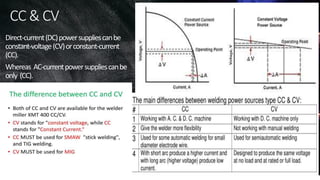

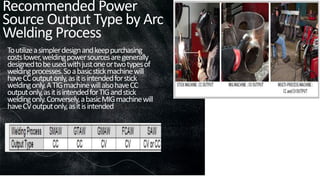

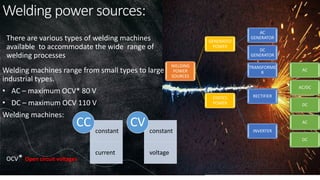

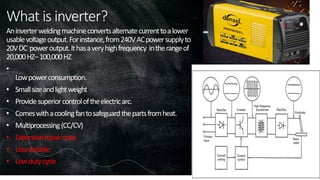

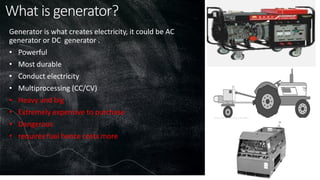

The document provides an overview of welding power sources and accessories, detailing the types of current used in welding machines (AC and DC) and the differences between transformers, rectifiers, inverters, and generators. It also compares various welding machines and their applications, emphasizing the specific needs for different welding processes. Additionally, it highlights the efficiency, cost, and practicality of different power sources in industrial settings.

![Comparison between AC &

DC welding machines

[SMAW, TIG,SAW] canperformon AC machines

[SMAW, TIG,SAW] canperform on DC machines](https://image.slidesharecdn.com/weldingpowersources-211118182657/85/Welding-power-sources-9-320.jpg)