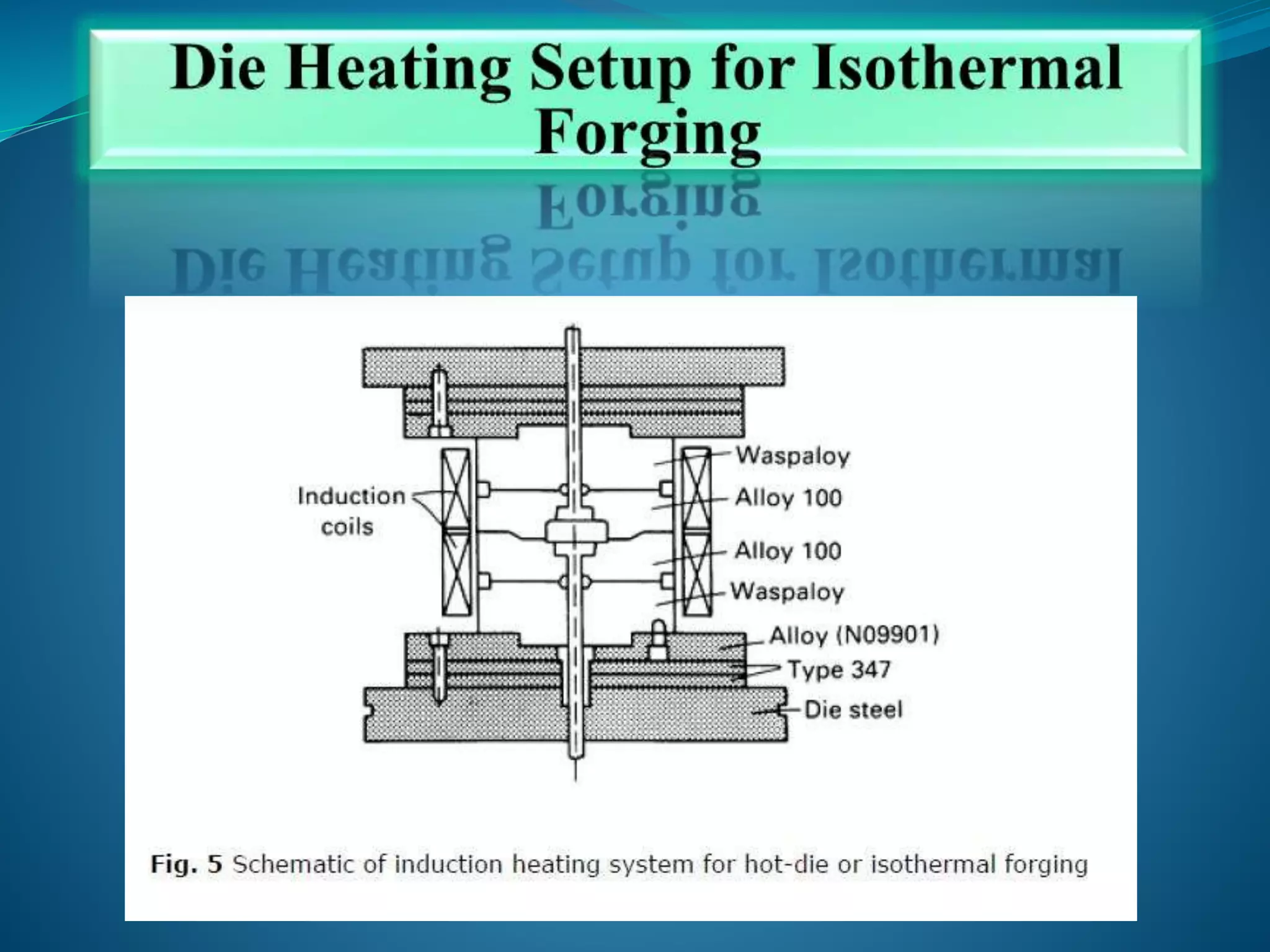

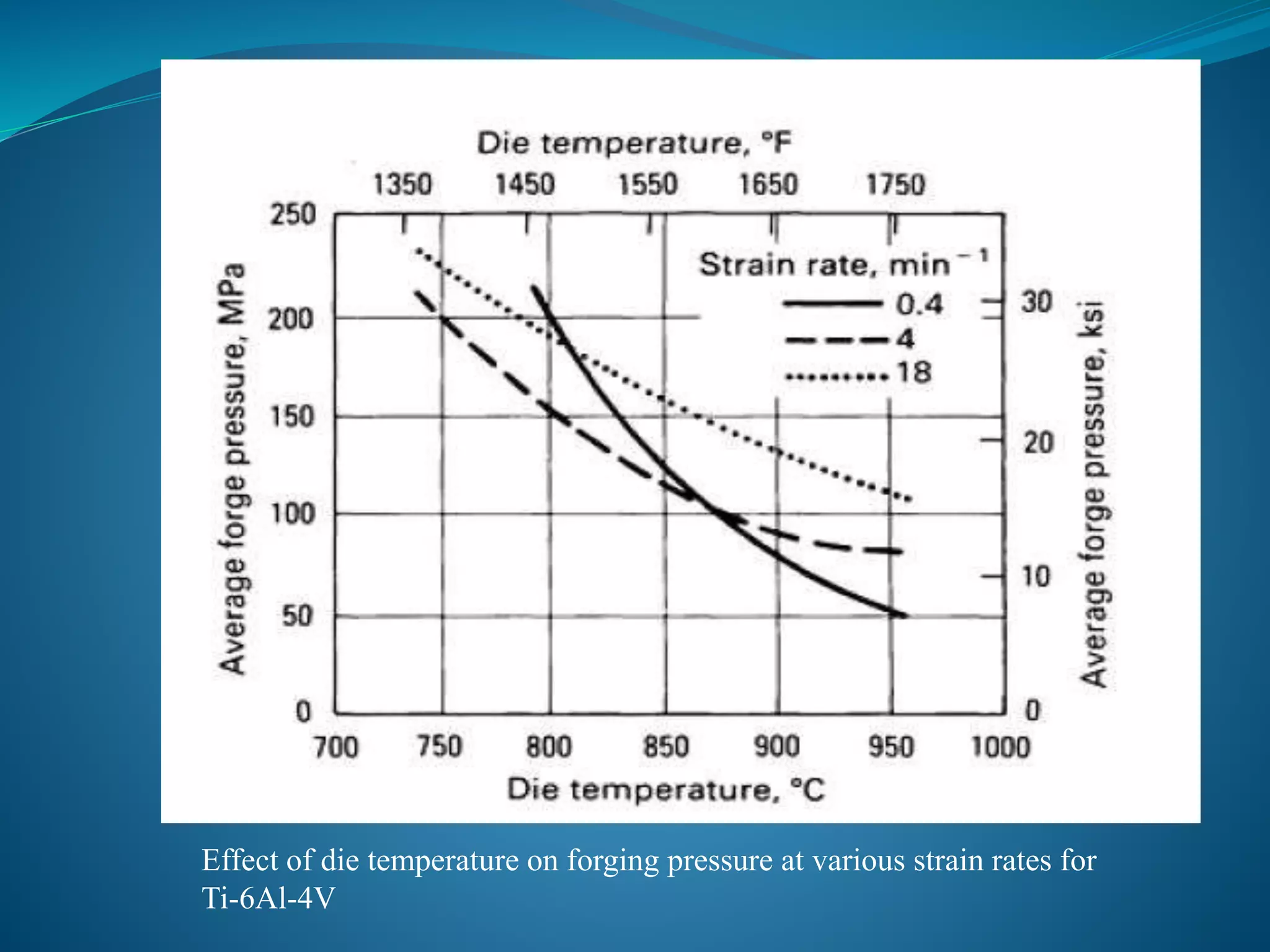

The document discusses isothermal forging, a process aimed at reducing die chilling by maintaining high temperatures in both the dies and workpieces, allowing for uniform plastic flow and the production of thin-section forgings. Techniques such as induction heating and gas-fired infrared heating are utilized to keep the dies heated during the operation, which is beneficial for forging expensive materials like titanium and super alloys. Despite the high initial costs associated with materials and setup, the process offers advantages such as reduced material waste and improved product uniformity.