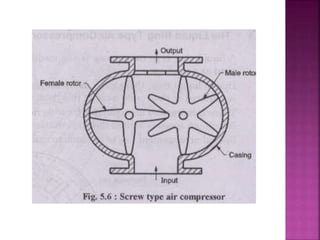

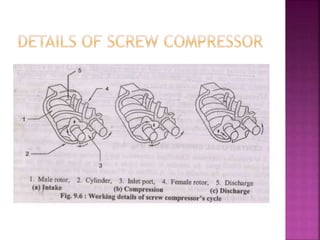

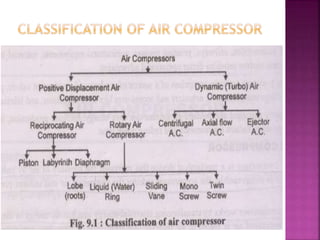

Rotary screw air compressors work by having two screws - a male and female rotor - rotate together to suck in and compress air. As the screws mesh and their lobes engage, they reduce the volume of the air pockets to continuously compress the air. There are different types of rotary screw compressors depending on their cooling method, stages, and drive type. They are more efficient than reciprocating compressors but also more expensive.