This document discusses redundancy in robotics. It defines a kinematically redundant robot as having more degrees of freedom than needed to place an end effector in a desired location. For example, a robot with more than six degrees of freedom can be redundant for tasks in three-dimensional space which only require six degrees. Redundancy allows for multiple feasible inverse kinematics solutions and can be used to achieve additional objectives like avoiding obstacles or singularities. However, redundant robots are also more complex, expensive, and difficult to control.

![Some tasks and their dimensions

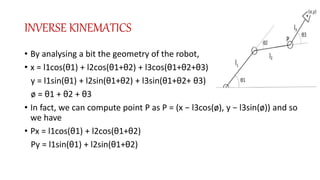

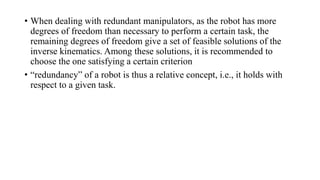

• A planar robot with N=3 joints is redundant for the task of positioning

its E-E in the plane (M=2), but NOT for the task of positioning AND

orienting the E-E in the plane (M=3).

TASKS [ For the end-effector(E-E)] DIMENSION(M)

Position in the plane 2

Position in 3D space 3

Orientation in the plane 1

Pointing in 3D space 2

Position and orientation in 3D space 6](https://image.slidesharecdn.com/robotics-190425135427/85/Robotics-4-320.jpg)