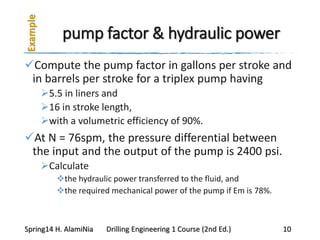

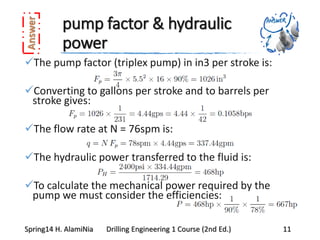

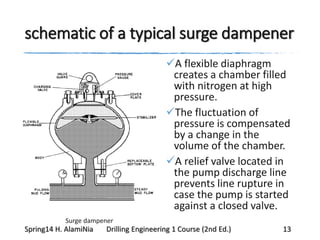

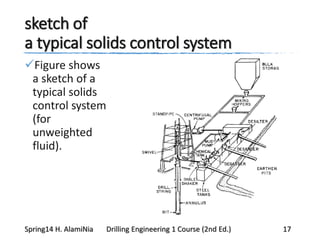

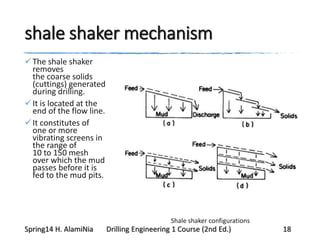

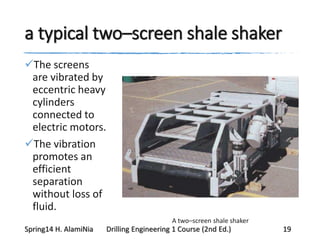

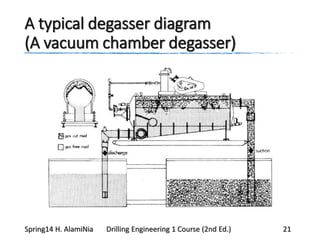

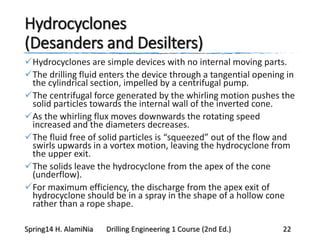

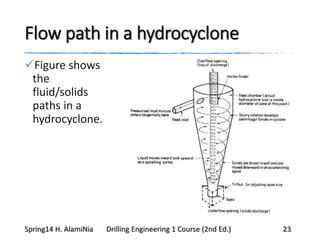

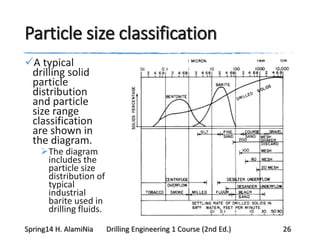

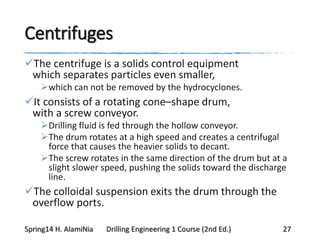

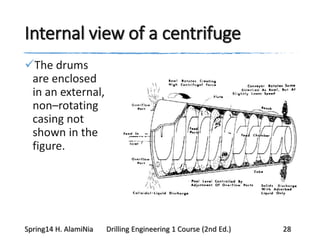

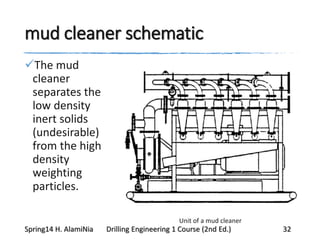

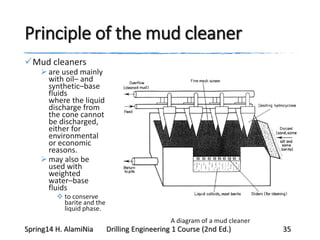

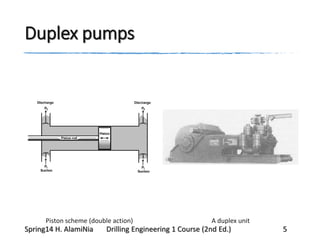

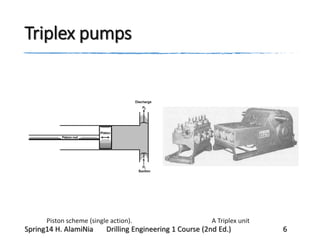

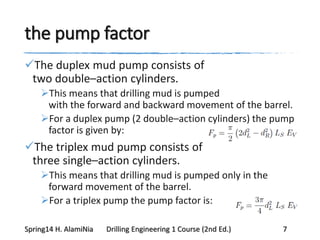

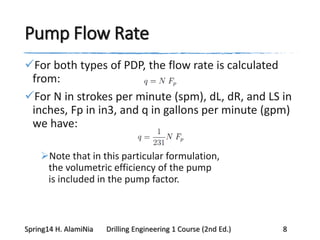

The document discusses drilling fluid systems used in oil and gas drilling. It describes the main components, including mud pumps that circulate drilling fluid, solids control equipment to remove cuttings from the fluid, and treatment/mixing equipment. It focuses on duplex and triplex mud pumps, explaining their piston configurations and how to calculate their flow rates and power requirements. Solids control equipment like shale shakers, hydrocyclones, centrifuges, and mud cleaners are also outlined.

![Pump Power

Pumps convert mechanical power into hydraulic

power. From the definition of power P=Fv

In its motion,

the piston exerts a force [F] on the fluid that is equal to

the pressure differential in the piston Δp times

the area A of the piston, and

the velocity v is equal to

the flow rate q divided by the area A, that is

For PH in hp, p in psi, and q in gpm we have:

Spring14 H. AlamiNia Drilling Engineering 1 Course (2nd Ed.) 9](https://image.slidesharecdn.com/alezckx3q0iudsxbttqx-140509203624-phpapp02/85/Q922-de1-l05-v1-9-320.jpg)