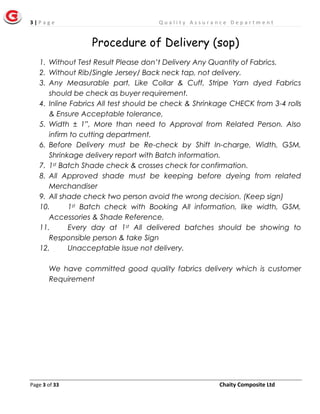

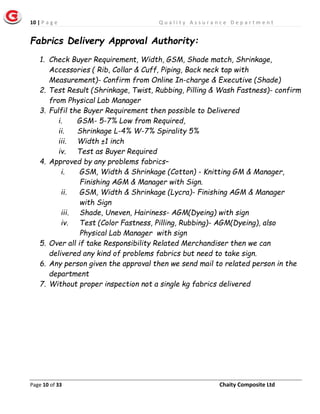

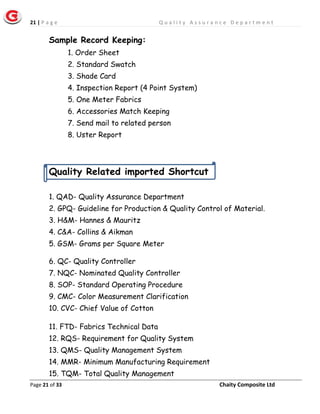

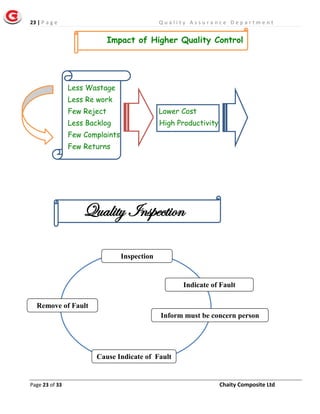

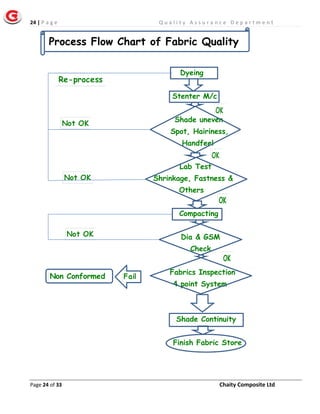

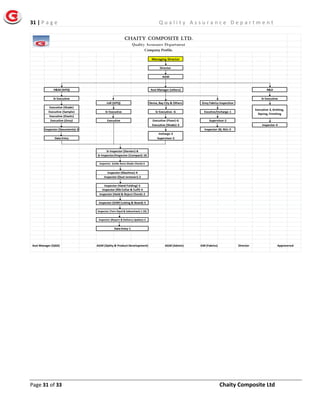

This document outlines responsibilities and procedures for the Quality Assurance Department of Chaity Composite Ltd. It defines key quality roles such as the AGM of Quality and Product Development who is responsible for planning, monitoring quality standards, and responding to customer complaints. It also describes the responsibilities of assistant managers for H&M quality and general quality assurance duties. Finally, it provides standard operating procedures for fabric inspection, delivery approval, and defining defects using a four point system.