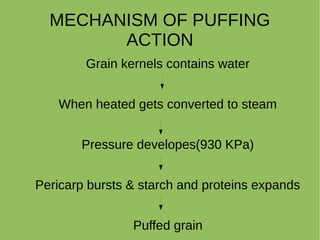

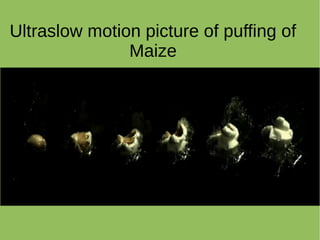

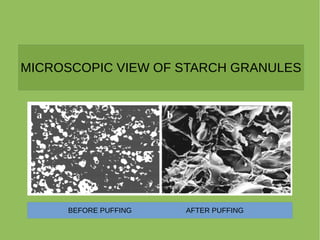

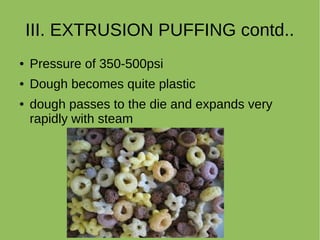

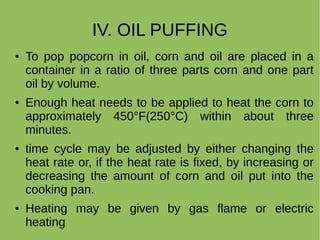

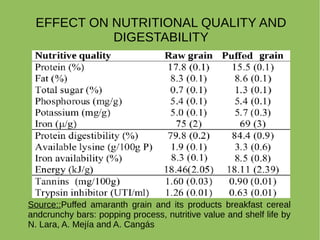

The document summarizes the process of making puffed grains. It describes how Dr. Alexander P. Anderson invented the modern puffing process using heat and steam to cause grains like rice, wheat, and corn to explode and increase dramatically in volume. The puffing process works by heating grain kernels that contain water, converting the water to steam which builds pressure until the grain's pericarp bursts, allowing the starch and proteins to expand into a puffed shape. Common puffing methods described are oven puffing, gun puffing, extrusion puffing, and oil puffing for popcorn. The puffing process increases the grain's volume 6-8 times and results in popular breakfast cereals like Rice Krispies and Cheerios