The document presents a rate analysis for slip form shuttering used in construction. It details the various cost components that make up the total cost per square meter of shuttering, including:

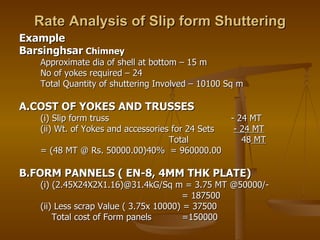

1) The cost of yokes, trusses and form panels totaling Rs. 1,500,000.

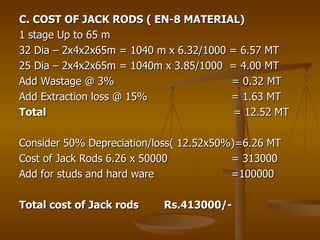

2) The cost of jack rods totaling Rs. 413,000.

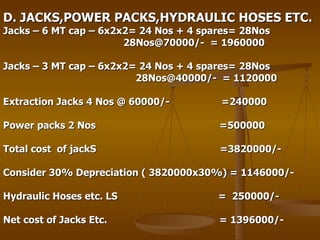

3) The cost of jacks, power packs and hydraulic equipment totaling Rs. 1,396,000 after depreciation.

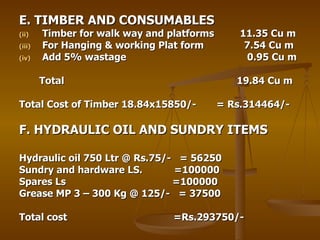

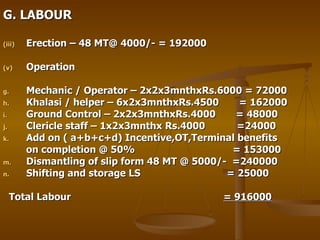

4) Additional costs for timber, consumables, labor, and dismantling totaling Rs. 2,856,000.

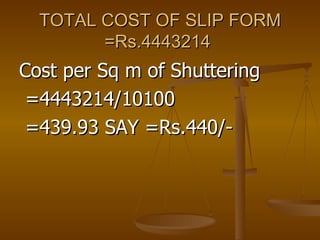

The total cost of the shuttering was Rs. 4,443

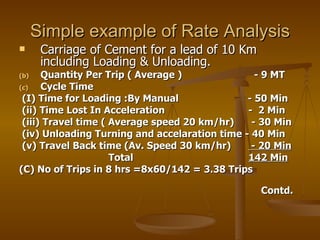

![(d) Quantity of Material transport in 8 hrs = 9MTX3.38 =30.42 MT (e) Cost of carriage per shift (i) Hire charges of truck with driver Rs.1500.00 (ii) Cost of Diesel [(3.38x(10x2)]+3 For Turning Etc. 1 ltr per 2.5 km, 20 km/2.5= 70.6 ltrs. @Rs.35.00 Rs.2471.00 (iii) Cost of Loading & Unloading 6 Coolie @ Rs. 100.00 Rs. 600.00 Cost per MT =4571.00/30.42=150.26 Add contractors profit 10 % = 15.00 Total cost per MT = 165.26 Say Rs.165.00](https://image.slidesharecdn.com/rateanalysissitemeeting-12623479550801-phpapp02/85/Rate-Analysis-Site-Meeting-11-320.jpg)