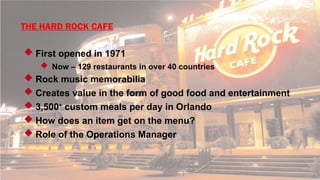

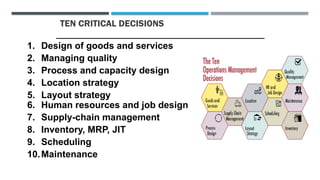

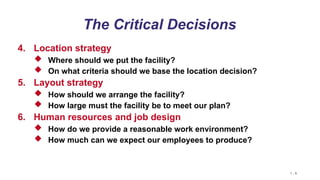

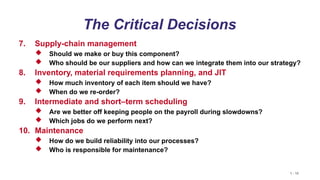

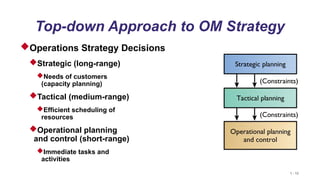

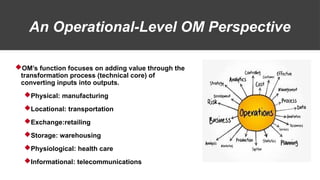

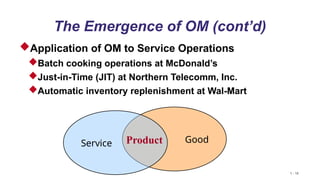

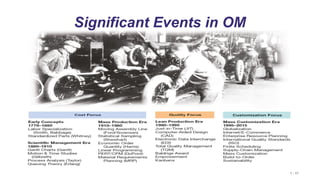

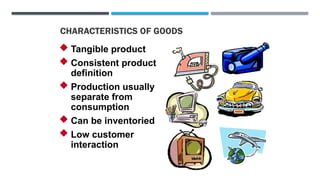

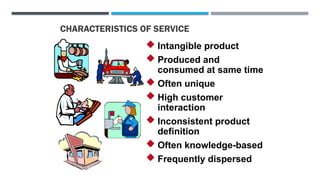

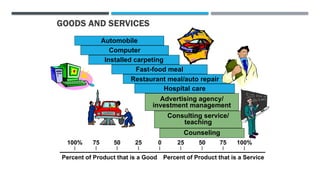

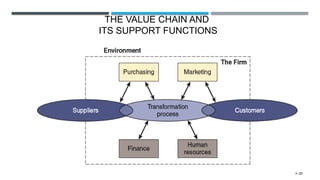

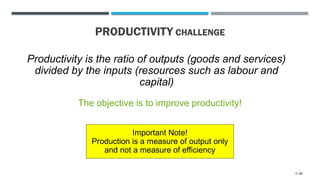

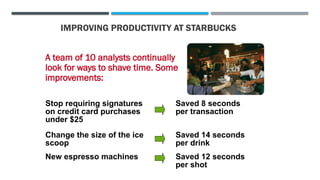

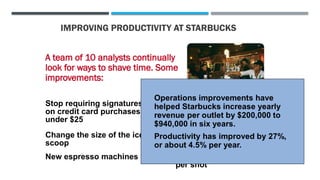

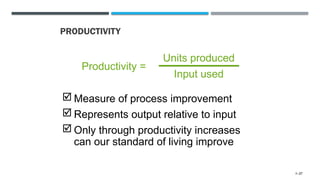

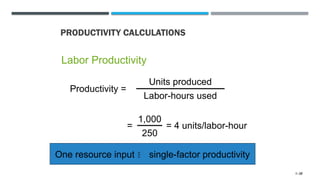

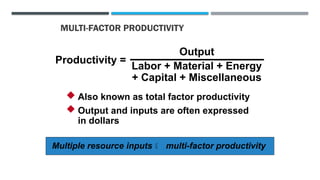

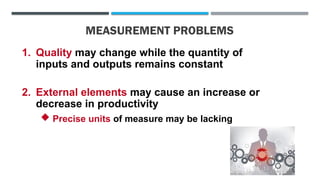

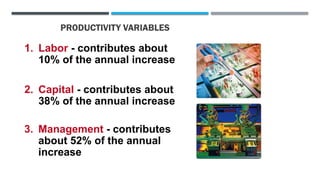

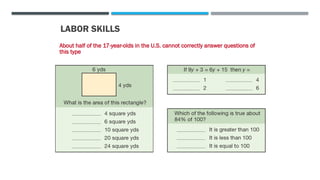

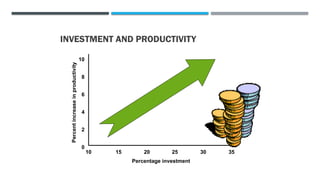

The document discusses operations management (OM) and its significance in creating value through the production of goods and services. It outlines key responsibilities of operations managers, critical decisions they make, and the evolution and trends in OM. Additionally, it highlights the contributions of OM to society, productivity challenges, and the importance of quality in both goods and services.