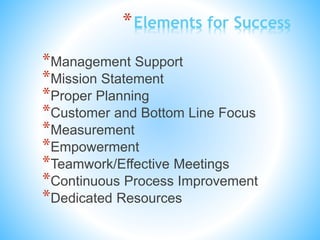

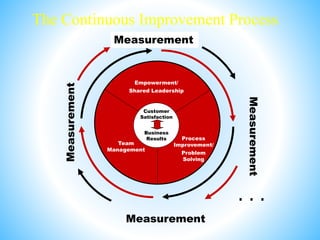

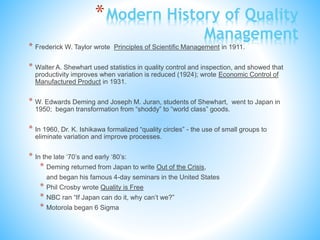

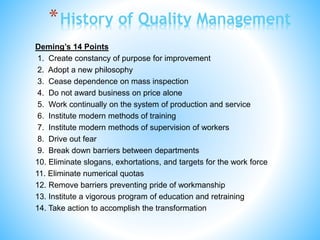

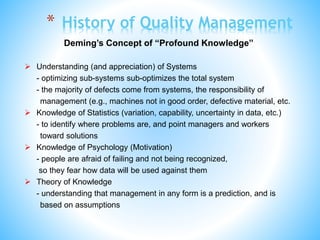

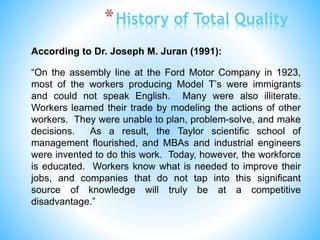

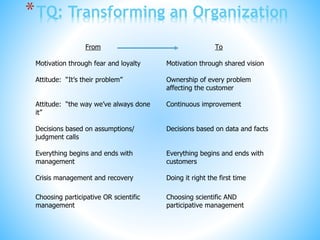

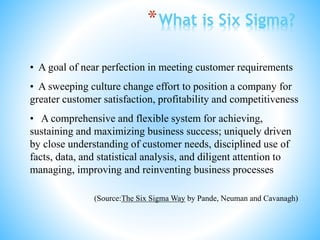

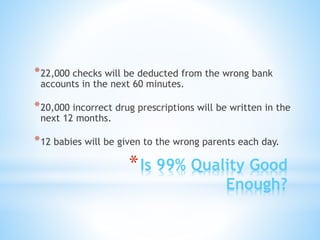

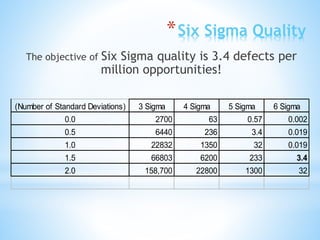

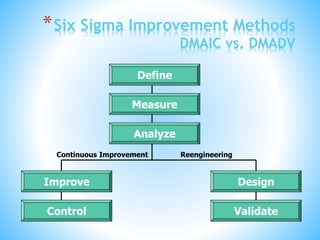

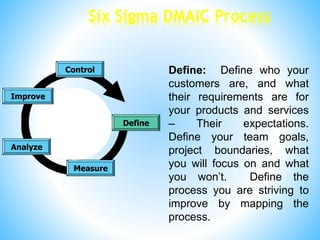

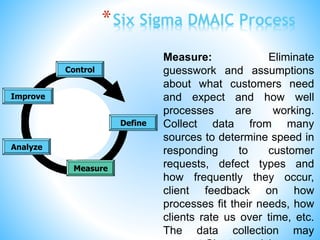

Total Quality Management (TQM) and Six Sigma are methodologies aimed at enhancing customer satisfaction, profitability, and competitiveness through a culture of continuous improvement, employee empowerment, and systematic quality management. The document outlines the historical evolution of quality management practices, emphasizing contributions from key figures such as Deming and Juran, and describes the Six Sigma process for achieving near-perfect quality by systematically reducing defects. It highlights the importance of data-driven decision-making and the need for businesses to adopt an inclusive approach that values insights from all employees for successful transformation.