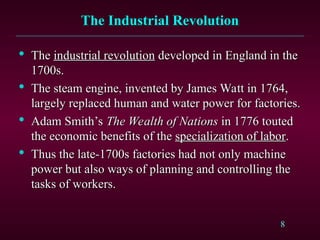

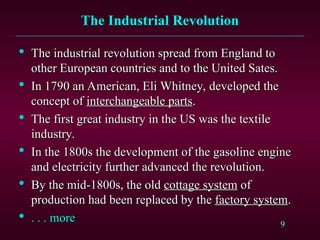

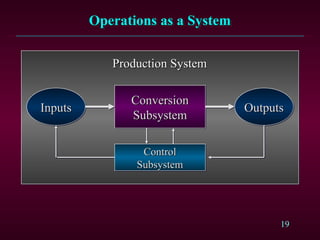

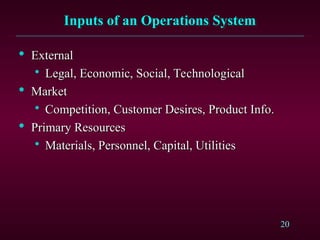

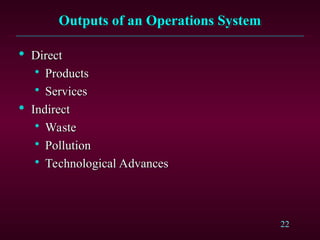

The document provides an overview of operations management, covering its definition, historical milestones, and key factors influencing it today. It discusses the evolution of production systems, the role of technological advancements, and the significance of strategic decision-making in organizations. Additionally, it highlights the growing importance of service operations management and the impact of global competition and advanced technologies on operations.