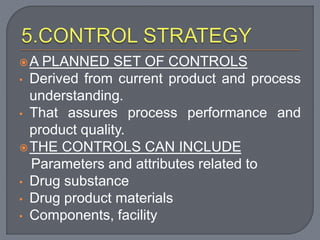

This document discusses Quality by Design (QbD), which is a systematic approach to pharmaceutical development that begins with predefined objectives and emphasizes product and process understanding based on sound science. The key aspects of QbD include defining critical quality attributes, establishing a design space of input variables and process parameters to ensure quality, and implementing a control strategy. The goals of QbD are to ensure a predefined quality and quality with effective control through understanding how formulation and manufacturing variables influence product quality.