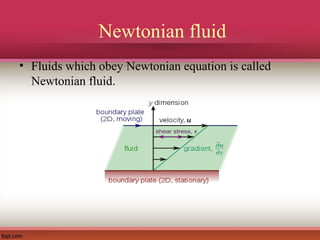

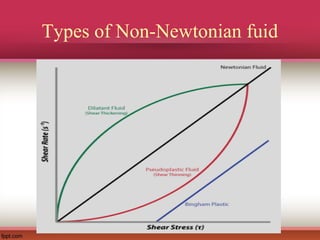

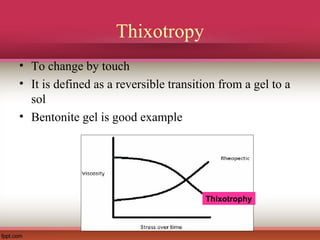

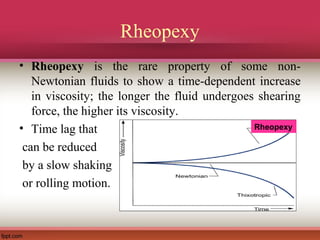

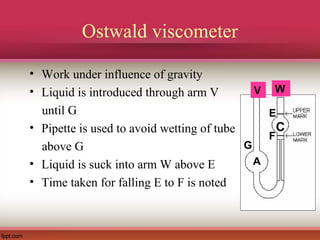

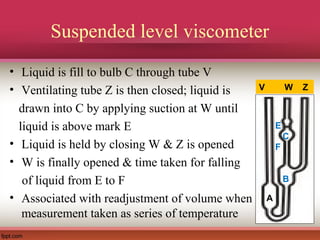

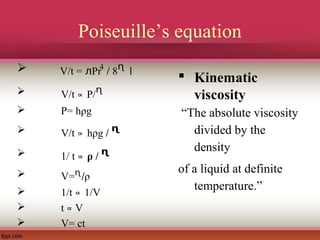

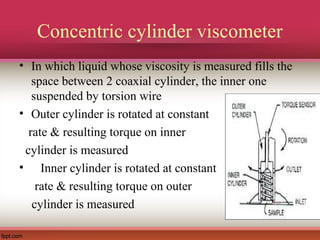

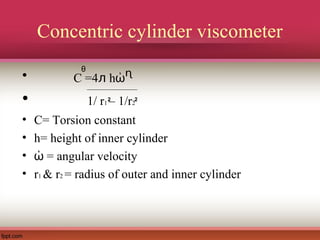

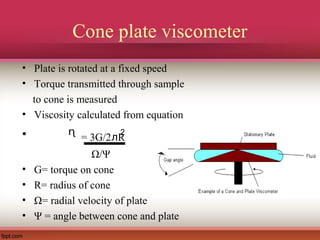

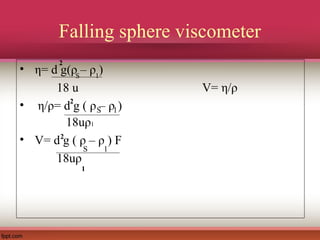

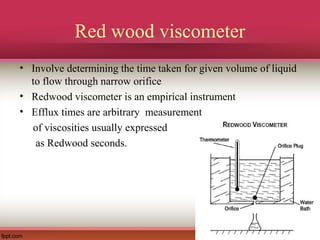

Rheology is the study of flow and deformation of materials under stress. There are two types of fluids - Newtonian fluids which follow a linear stress-strain relationship and non-Newtonian fluids which do not follow this relationship. Various types of non-Newtonian fluids exist such as plastic, pseudoplastic, dilatant, thixotropic and rheopectic fluids. Flow properties of fluids can be determined using viscometers such as capillary, rotating cylinder and cone plate viscometers. Rheology has applications in various areas including pharmaceuticals, cosmetics, food and construction materials.