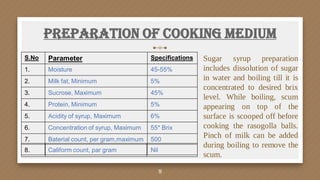

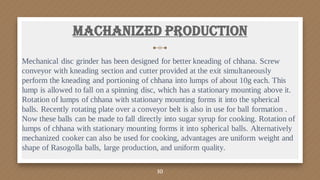

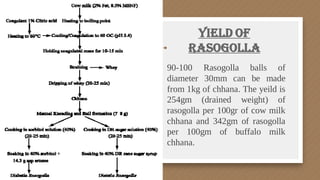

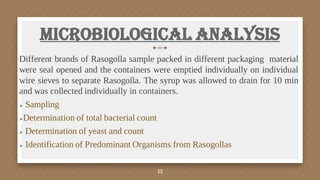

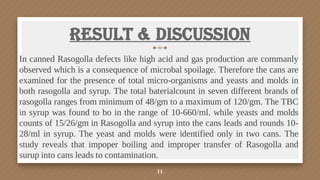

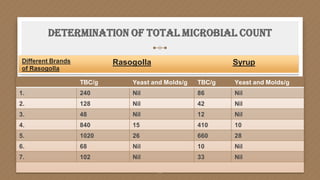

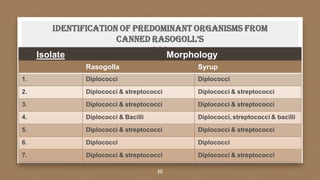

This document discusses the preparation, chemical and microbial analysis of rasogolla, a popular Bengali sweet. It begins with an introduction to rasogolla and its production. The objectives are to prepare and mechanically produce rasogolla and analyze it chemically and microbiologically. A literature review covers the effects of different parameters on rasogolla quality. The document then describes the materials and methods for traditional and mechanized rasogolla production. It provides details on the chemical composition and specifications of rasogolla and analyzes samples of different brands. Microbial analysis finds total bacterial counts within standards but some contamination issues. The conclusion discusses optimizing rasogolla quality through ingredients and production methods.

![Packaging

Balls are usually packed hot at 90*C in

lacquired tin cans of 1kg capacity.

[Empty containers are first sterilized in

hot air inside closed chamber.

Rasogolla balls with hot sugar syrup

and permissible preservatives {sorbic

acid and its sodium, potassium and

calcium salts calculated as sorbic acid

maximum 1000ppm and benzoic acid

maximum 300ppm} are filled into

containers and pass through steam

chest.]

Shelf Life

Rasogolla can be stored for 2

to 3 days at room temperature

without any packaging and

added preservation. Shelf life

of rasogolla in tin cans is

reported to be 6 months.

12](https://image.slidesharecdn.com/aryangurjar1803872vdt-514-201221135801/85/Dairy-Technology-12-320.jpg)

![Chemical Analysis

Moisture, fat, protein, sucrose and titrable acidity were estimate

as per the method of BIS[1989]. Moisture content waqs

measured by using drying over method. Fat content was

estimated by using mojonnier fat extraction appratus. Protein

content was estimated as per microkjeldhal method. Sucrose was

estimated as per laneeyon method lactose content was

determined by using the colorimetric method as described by

Nicker son etal. [1976]

17](https://image.slidesharecdn.com/aryangurjar1803872vdt-514-201221135801/85/Dairy-Technology-17-320.jpg)

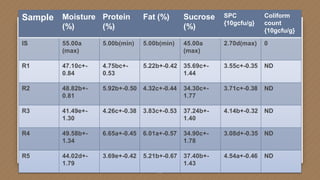

![Result & Discussion

Moisture content of Rasogolla samples was found between 41.49 to 49.58% and was

significantly lower than the indian standar of 55.00% maximum moisture content.

Chavan et al.[2009] & Arora et al [1996] also reported a similar result. The protein

content from source R3 and R5 was found significantly (P<0.05) lower than the BIS

specification. It might be due to the lower protein content in chhana used for rasogolla

preparation. Fat content from R2 and R3 were observed significantly (P<0.05) lower

than indian standard. It might be due to lower fat content in chhana used for the

preparation. Fat content (chavan et al 2009) also indicated similar result but { Arora

et al1996} reported slightly higher [7.3%] fat content than the result of the present

study. Sucrose content of rasogolla was found significantly (P<0.05) lower than the

indian standard of 45% maximum sucrose content. Similar result also reported by

(chavan et al 2009)

18](https://image.slidesharecdn.com/aryangurjar1803872vdt-514-201221135801/85/Dairy-Technology-18-320.jpg)

![References

Aneja RP, Mathura BN, Chandan RC, Banerjee AK(2002) Technology of indian

milk product. In dairy india publish .

Sahu JK, Tiwari A [2008] constraints and solution for mechanization of dairy

products. Manufacturing in north eastern india. Indian Dairy man 60[6]:17-29.

Despite AD, Datto SC [1993] preparation of chhana for rasogolla manufacture.

Ind J dairy sci 46:95-96.

IS: indian standard specification for canned rasogolla, 4079-1967.

RP Aneja: Traditional milk specialities – A survey Dairy India,259-262{1992}.

Anonymous: Report of national dairy research institute report instituteno,17,24{1955-56}.

21](https://image.slidesharecdn.com/aryangurjar1803872vdt-514-201221135801/85/Dairy-Technology-21-320.jpg)