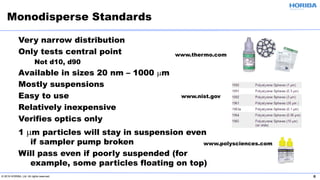

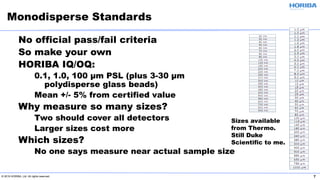

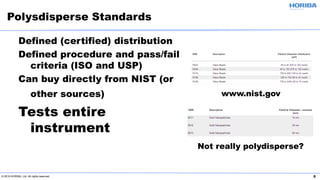

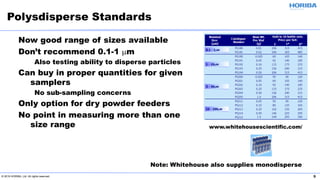

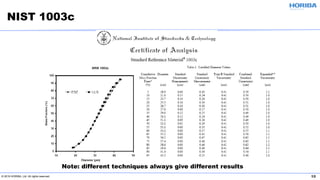

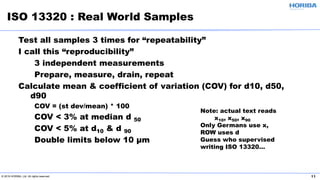

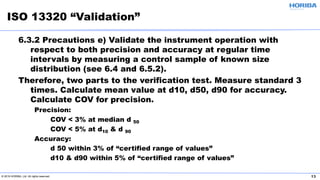

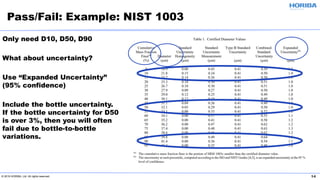

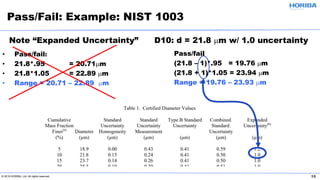

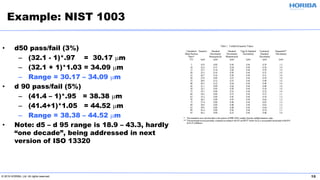

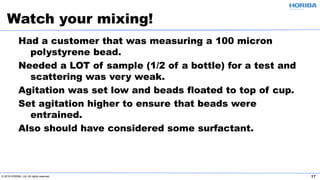

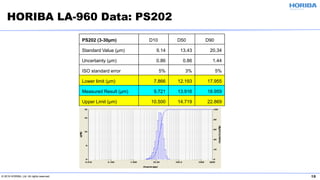

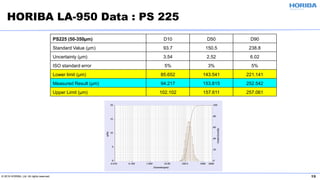

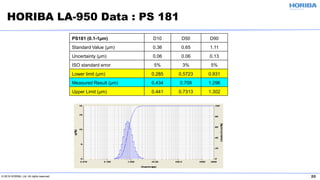

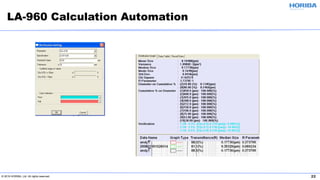

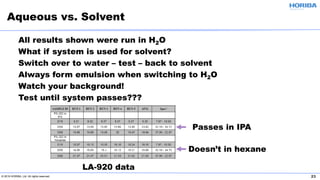

The document discusses the verification and calibration procedures for particle characterization instruments, emphasizing the importance of using standard reference materials and the need for regular validation to ensure instrument accuracy and precision. It details specific methodologies for measuring and calculating particle sizes, including guidelines from ISO standards, and highlights the distinction between monodisperse and polydisperse standards. Additionally, it addresses challenges faced in measurement accuracy, including sample preparation and environmental factors.