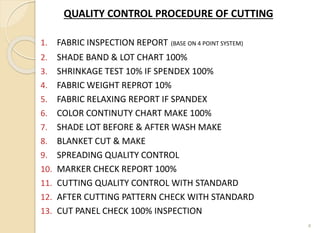

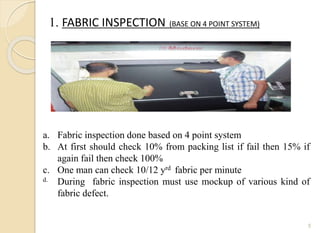

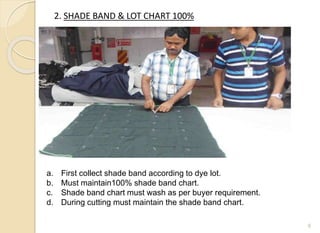

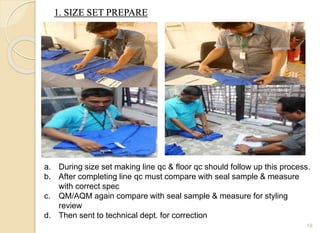

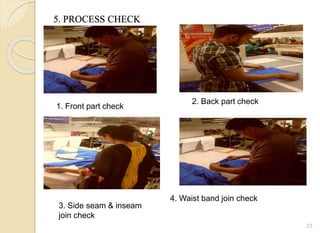

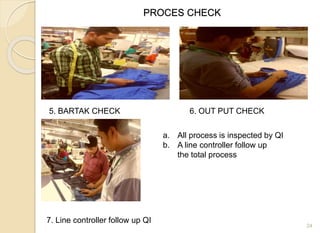

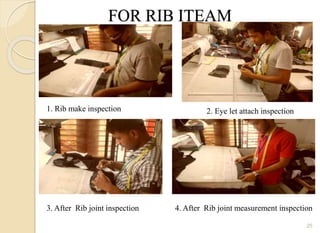

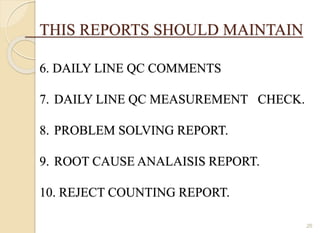

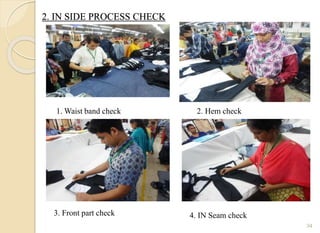

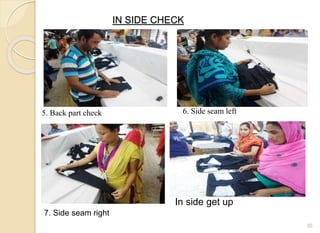

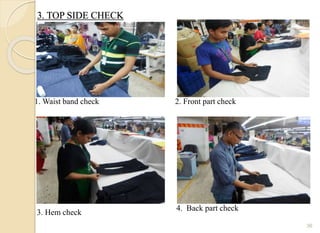

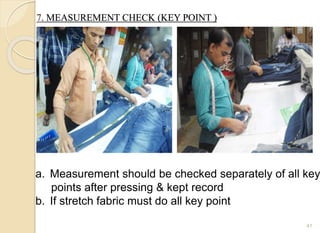

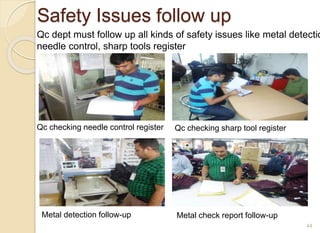

The document outlines a comprehensive quality control procedure for woven garments, emphasizing defect prevention and quality assurance across various stages including fabric inspection, cutting, sewing, and finishing. It details specific inspection methods, testing protocols, and record-keeping practices to ensure quality throughout the manufacturing process. The procedure is designed to maintain high standards and facilitate problem-solving through systematic audits and meetings.