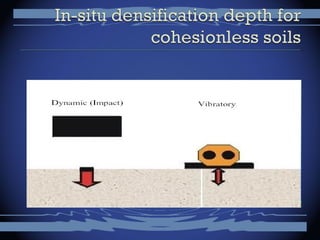

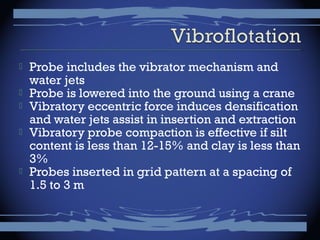

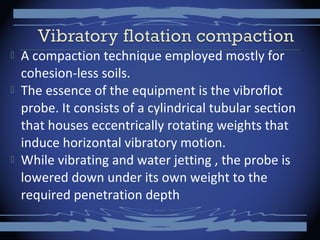

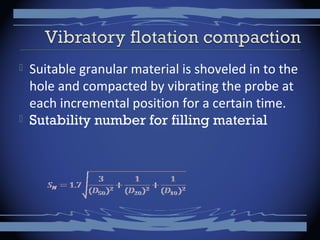

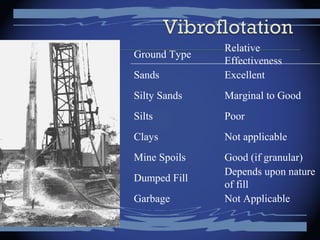

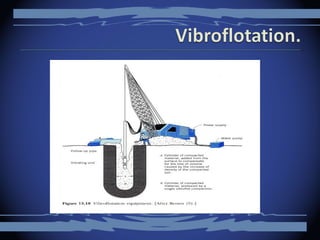

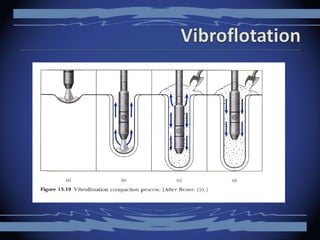

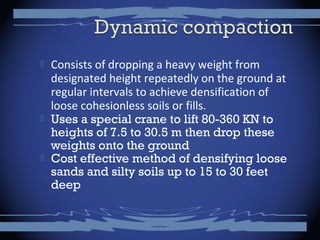

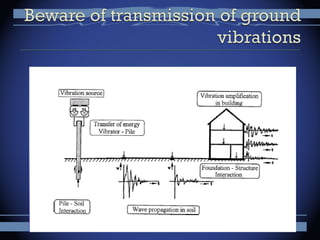

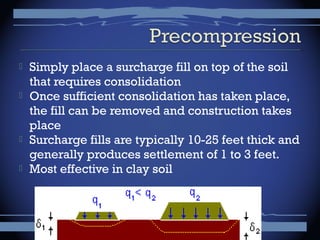

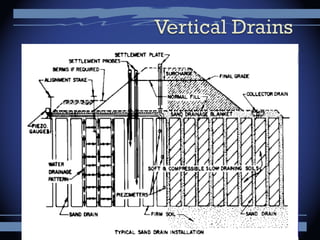

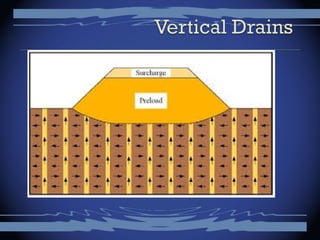

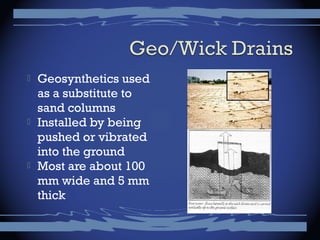

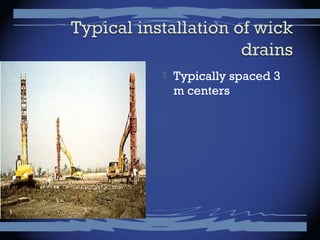

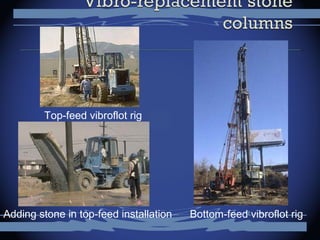

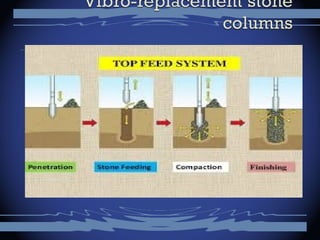

The document discusses various ground improvement techniques including removal and replacement, in-situ densification methods like dynamic compaction, preloading, use of vertical drains and stone columns. It provides details on specific in-situ densification methods like vibro-float compaction using a vibrating probe, dynamic compaction using heavy weights, and explosive compaction using detonated charges. The document also summarizes advantages and limitations of preloading using surcharge fills and uses of vertical drains and geosynthetics to accelerate consolidation.