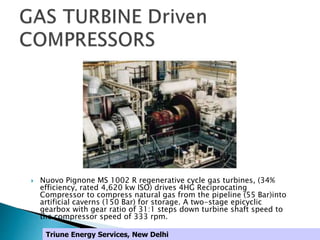

A gas turbine drives a reciprocating compressor to compress natural gas from a pipeline at 55 bar into underground storage caverns at 150 bar. A two-stage gearbox connects the gas turbine to the compressor, stepping down the turbine speed of 333 rpm for the compressor. Gas turbines convert the heat of fuel into mechanical energy via compression, combustion, and expansion components to power generators or machinery. They are more efficient than other internal combustion engines due to operating in a continuous thermodynamic cycle.