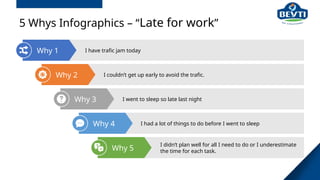

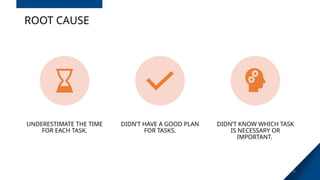

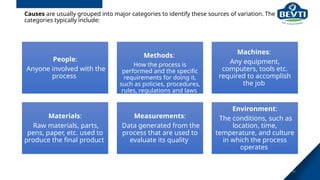

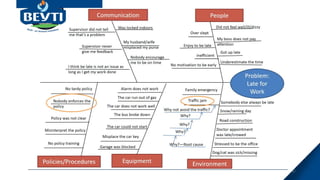

The document provides an overview of systematic troubleshooting approaches, emphasizing the importance of mental and technical methods for identifying and resolving issues effectively, including methodologies like Root Cause Analysis (RCA) and the 5 Whys technique. It highlights key aspects such as humility, neutrality, data collection, and various tools like fishbone diagrams to analyze problems. The document aims to equip engineers with skills and strategies to enhance troubleshooting efficiency and reduce downtime.