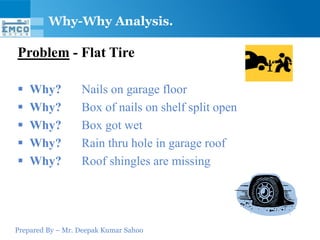

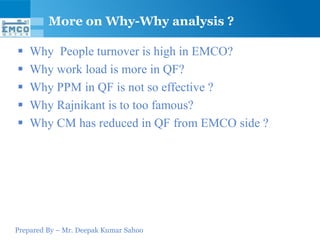

Here are some potential why-why analyses for the questions provided:

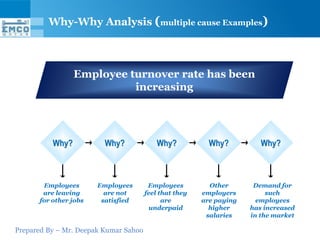

Why people turnover is high in EMCO?

- Employees are overworked

- Pay/benefits are not competitive

- No growth opportunities

- Poor management/culture

Why workload is more in QF?

- Inadequate staffing levels

- Processes not optimized

- Unclear responsibilities

- Too many changes/priorities

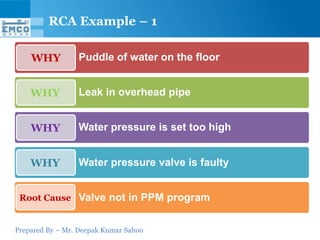

Why PPM in QF is not effective?

- Lack of commitment from leadership

- No accountability for completion

- Tasks not prioritized

- Resources/training insufficient

Why Rajnikant is too famous?

- Excellent acting skills

- Charismatic