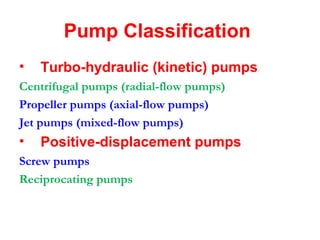

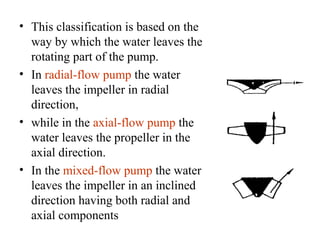

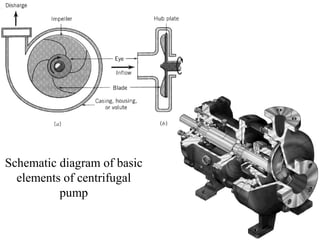

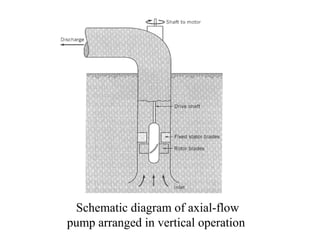

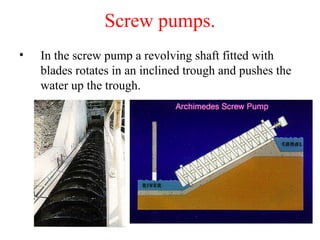

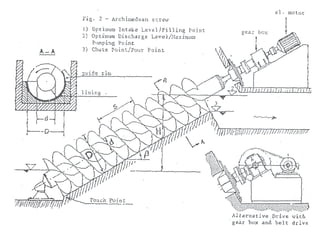

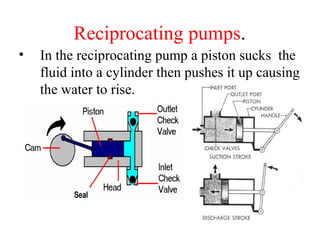

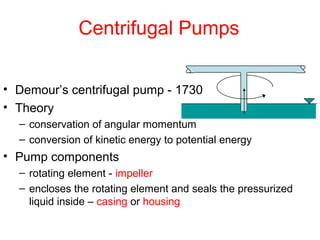

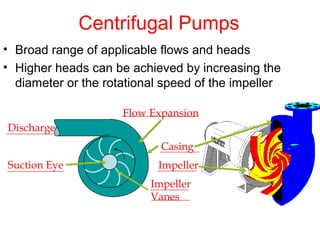

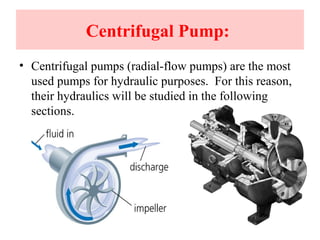

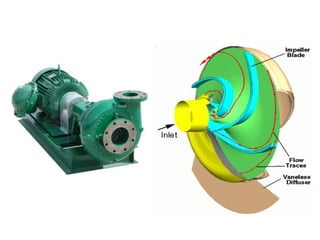

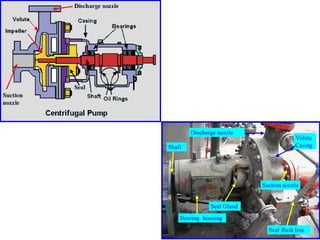

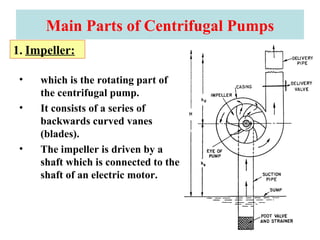

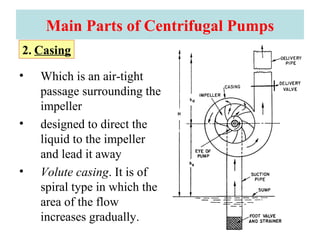

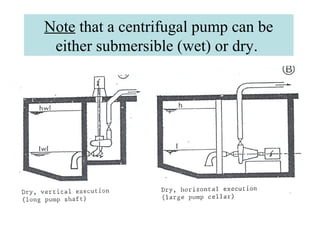

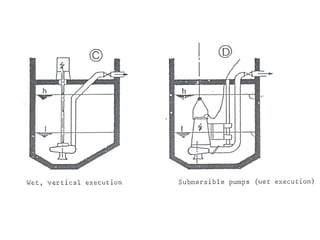

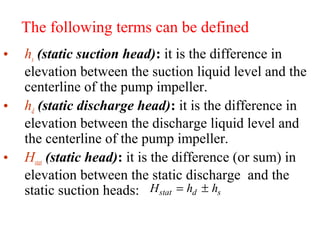

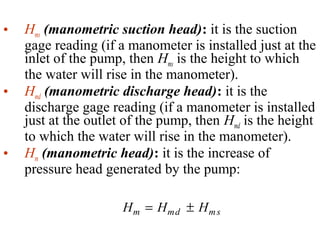

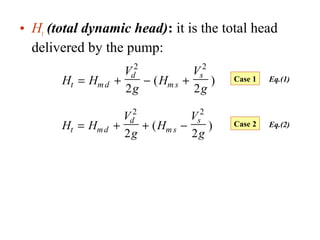

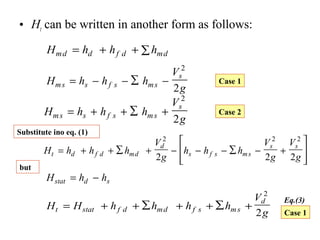

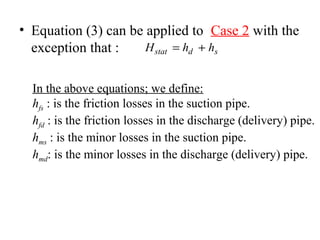

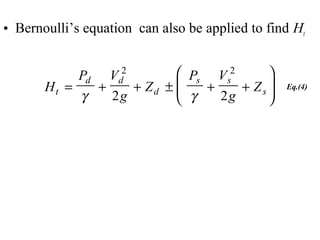

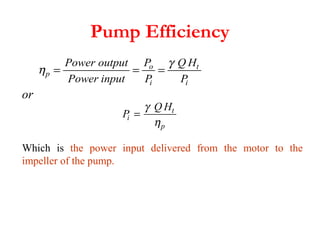

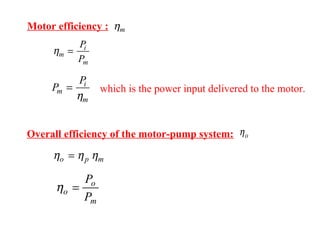

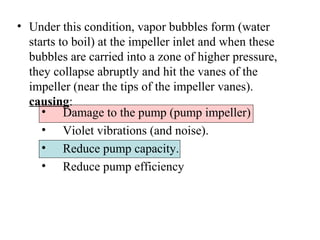

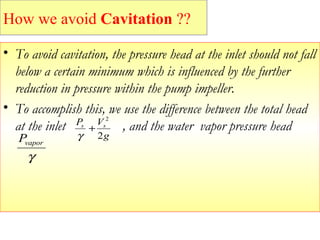

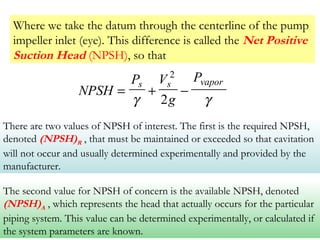

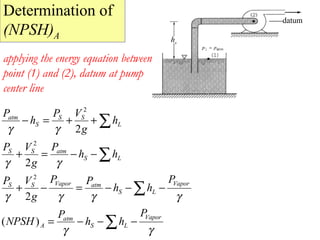

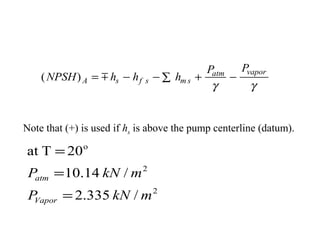

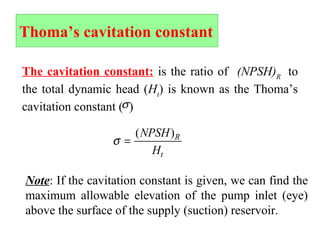

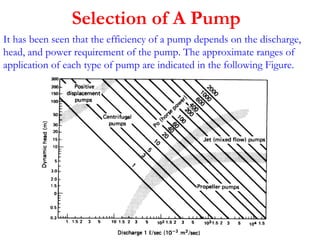

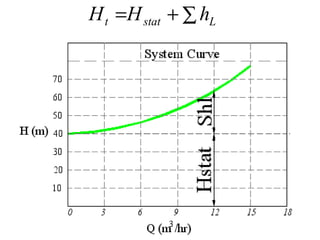

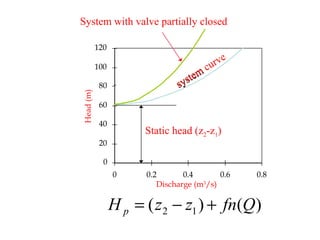

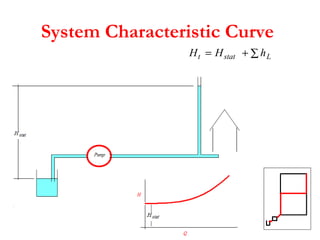

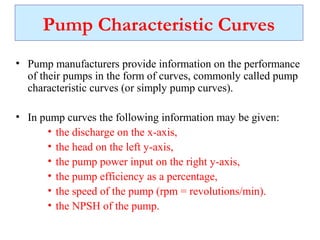

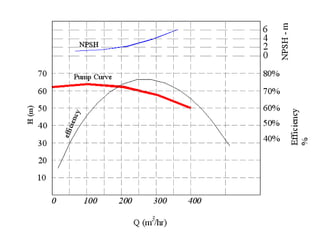

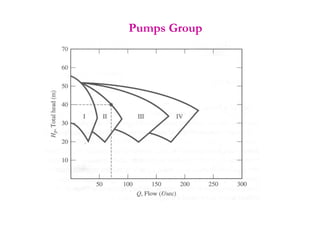

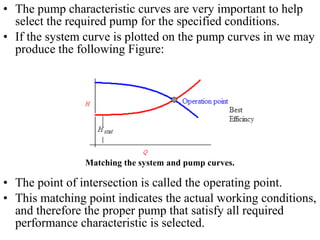

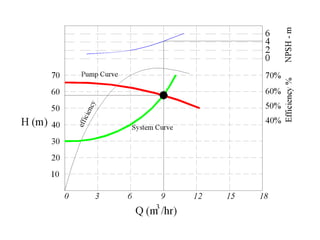

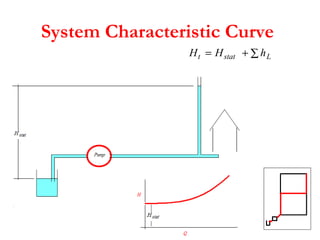

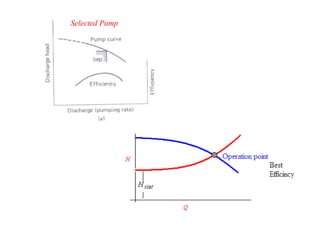

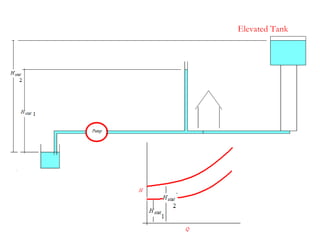

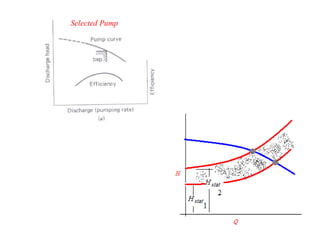

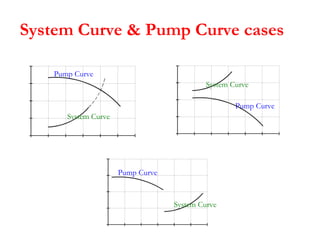

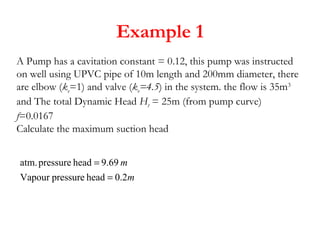

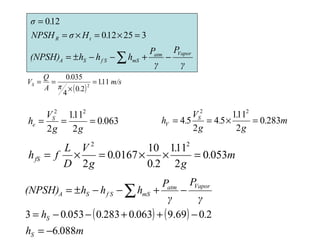

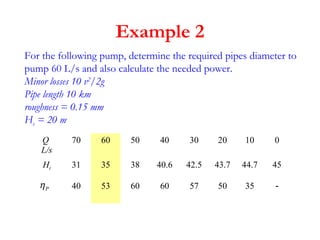

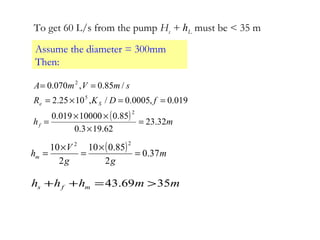

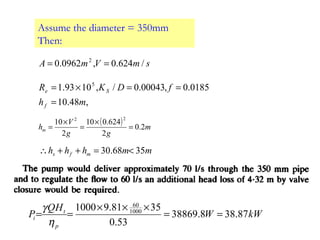

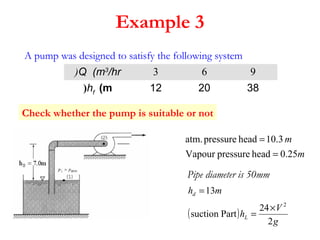

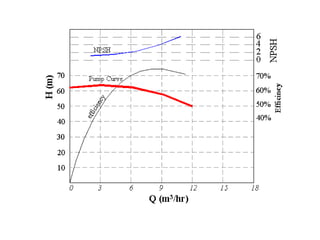

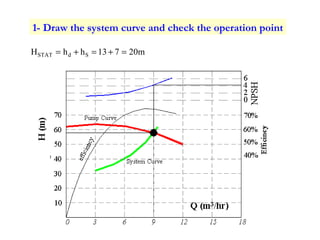

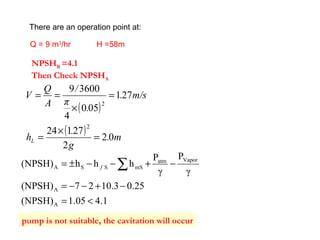

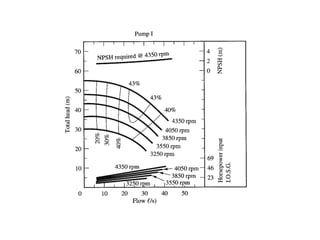

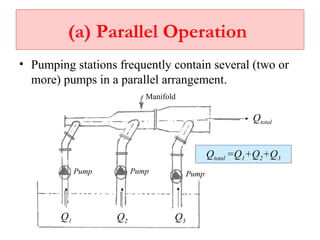

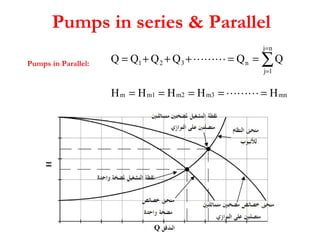

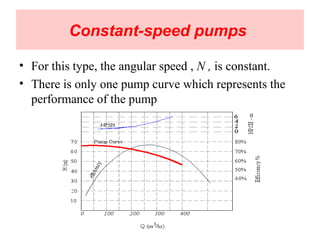

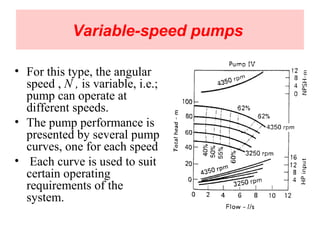

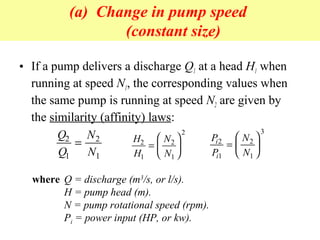

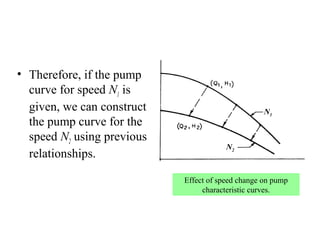

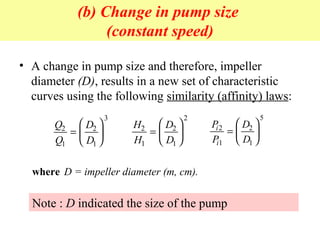

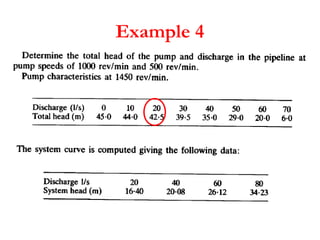

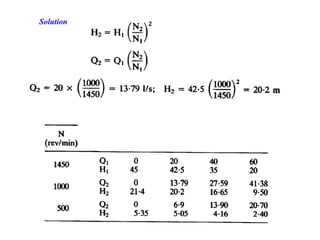

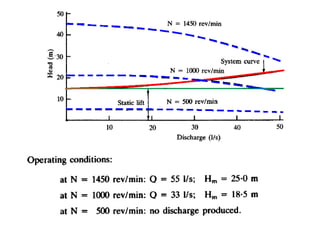

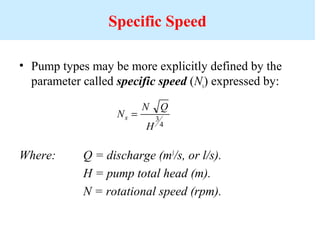

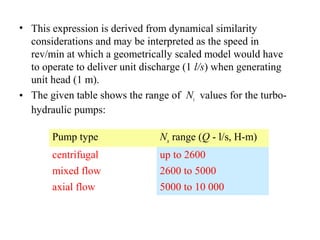

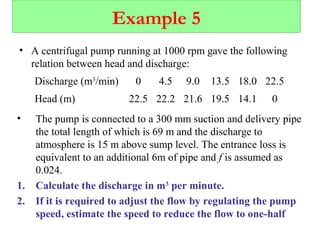

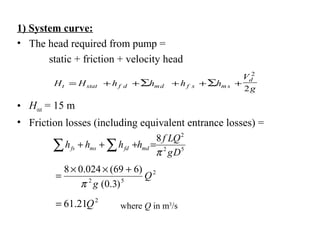

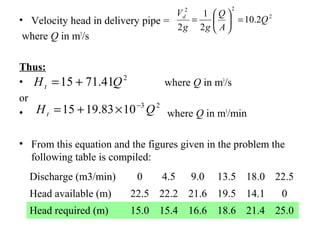

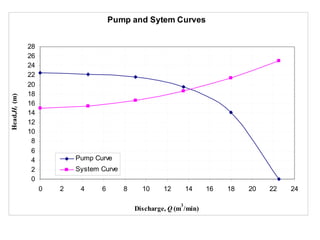

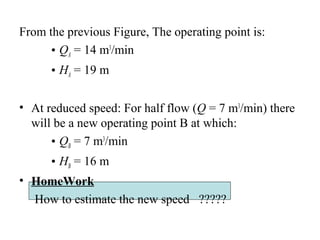

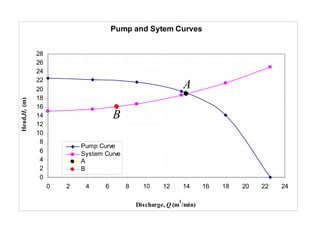

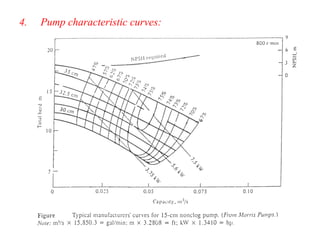

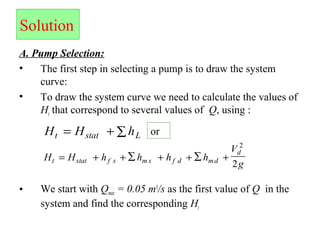

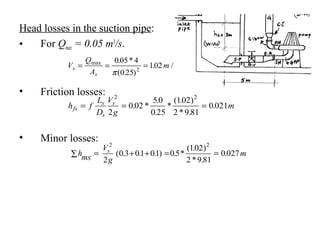

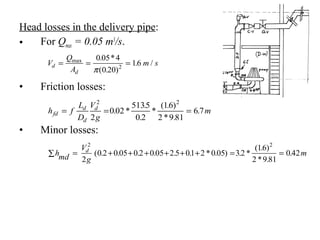

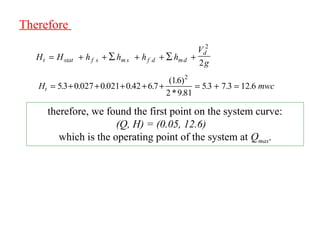

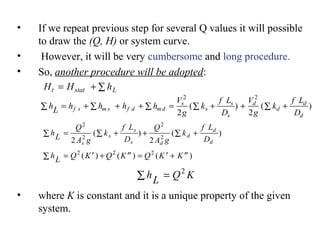

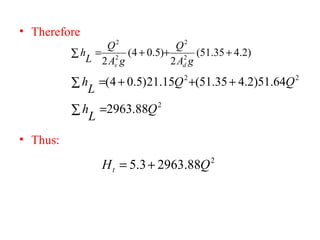

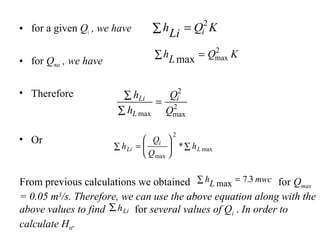

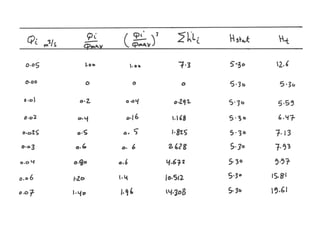

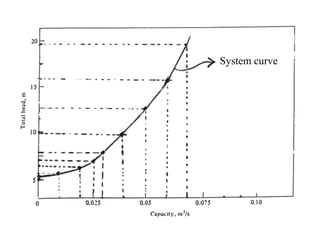

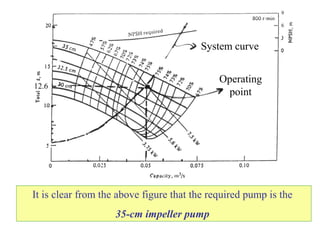

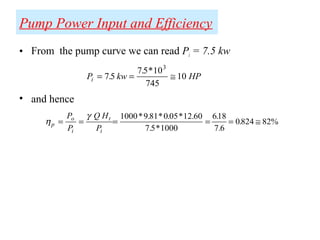

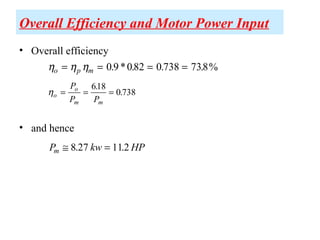

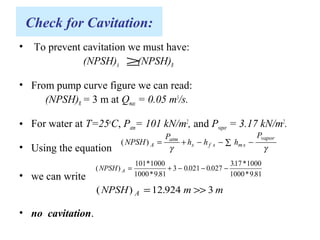

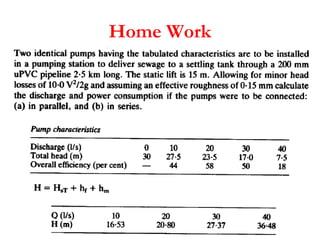

This document discusses water pumps, including their definition, classification, components, and operation. It describes how pumps work to convert mechanical energy into hydraulic energy to move water from lower to higher points. Pumps are classified as either turbo-hydraulic (centrifugal or positive displacement). Centrifugal pumps are the most common and their components and operation are explained in detail. Key concepts discussed include pump efficiency, cavitation, net positive suction head (NPSH), and selecting the appropriate pump based on system characteristics.