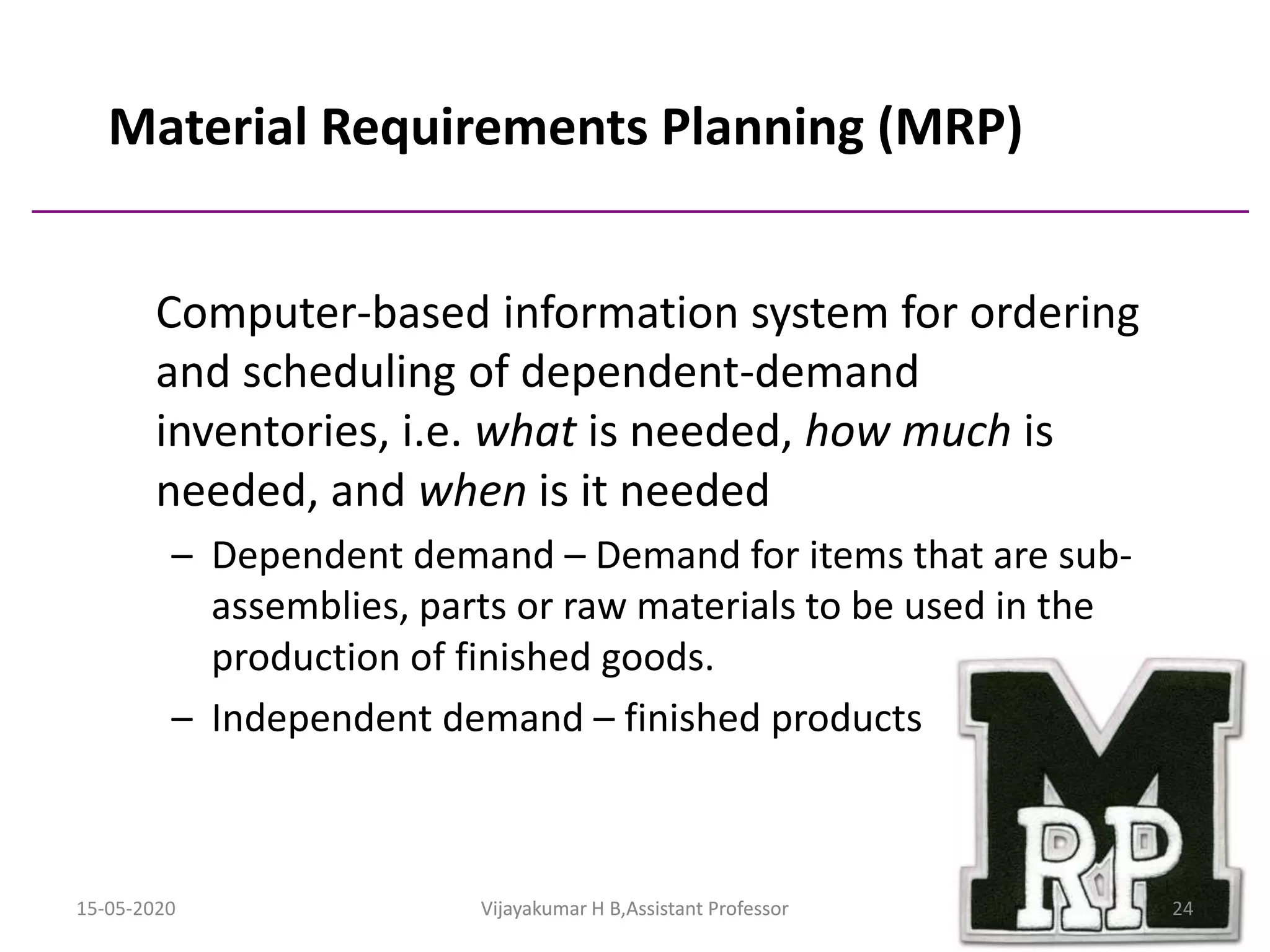

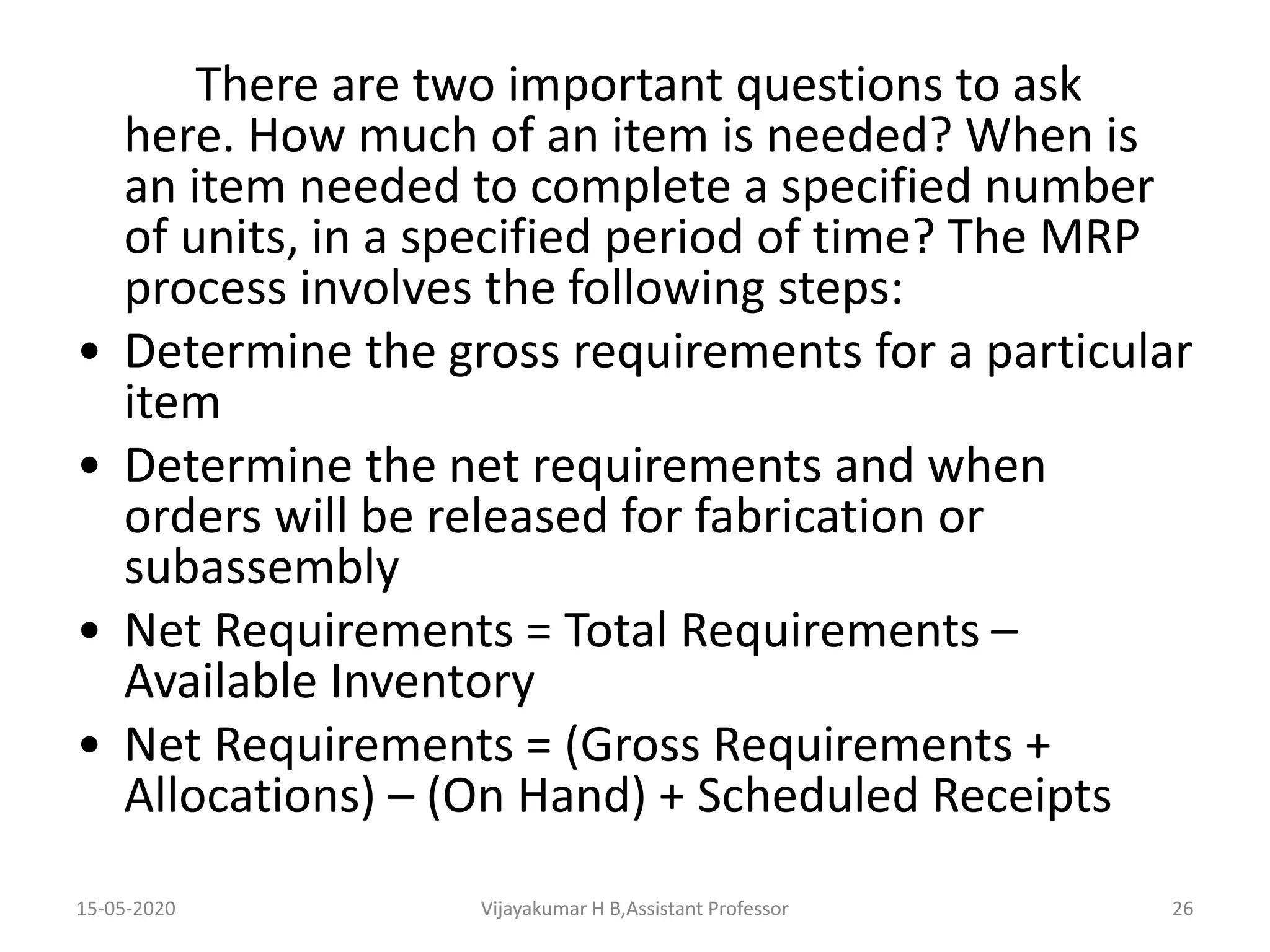

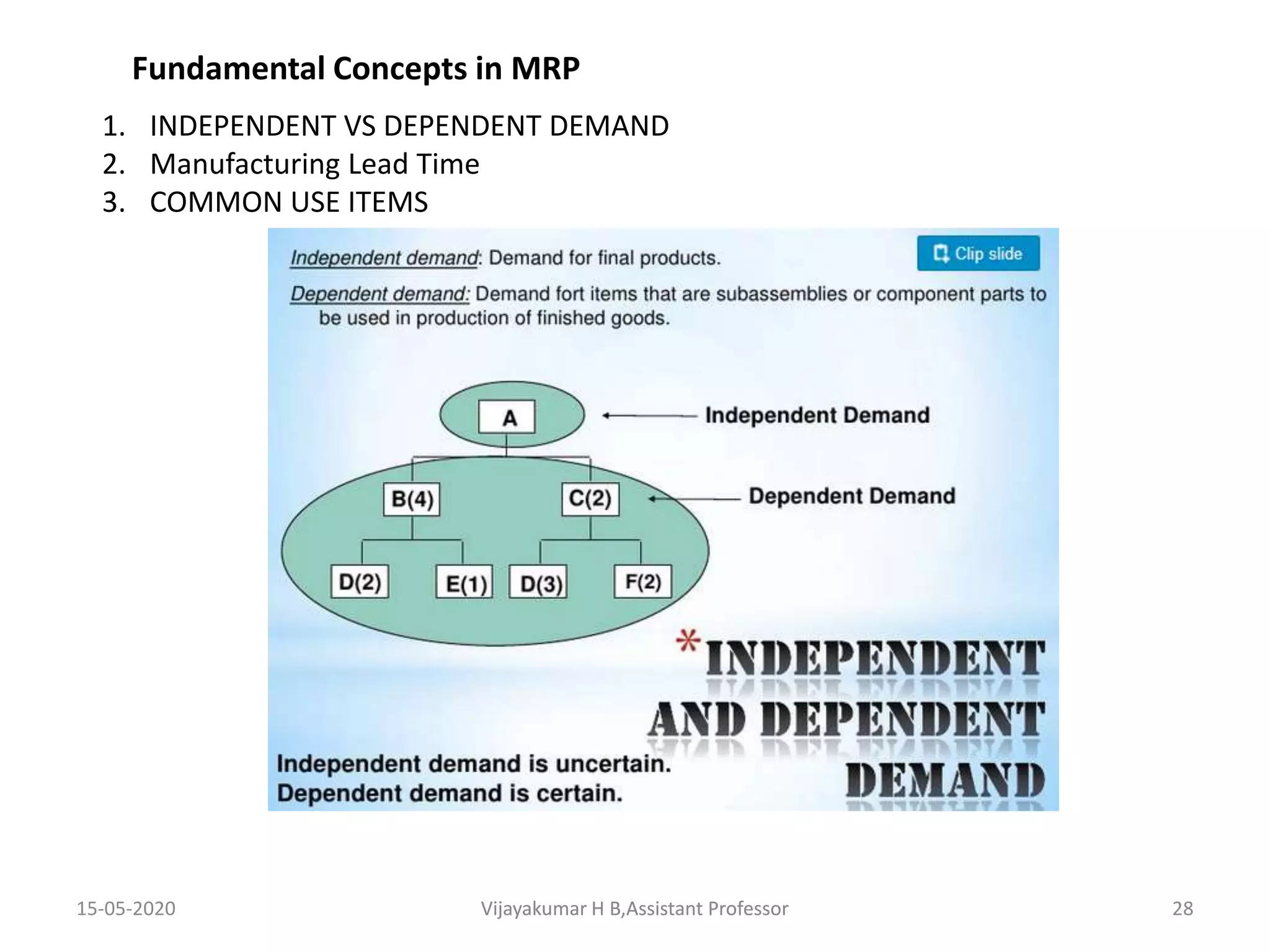

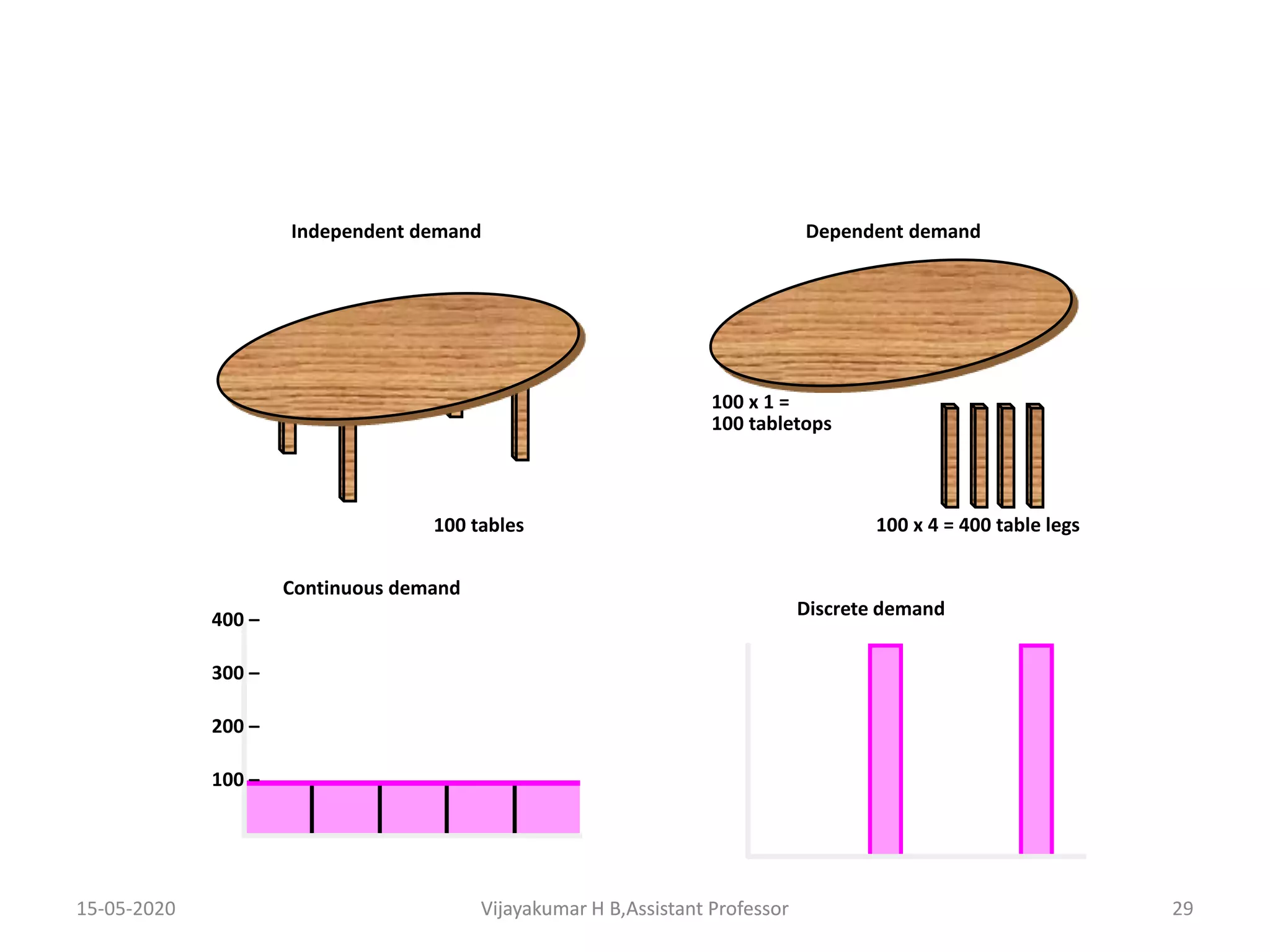

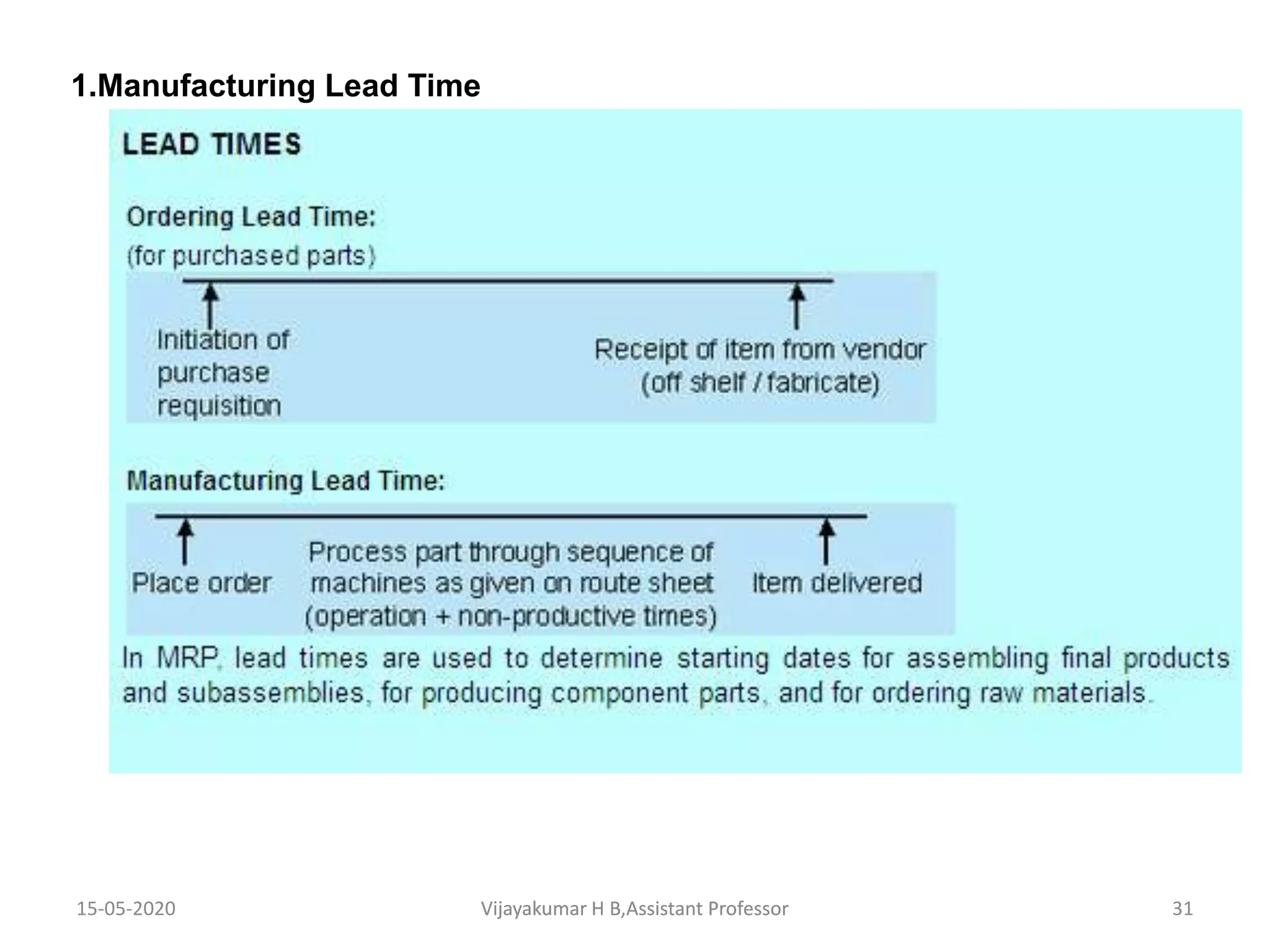

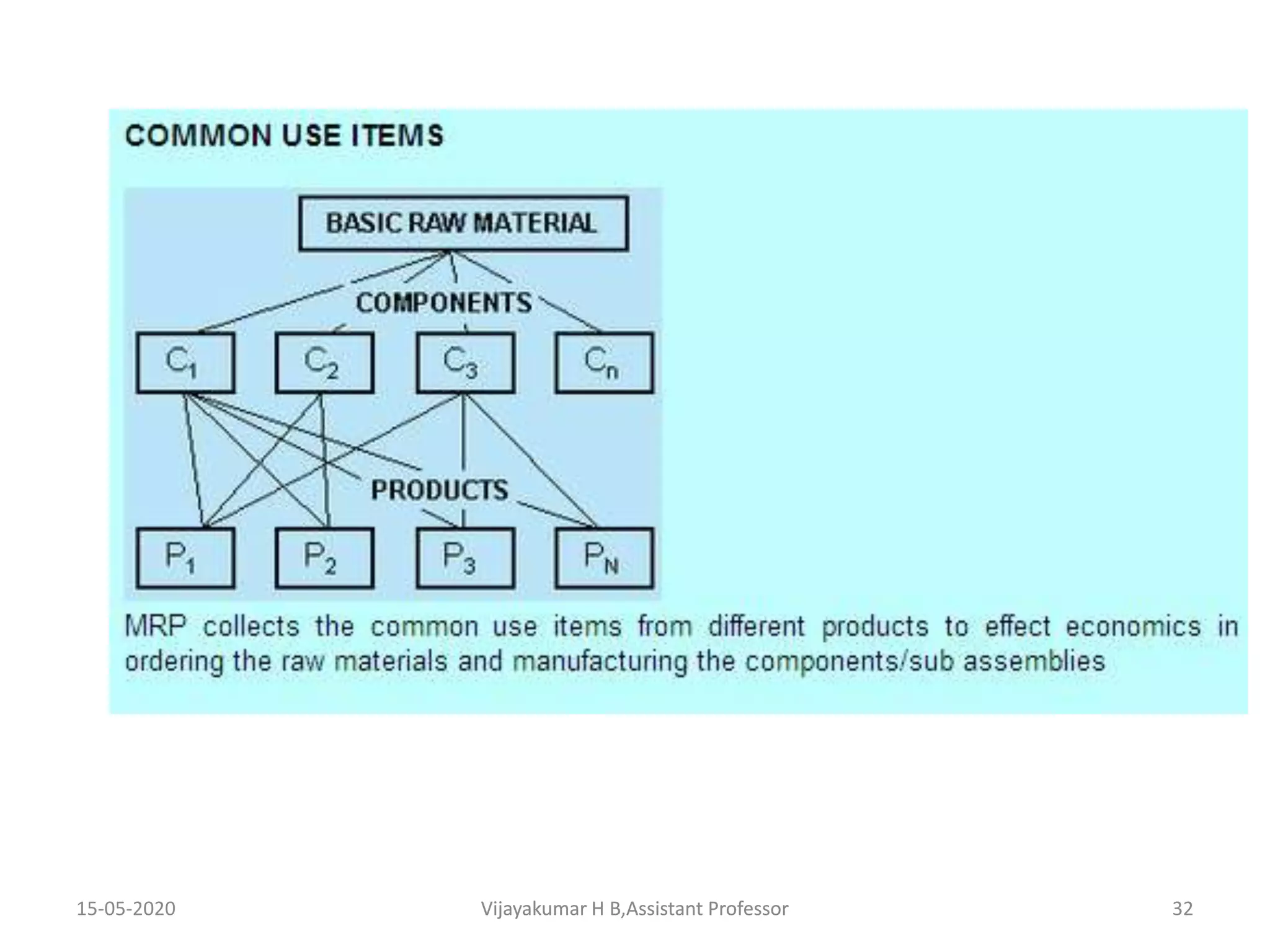

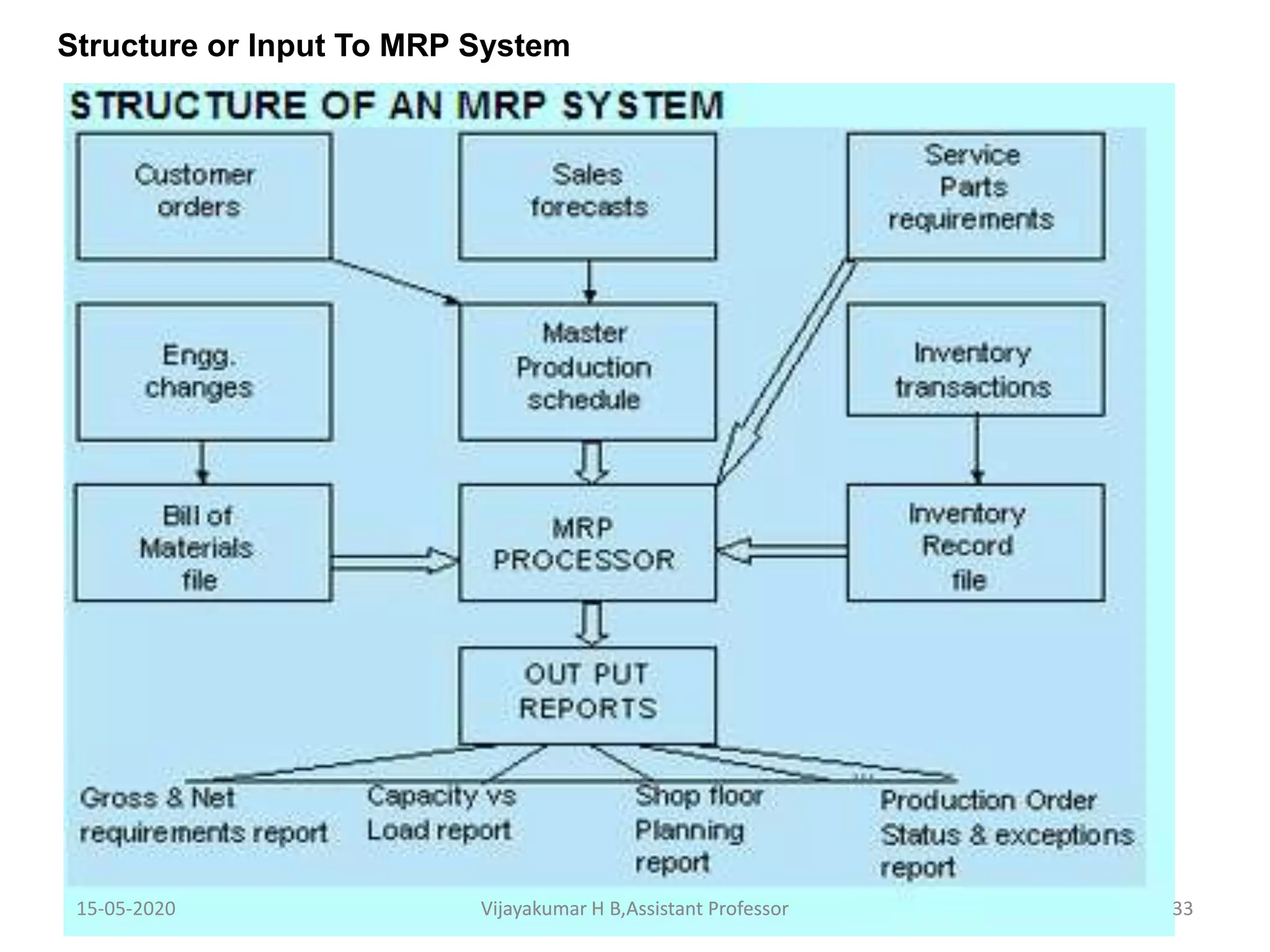

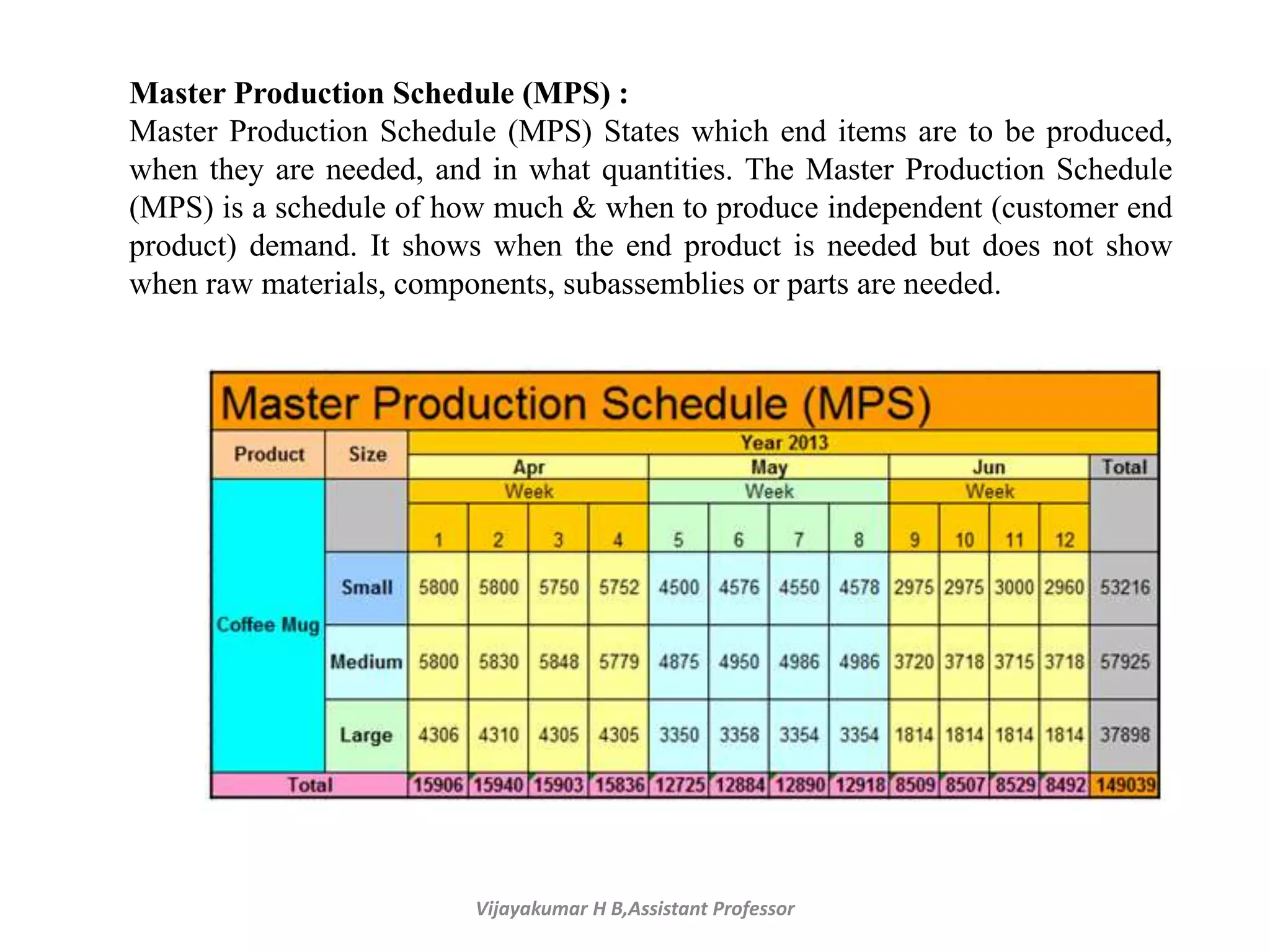

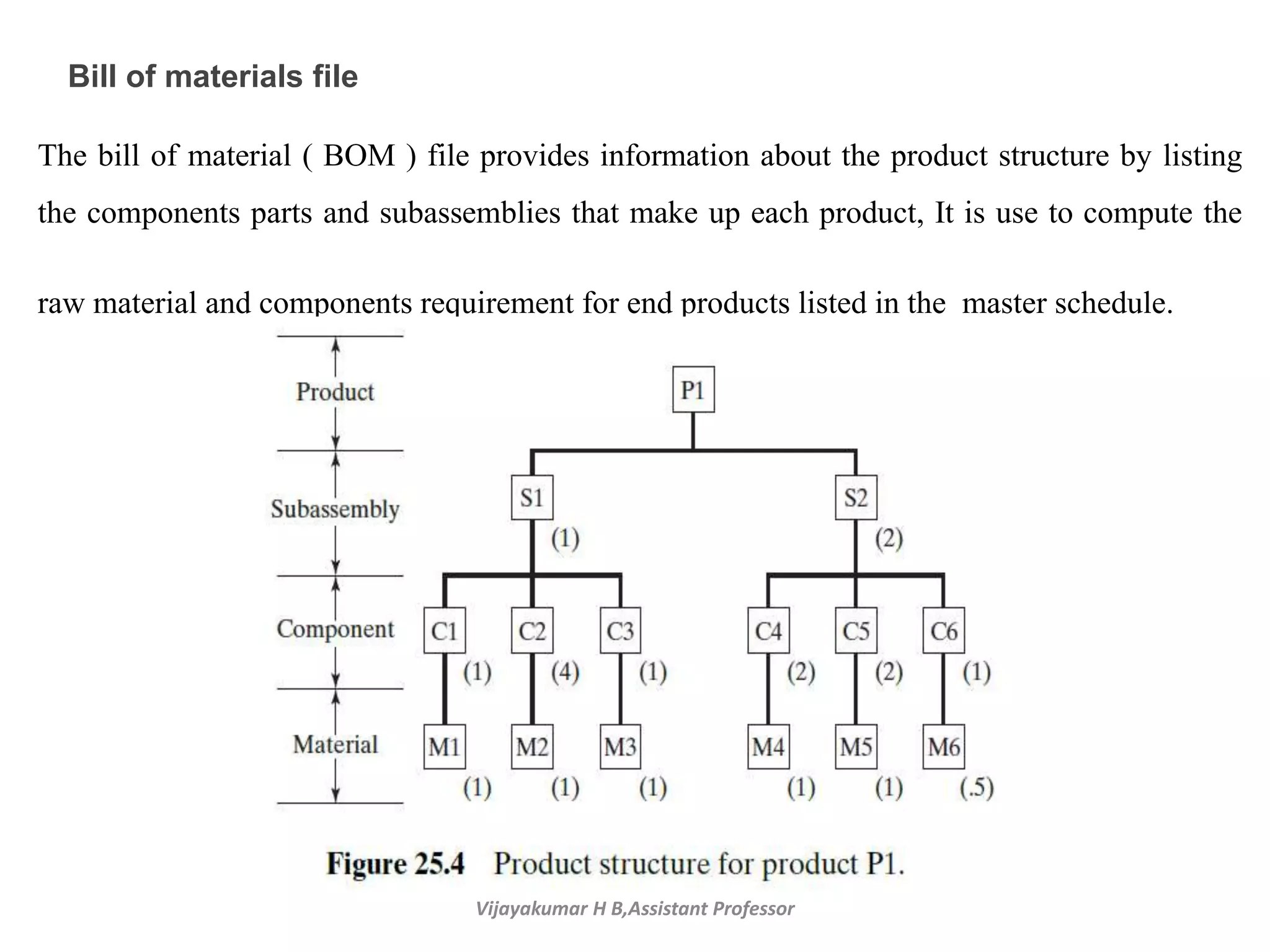

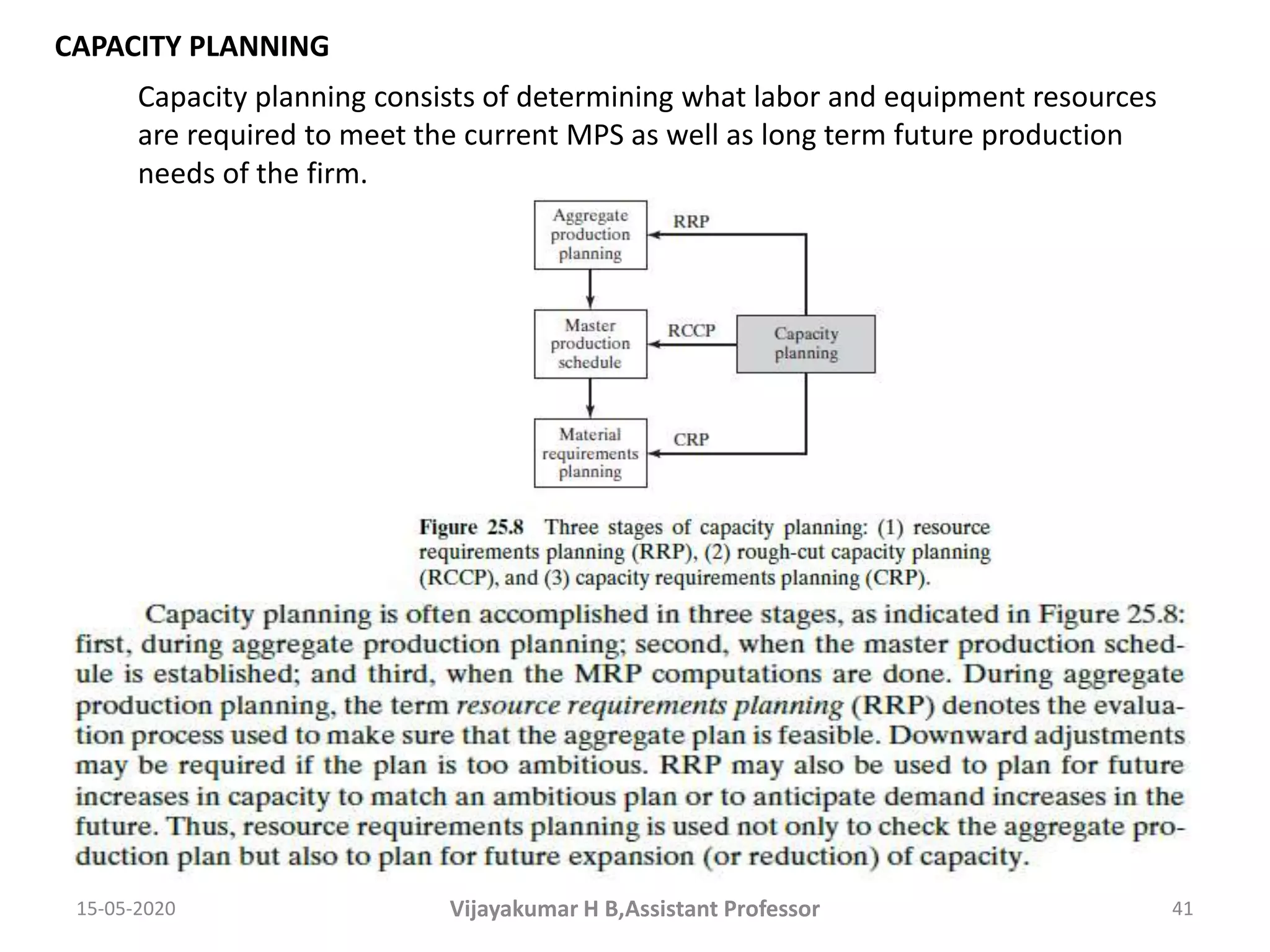

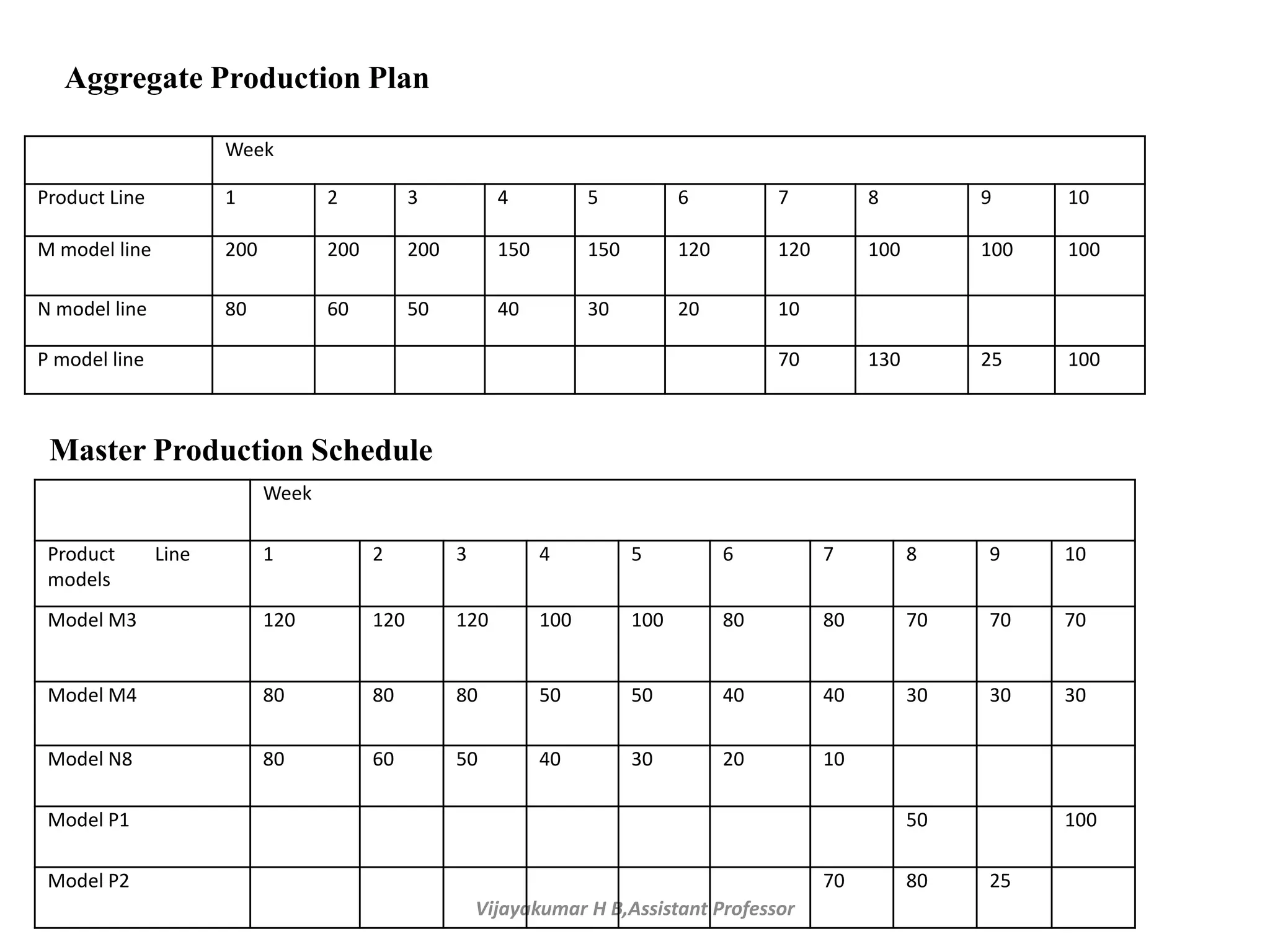

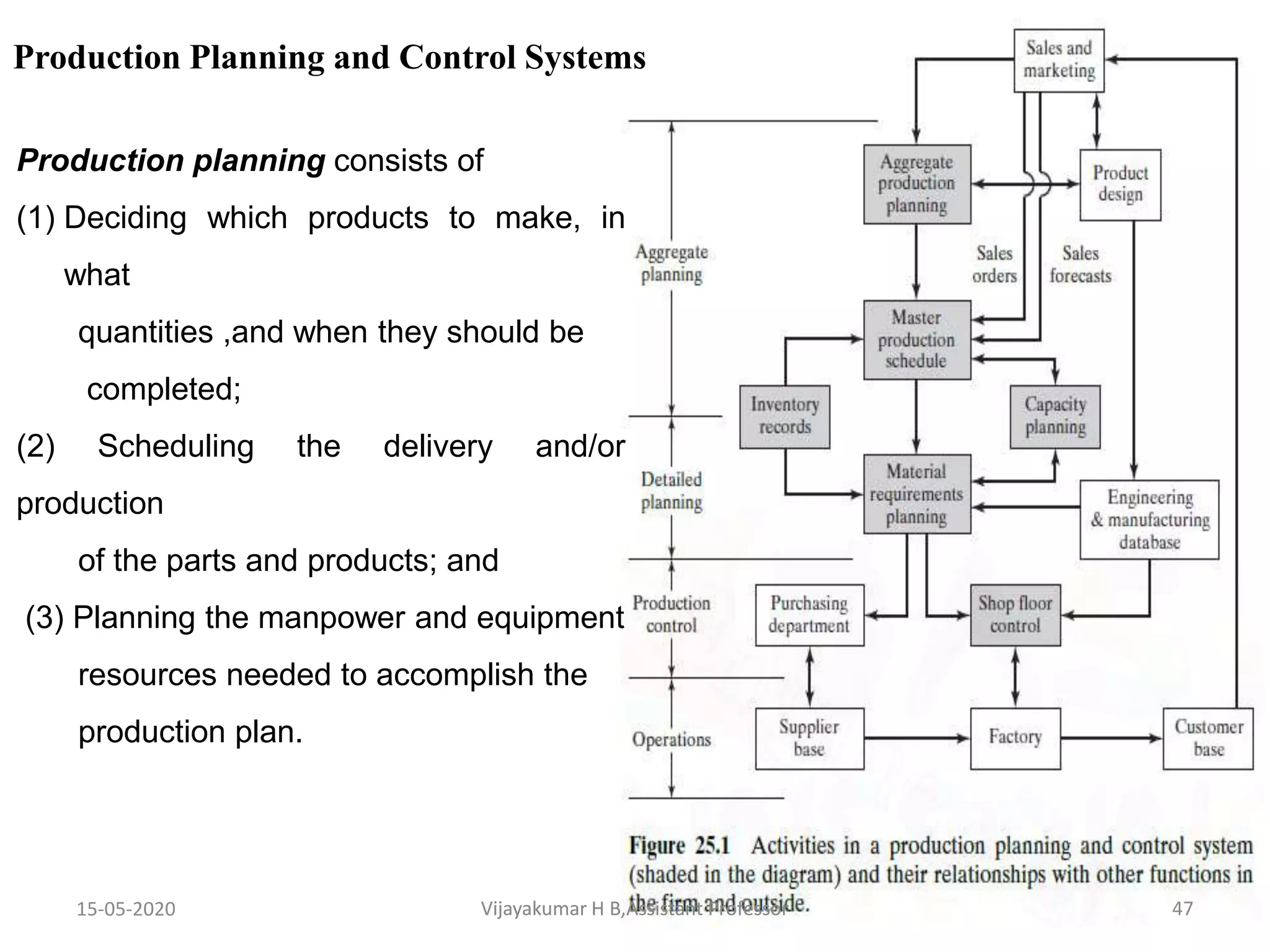

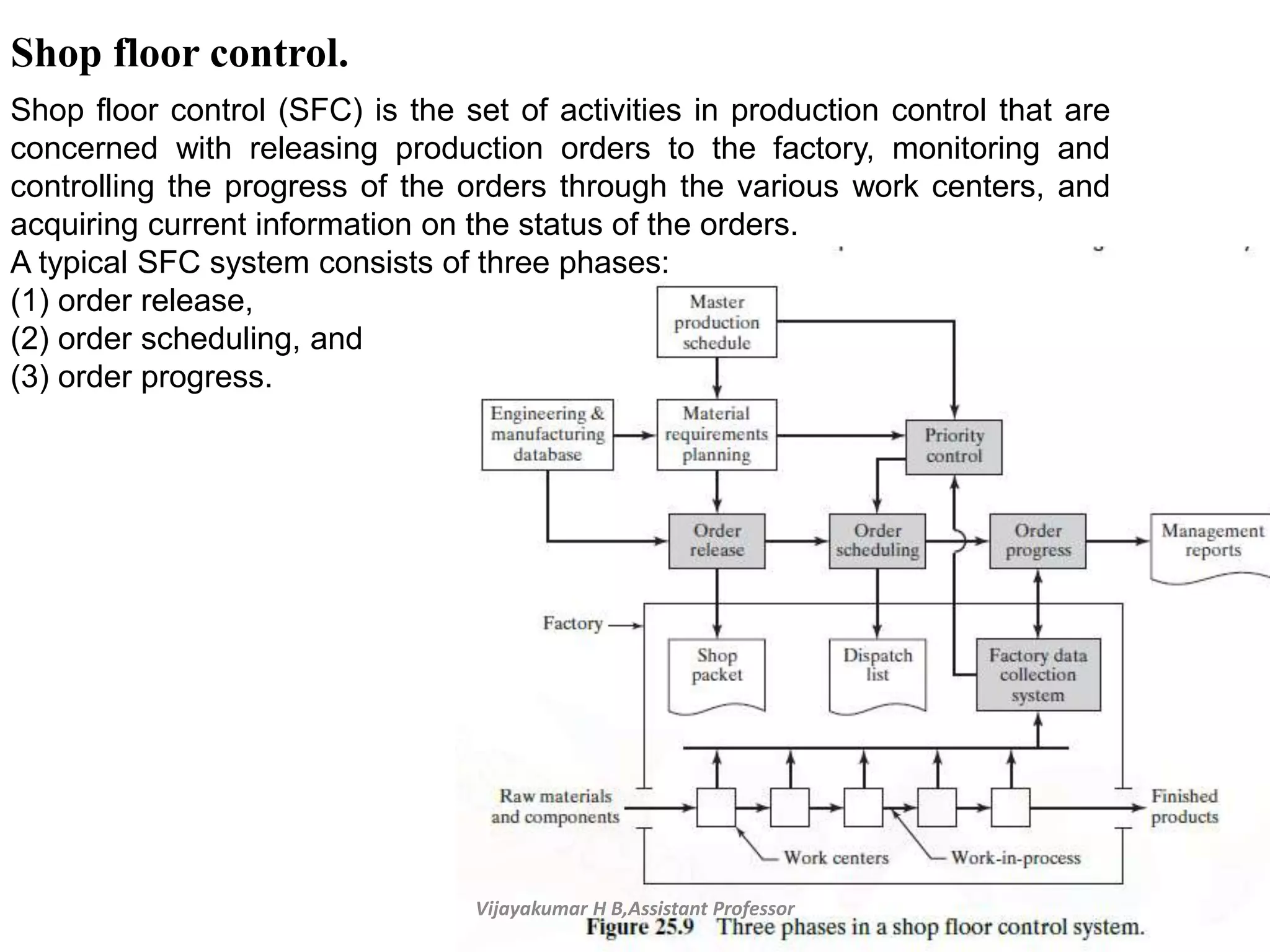

The document discusses production planning and control systems. It describes aggregate planning, master production planning, material requirements planning, and capacity planning as the key activities in production planning. It also discusses shop floor control, inventory control, manufacturing resource planning, and enterprise resource planning as important aspects of production control. The document provides details on various concepts such as the master production schedule, bill of materials, order release, order scheduling and order progress in shop floor control.