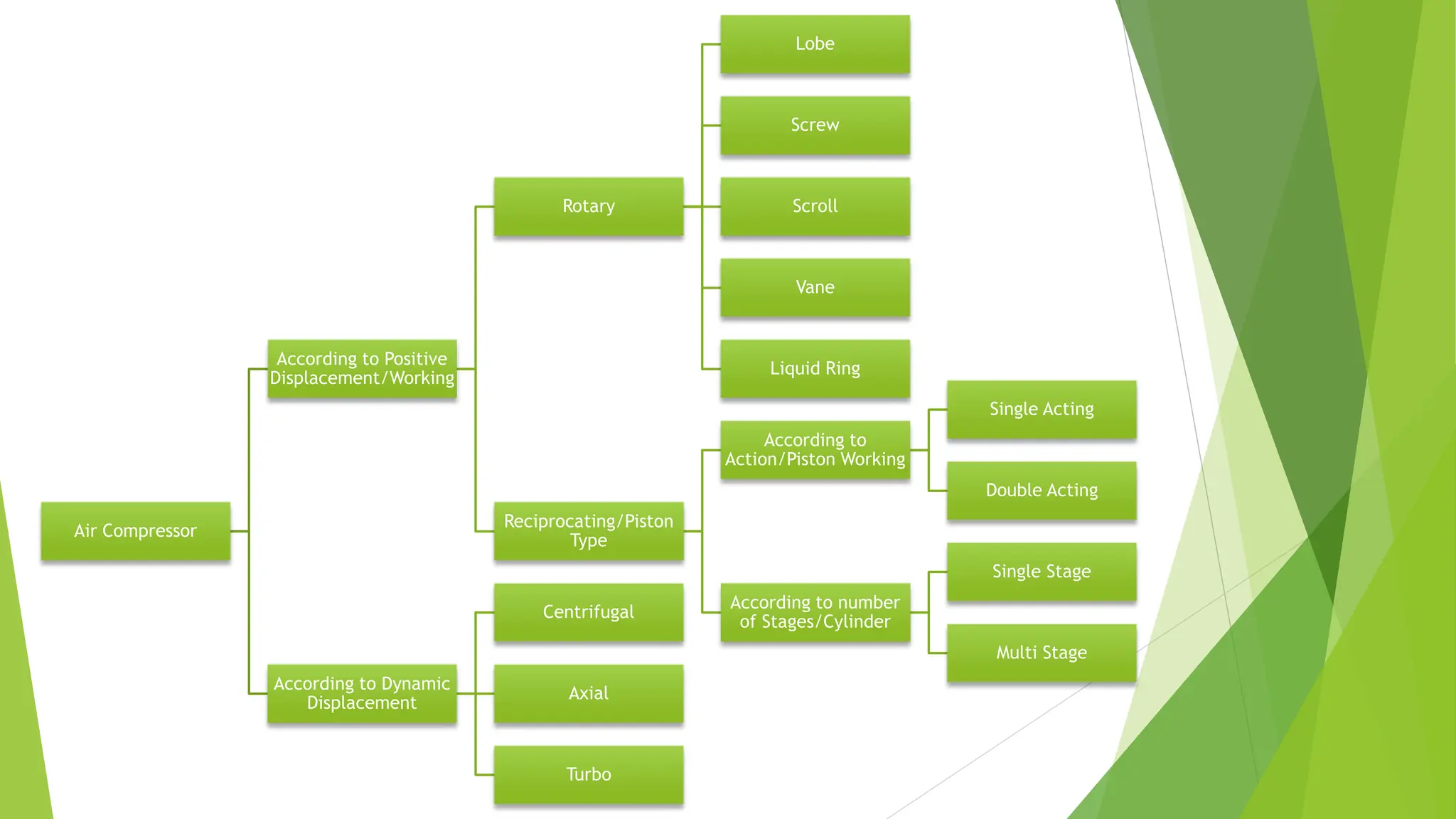

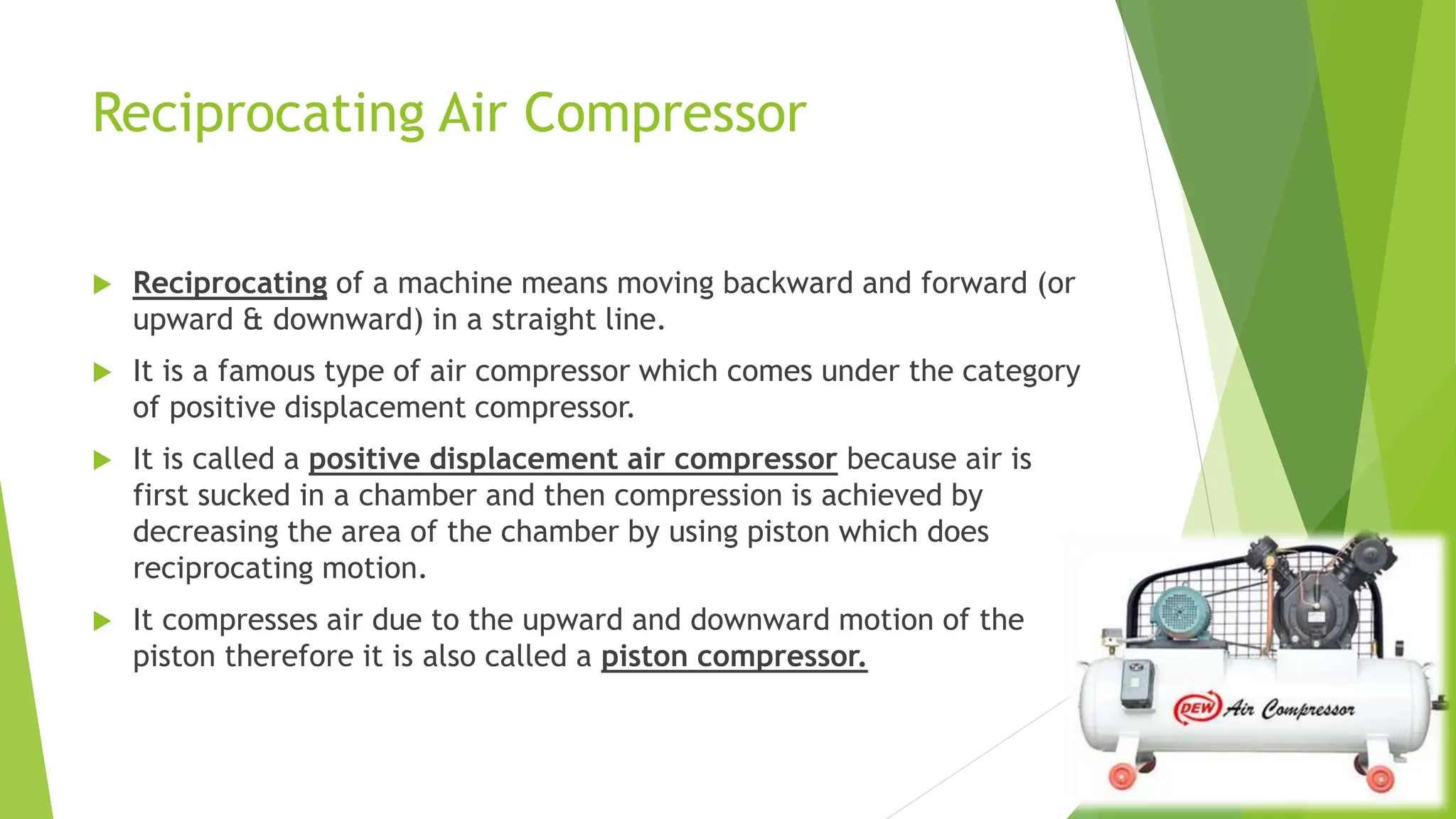

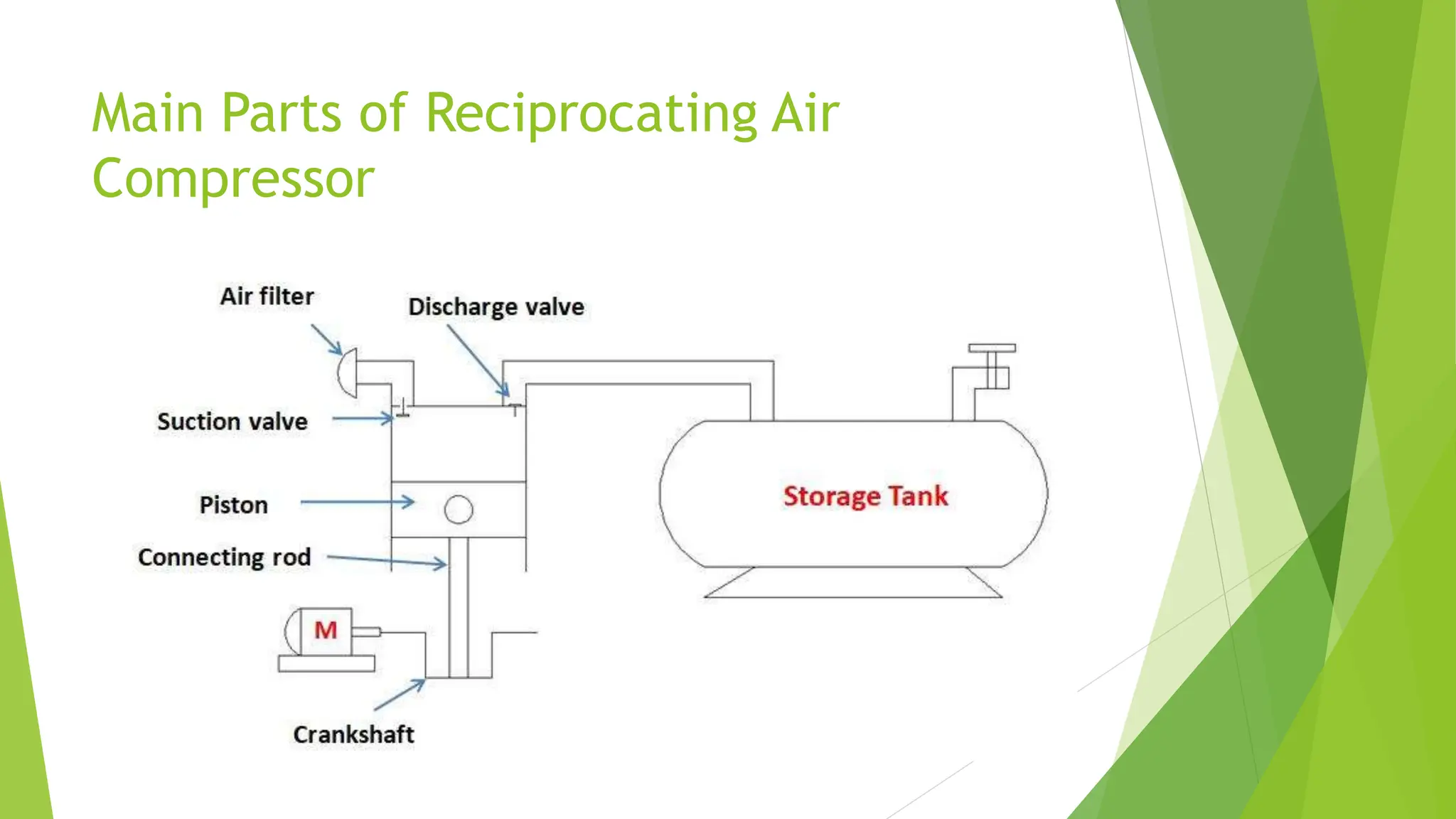

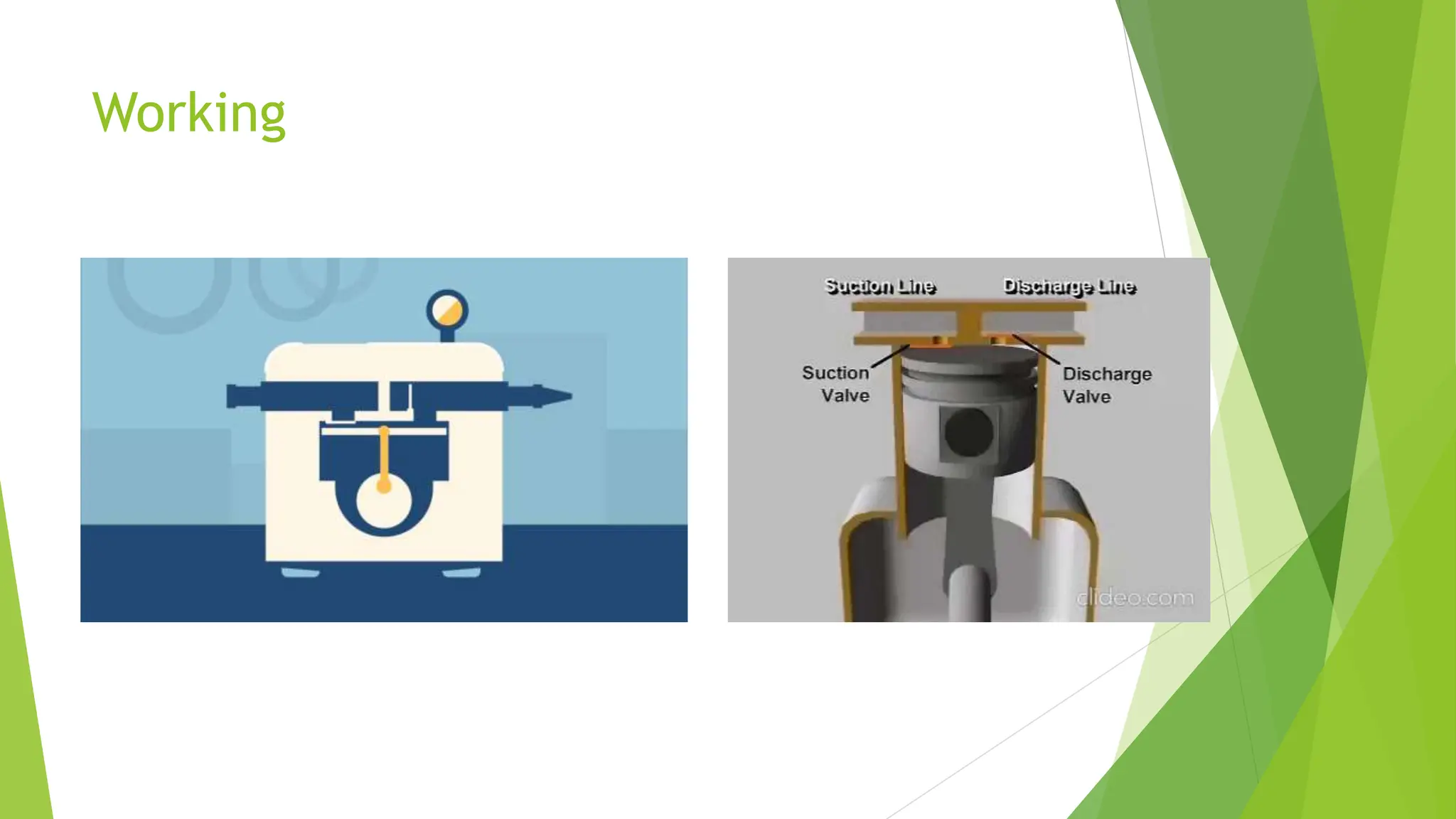

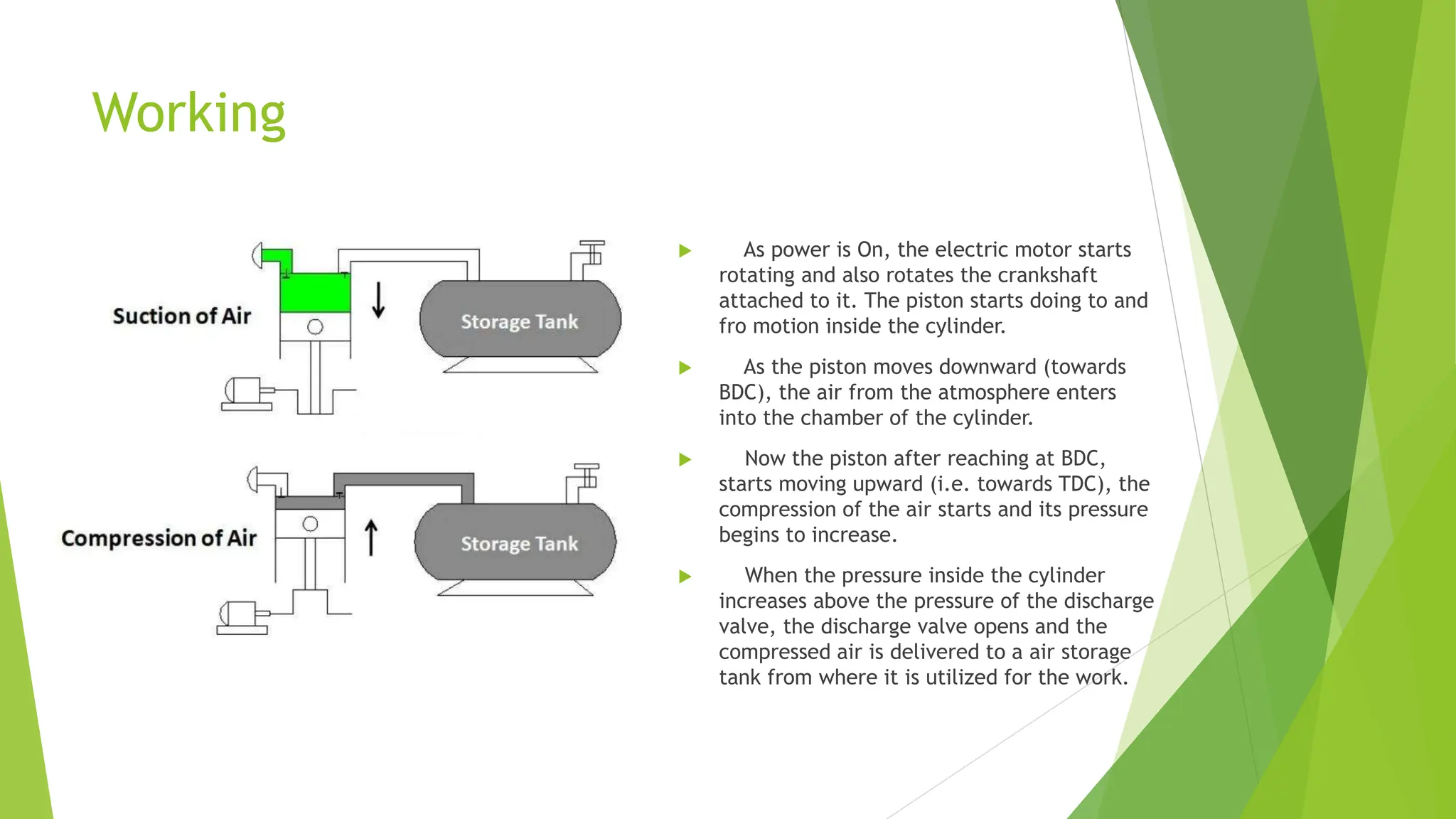

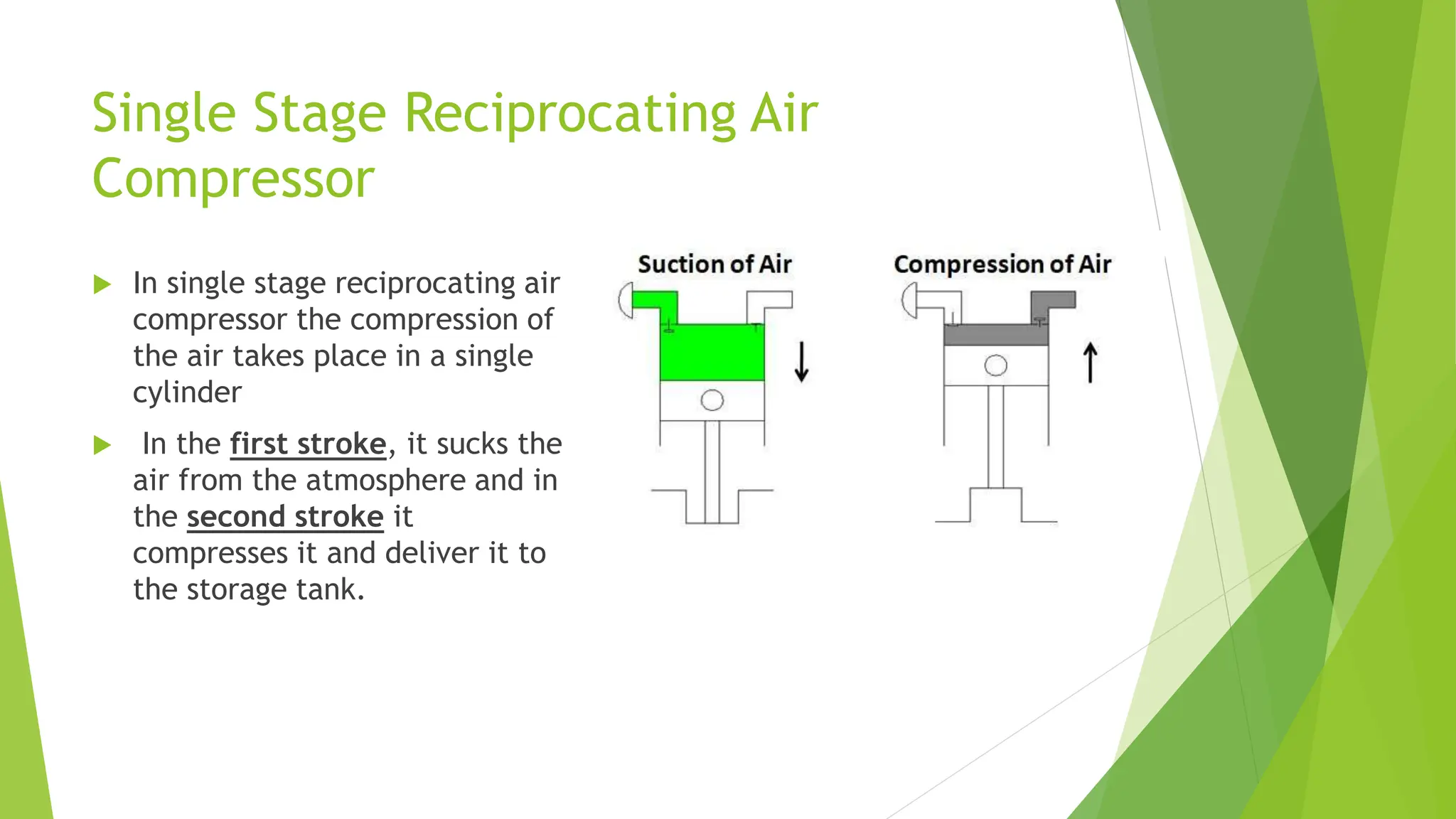

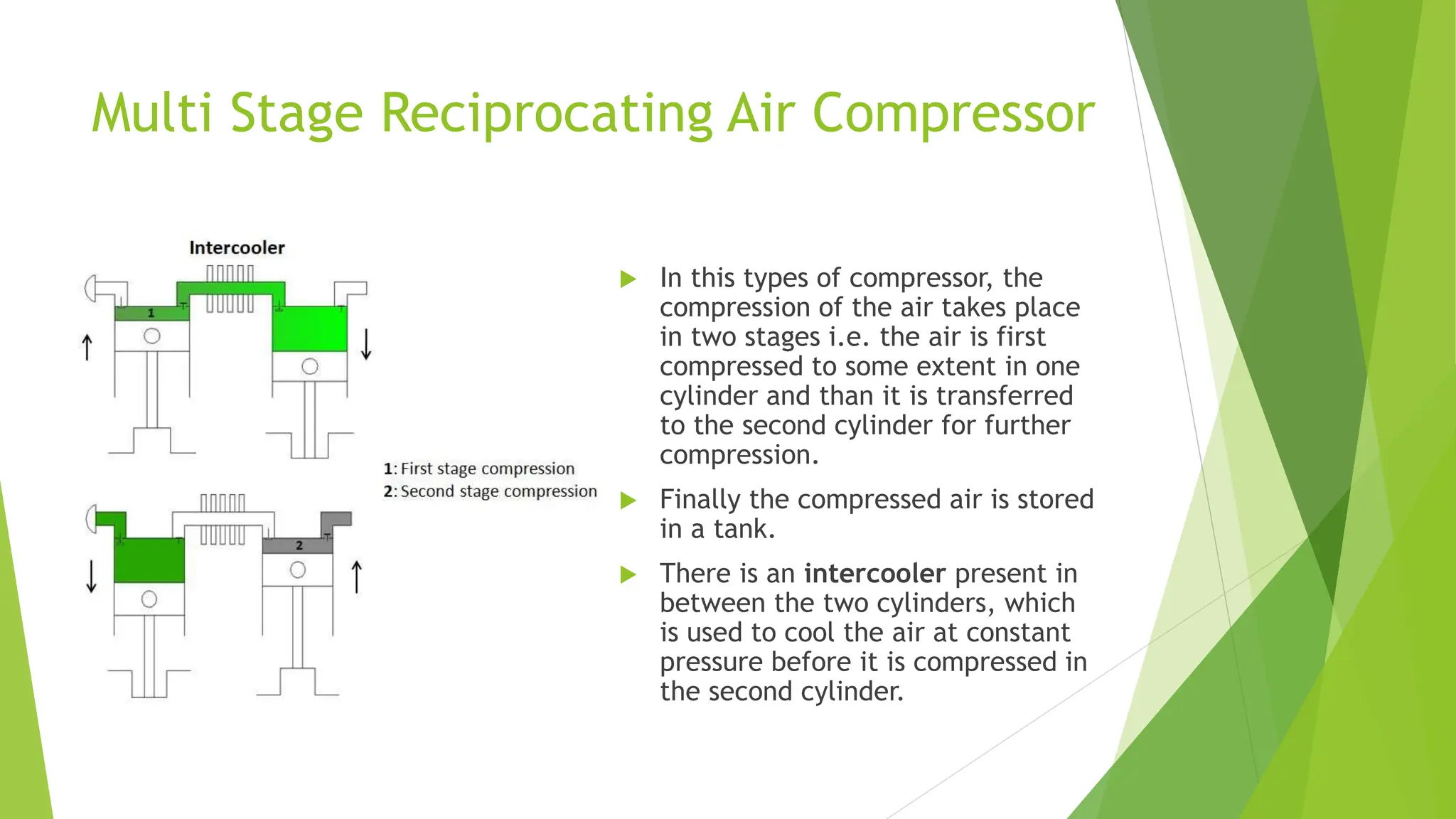

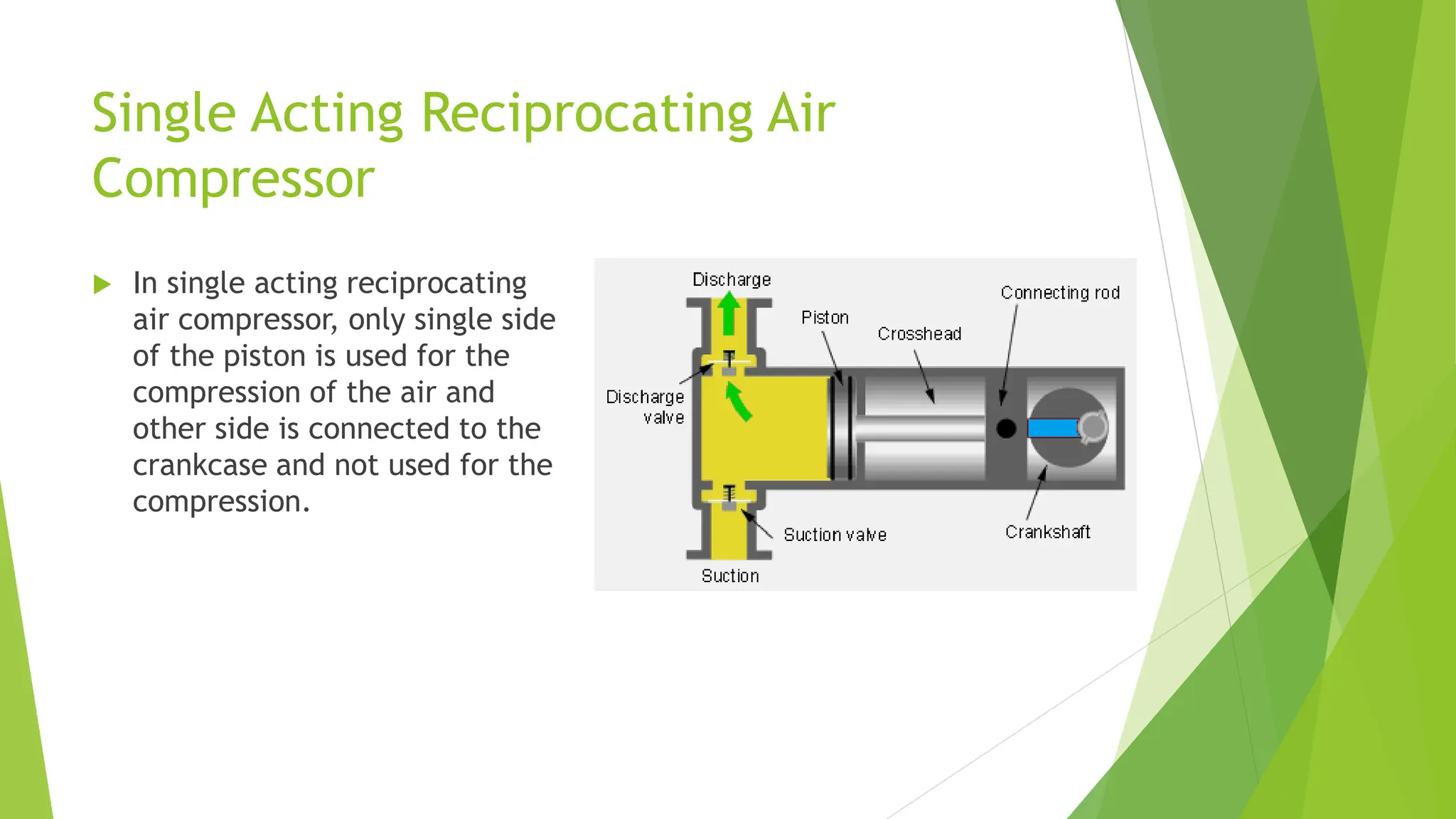

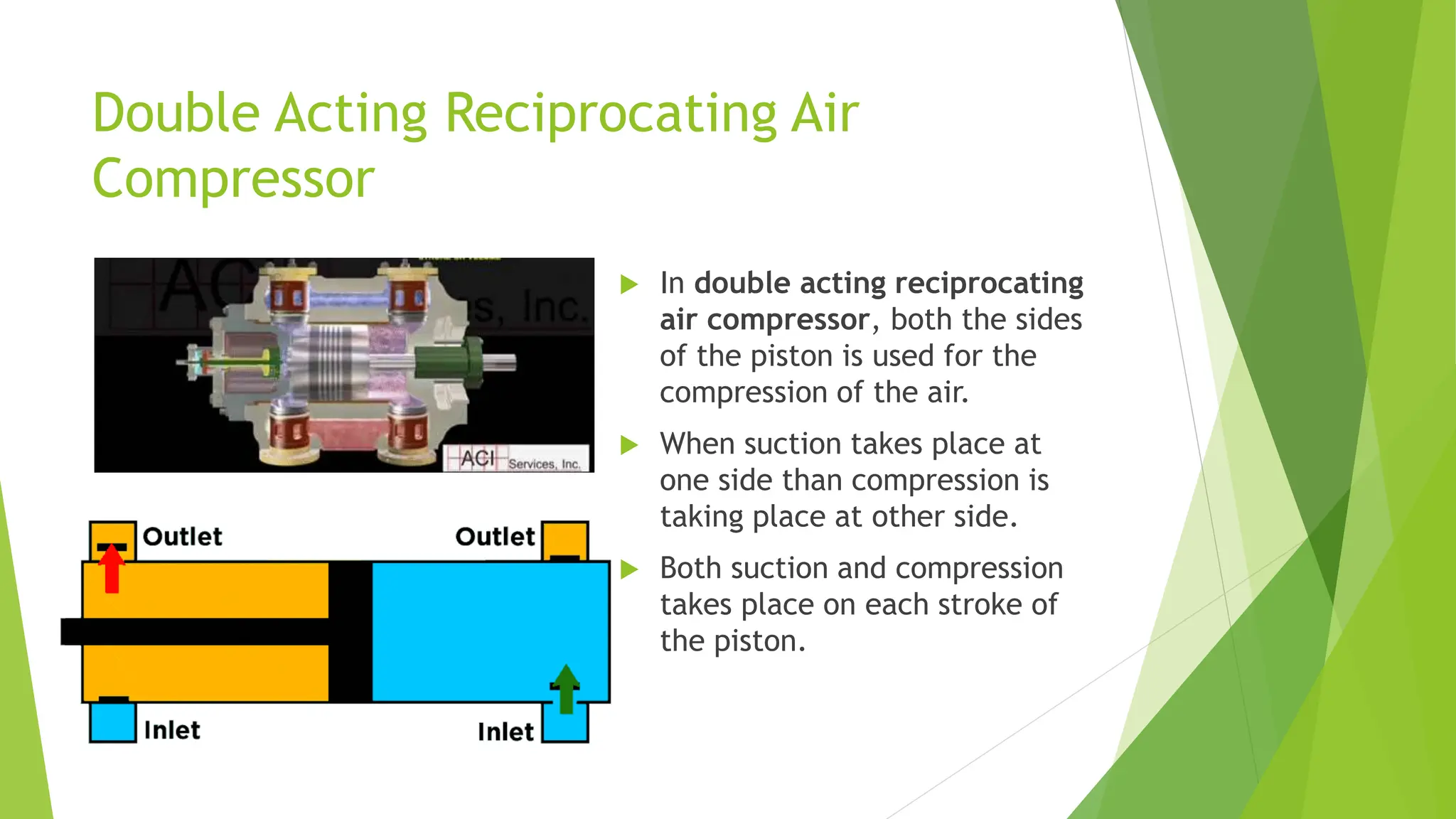

The document provides an overview of reciprocating air compressors, including their classification, main components, and operational mechanics. It explains the differences between single-stage and multi-stage compressors, as well as single acting and double acting types. Additionally, it discusses various applications, advantages, and disadvantages of reciprocating air compressors.