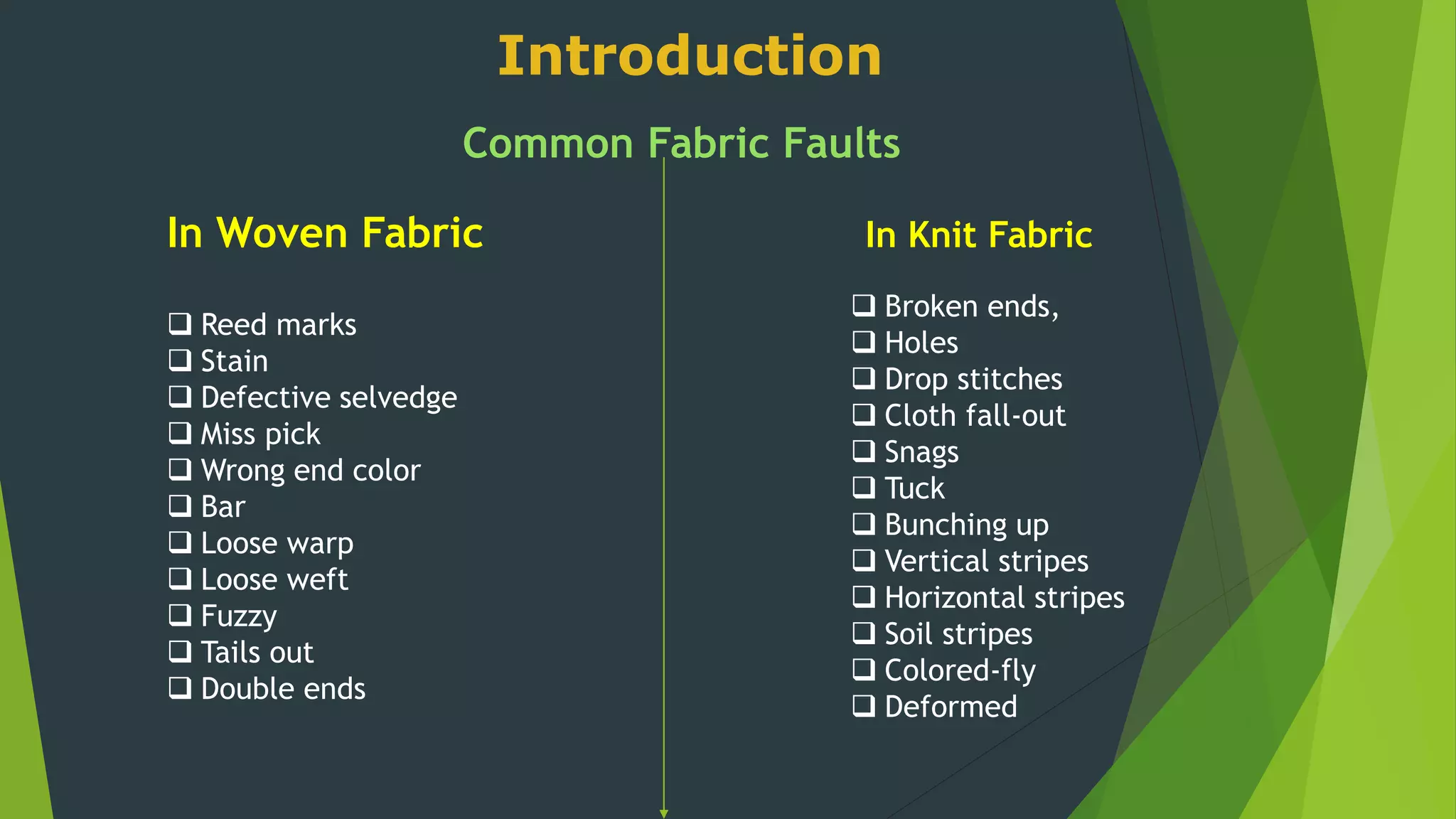

The document outlines the importance of fabric inspection in garment manufacturing, emphasizing its role in identifying defects to ensure quality and minimize rejects. It describes two main inspection systems: the 4-point system and the 10-point system, detailing their grading criteria and procedures. The findings highlight that effective fabric inspection leads to improved quality, reduced manufacturing losses, and the maintenance of desired fabric characteristics.