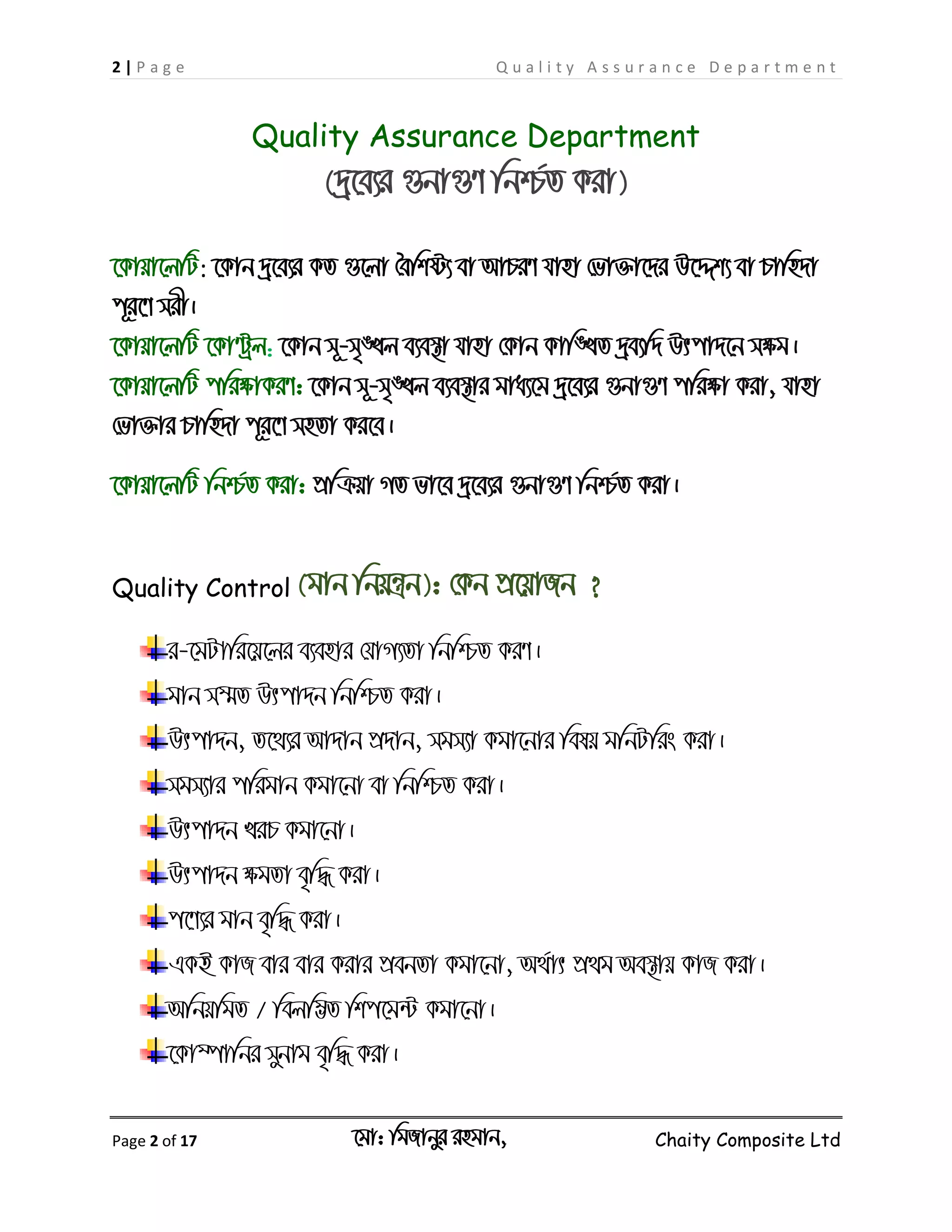

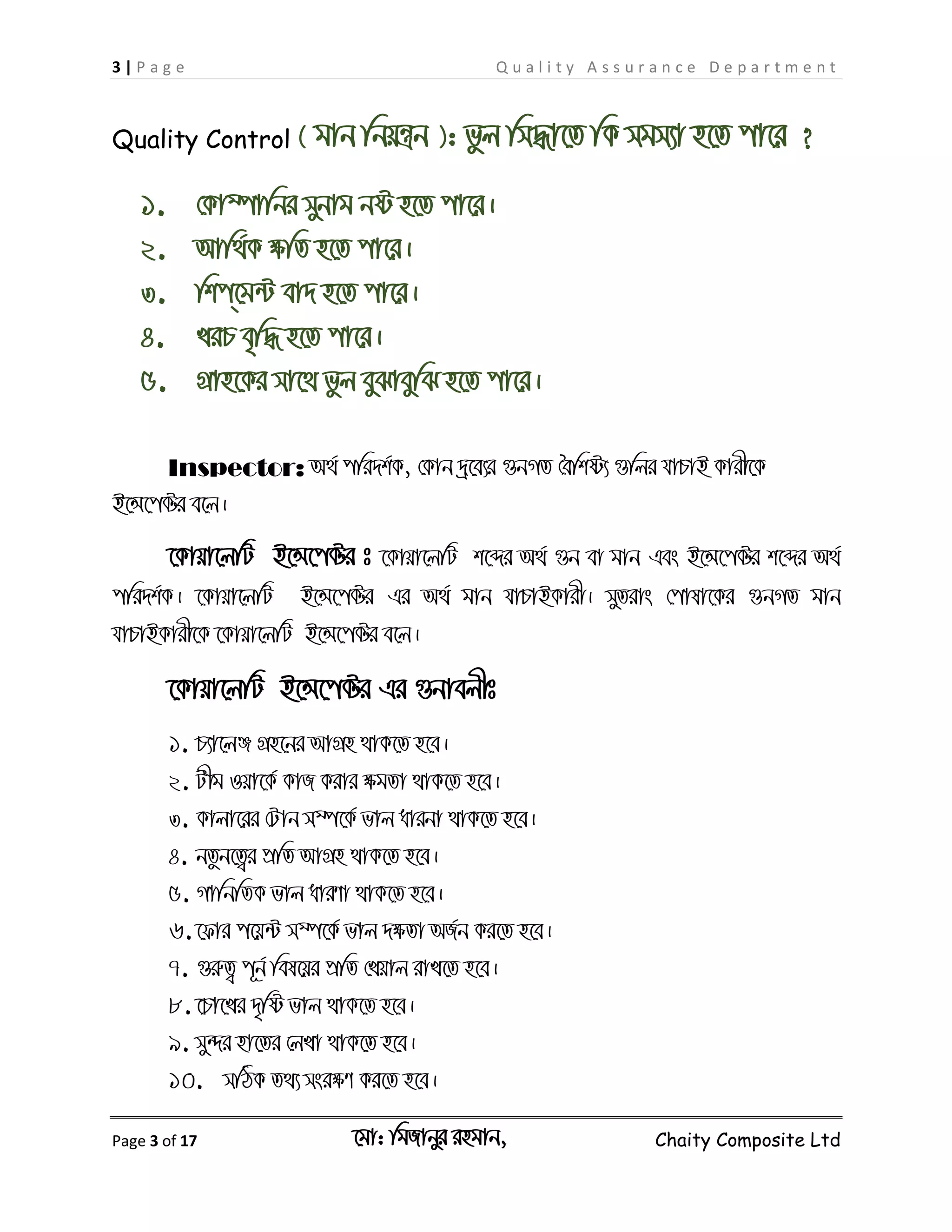

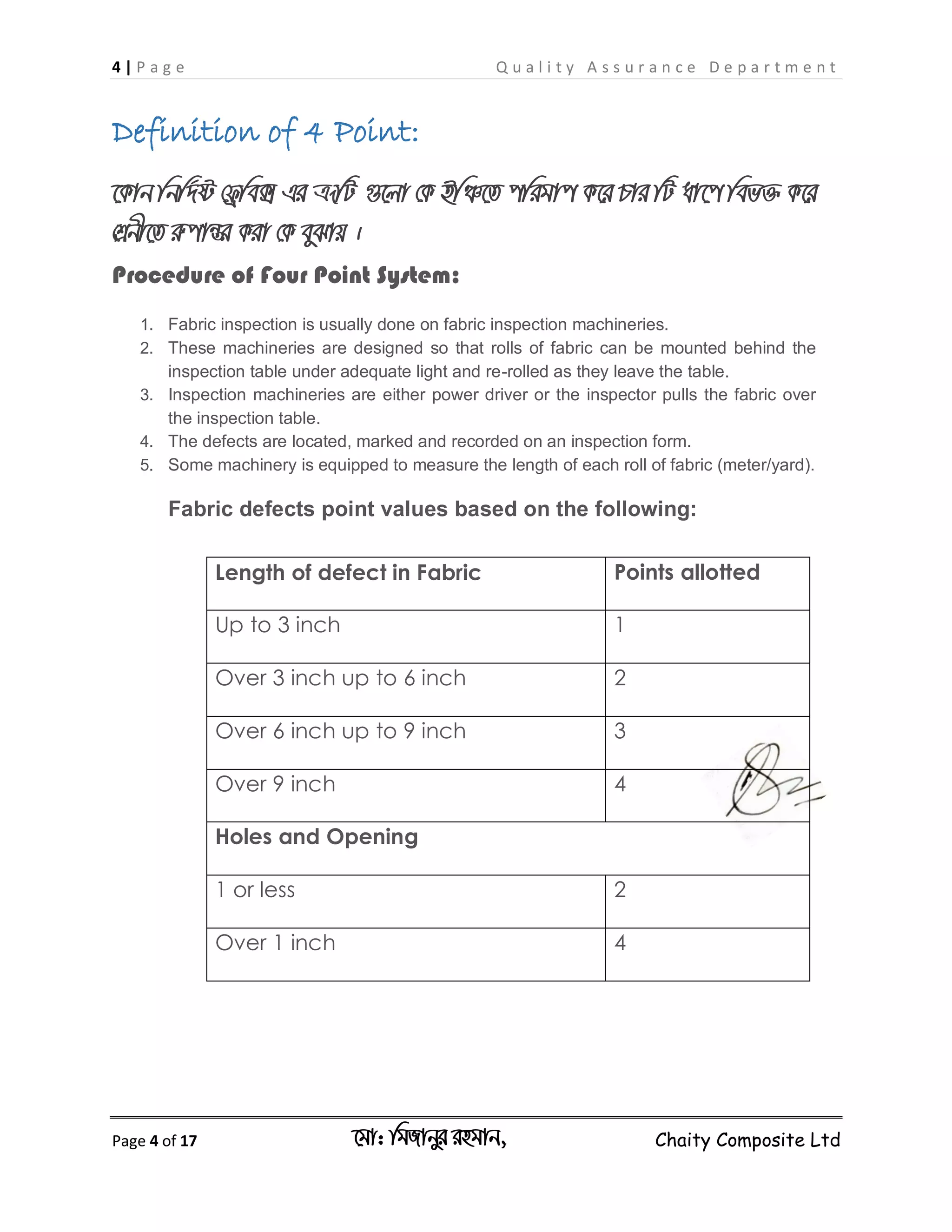

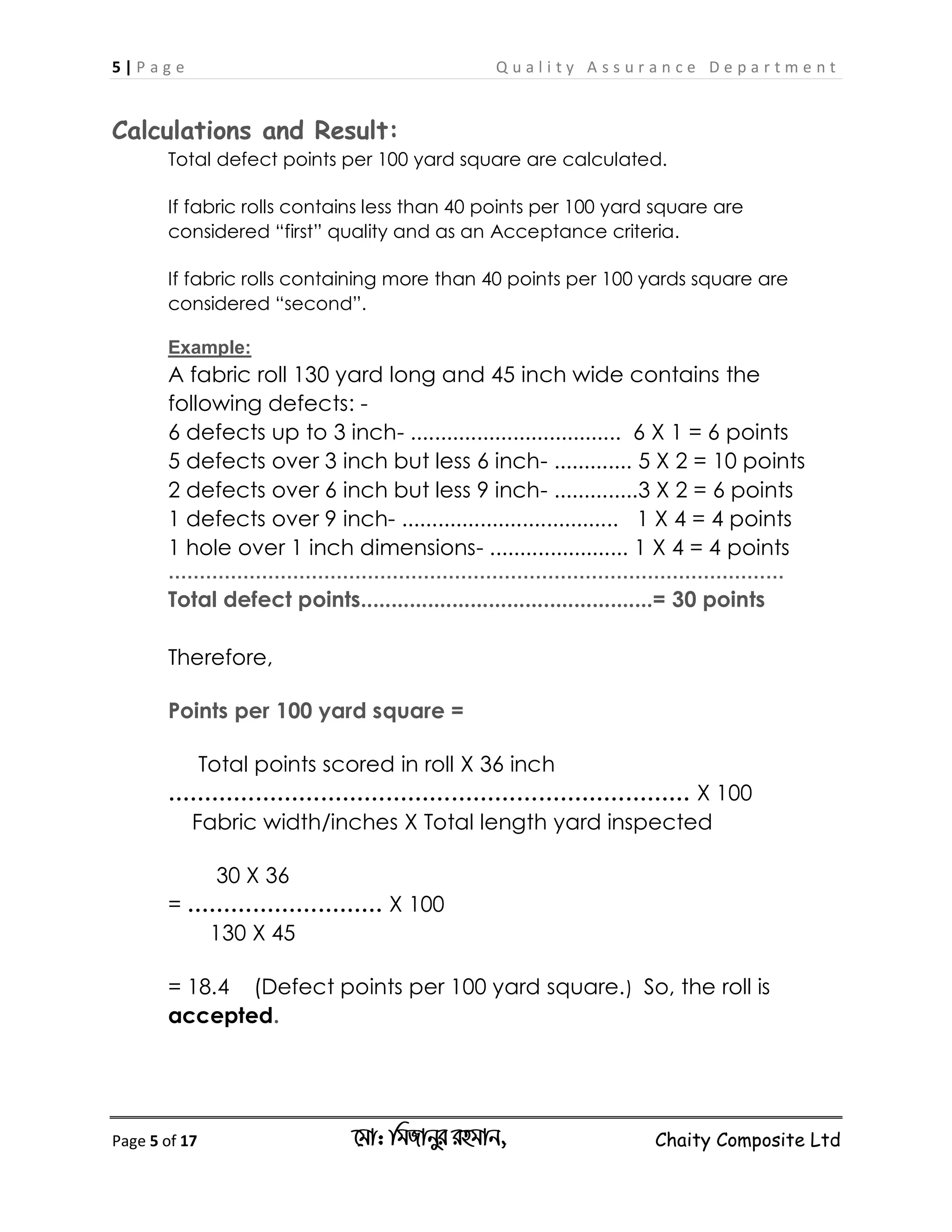

This document discusses quality assurance and control processes. It defines key terms like quality assurance, quality control, and inspectors. It describes the four point grading system for fabric inspection where defects are given point values based on their size. It provides examples of calculating total defect points for a fabric roll and criteria for first and second quality fabrics. The roles and responsibilities of inspectors are outlined. Quality policies aim to continuously improve product quality, understand buyer demands, and maintain clean workstations with a responsible workforce.