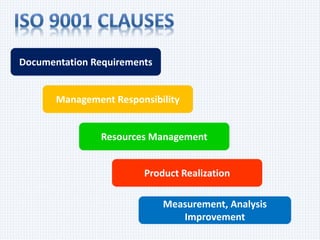

This document discusses key concepts and thinkers related to quality management including Deming, Juran, Shewhart, Taguchi, Ishikawa, Ohno, and Shingo. It also defines terms like quality assurance, quality control, total quality management, and Six Sigma. Finally, it outlines the history and evolution of the ISO standards for quality management systems from ISO 9000 in 1987 to the current ISO 9001:2008 standard which emphasizes customer focus, leadership, engagement of people and continual improvement.