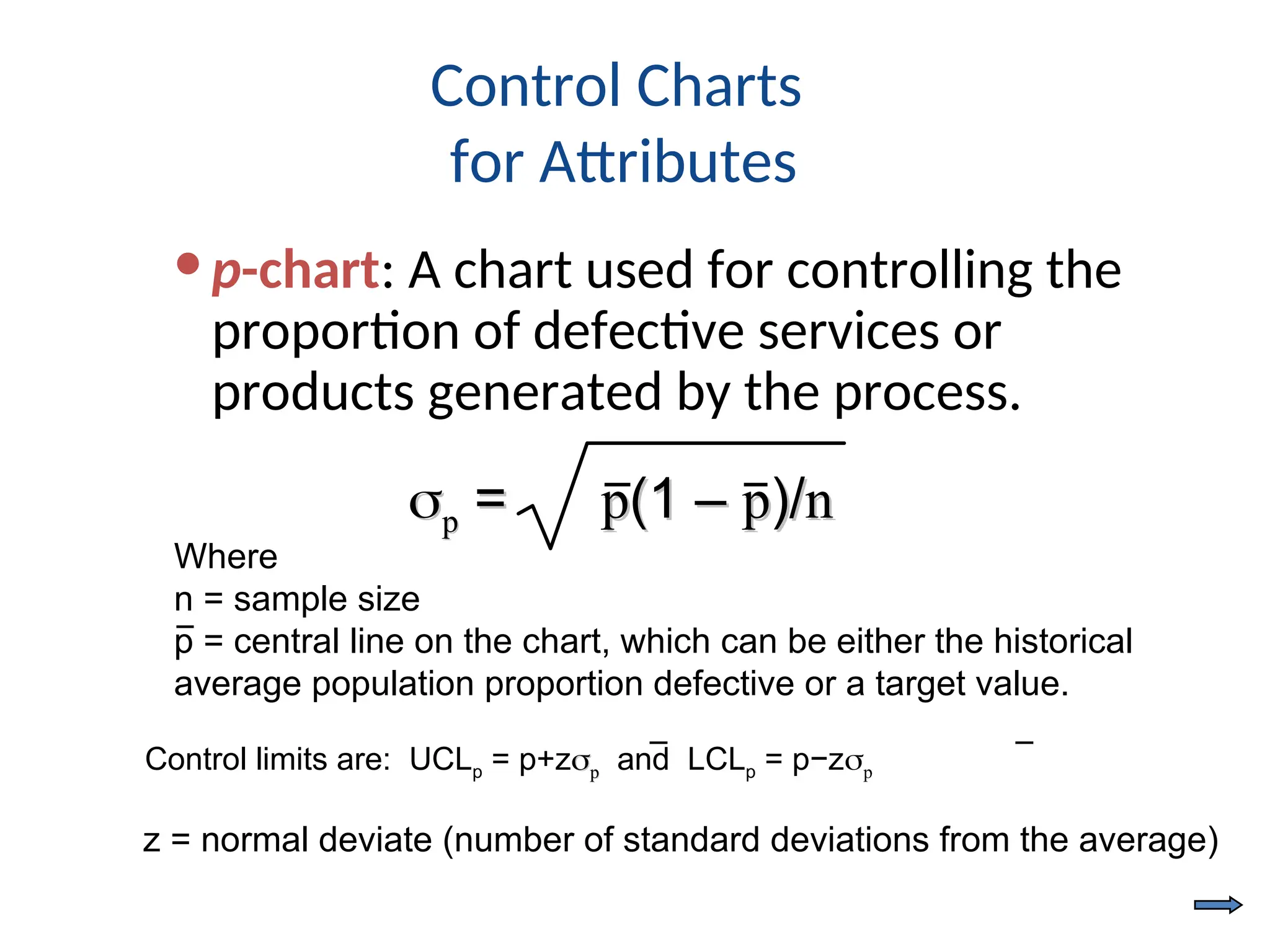

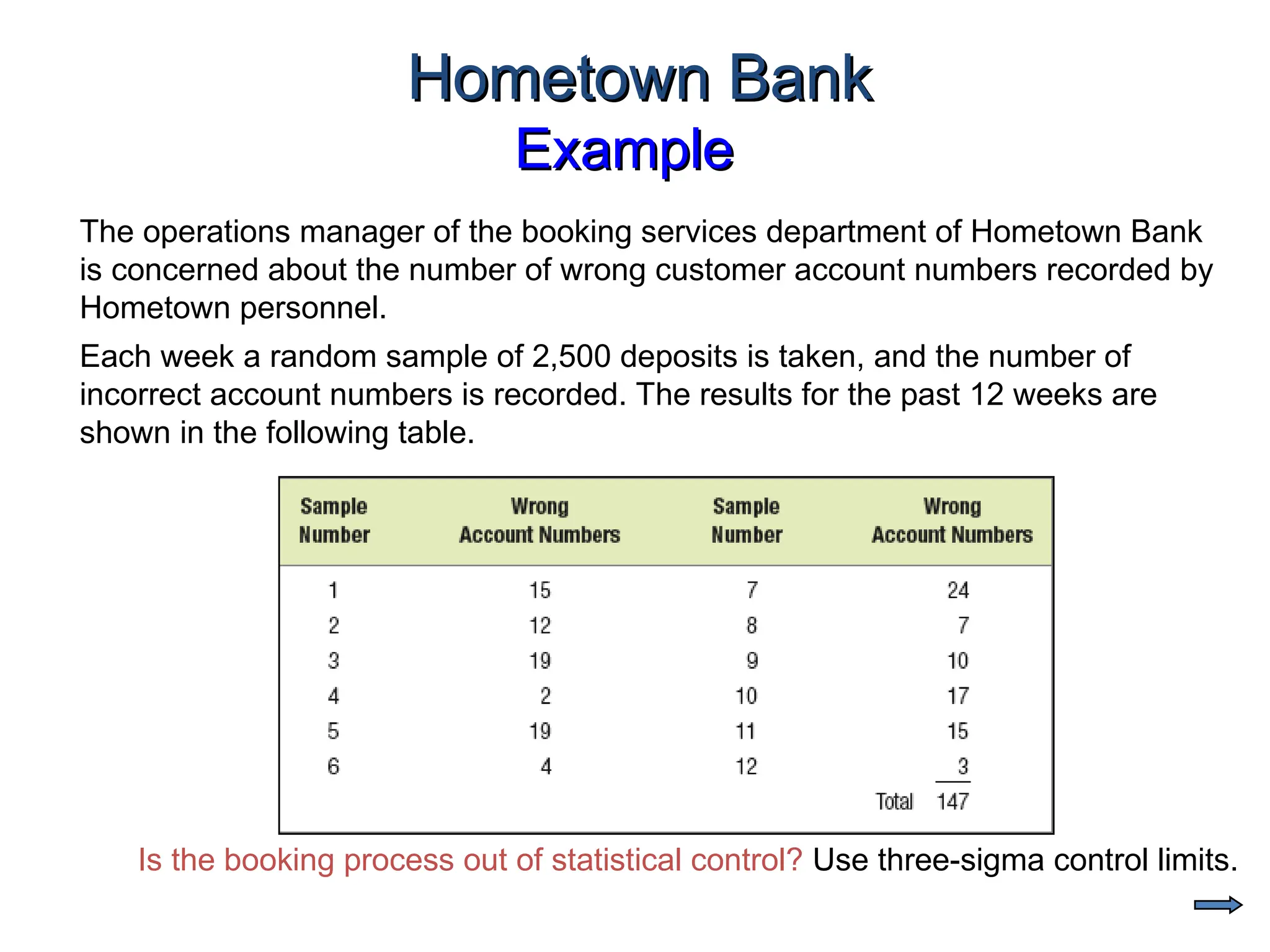

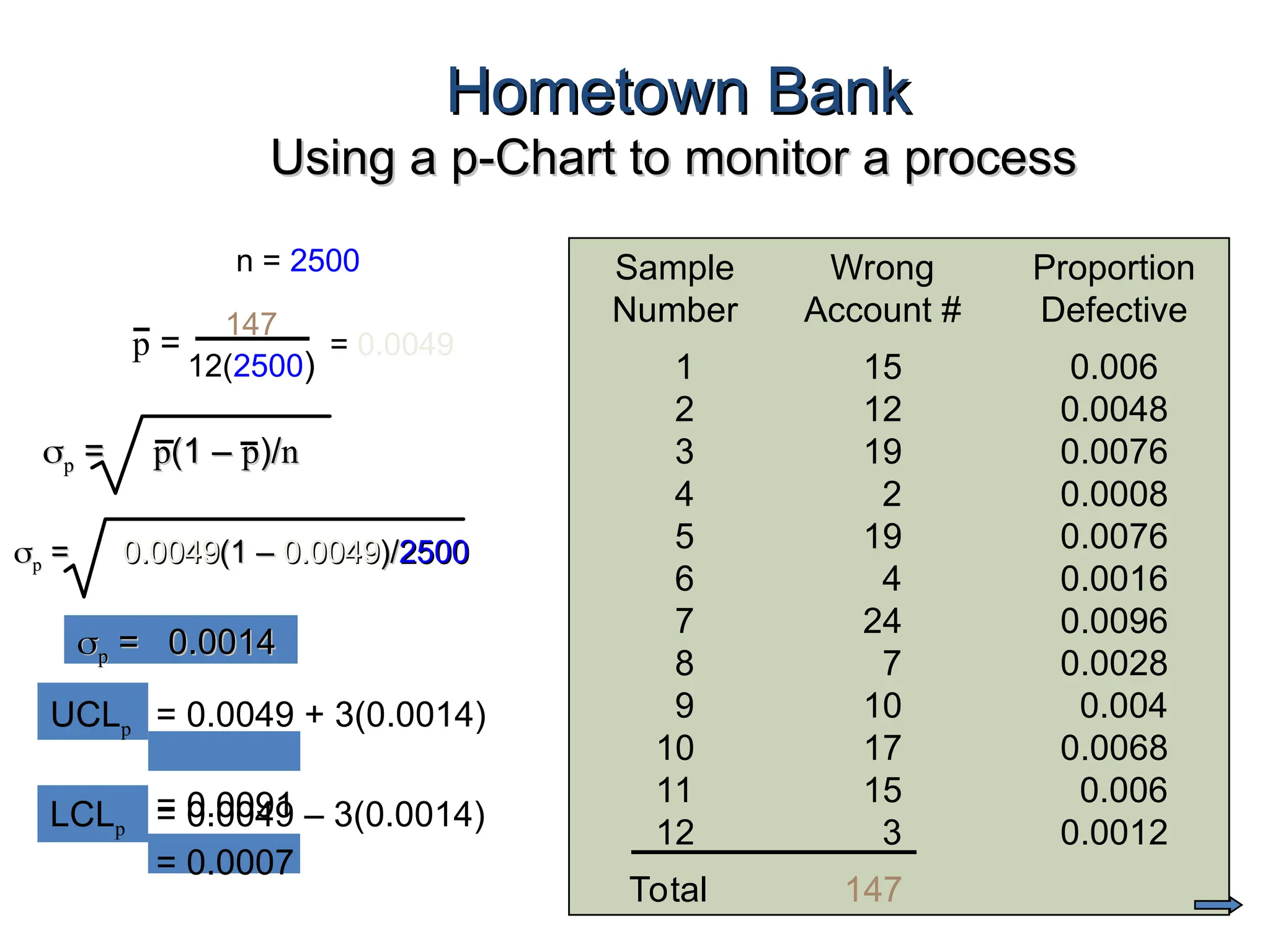

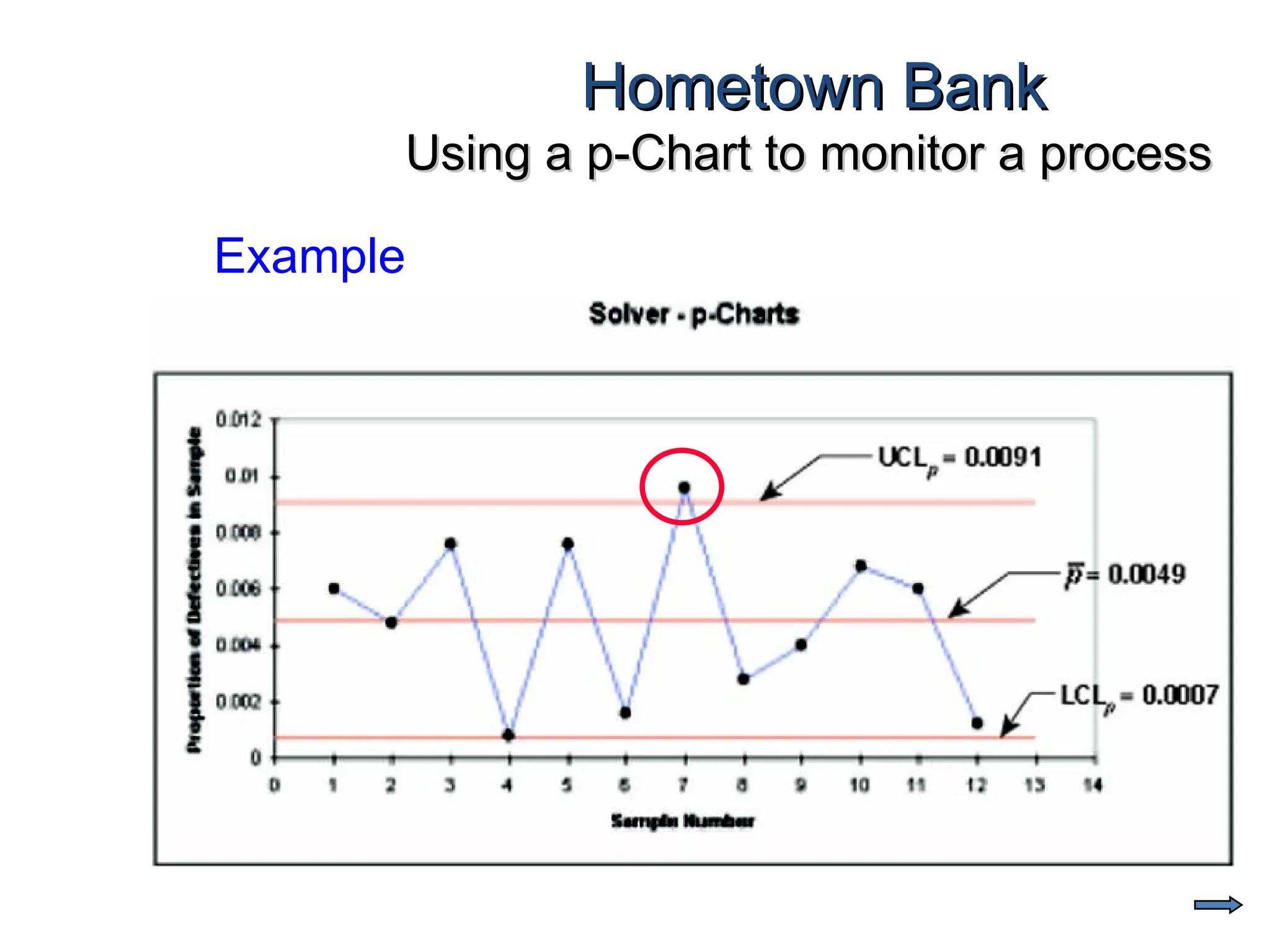

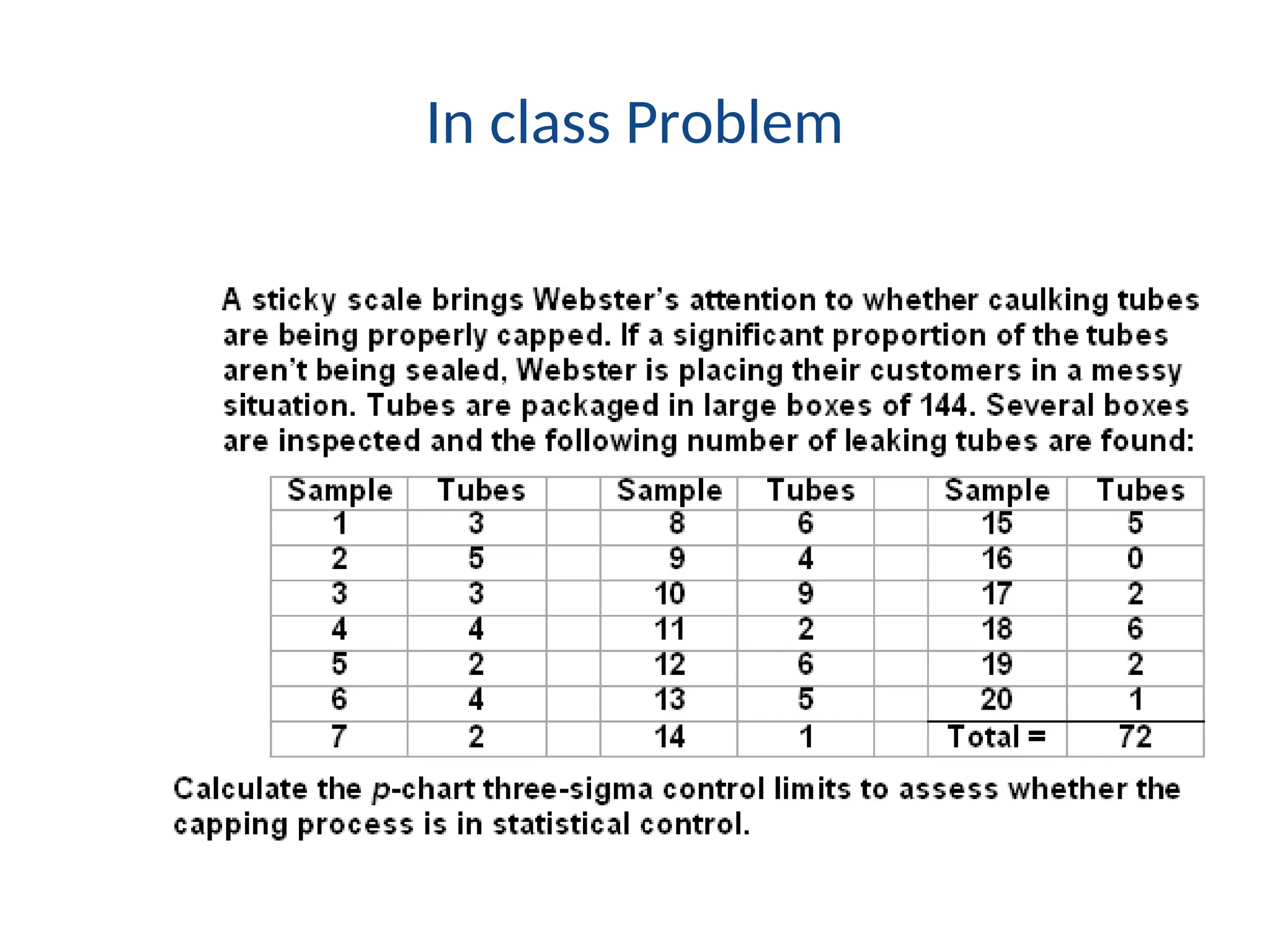

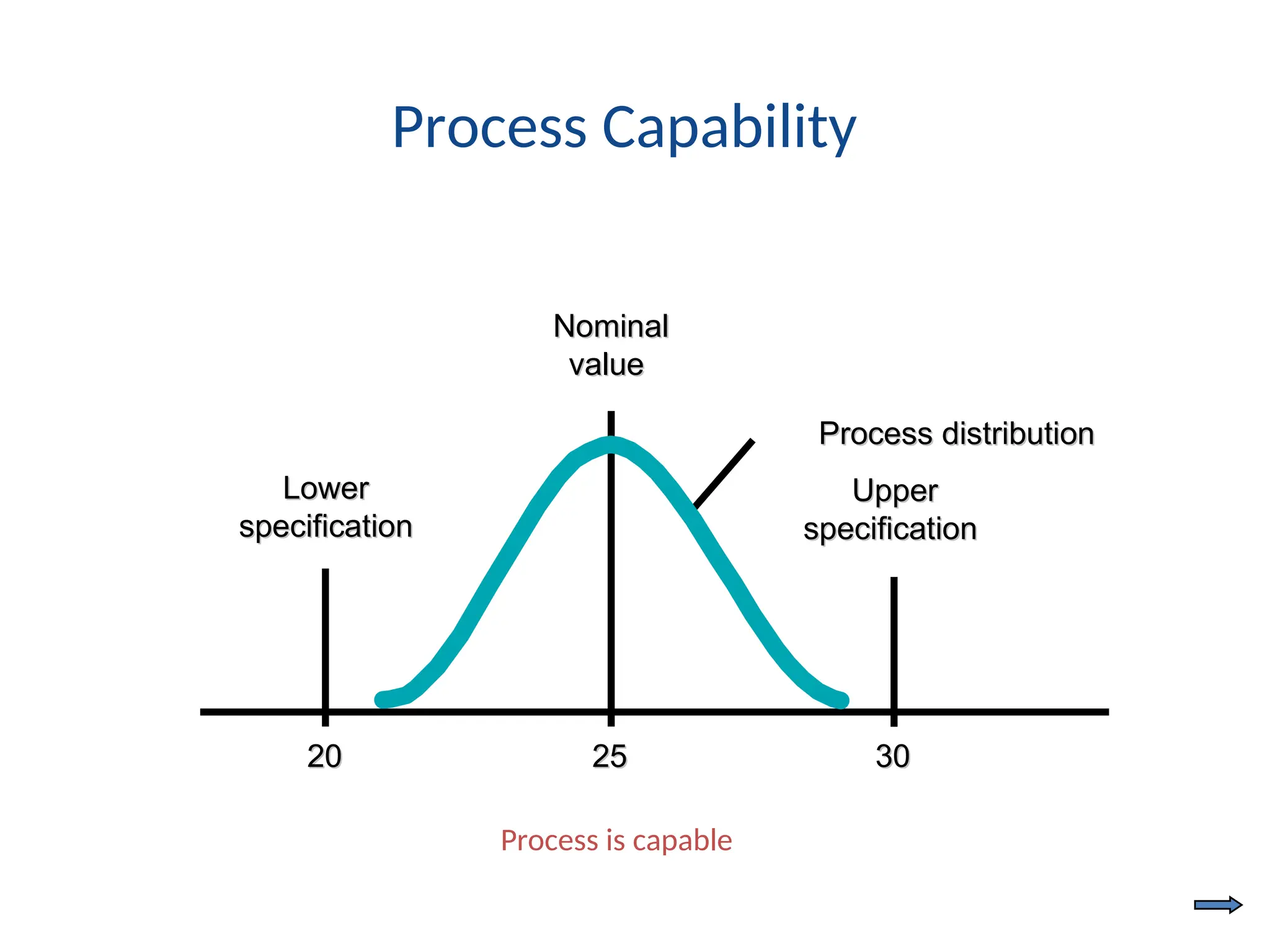

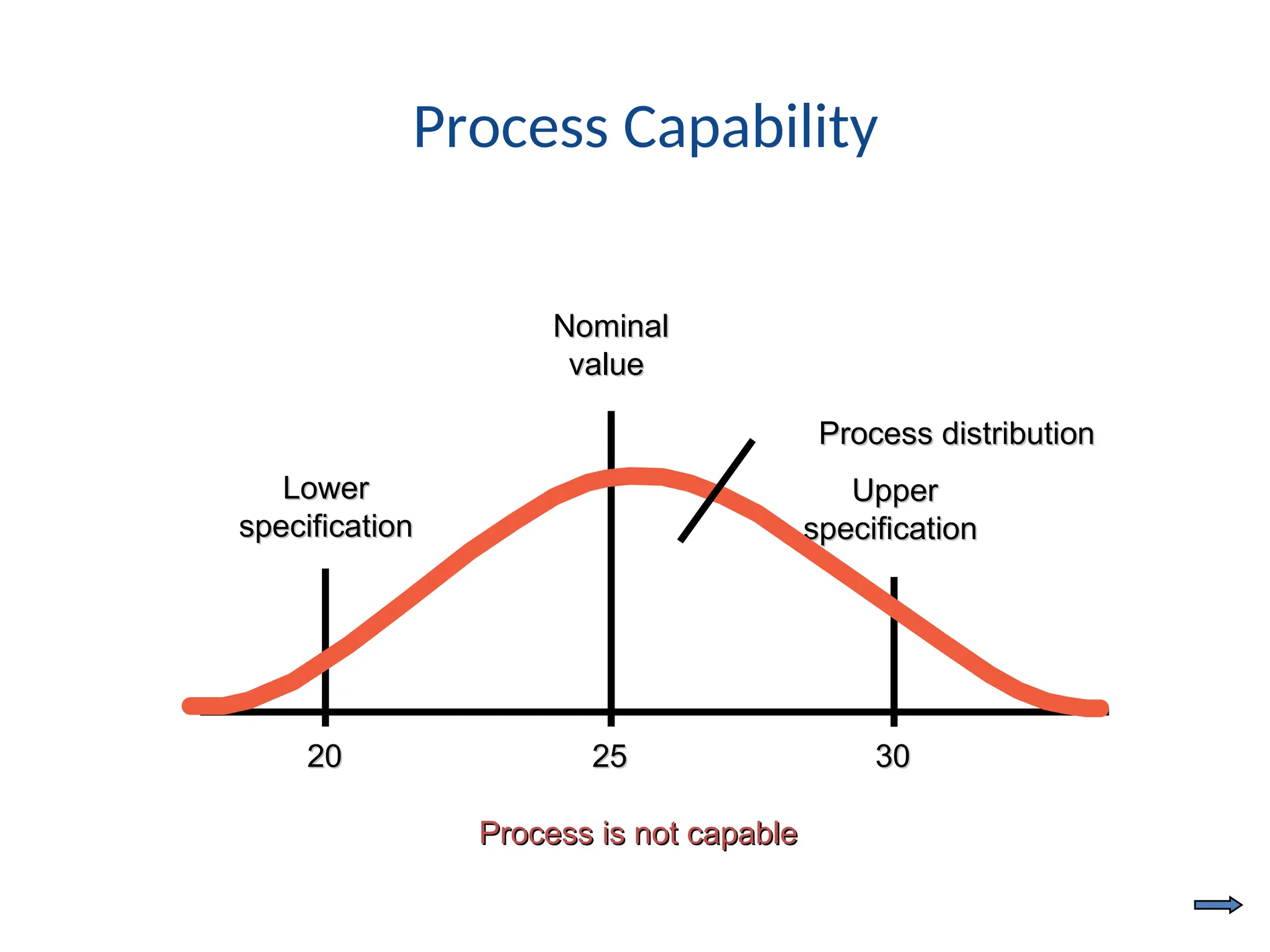

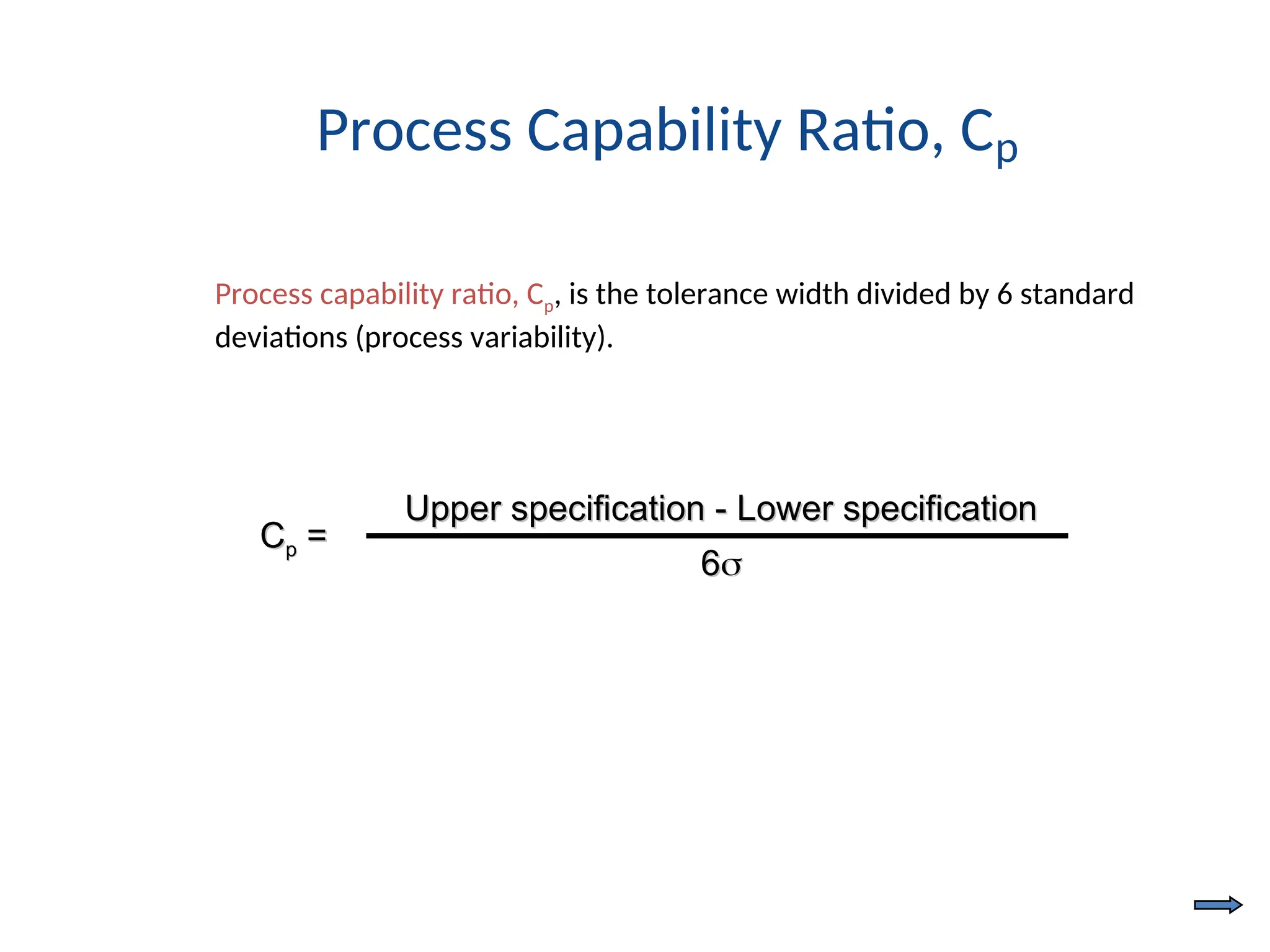

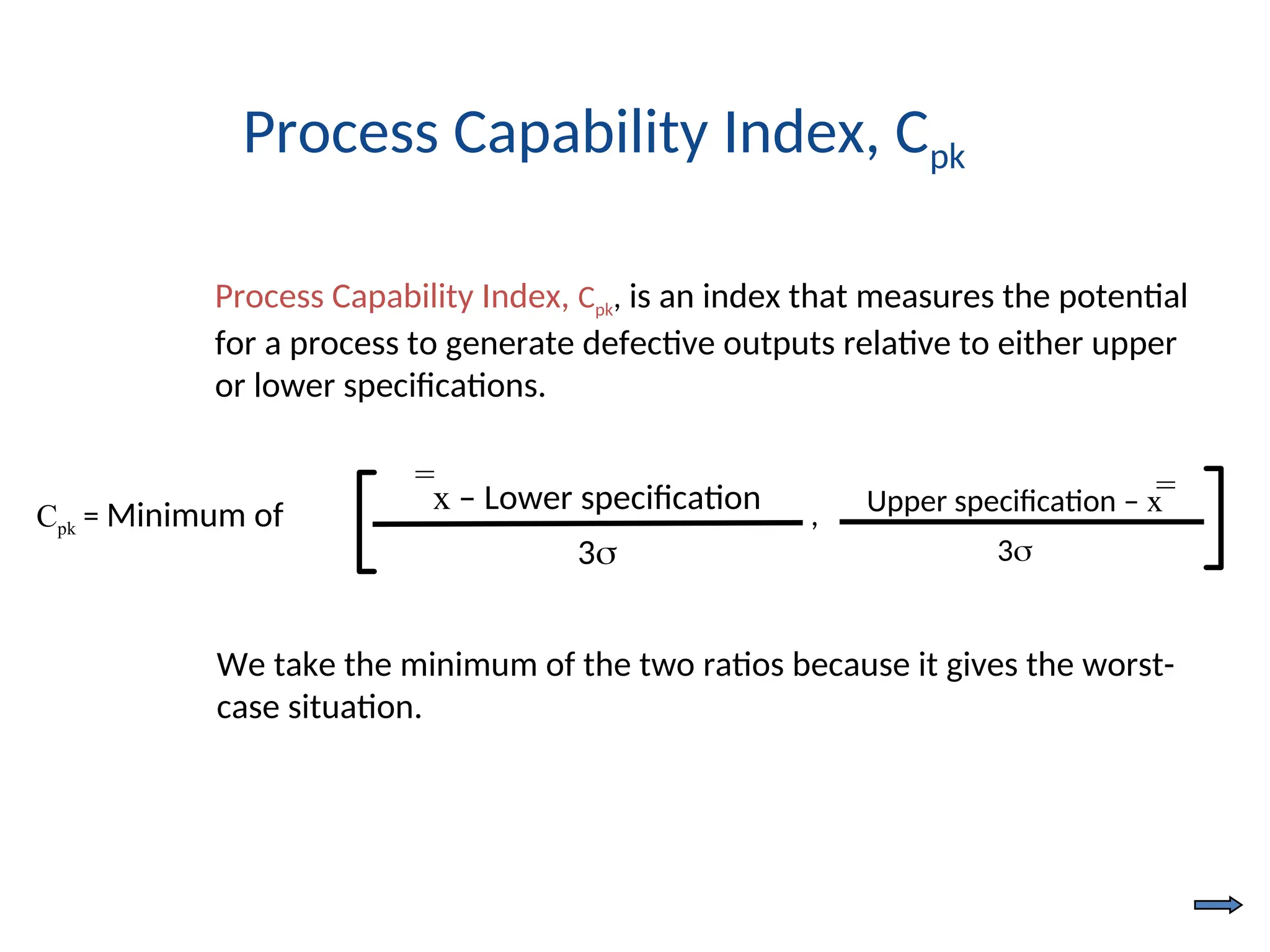

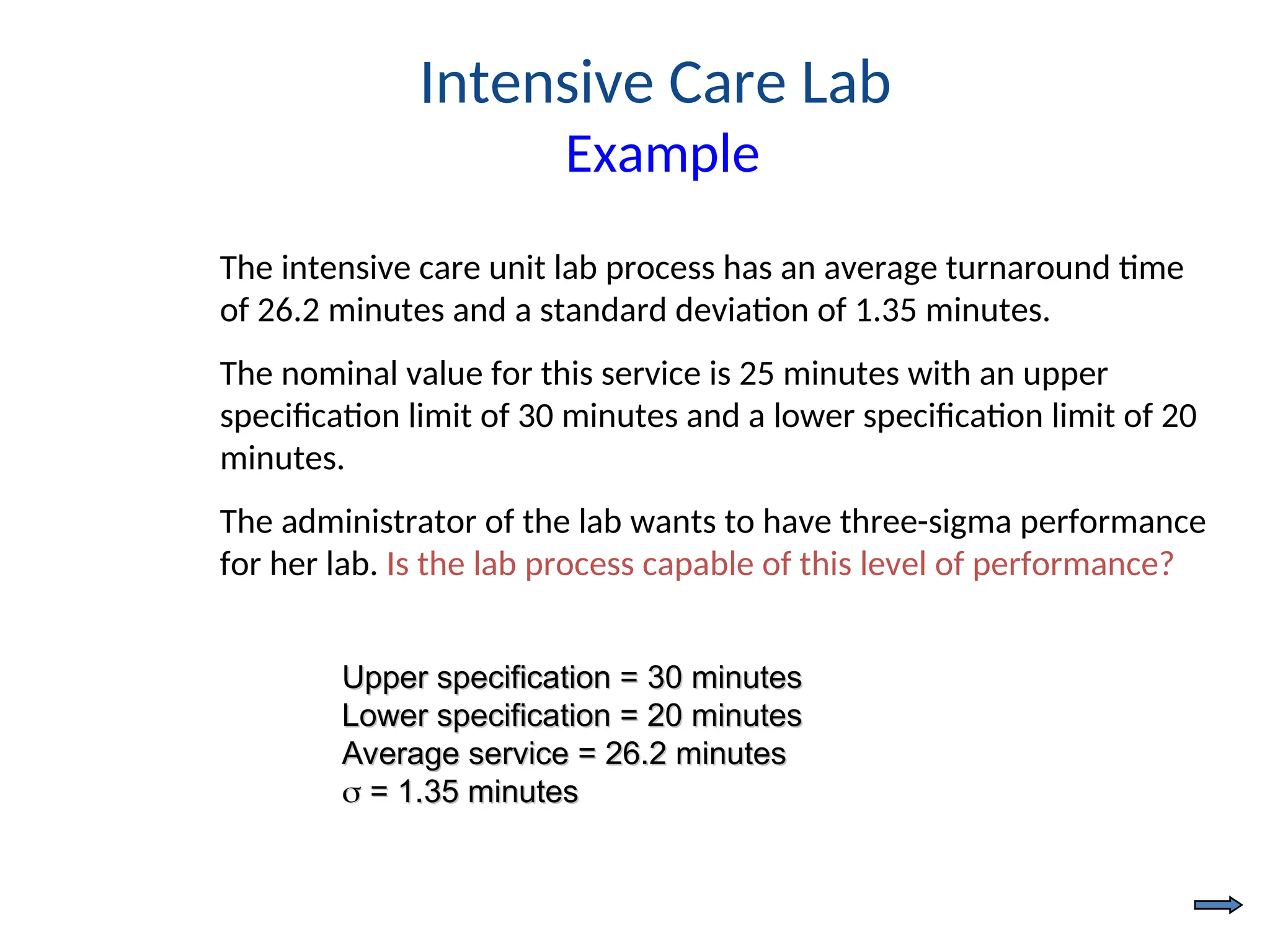

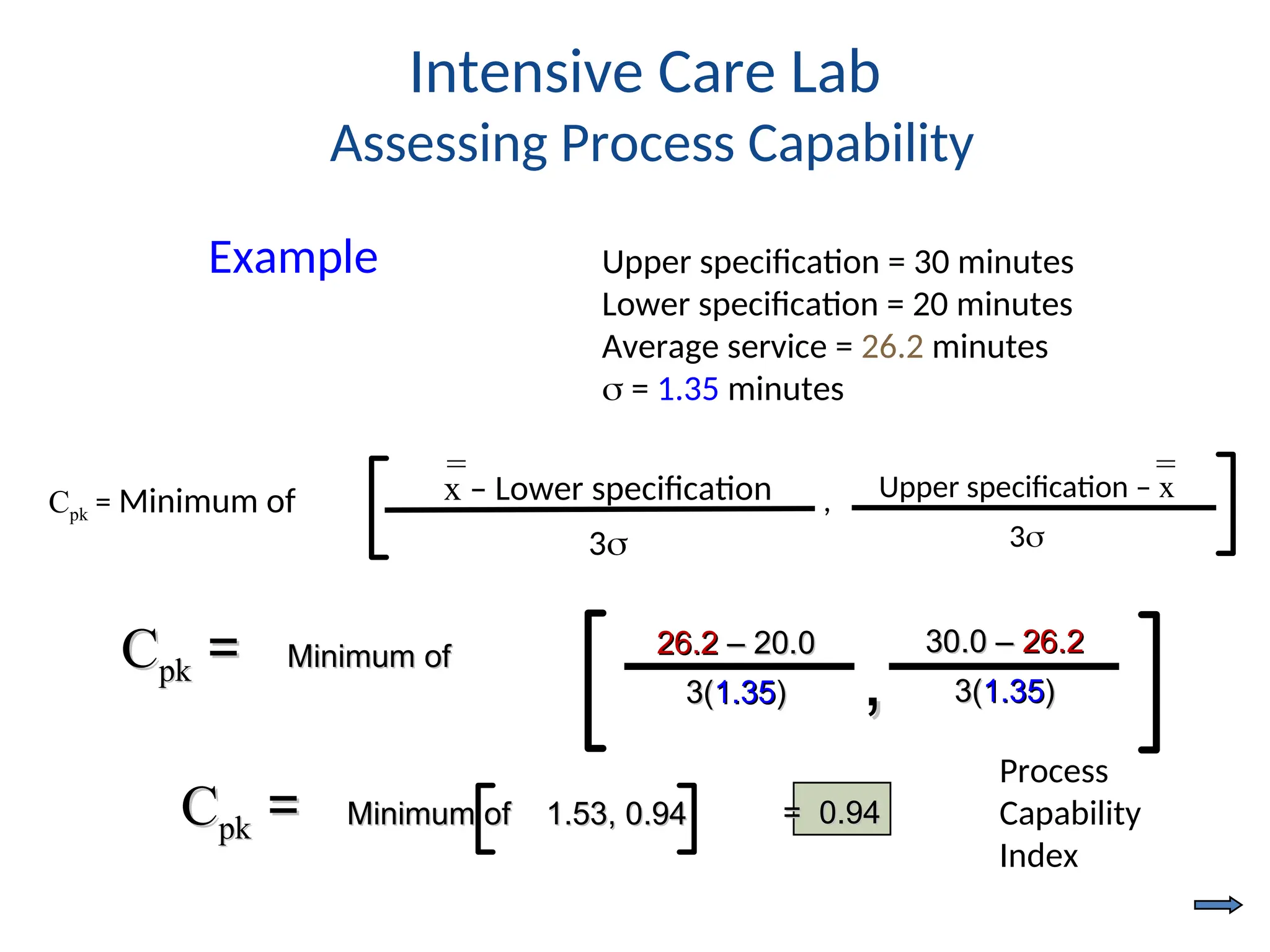

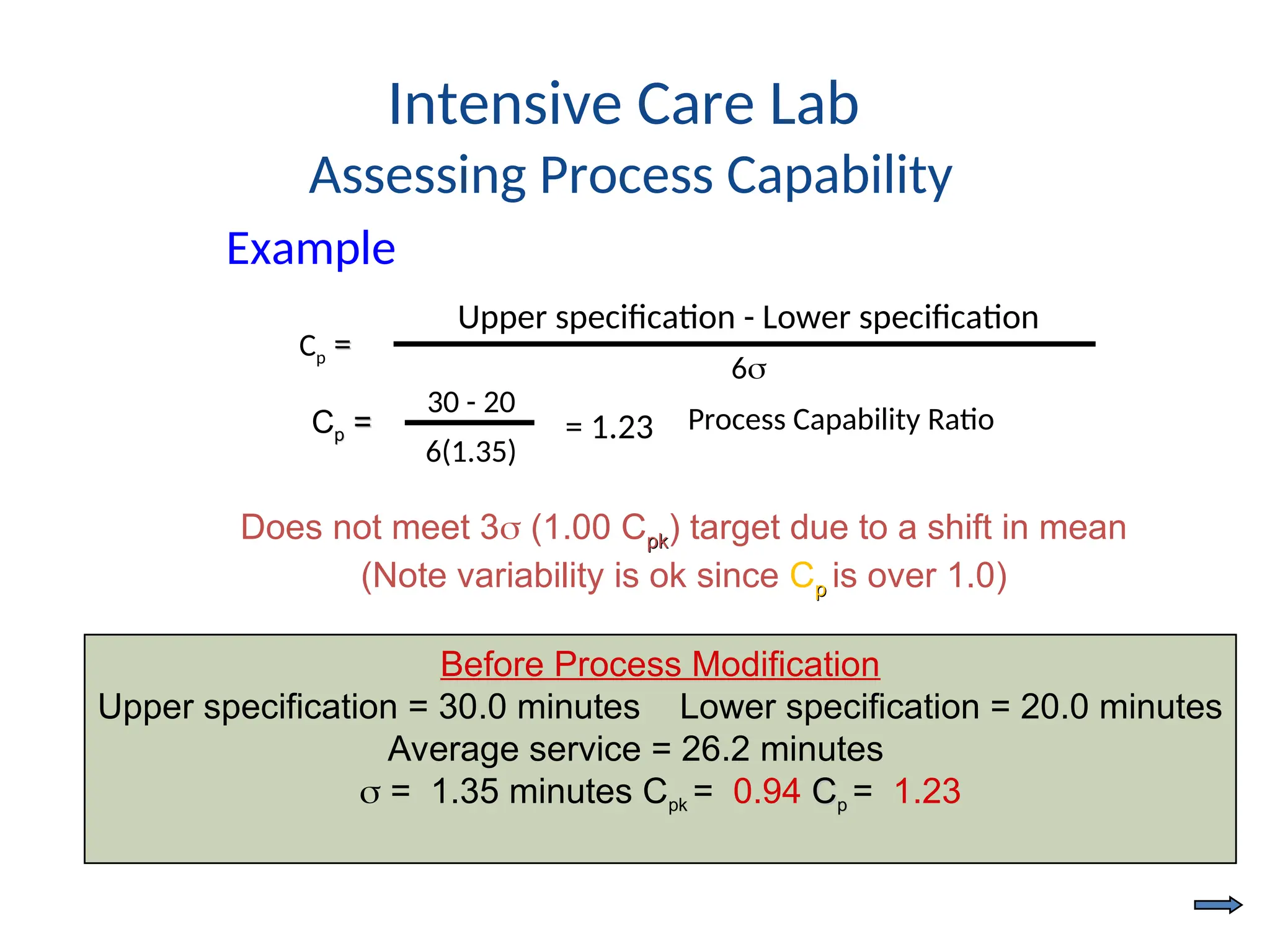

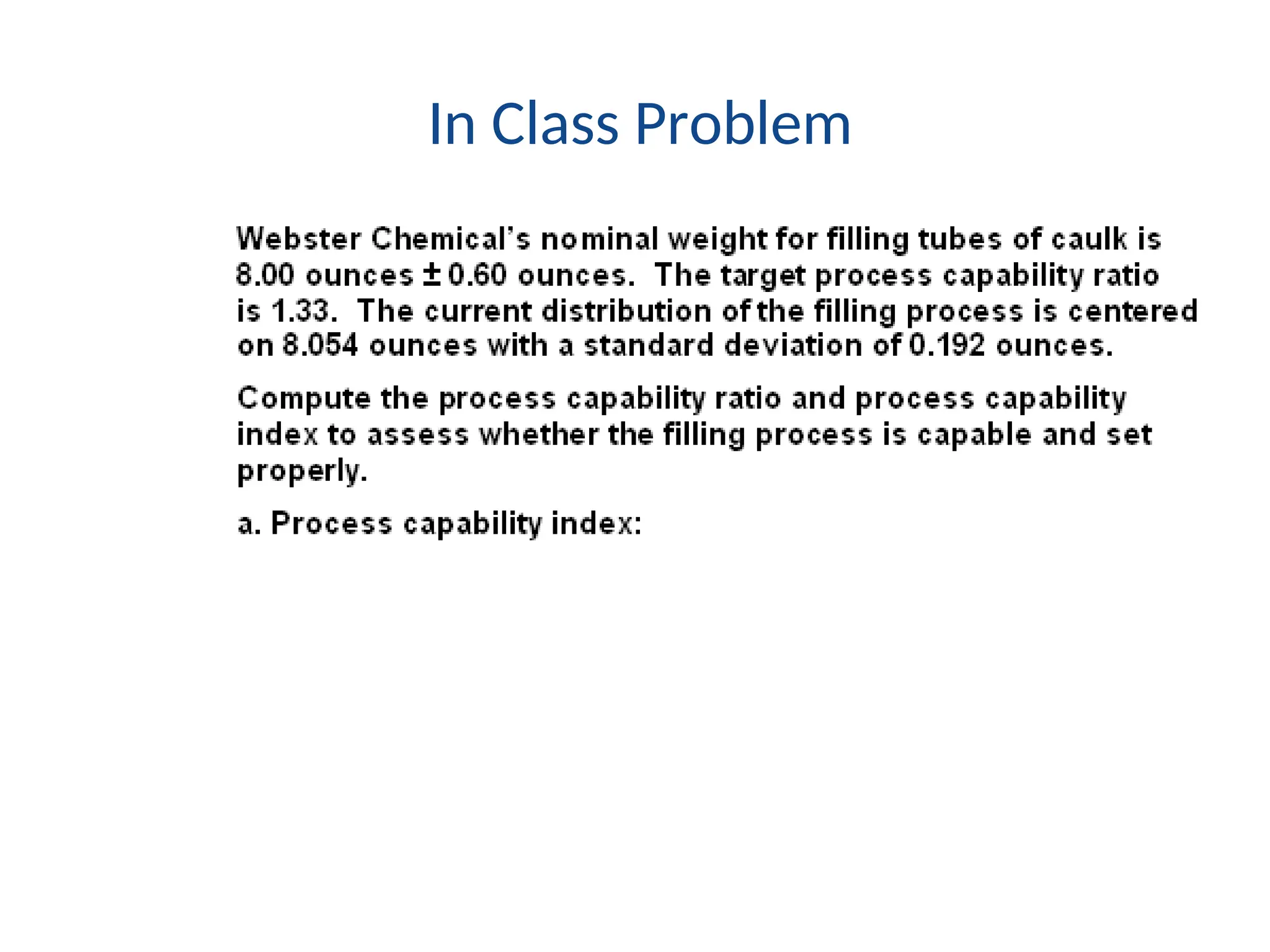

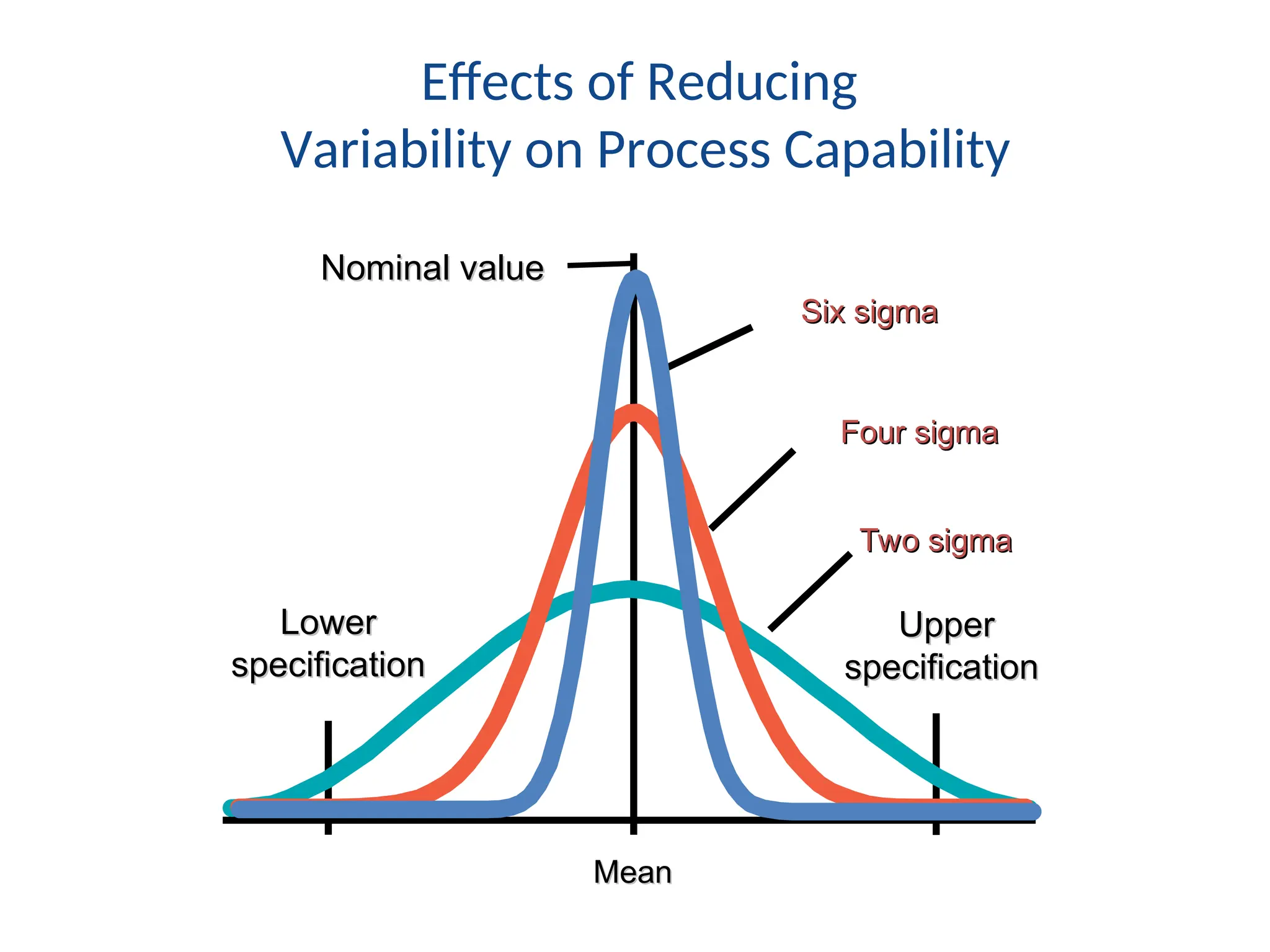

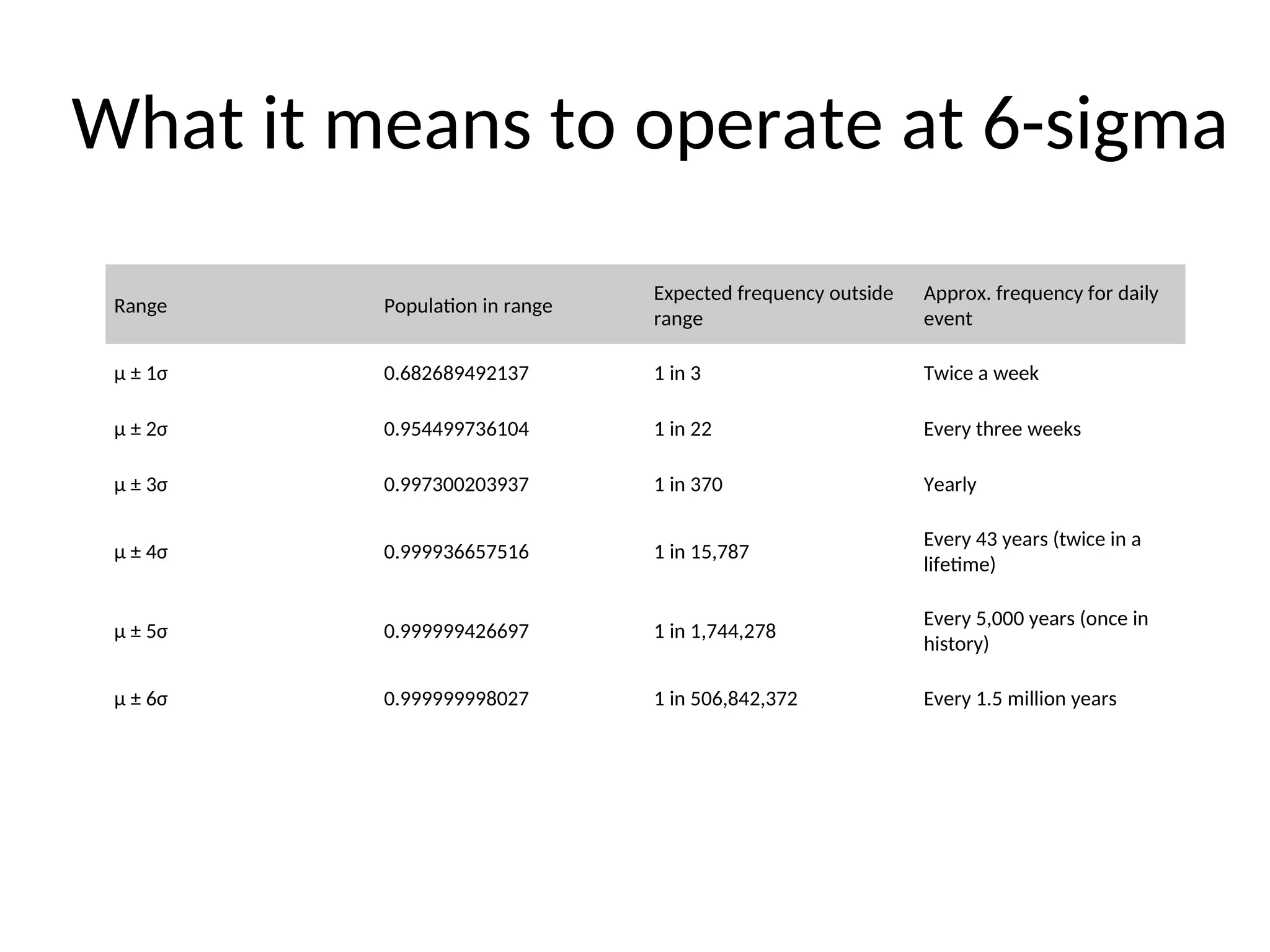

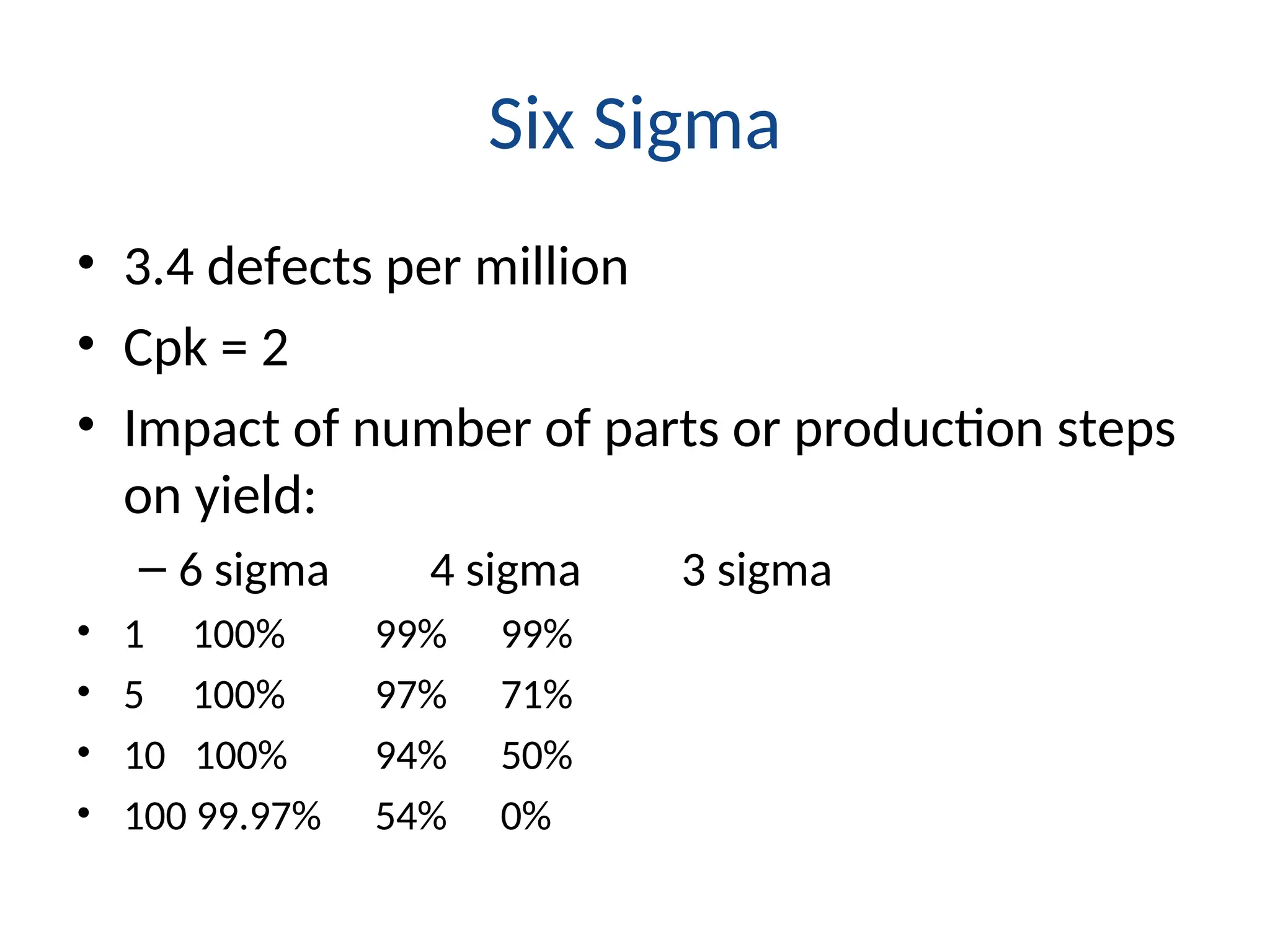

The document discusses statistical control charts, particularly p-charts, which are used to monitor the proportion of defective services or products. It emphasizes the importance of process capability, explaining metrics like the process capability ratio (Cp) and index (Cpk) to measure a process's ability to meet specifications. Additionally, it outlines the Six Sigma methodology for improving processes through a structured approach and highlights standards for quality documentation such as ISO 9000 and 14000.