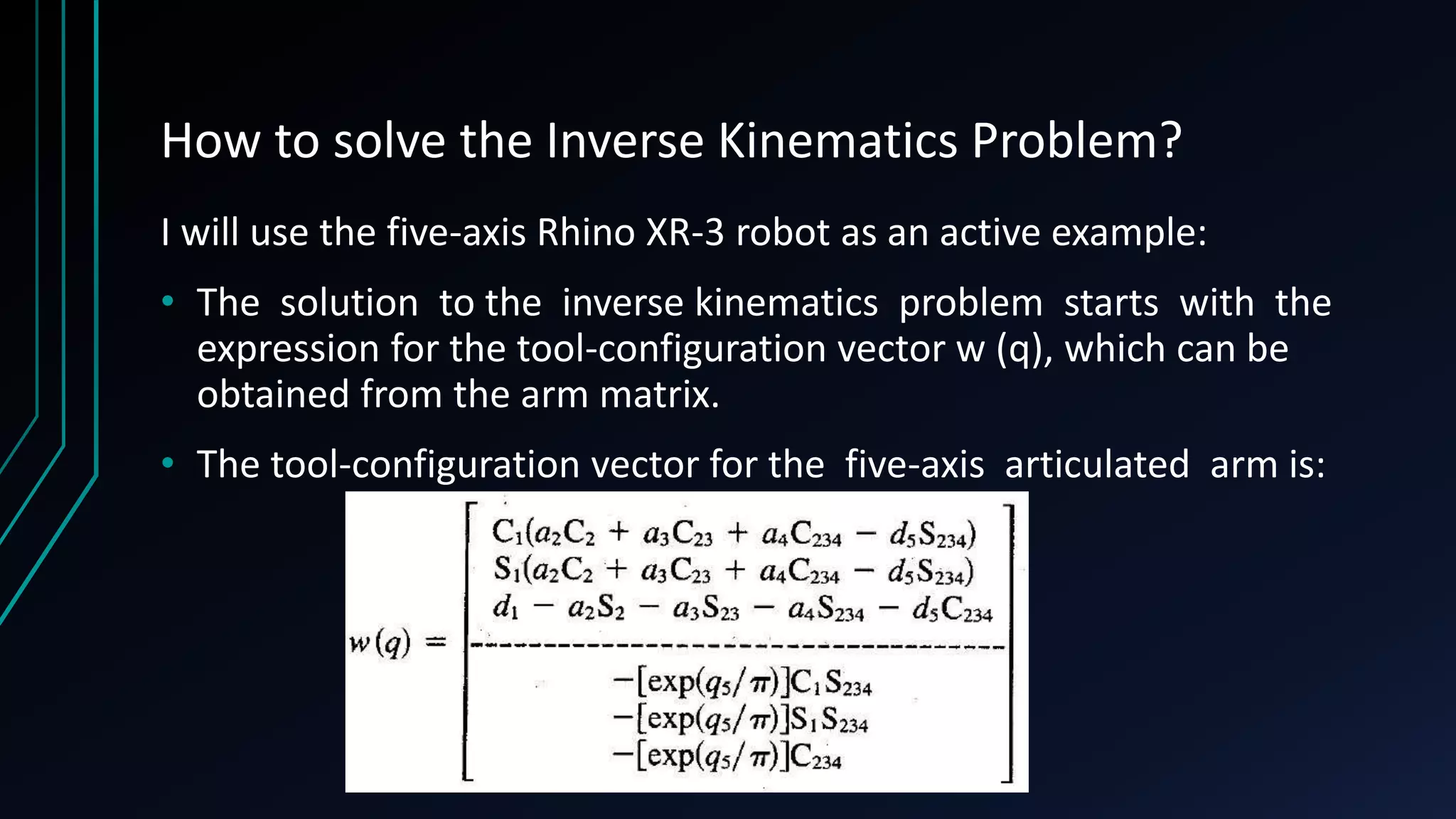

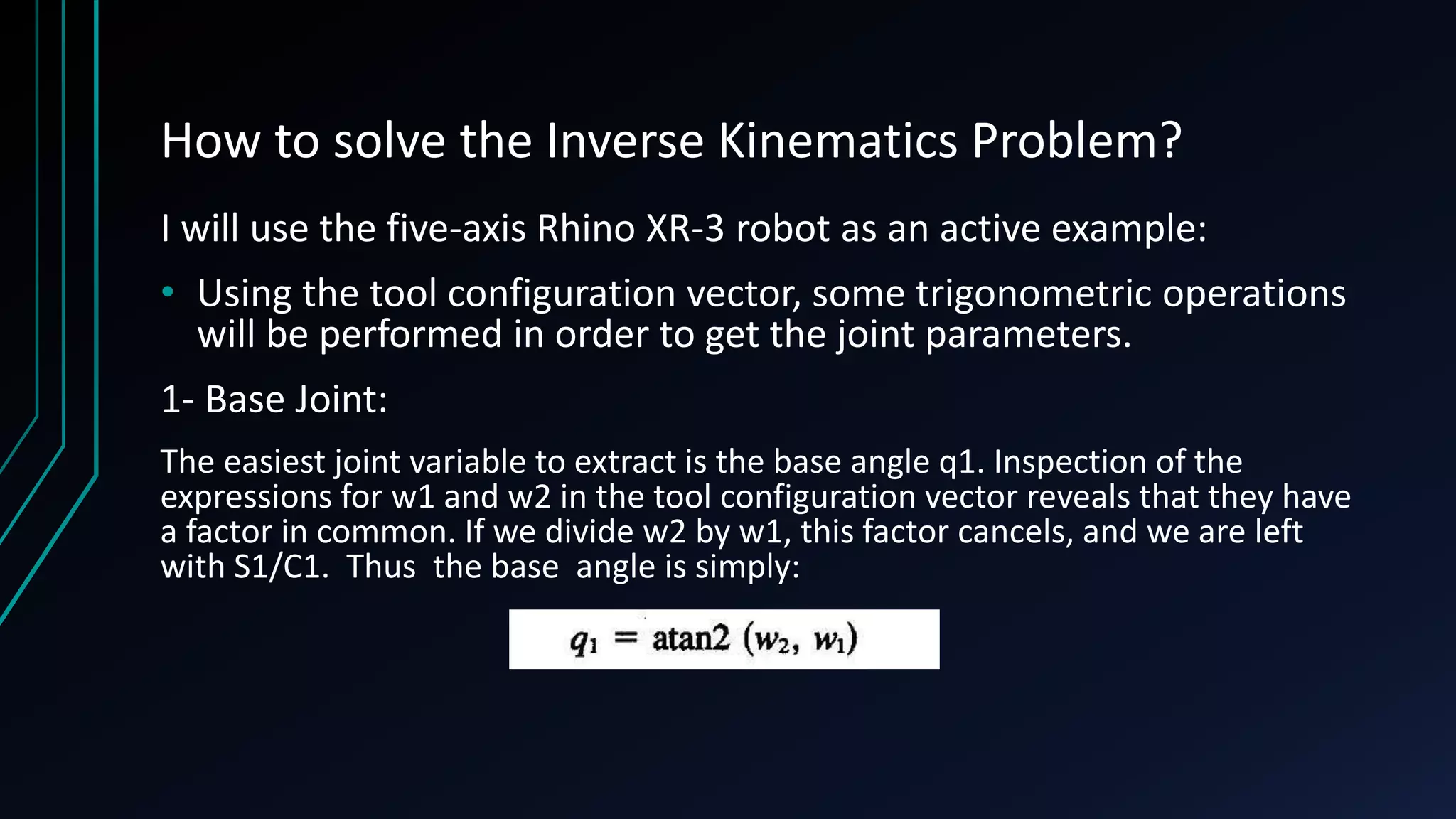

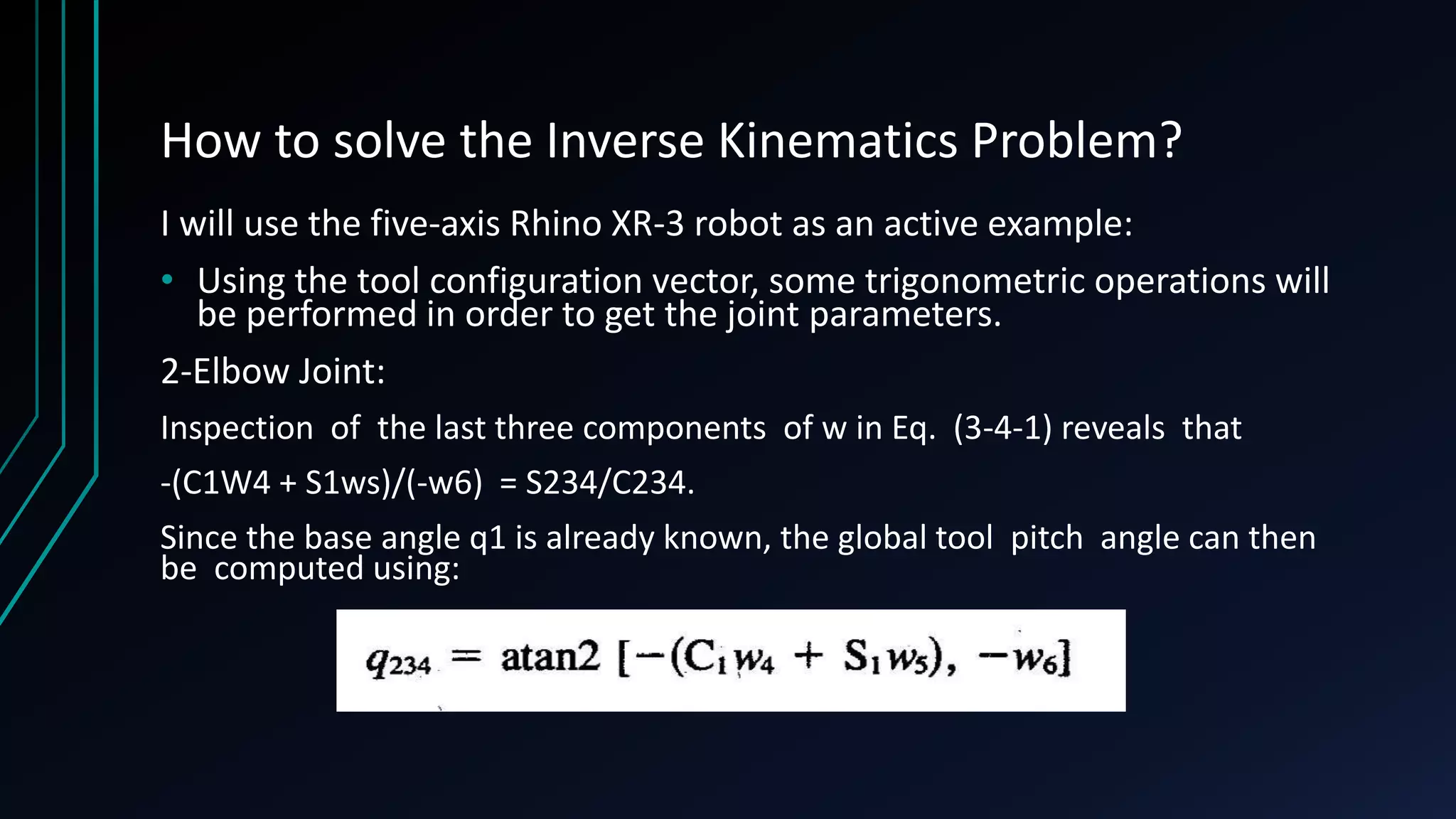

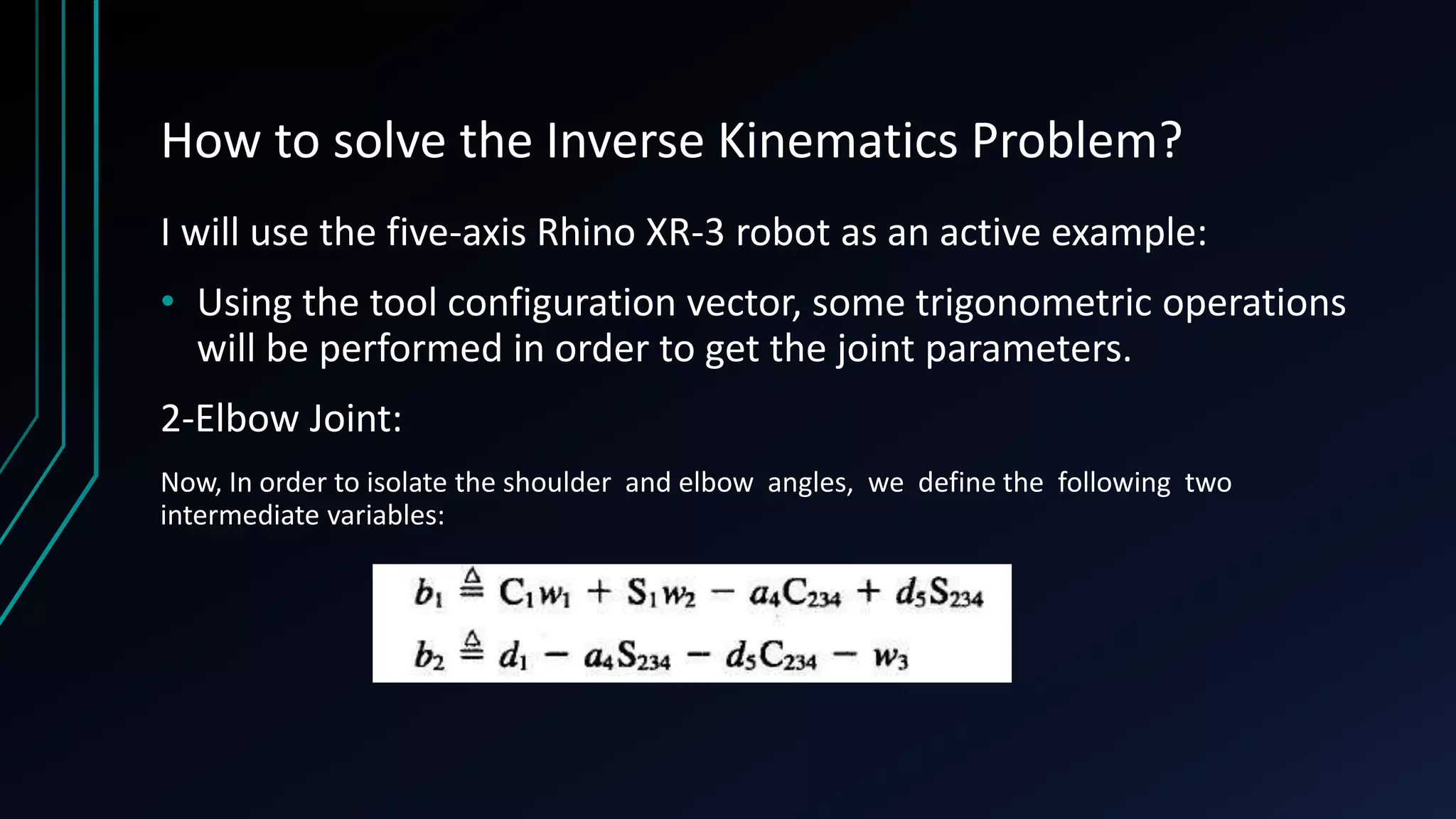

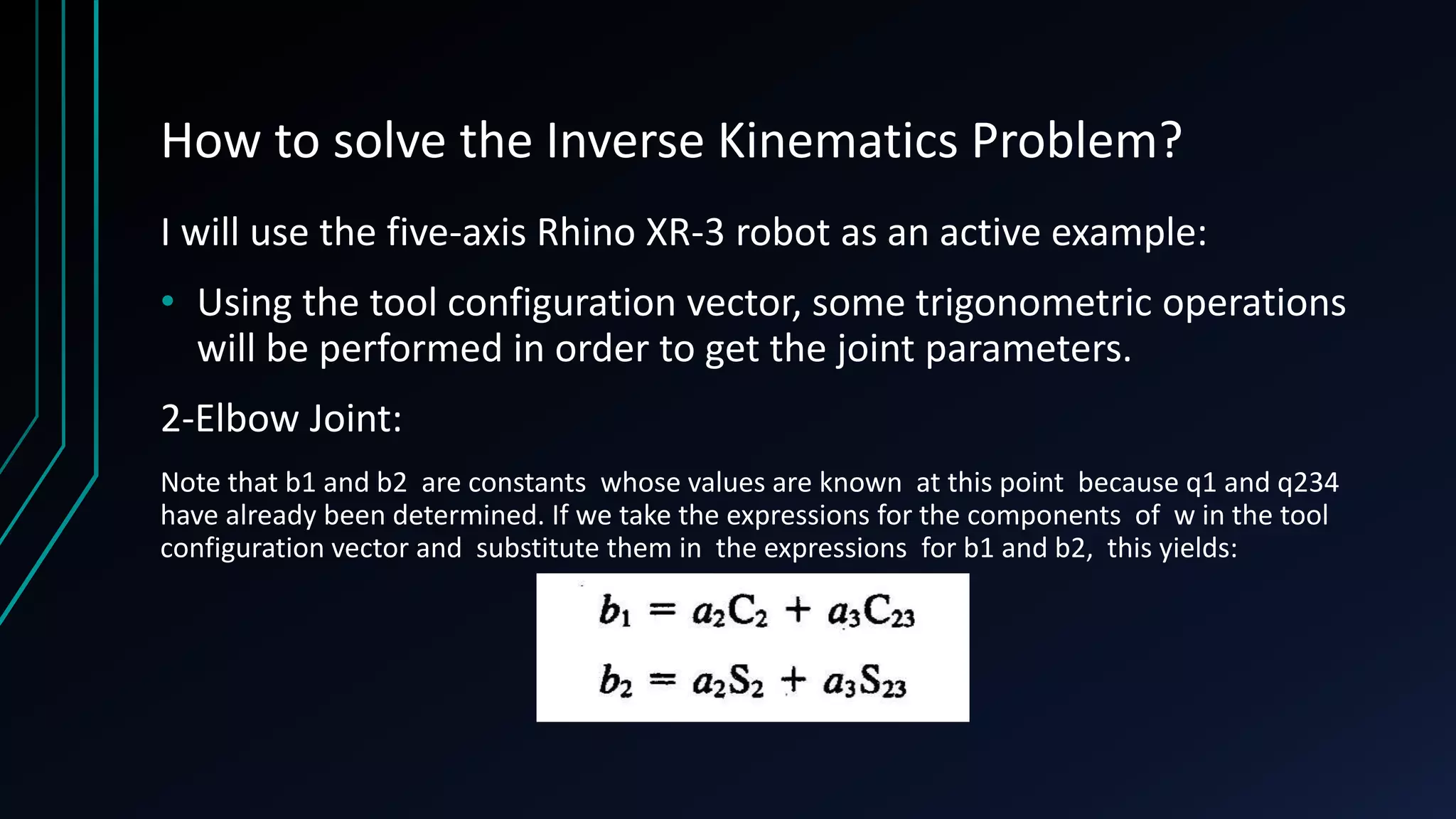

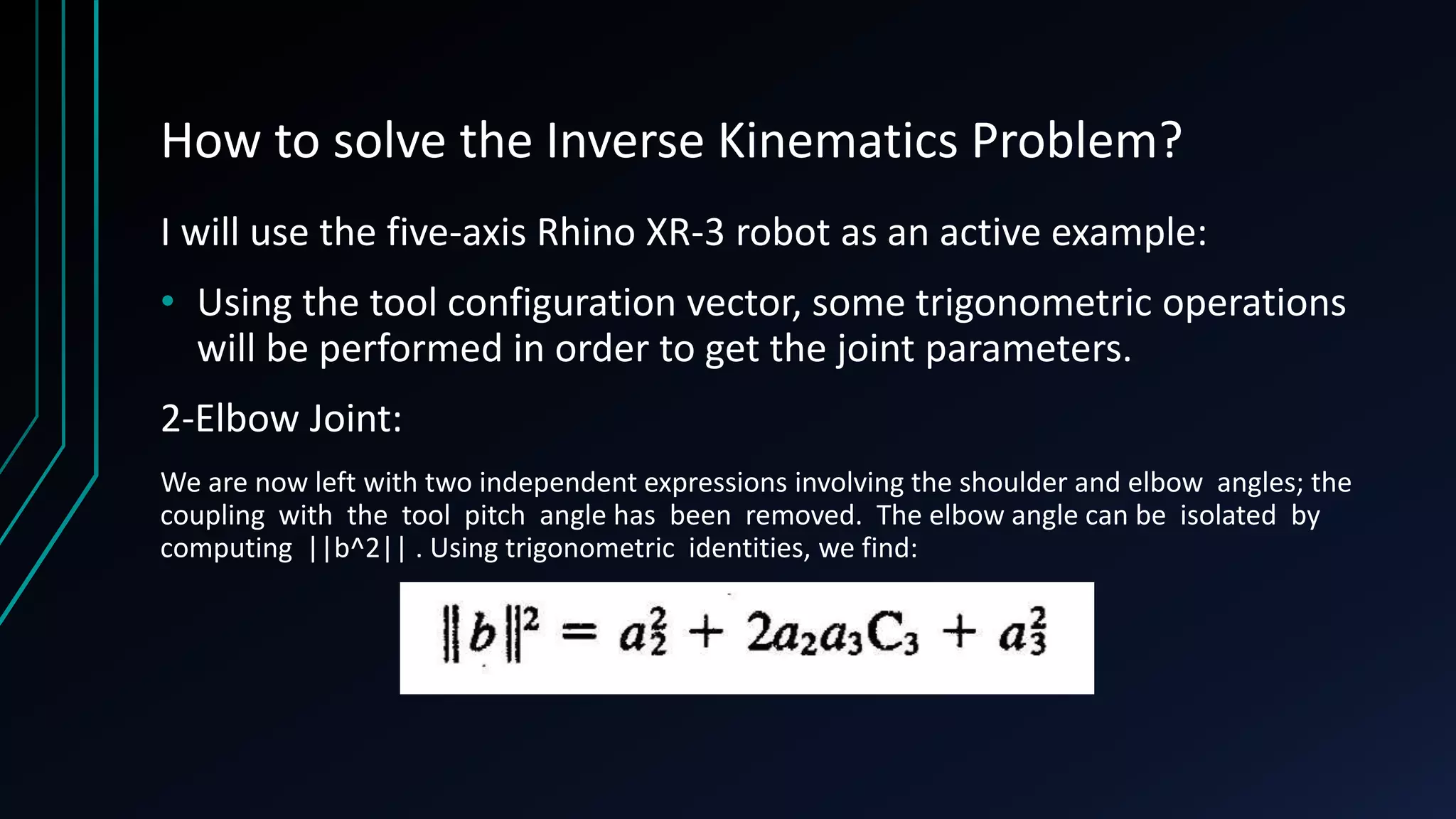

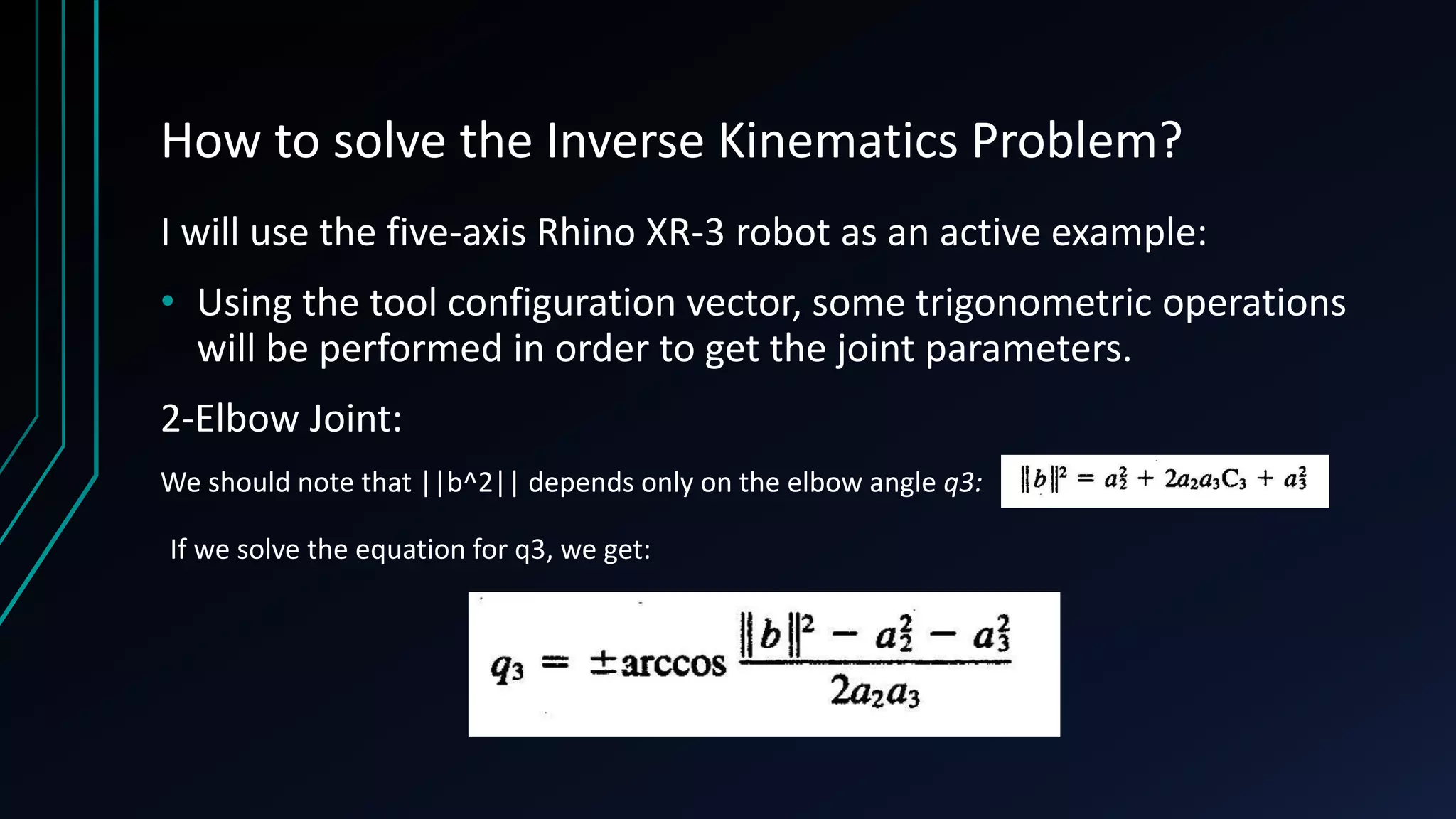

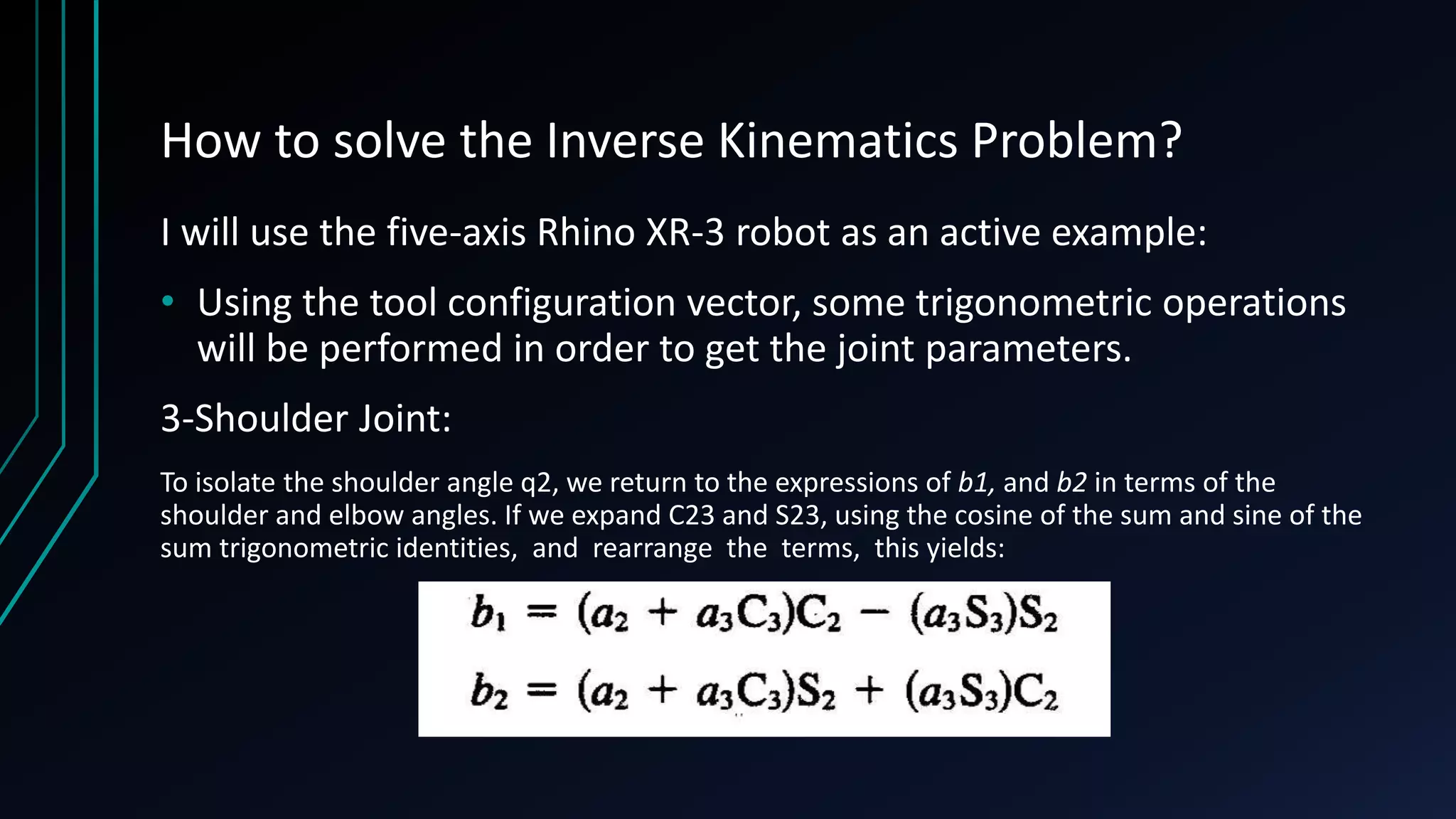

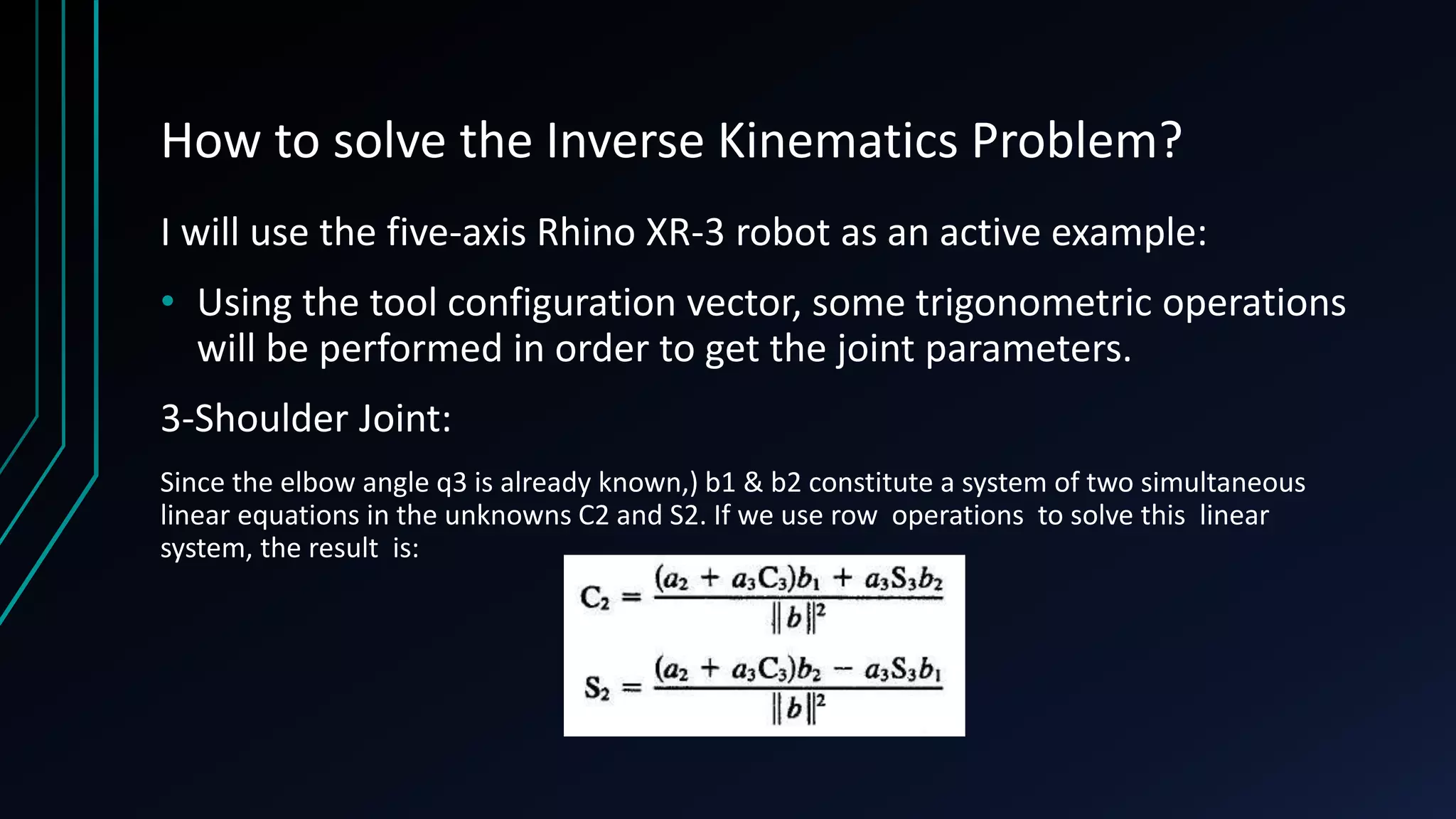

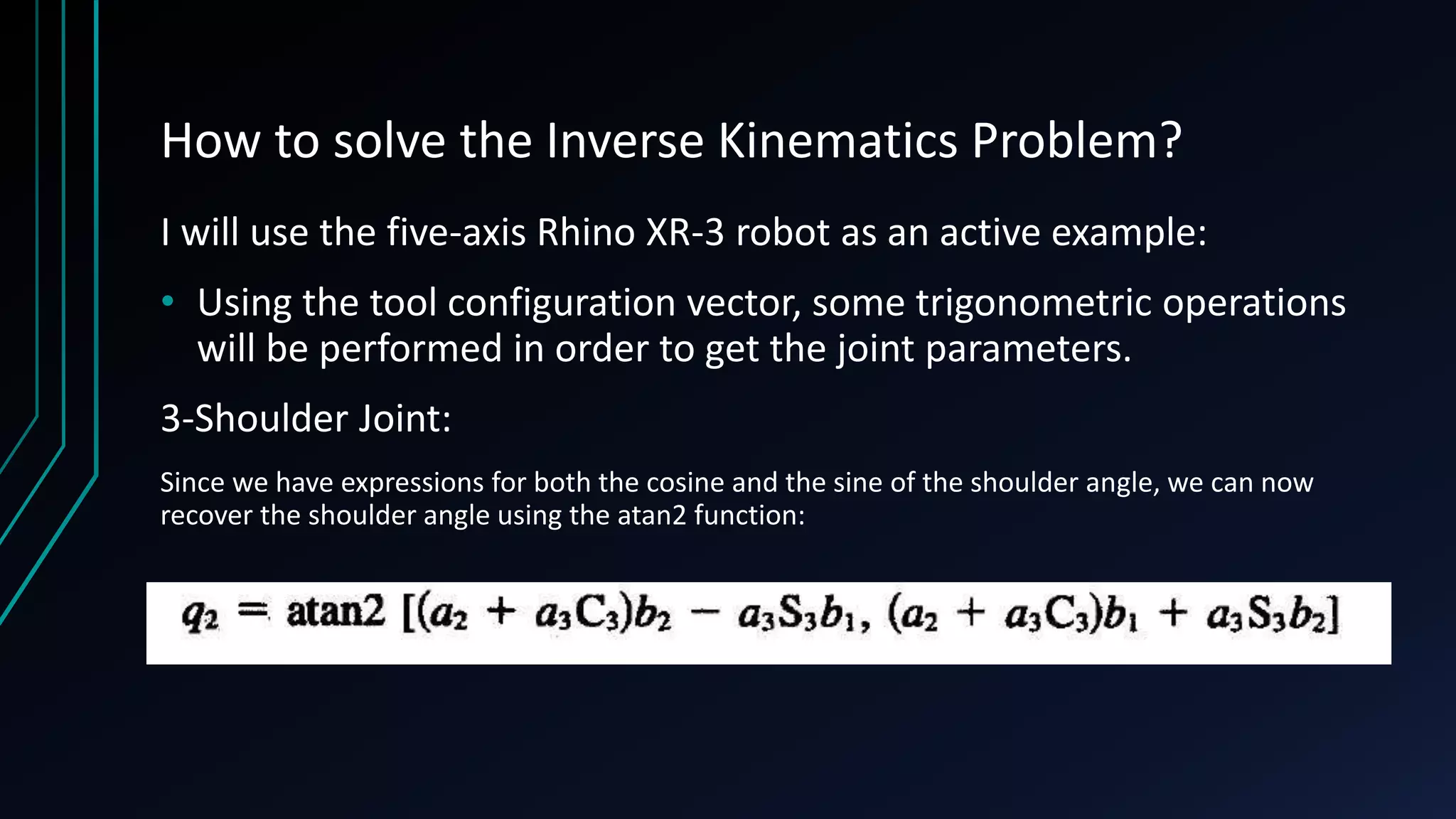

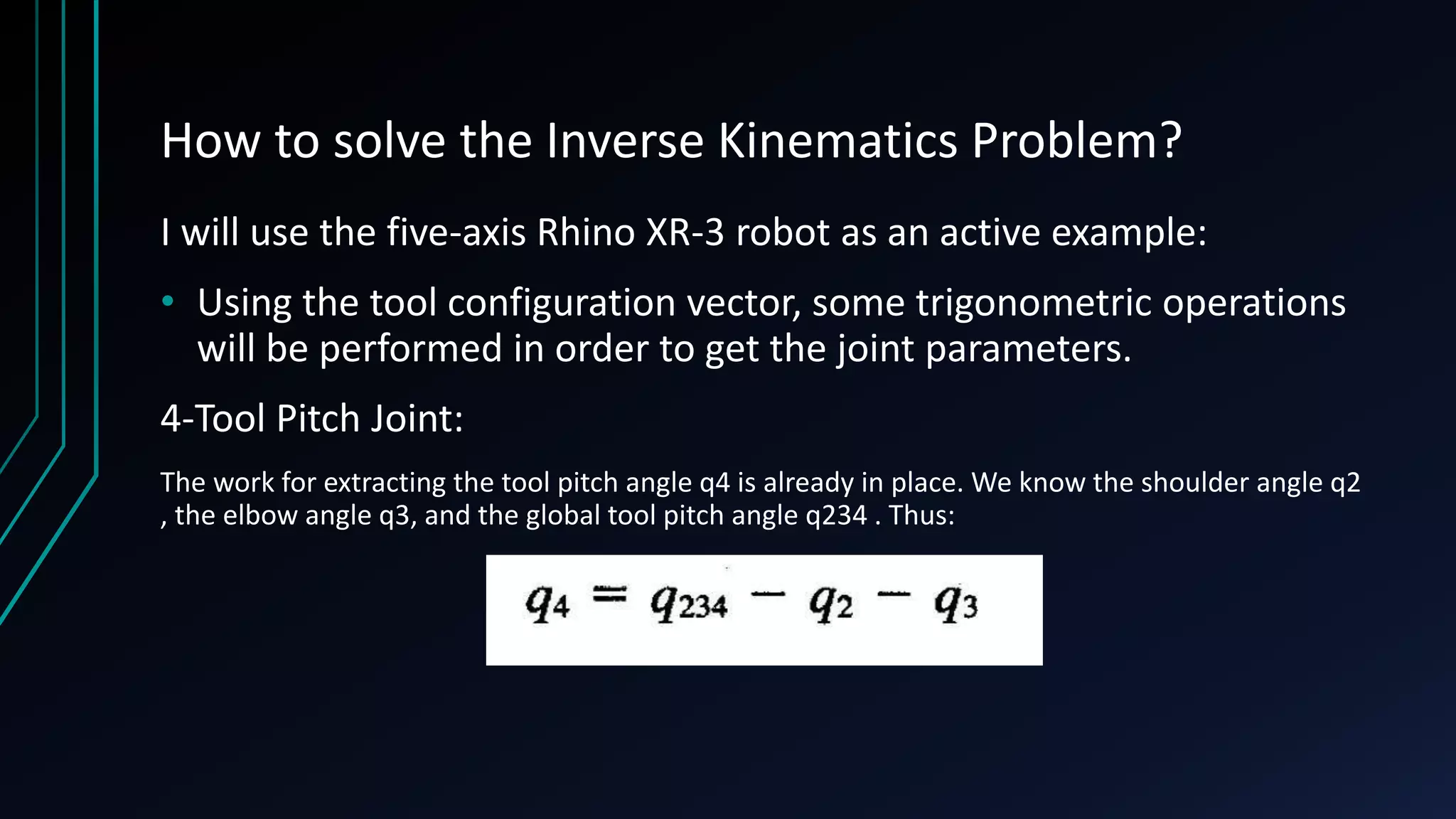

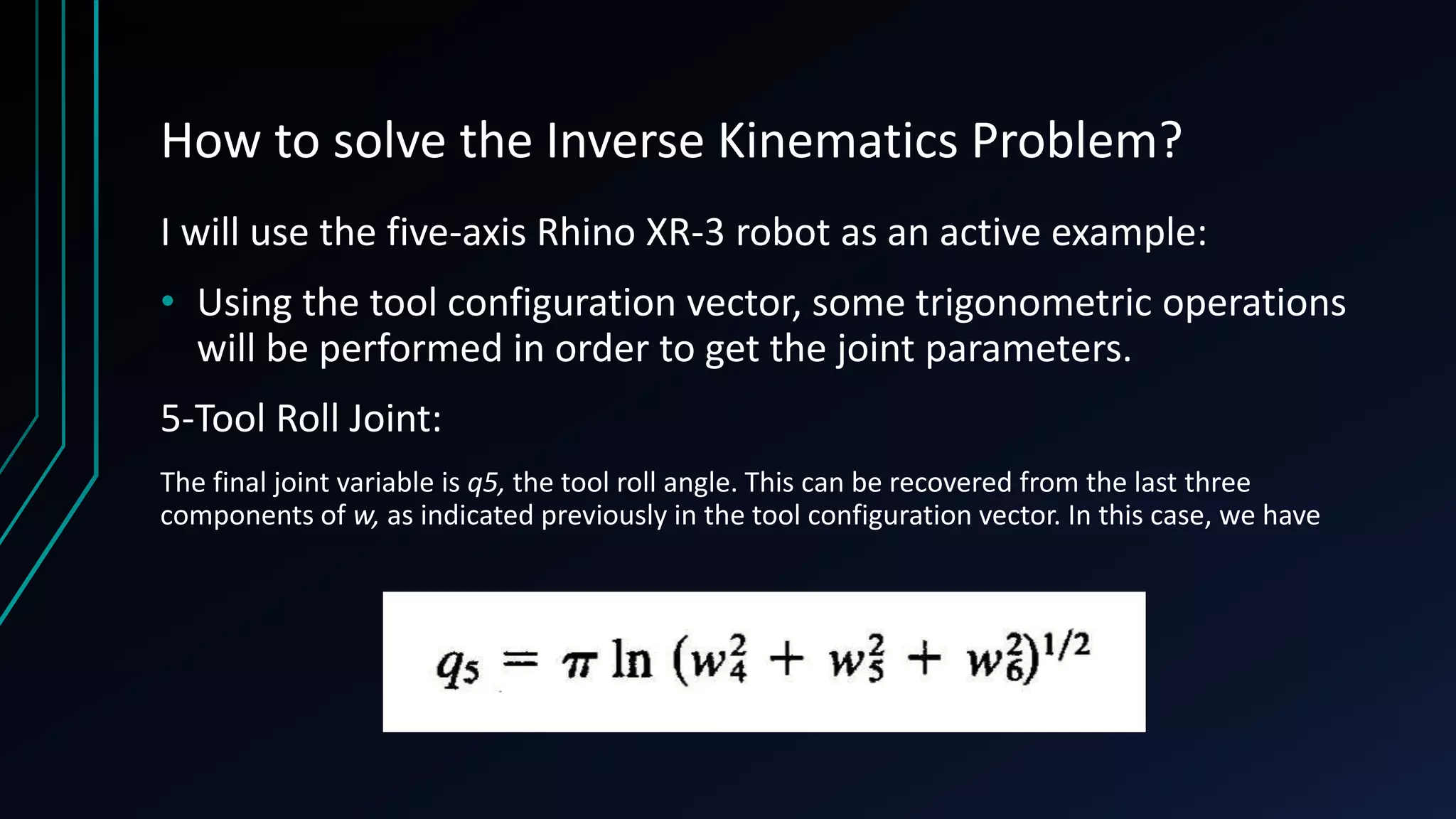

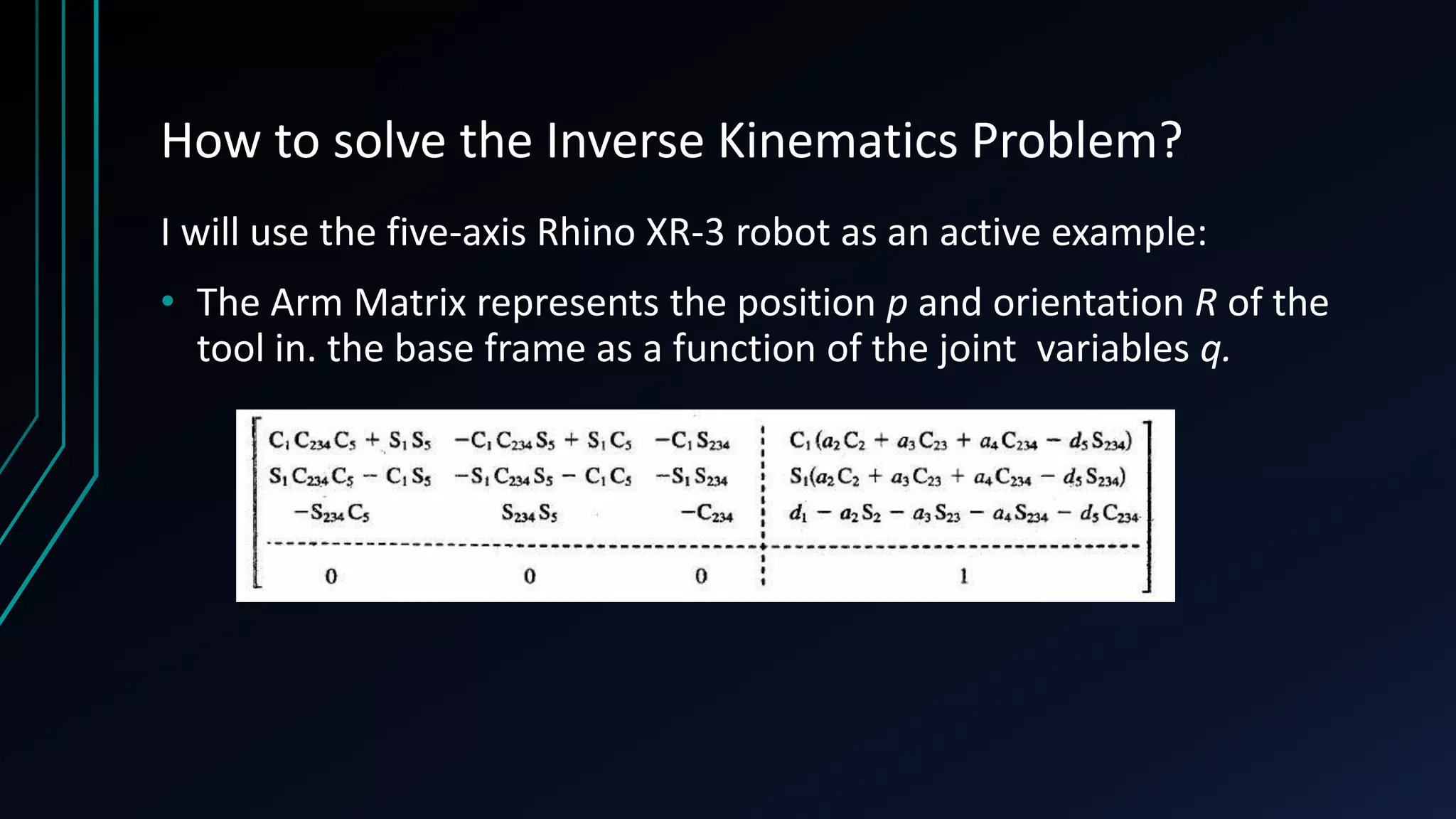

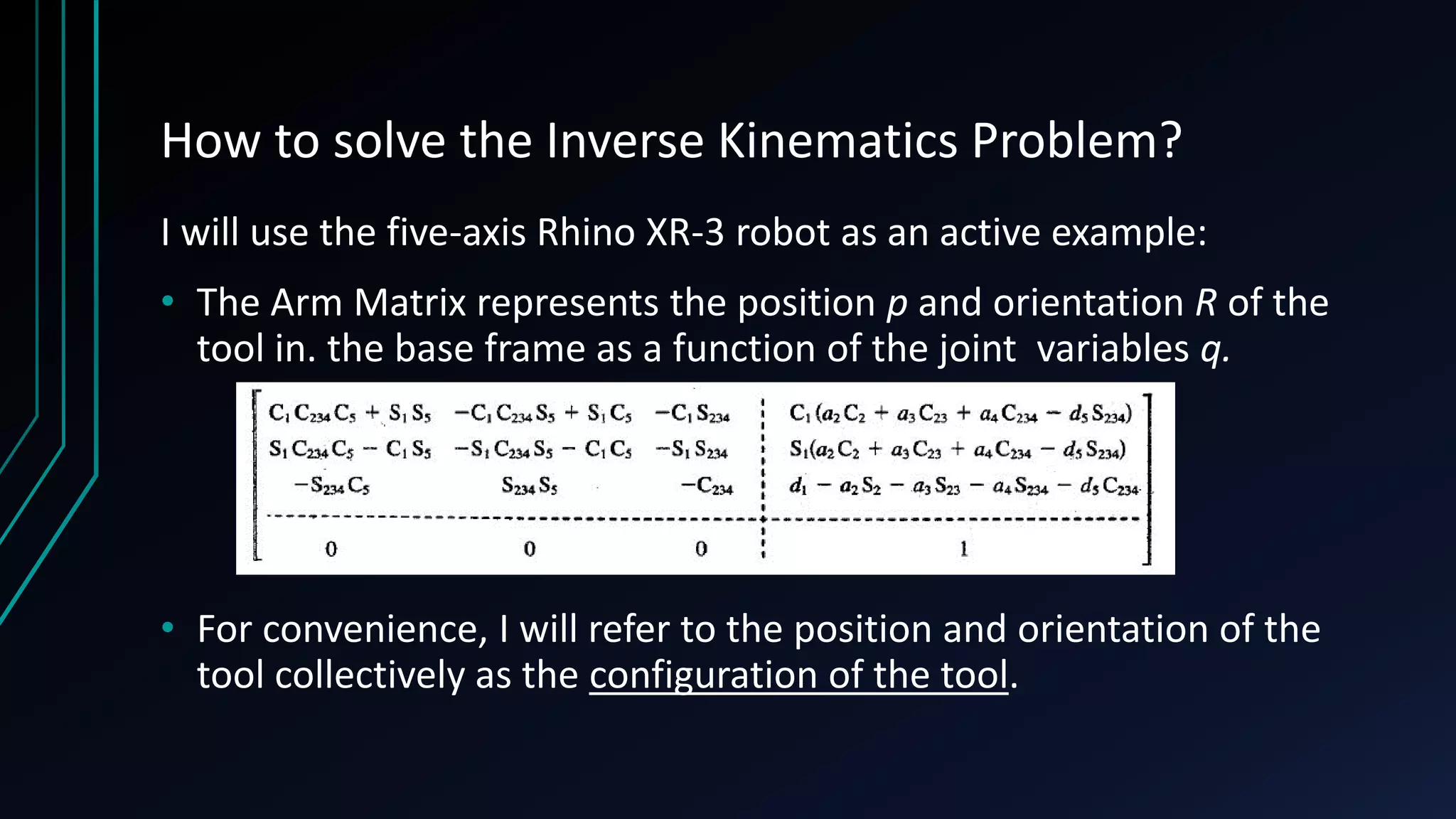

The document discusses inverse kinematics and how to solve the inverse kinematics problem for a robotic manipulator. It uses a 5-axis Rhino XR-3 robot as an example. It explains that inverse kinematics determines the joint variables given a desired position and orientation of the tool, which is important for tasks planned using external sensors. It then outlines the step-by-step process used to solve the inverse kinematics problem, which involves using the tool configuration vector obtained from the arm matrix and performing trigonometric operations to isolate each joint variable.

![How to solve the Inverse Kinematics Problem?

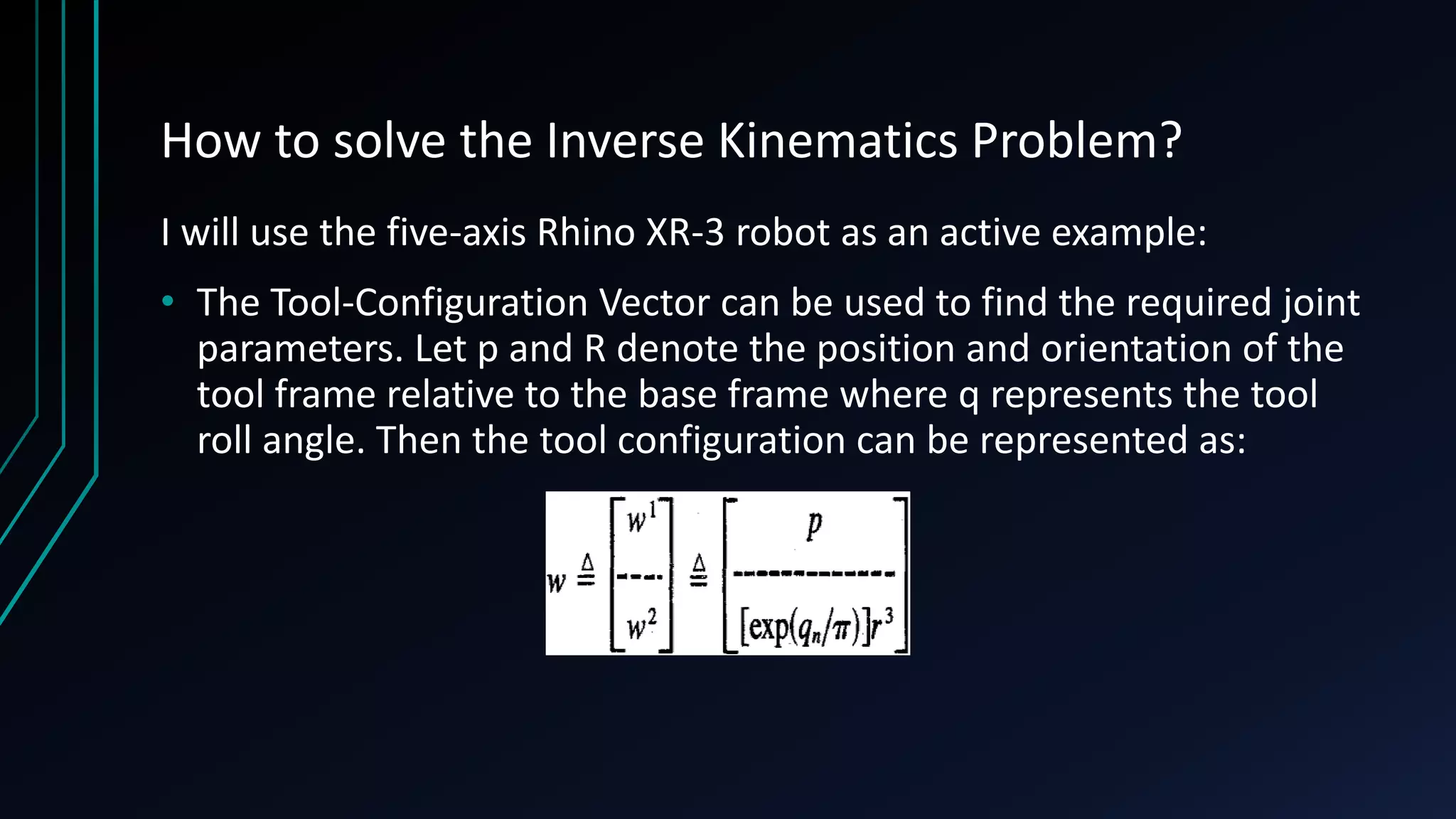

I will use the five-axis Rhino XR-3 robot as an active example:

• The term ([exp(q/pi)]r3) is called “Scaling Factor”.

• Its used to augment the last joint parameter (q5) into the tool

configuration vector. In order to satisfy the mathematical

requirements.](https://image.slidesharecdn.com/theinversekinematicsproblem-aimanh-180417224201/75/The-inverse-kinematics-problem-Aiman-Al-Allaq-11-2048.jpg)