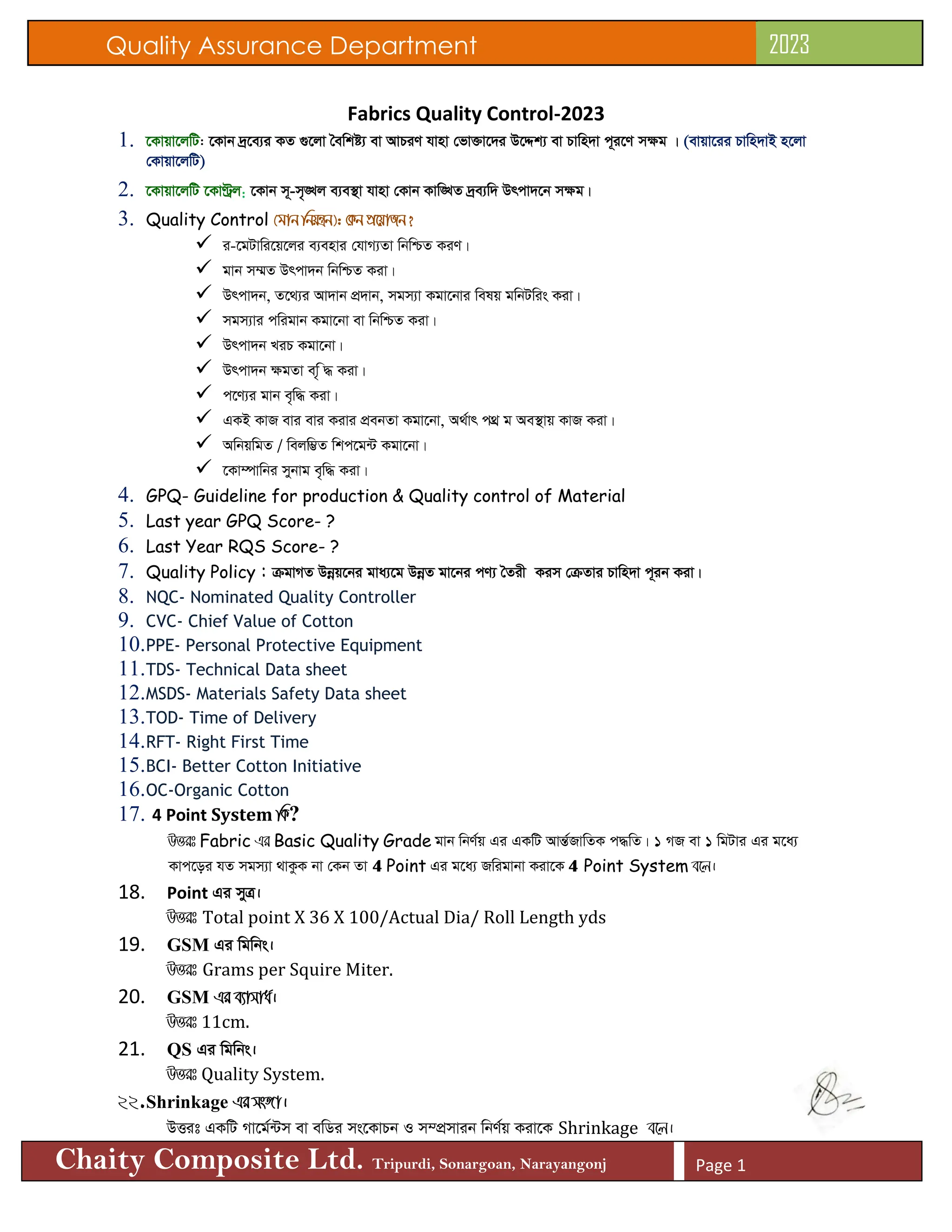

This document provides definitions and guidelines for various quality assurance terms and processes for Chaity Composite Ltd. Key points include:

1. Quality control aims to ensure products meet customer needs and requirements.

2. Various terms are defined such as quality control, guidelines for production and quality control, 4-point system, and definitions for GSM, shrinkage, and twisting.

3. Inspection procedures and requirements are outlined for processes like running shade matching, light box usage, and online and offline sampling percentages.