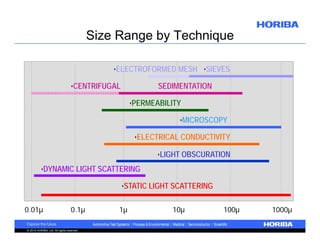

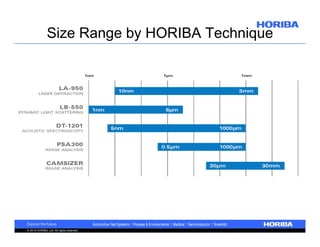

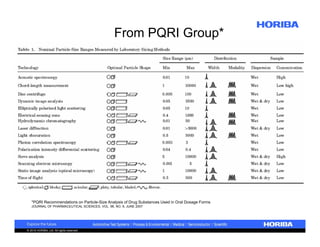

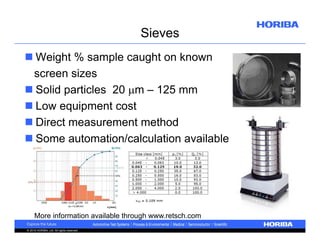

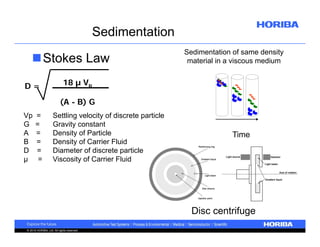

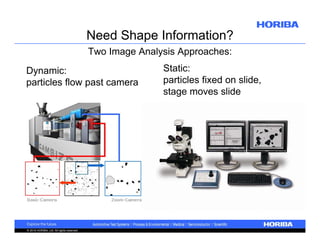

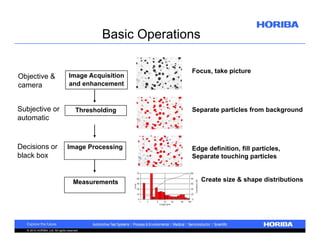

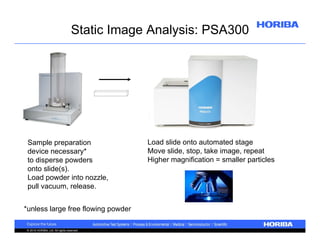

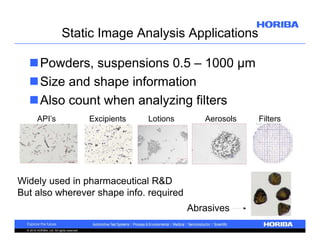

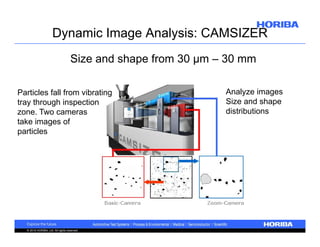

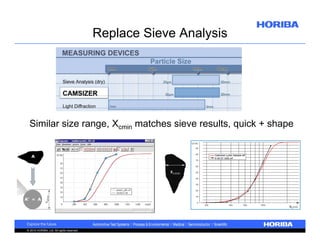

The document discusses the selection of particle characterization analyzers based on specific application needs, including factors such as measurement purpose, sample type, and data requirements. It reviews various techniques for particle characterization, including size analysis, zeta potential measurement, and image analysis, highlighting the importance of understanding sample behavior, type, and industry standards. The document emphasizes the necessity of defining suitable methods for accurate analysis, suggesting that no single technique fits all applications.

![Dynamic Image Analysis Applications

Powders 30 µm – 30 mm

Glass beads

Sugar spheres

Fertilizers

Catalysts

Coating thickness

q3 [%/mm]

Q3 [%]

CoMo2-0,1%Absch_xc_min_001.rdf

90

180

80

160

70

140

60

120

50

100

40

80

30

60

20

40

10

20

0

0

1.4

1.6

1.8

2.0

2.2

2.4

x1

© 2010 HORIBA, Ltd. All rights reserved.

2.6

2.8

x2

x [mm]](https://image.slidesharecdn.com/technologyseries-selectingthebestparticlesizeanalyzer-110707223450-phpapp01/85/Selecting-the-Best-Particle-Size-Analyzer-for-your-Application-34-320.jpg)