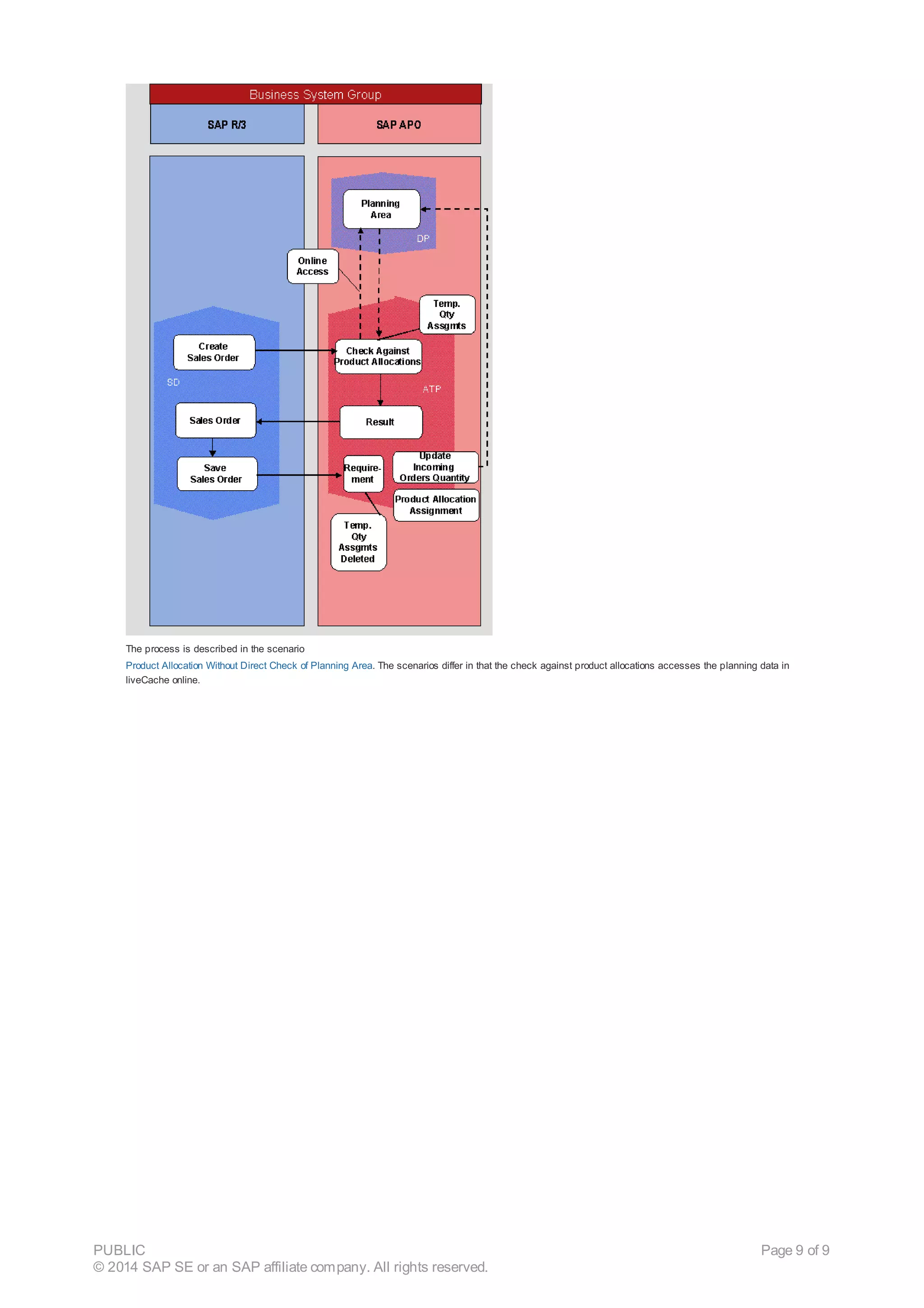

1. The document describes product allocation during sales order entry between SAP R/3 and SAP APO. It can be done with or without directly checking the planning area.

2. Key steps include creating a sales order in SAP R/3, checking availability in SAP APO which may result in a delivery proposal, and adopting the results in SAP R/3.

3. Settings must be configured in both SAP R/3 and SAP APO for the systems to communicate properly during the product allocation check.