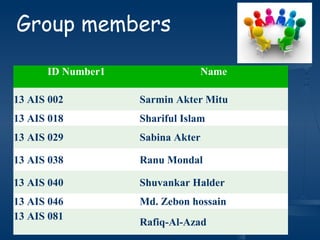

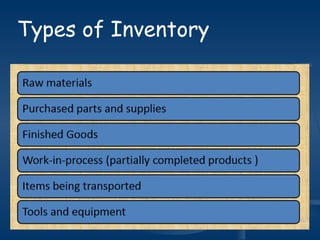

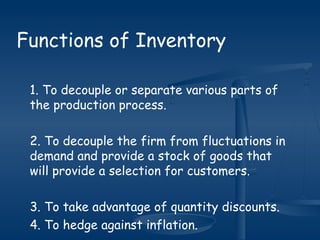

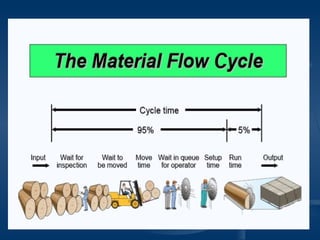

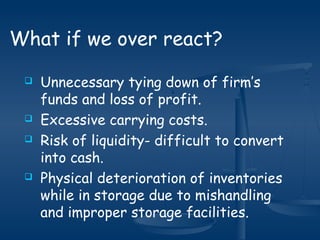

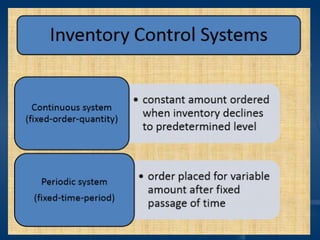

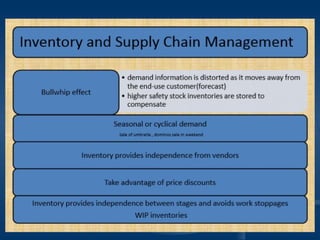

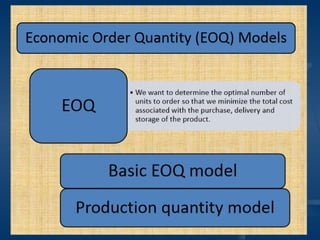

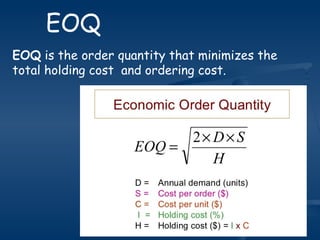

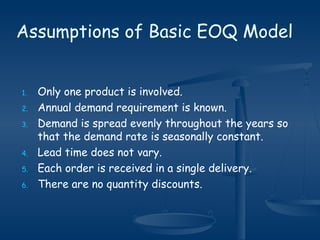

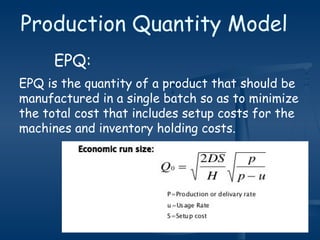

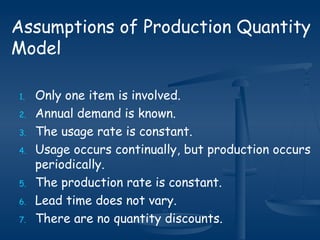

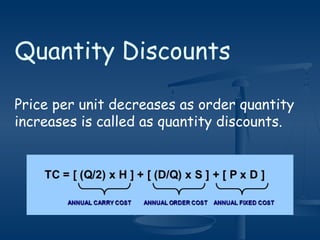

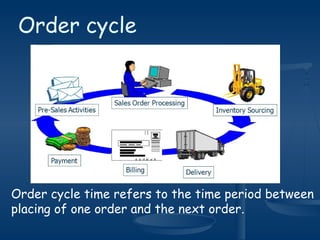

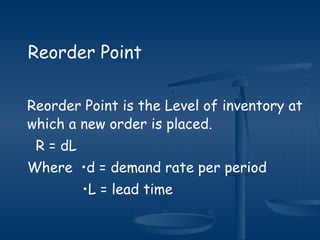

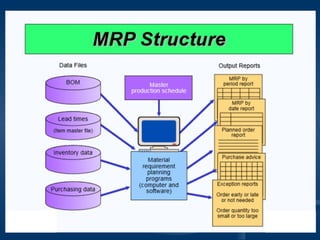

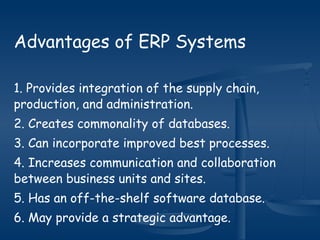

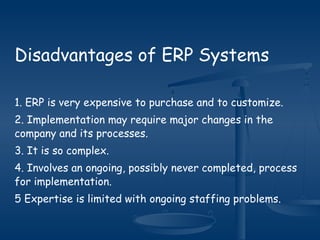

This presentation introduces inventory and inventory management. It is presented by a group of students from the Department of Accounting & Information Systems at University of Barisal. The presentation defines inventory, discusses types and functions of inventory. It explains concepts related to inventory management including classification of inventory costs, overall concerns, objectives and scope. It also covers inventory control systems and models like EOQ, EPQ and reorder point. Other topics include order cycle, material requirement planning, enterprise resource planning and their advantages and disadvantages.