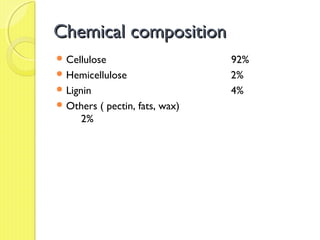

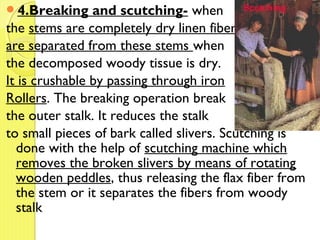

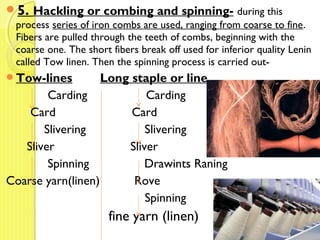

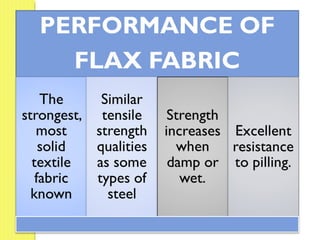

Flax is a natural cellulose bast fiber that comes from the stem of the Linum usitatissimum plant. It is classified as a heavy fiber due to its high cellulose (92%) content. The manufacturing process of linen involves several steps: harvesting flax plants, retting to separate fibers from stems, breaking and scutching, hackling and combing, spinning into yarn, weaving, and finishing/dyeing. Flax fibers are long, thin cells that provide strength and moisture absorption properties to linen textiles.