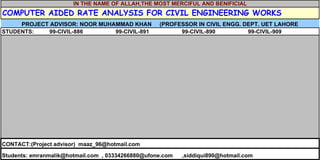

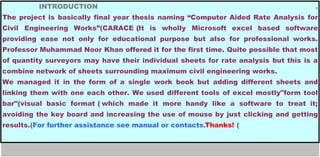

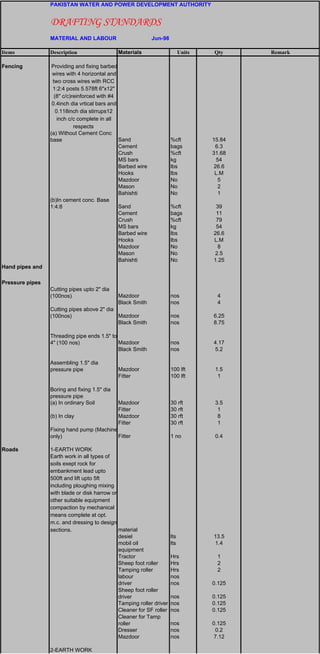

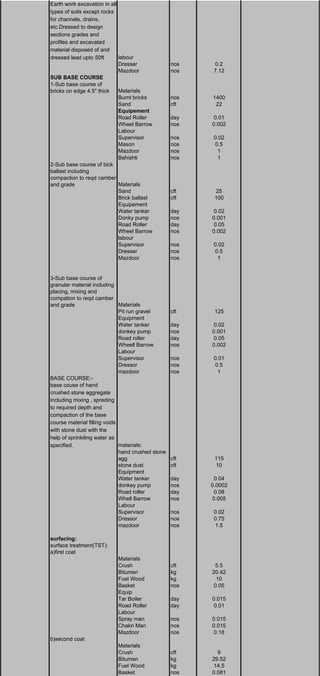

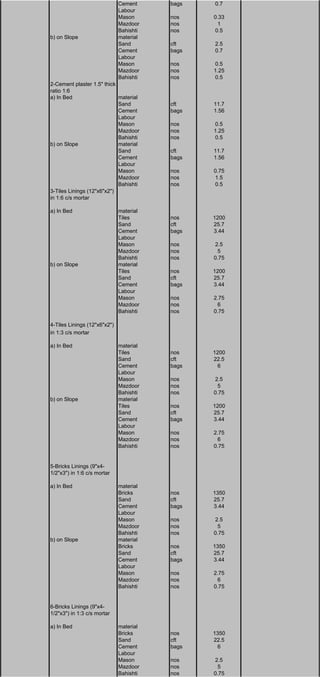

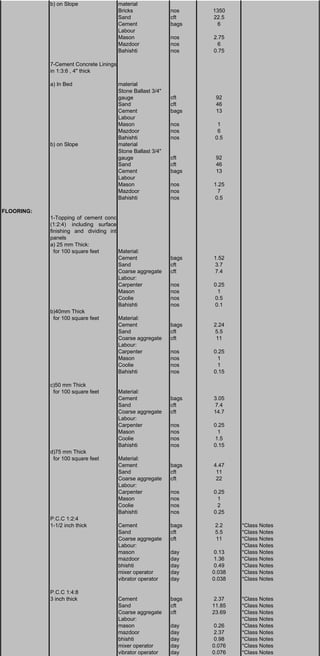

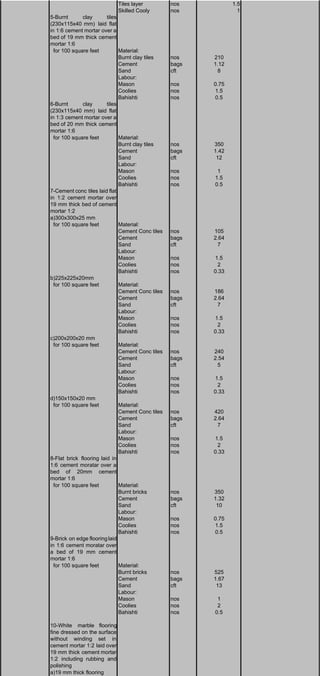

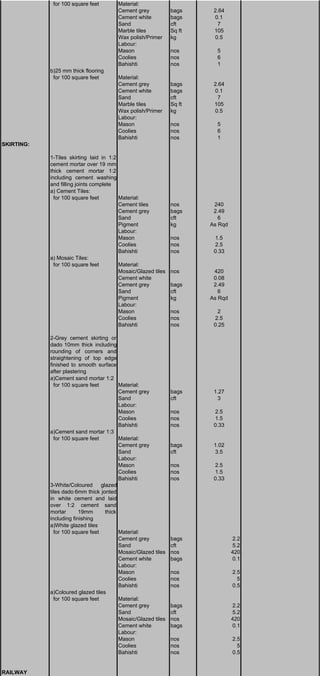

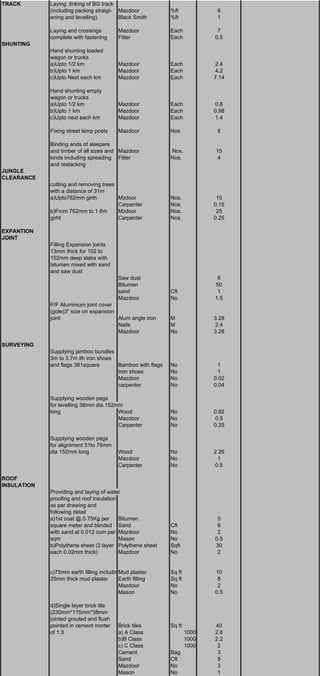

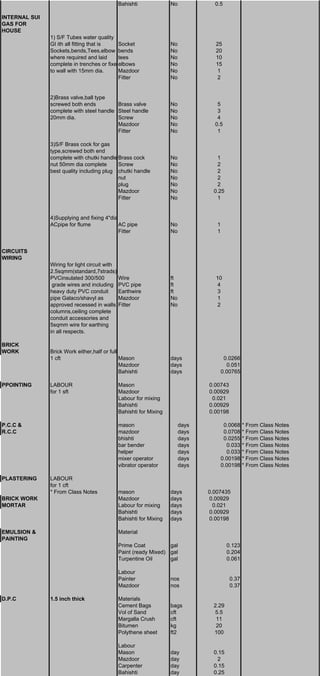

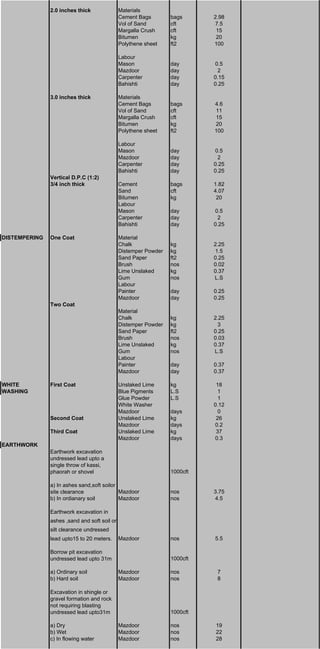

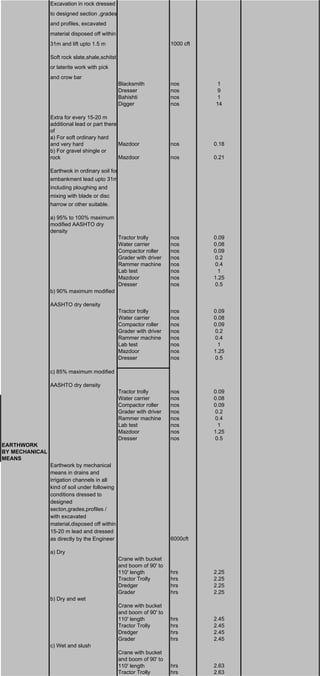

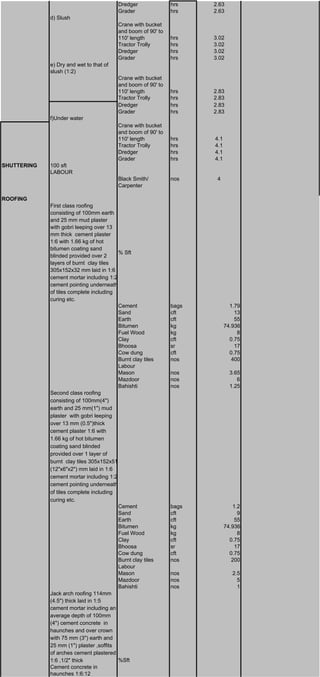

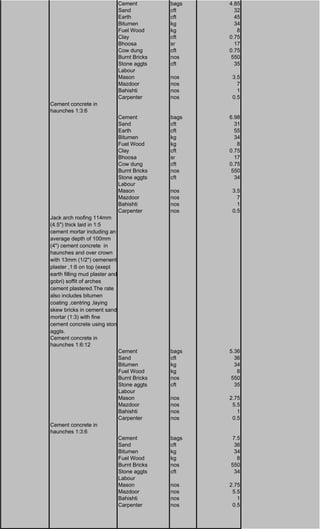

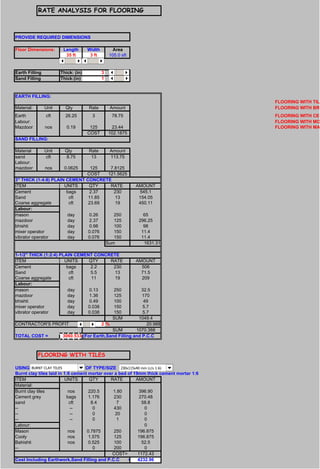

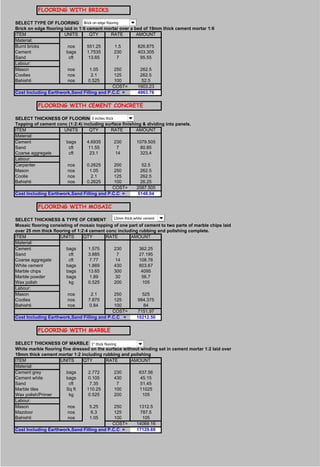

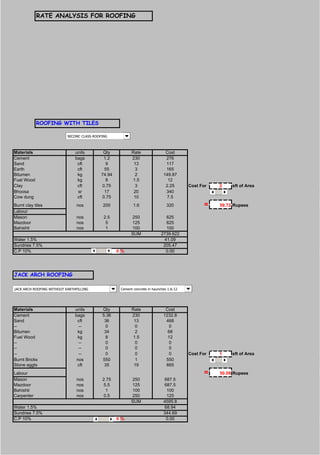

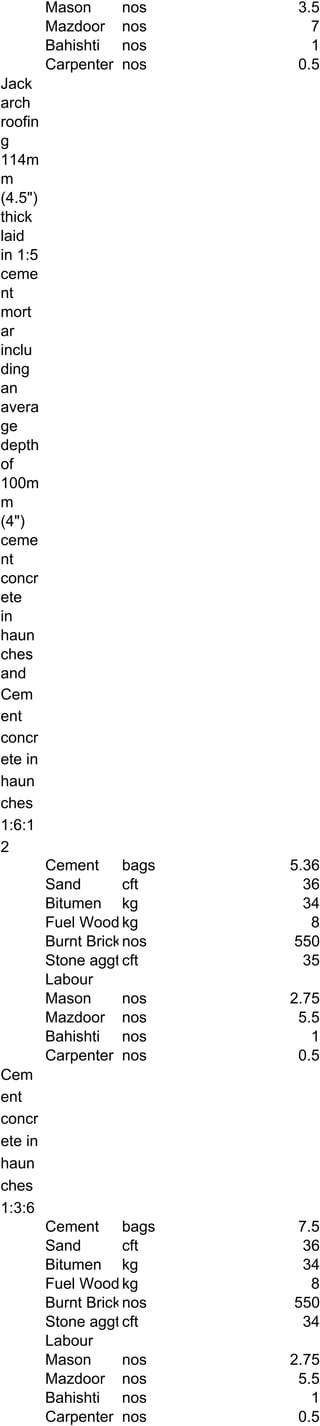

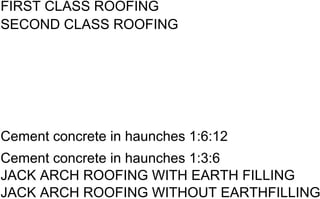

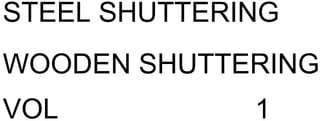

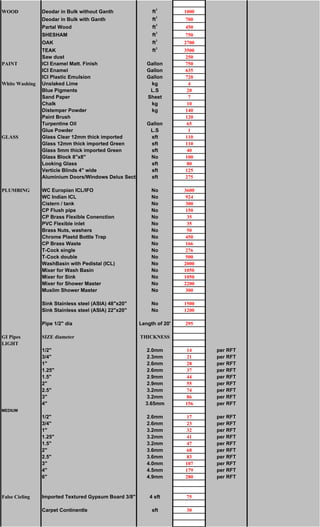

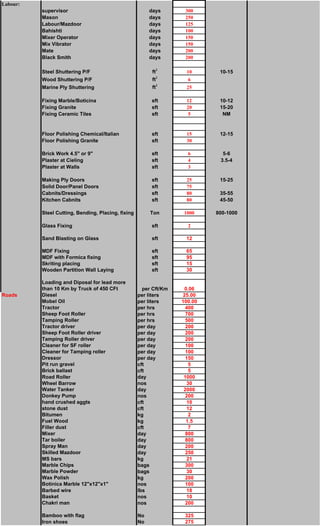

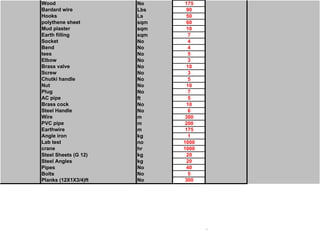

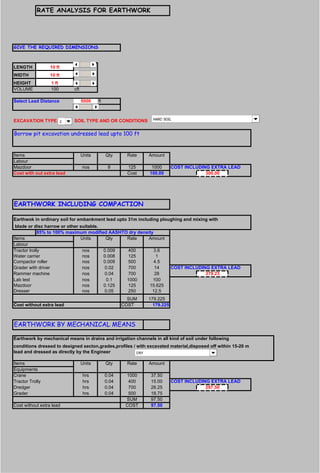

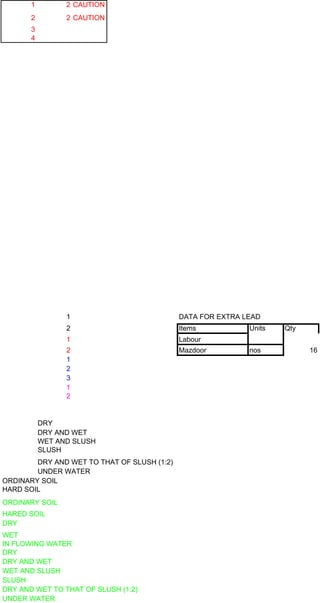

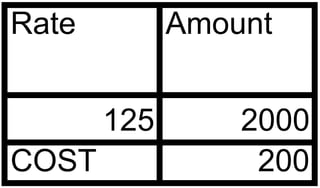

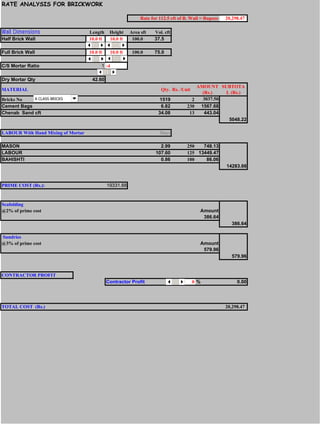

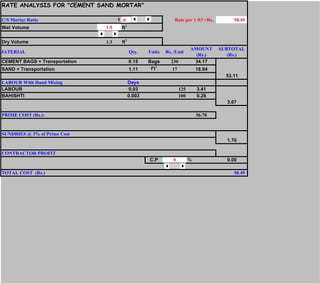

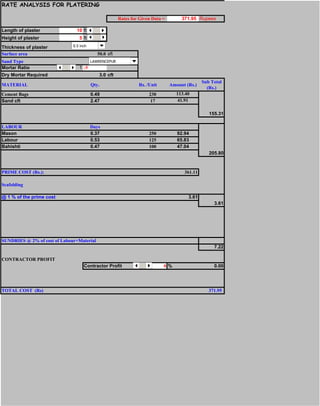

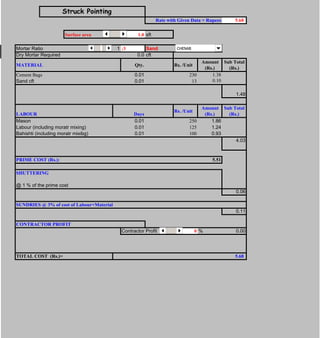

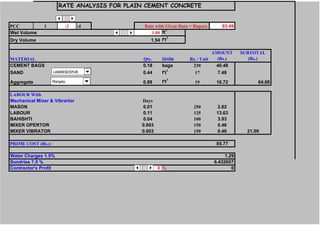

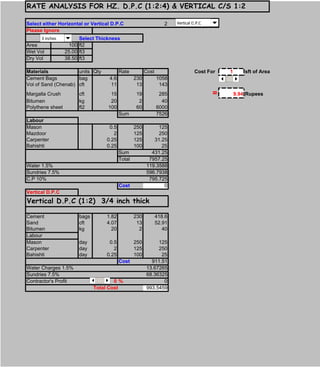

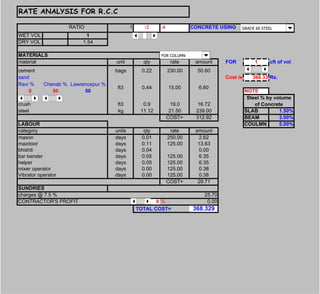

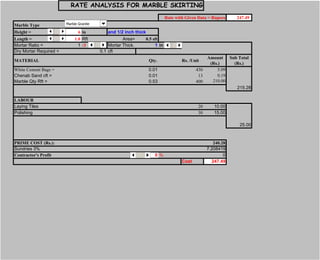

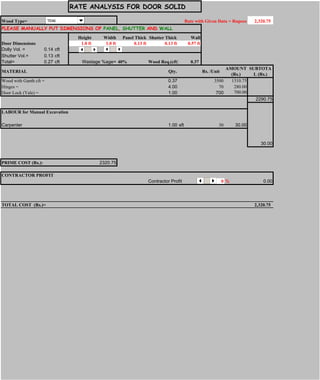

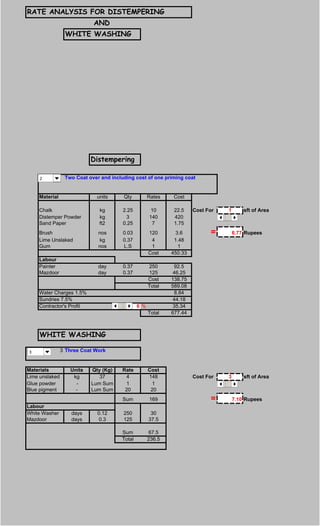

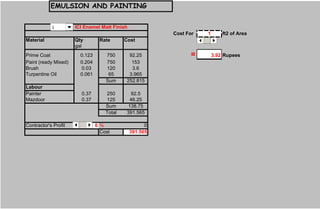

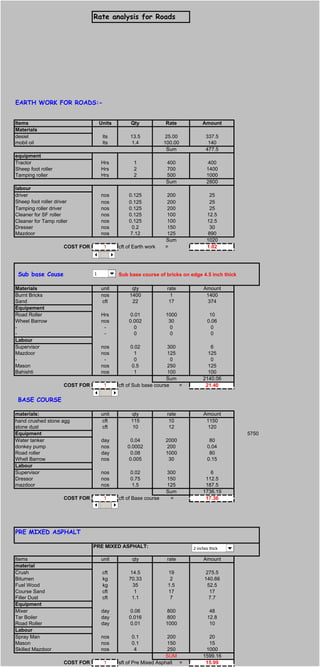

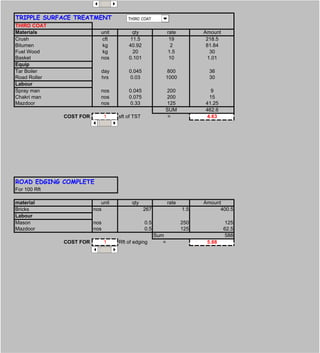

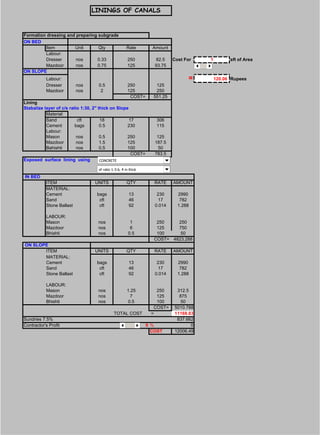

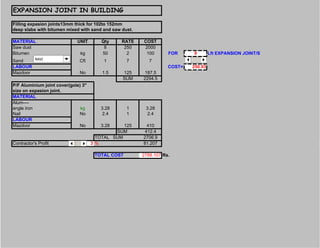

This document contains rate analysis information for various civil engineering works, including materials, equipment, labor, and unit rates. It includes rate schedules for fencing, hand and pressure pipes, roads, canal linings, flooring, and other construction items. Contact information is provided for the project advisor and students. The rate analysis is intended to provide ease for both educational and professional quantity surveying work.