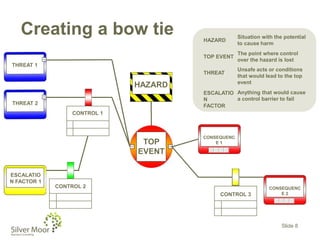

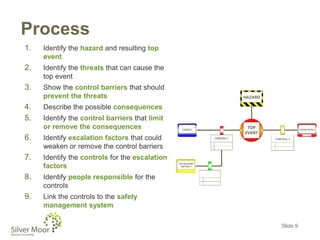

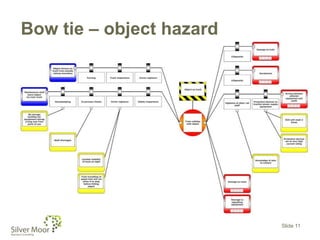

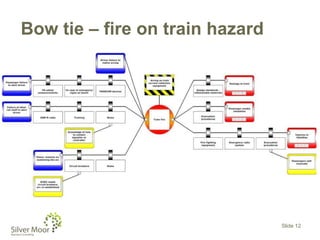

The bow tie method is a risk assessment and communication tool that graphically displays the relationship between potential hazards, threats, consequences, and control measures. It takes the shape of a bow tie, with the hazard and potential consequences at either end connected by a causal chain of threats and control barriers. The document explains the origins and development of the bow tie method, provides examples of its application in different sectors, and outlines the process for creating a bow tie diagram. Strengths of the bow tie method include its ability to visually depict risk assessments, promote stakeholder involvement, distinguish preventative from resilience controls, and consider all credible scenarios.