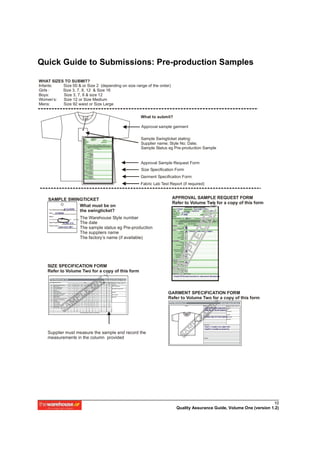

Please submit the following for 1st approval:

- Approval sample garment(s) in specified sizes

- Size specification form with sample measurements filled in

- Garment specification form

- Sample swing ticket

- Fabric/accessory samples for approval (if applicable)

- Labelling/packaging samples (if applicable)

Ensure samples match specs provided. Measure samples and fill out forms completely before submitting.

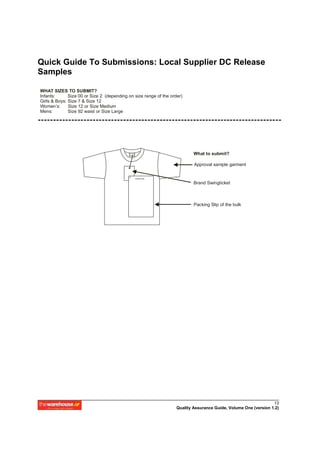

What to submit?

- Approval sample garment(s)

- Size specification form

- Garment specification form

- Sample swing ticket

- Fabric/accessory samples (if applicable)

- Labelling/packaging samples (if applicable)

- Original sample (if