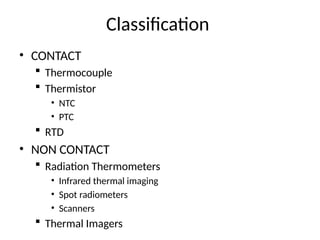

The document provides a comprehensive overview of various temperature sensors, including MEMS thermal sensors, thermocouples, and thermistors, detailing their principles of operation and classifications. It explains the temperature coefficient of resistance and how it varies across different materials, leading to distinctions between positive and negative temperature coefficients. Additionally, it highlights specific types of thermocouples, their applications, and the innovative D6T MEMS thermal sensor for detecting human presence and maintaining optimal temperature levels.

![• Consider a conductor whose resistance at 0°C is R0 and the

resistance at a temperature T°C is RT. The relation between

temperature and resistances R0 and RT is approximately given as

• RT = R0 [1+ α (T-T0)];

• RT = R0 [1+ α (∆T)]

• The above equation that the change in electrical resistance of any

substance due to temperature depends mainly on three factors –

– The value of resistance at an initial temperature.

– The rise in temperature.

– The temperature coefficient of resistance α.

• The value of α can vary depending on the type of material.

• In metals, as the temperature increases the electrons attain more

kinetic energy, thus more speed to undergo frequent collisions.

• We know that the resistivity of any substance is given by

• ρ = m/nq2

τ

RELATION BETWEEN TEMPERATURE AND RESISTANCE](https://image.slidesharecdn.com/memsthermalsensors-240927032624-9b6d5862/85/MEMS-Thermal-Sensors-pptx-5-320.jpg)