The document summarizes research on producing Cu2ZnSnS4 (CZTS) thin films for solar cell applications using spray pyrolysis deposition. Key points:

1) CZTS thin films were successfully deposited using a simple and inexpensive spray pyrolysis technique involving spraying a precursor solution containing copper, zinc, tin, and sulfur compounds onto a heated substrate.

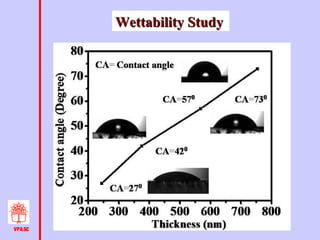

2) Characterization of the films showed that increasing thickness improved crystallinity, grain size, optical absorption in the desired 1.6-1.67eV range, and electrical conductivity.

3) The research demonstrated the spray pyrolysis technique can effectively produce CZTS thin films for solar cells in a single-step process without vacuums or