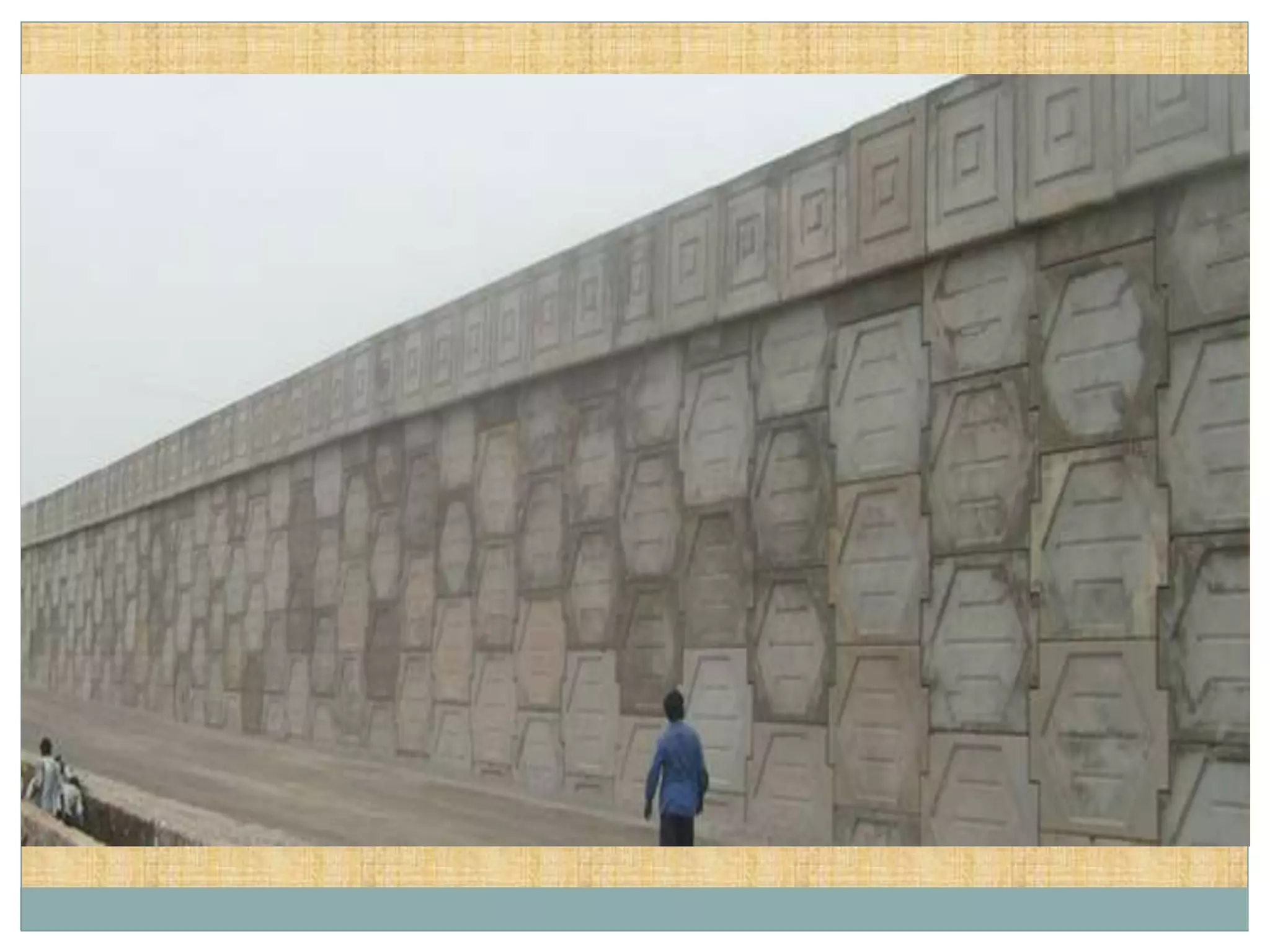

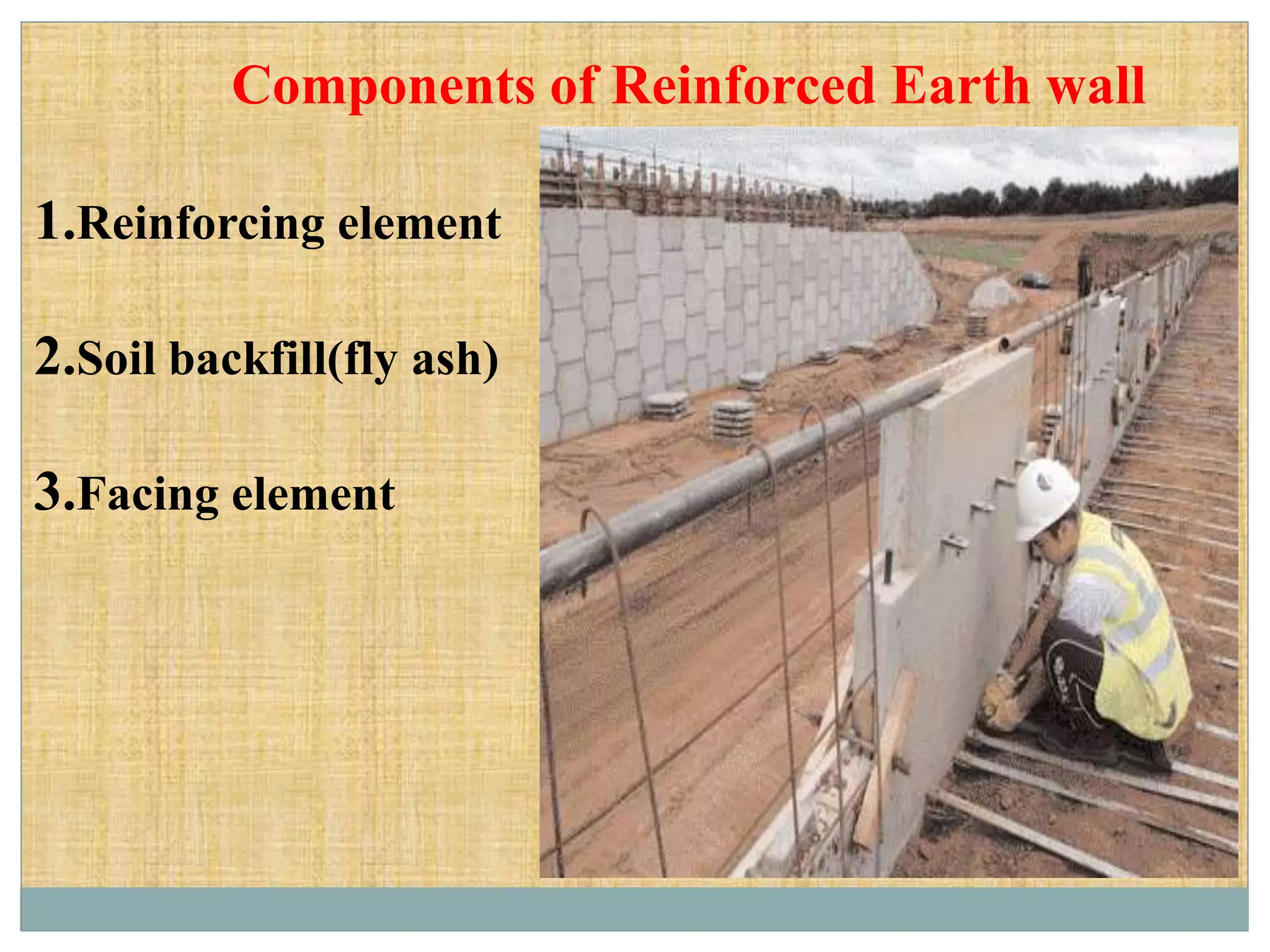

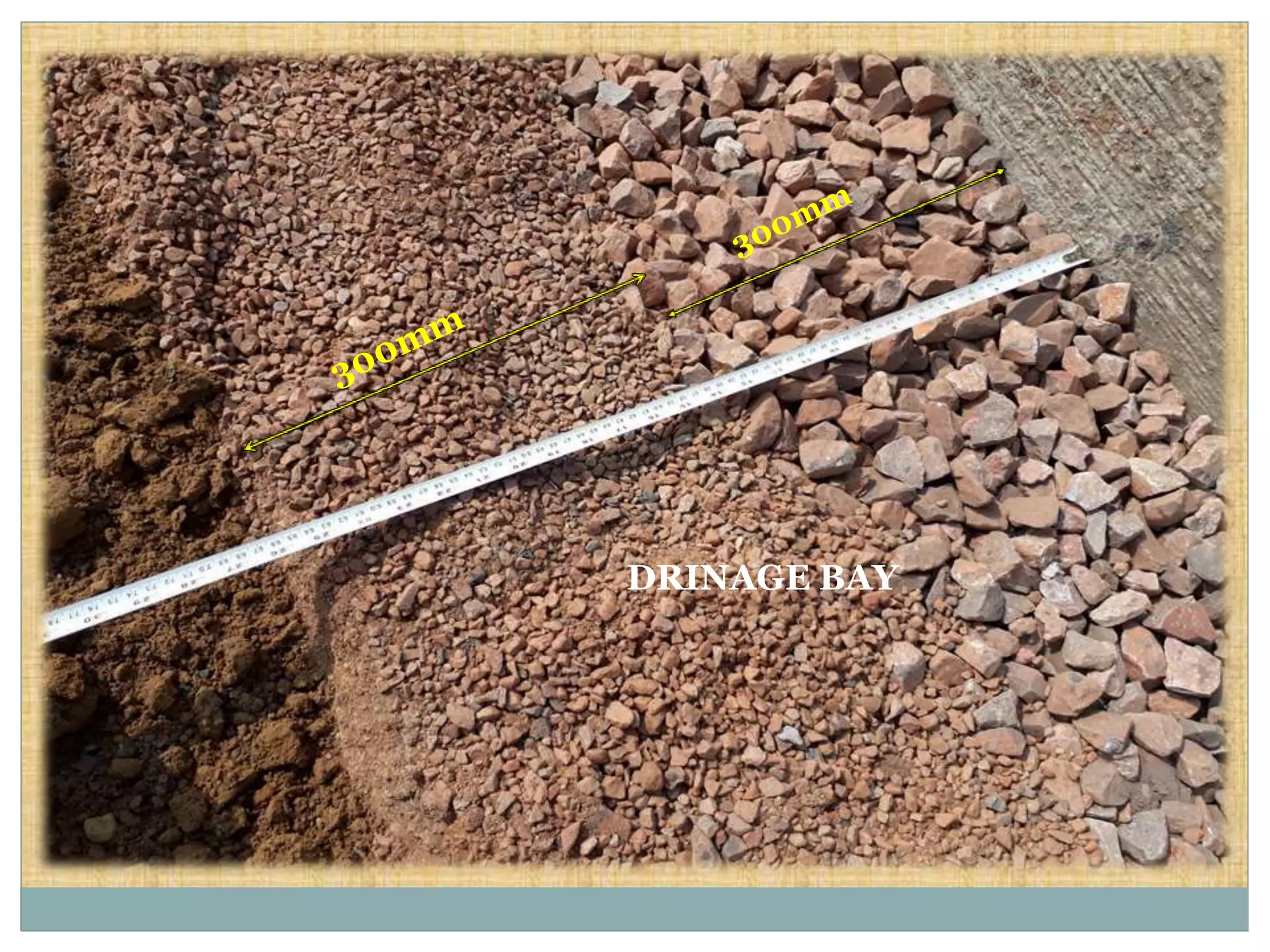

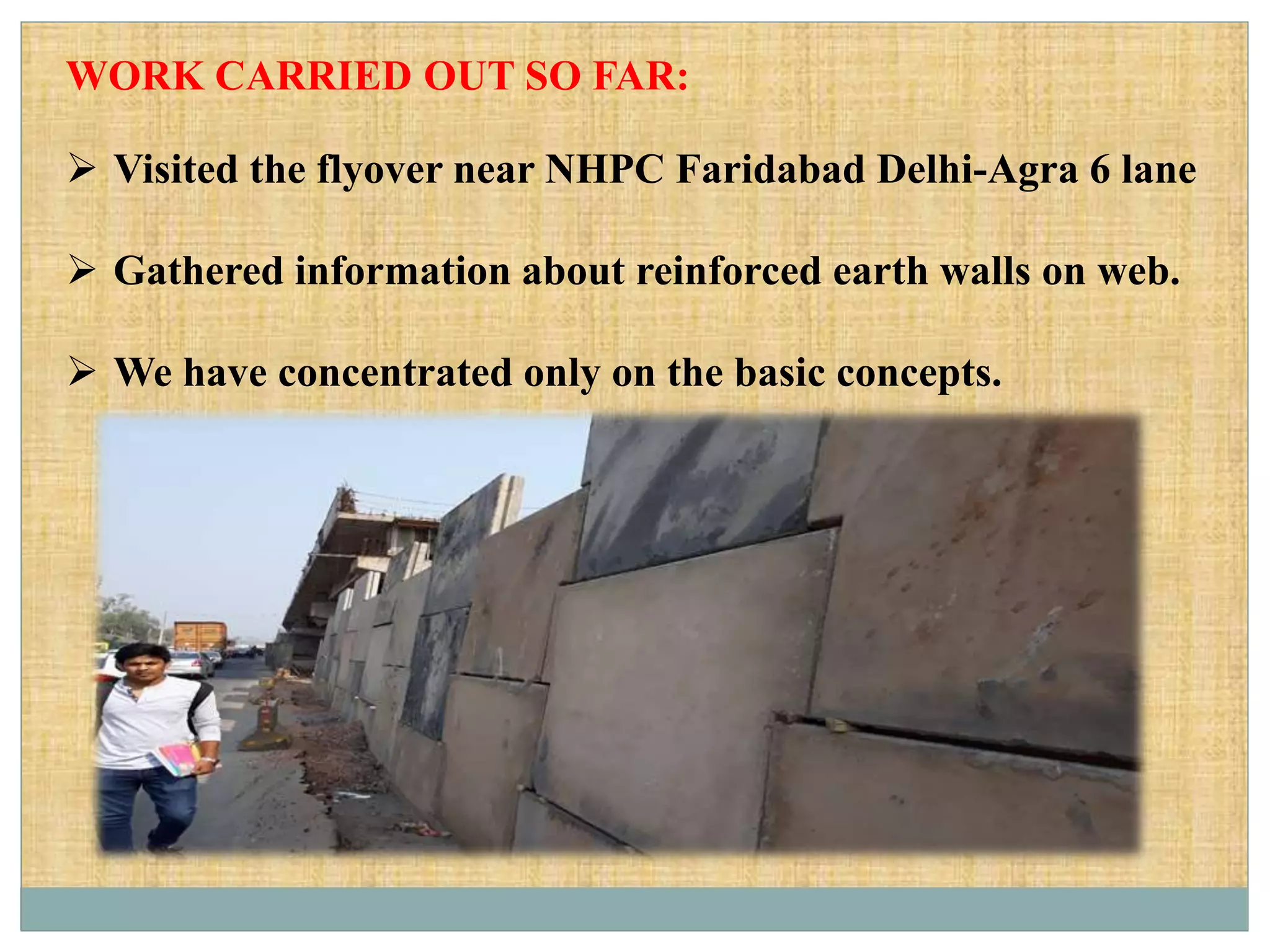

This document provides information on reinforced earth walls, including their components and construction methodology. It discusses that reinforced earth walls combine earth and linear reinforcing strips to bear large tensile stresses. The key components are reinforcing elements, soil backfill (which can be replaced with fly ash), and a facing element. Geogrids are used as reinforcements and provide strength in tension, while fly ash or soil in the backfill provides compression strength. The document also outlines design considerations around drainage, joint materials, and stability checks for these types of walls.