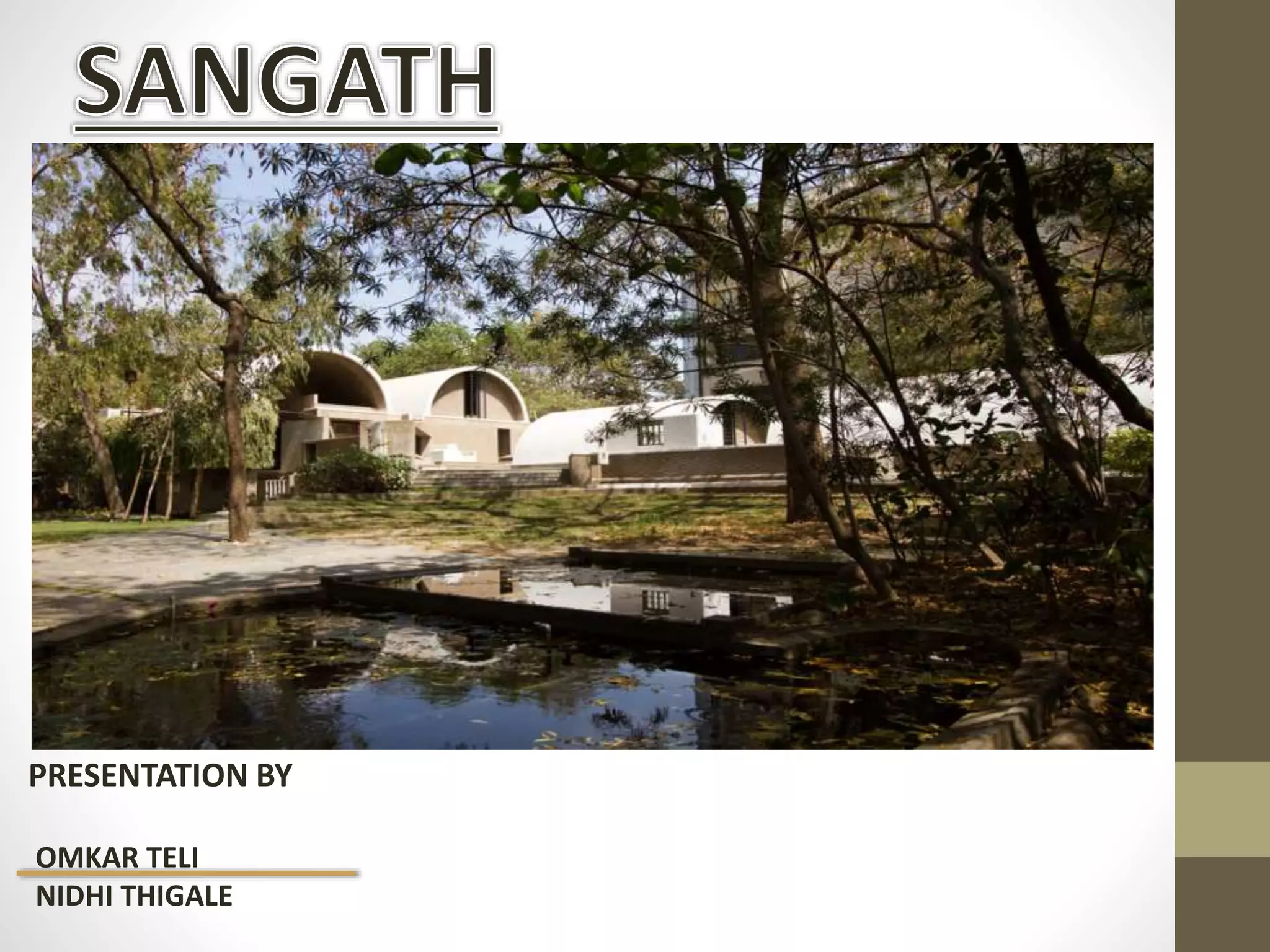

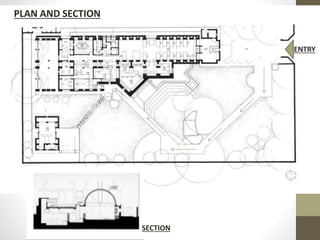

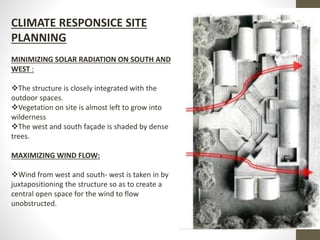

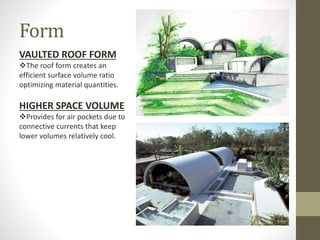

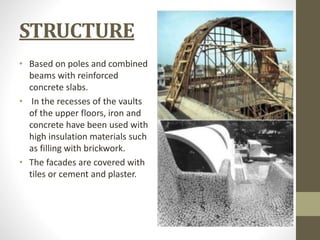

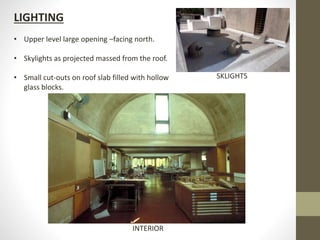

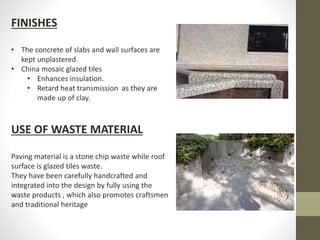

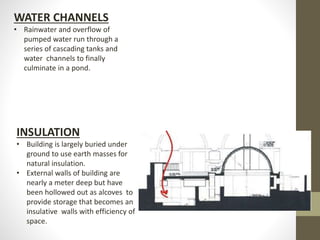

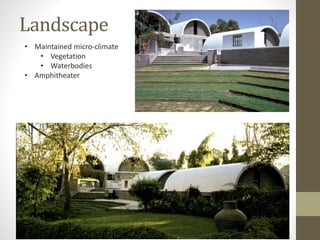

The document presents a design overview of an architect's office located in Ahmedabad, featuring a building complex with a climate-responsive structure and extensive use of vegetation. Key architectural elements include vaulted roofs, natural insulation, and reduced reliance on mechanical energy, resulting in significant energy efficiency and comfortable thermal conditions. The design integrates rainwater management and repurposed materials, promoting sustainability and craftsmanship.