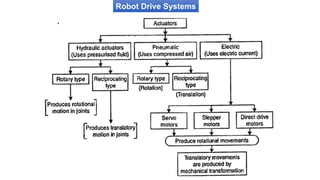

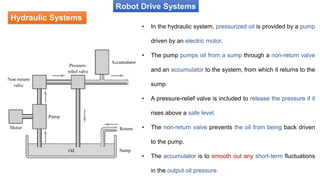

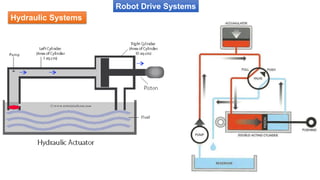

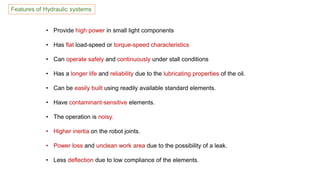

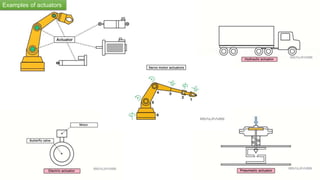

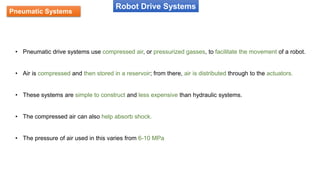

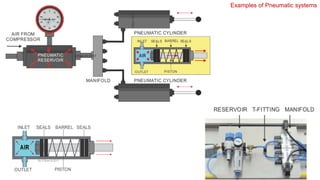

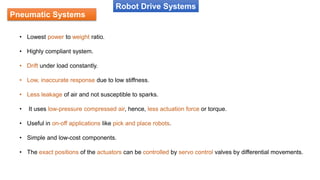

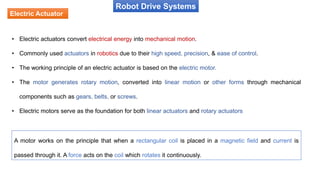

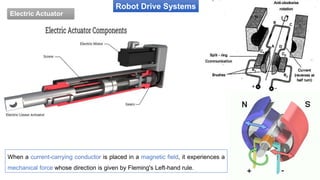

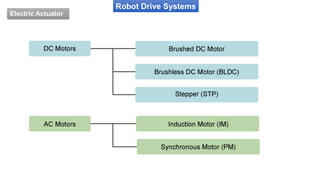

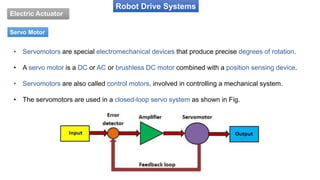

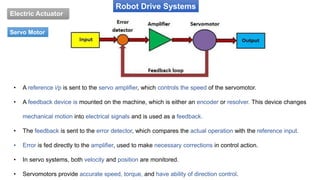

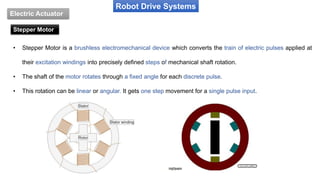

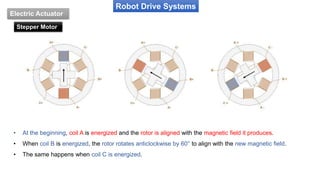

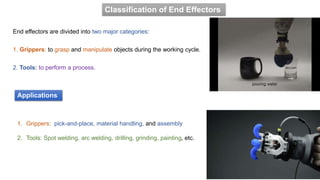

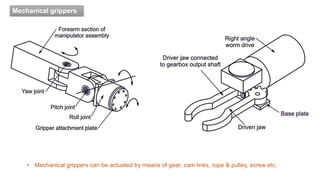

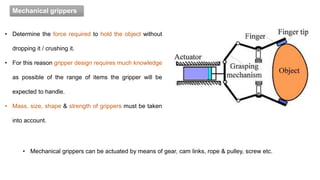

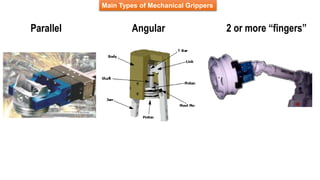

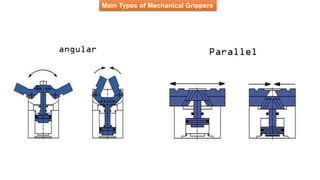

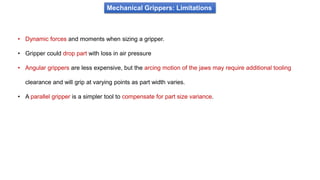

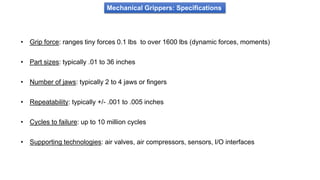

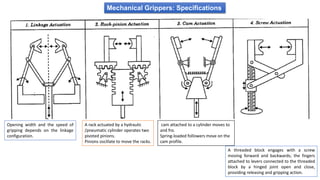

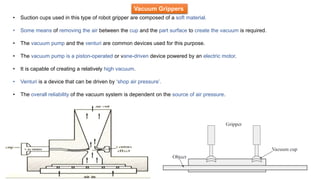

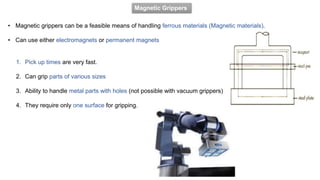

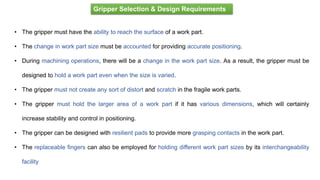

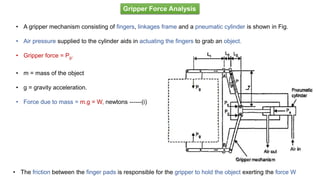

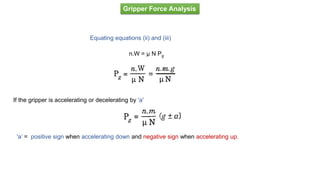

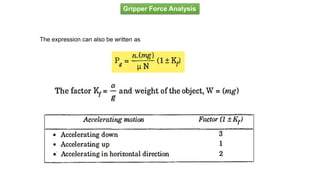

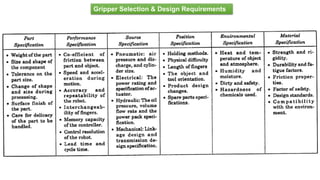

The document outlines the course on Fundamentals of Robotics and Applications, detailing resources, assessments, and learning goals such as understanding robot drives, end-effectors, and their applications. Key components discussed include hydraulic, pneumatic, and electric drive systems, along with various types of end-effectors like mechanical, vacuum, magnetic, and adhesive grippers. The course emphasizes practical applications and design considerations for robotic systems in industrial settings.