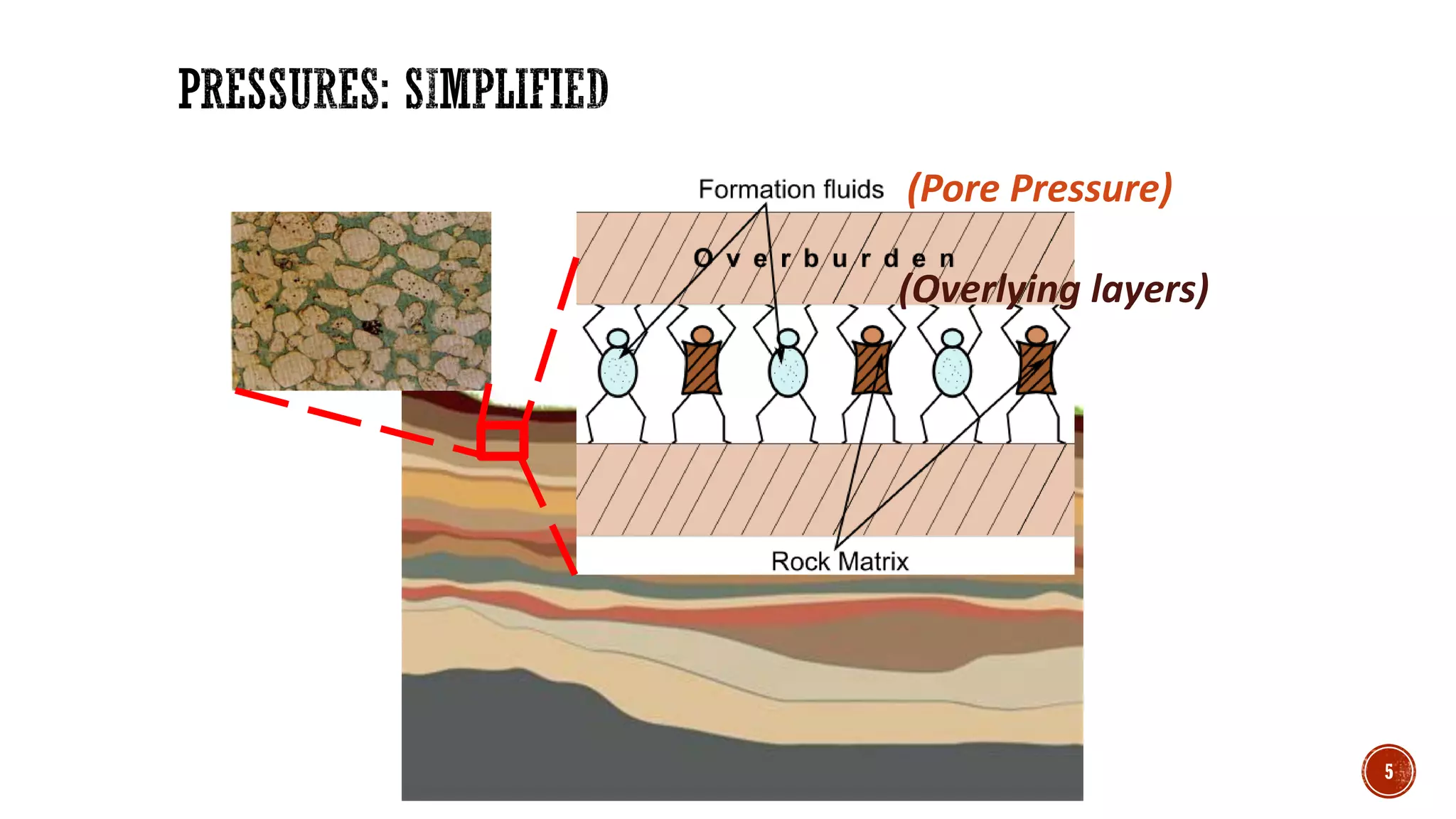

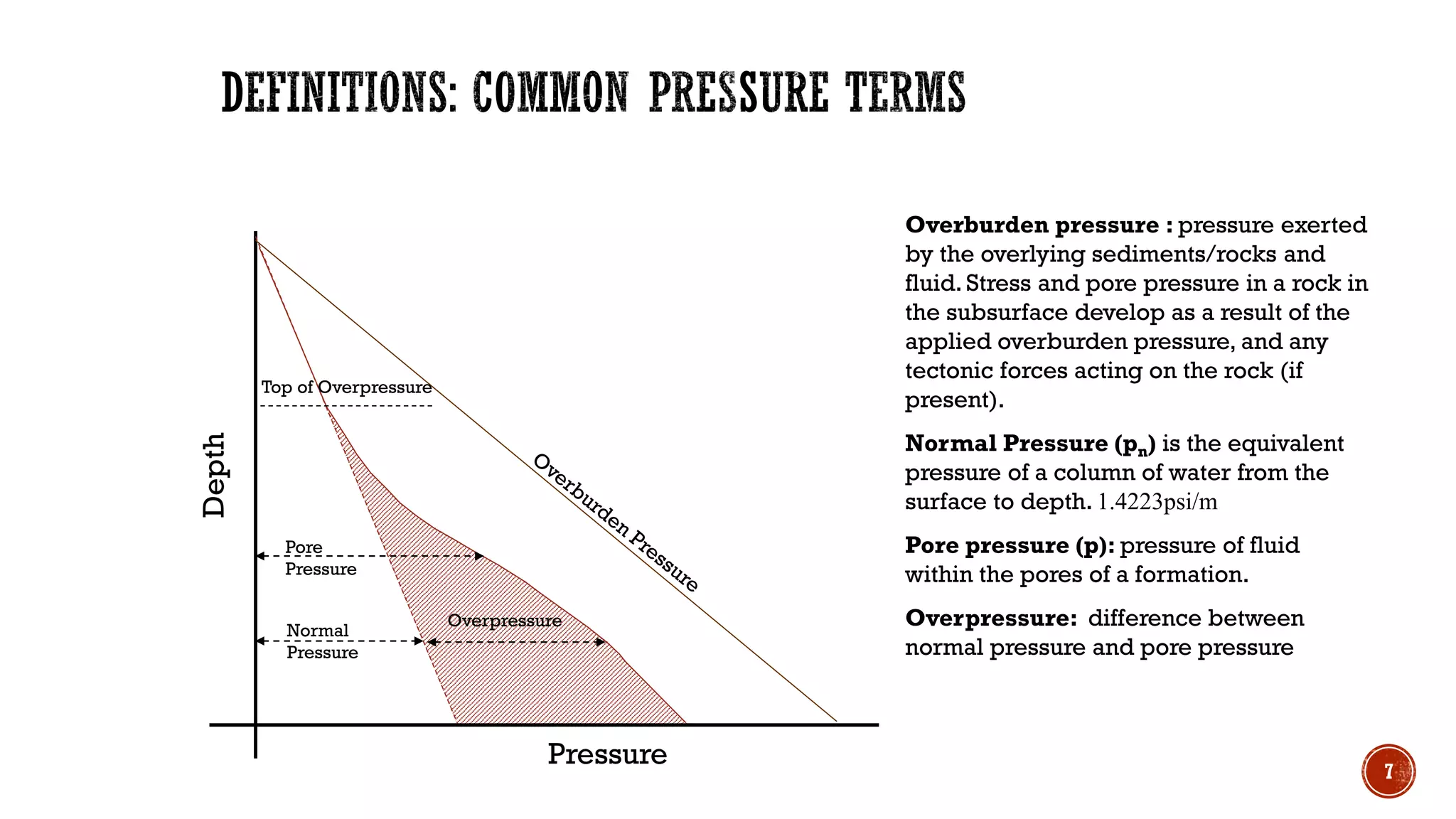

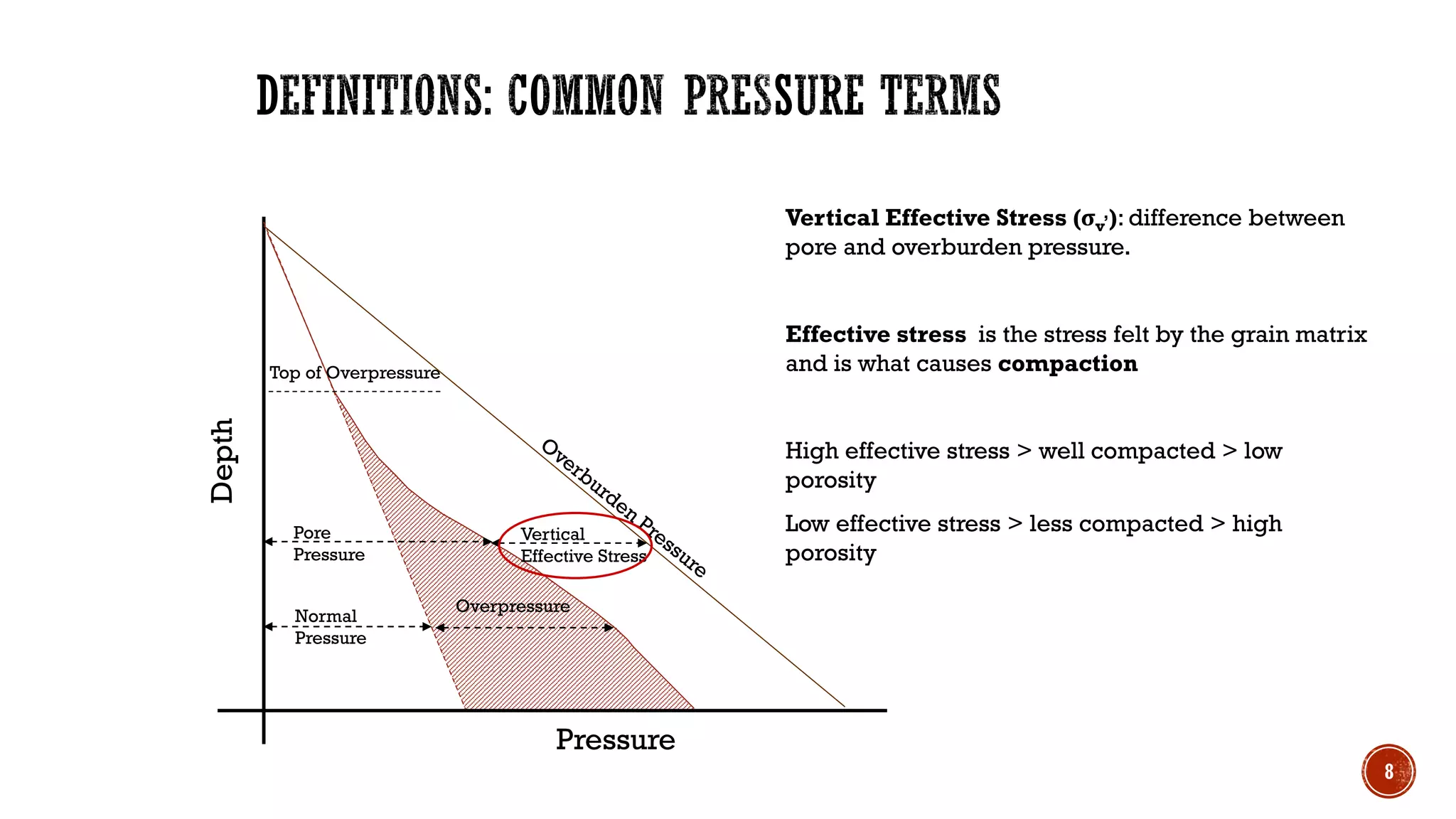

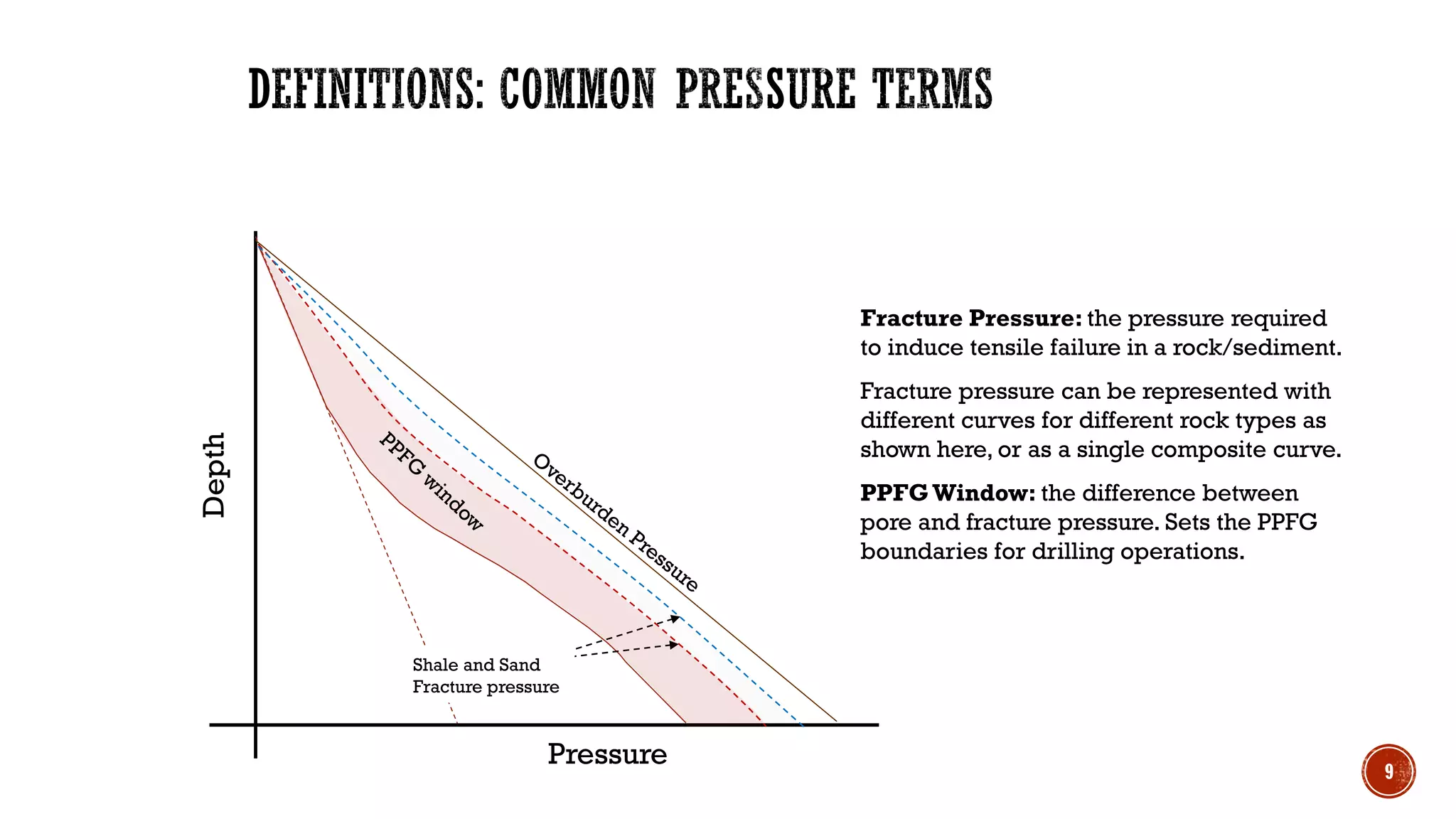

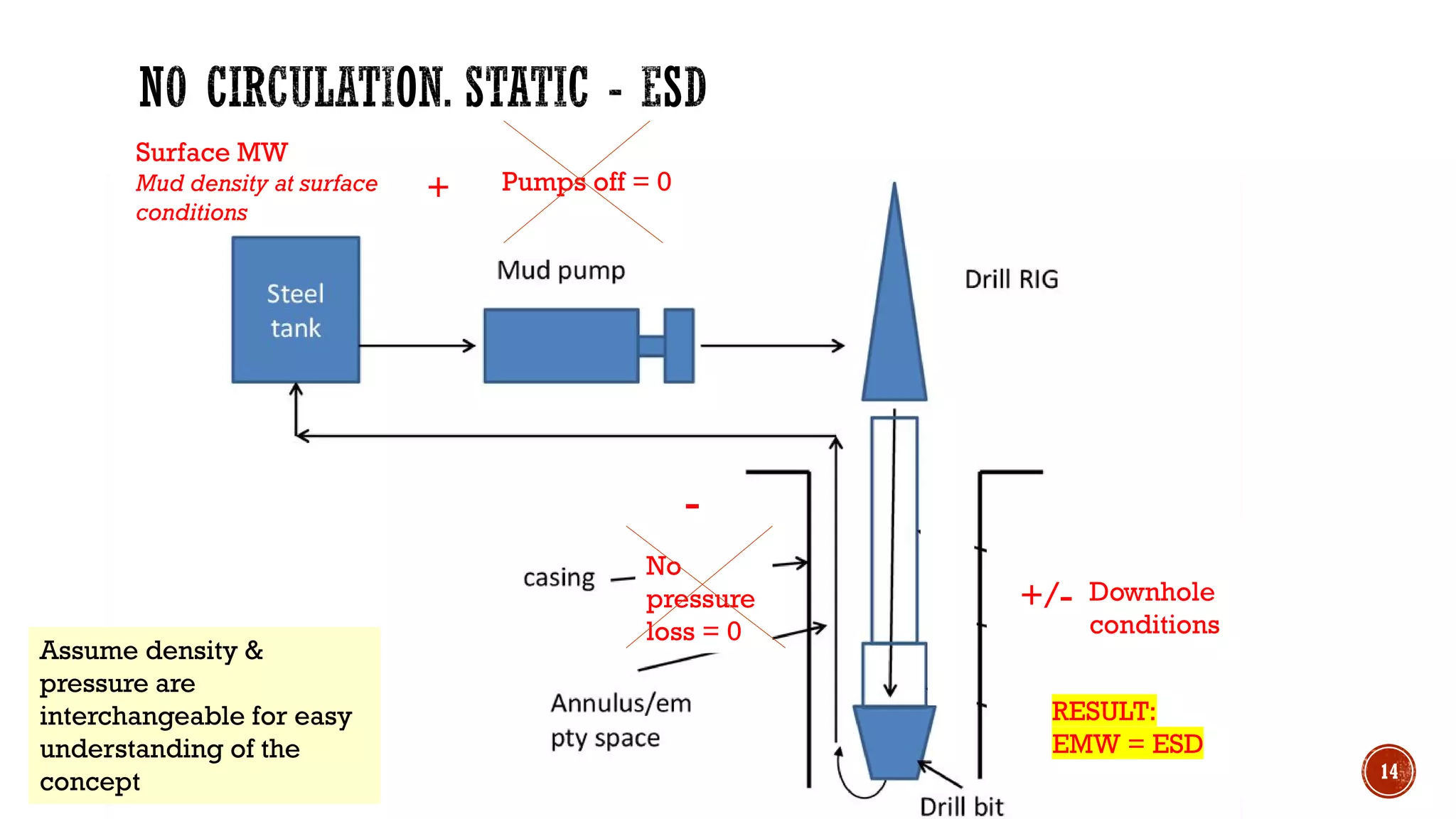

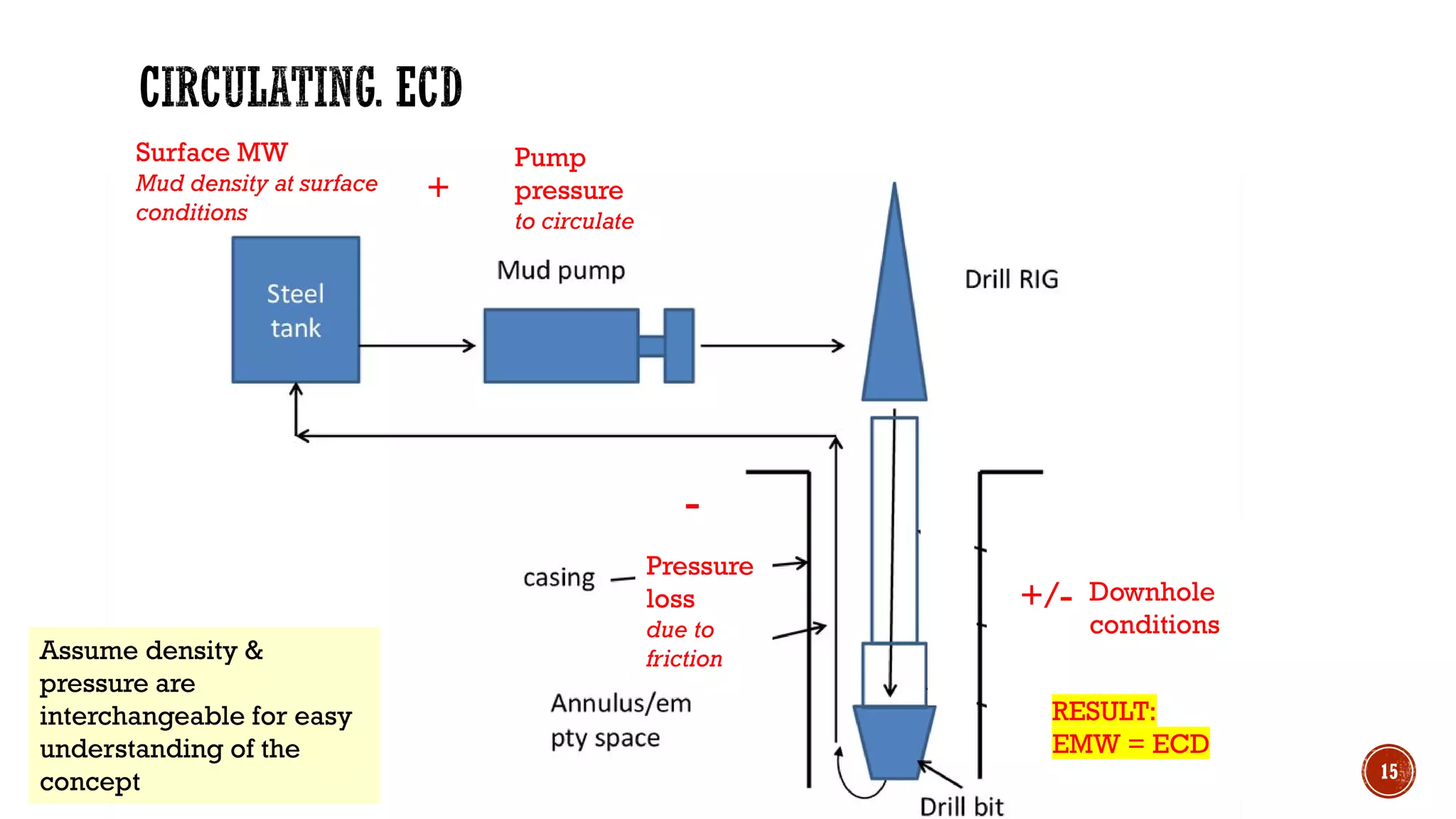

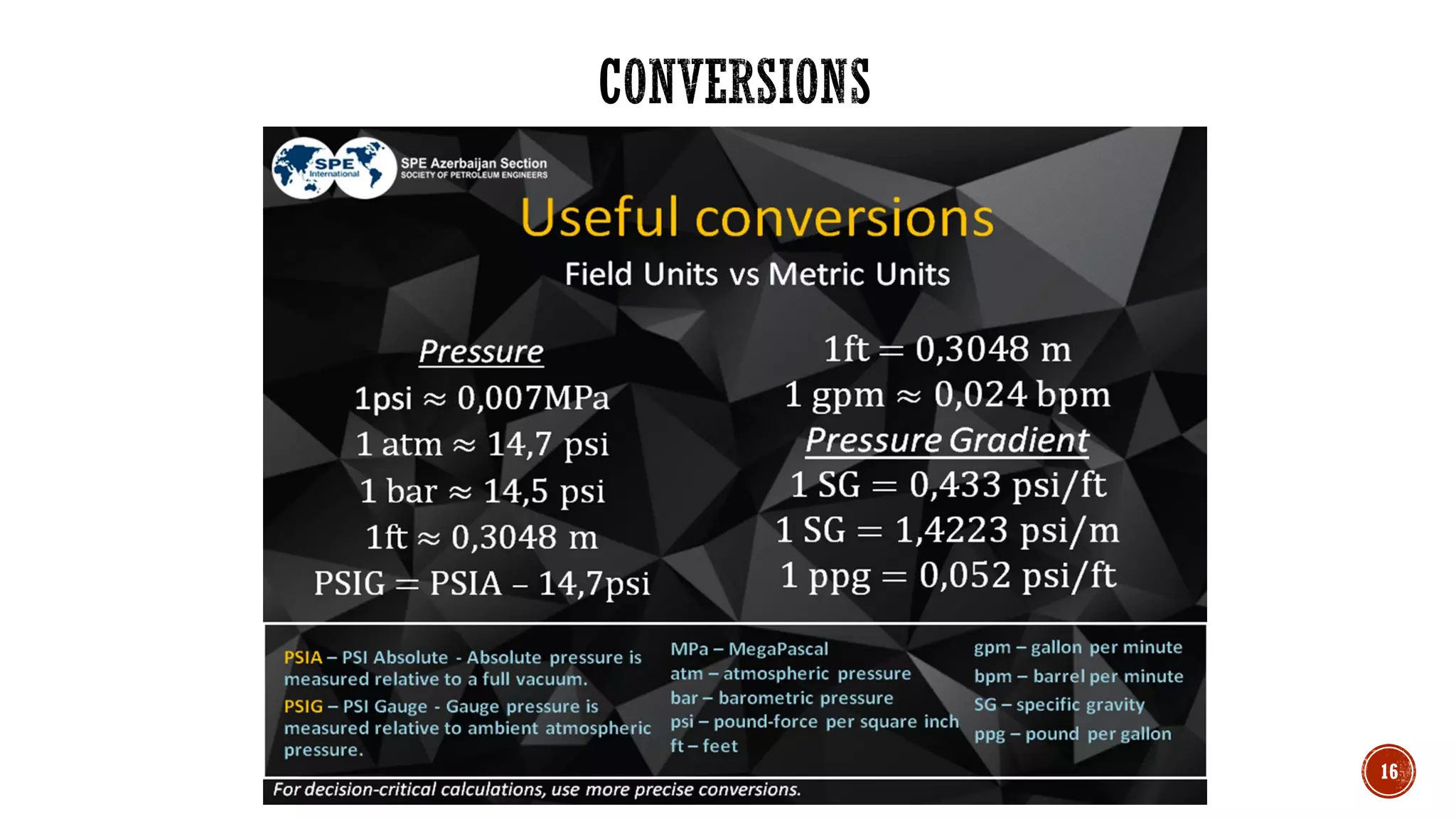

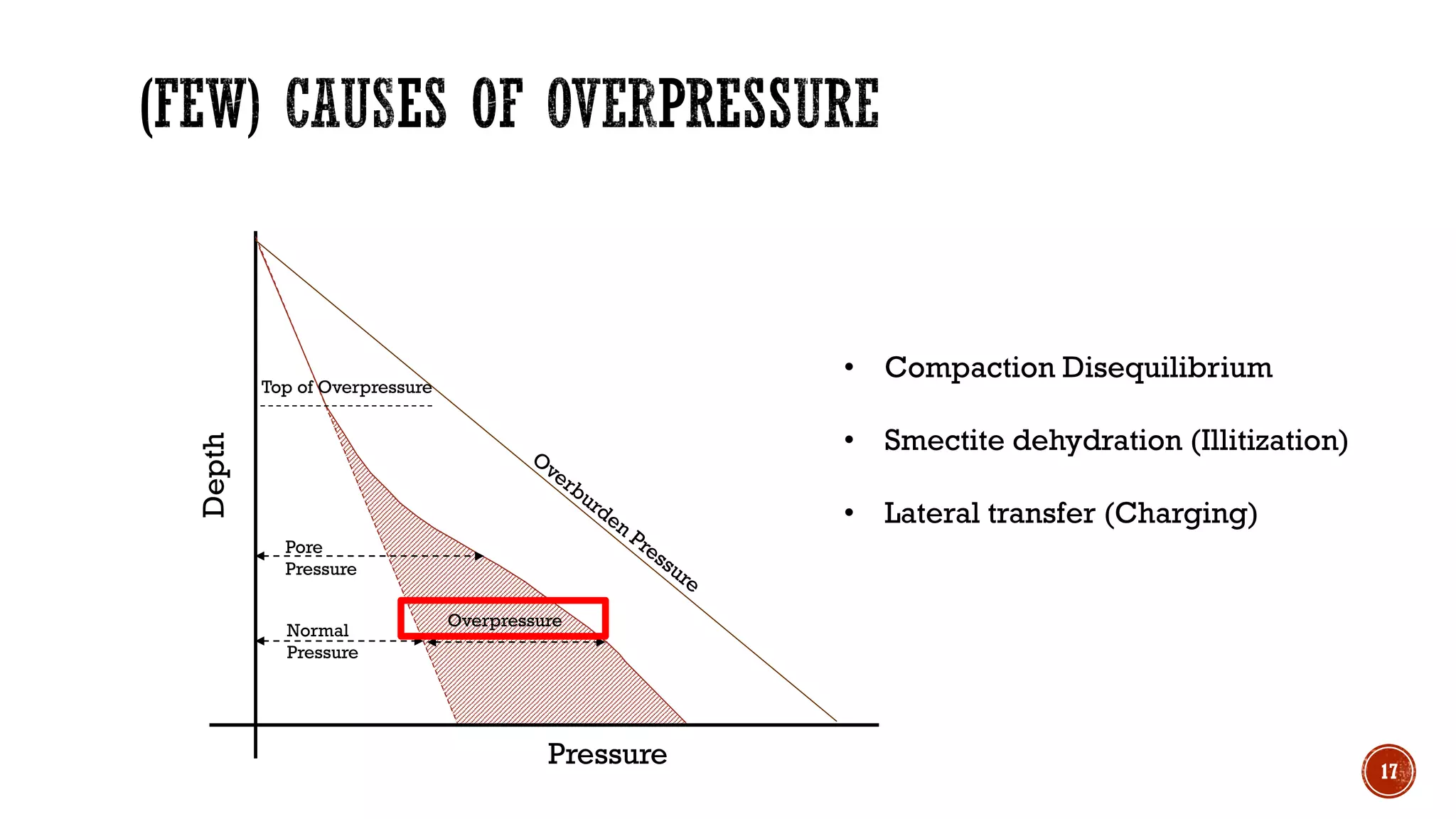

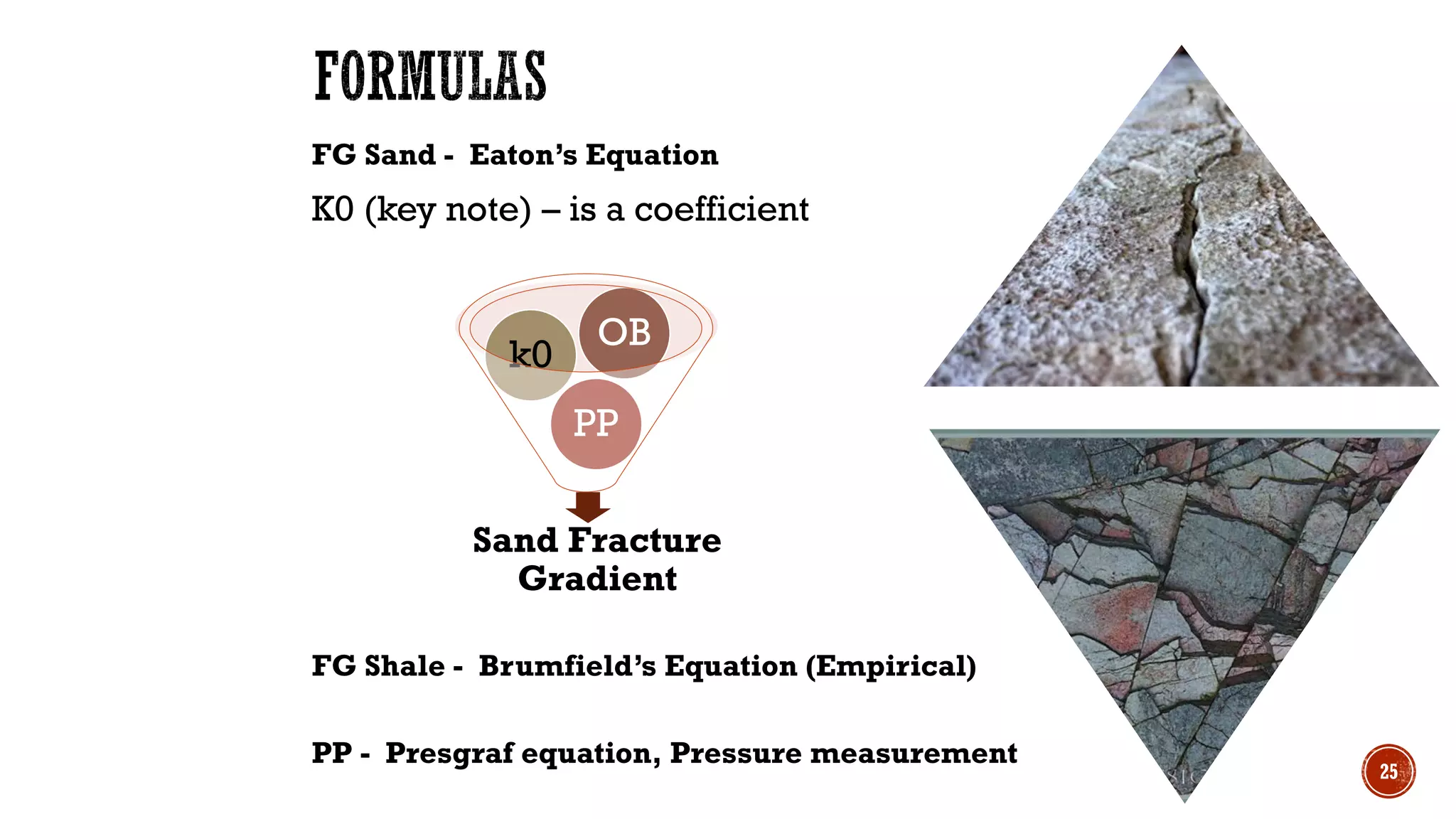

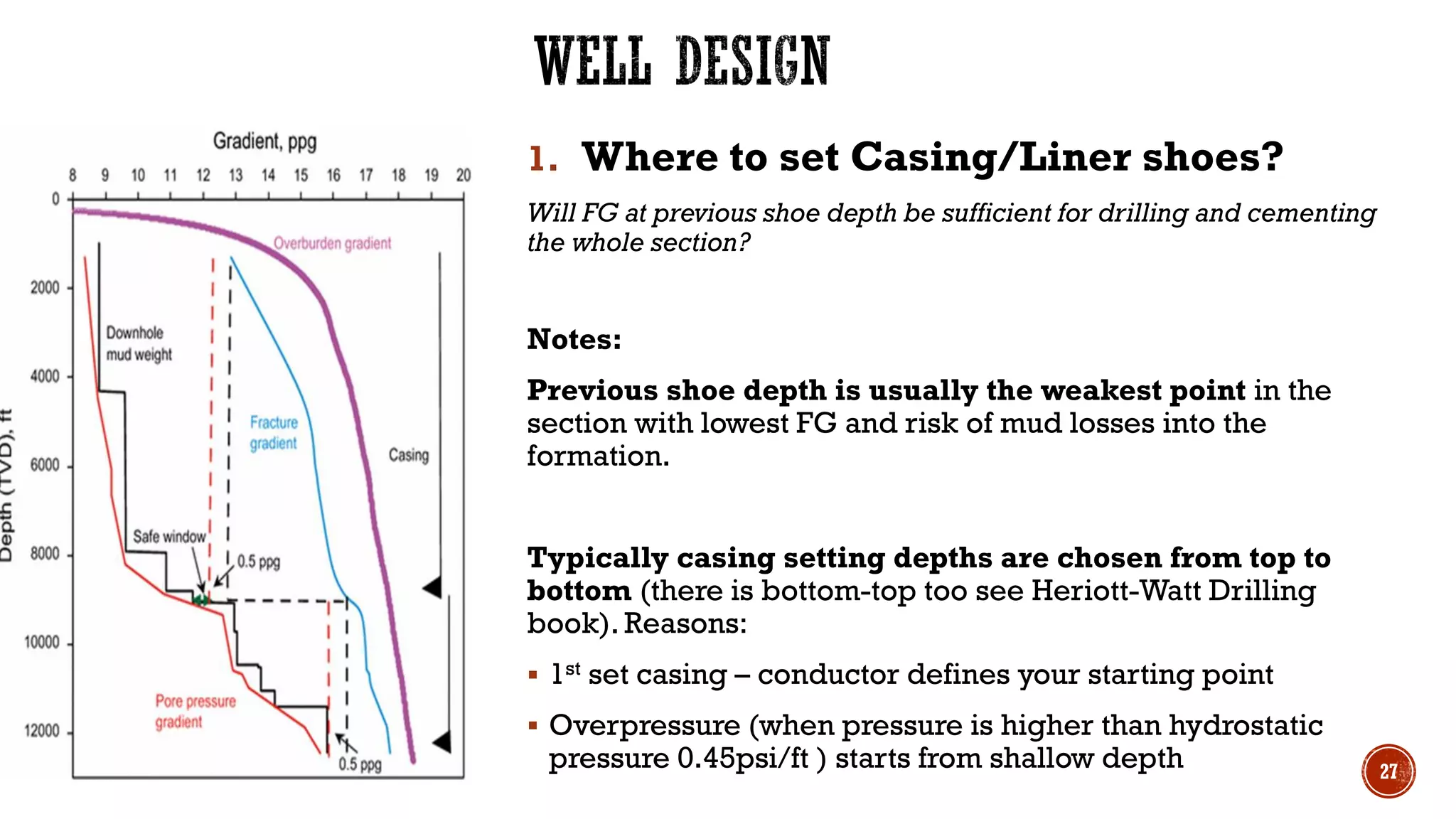

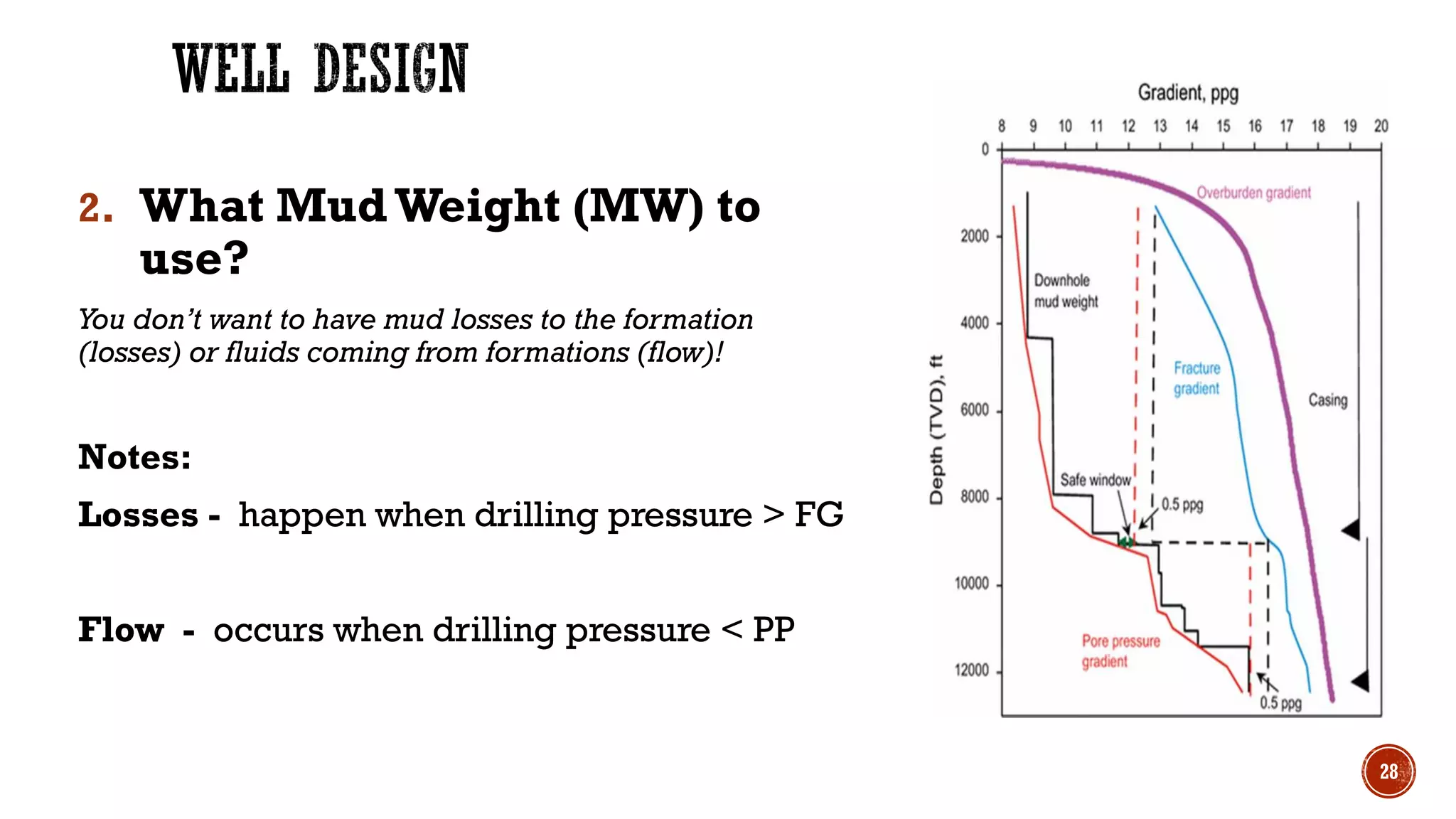

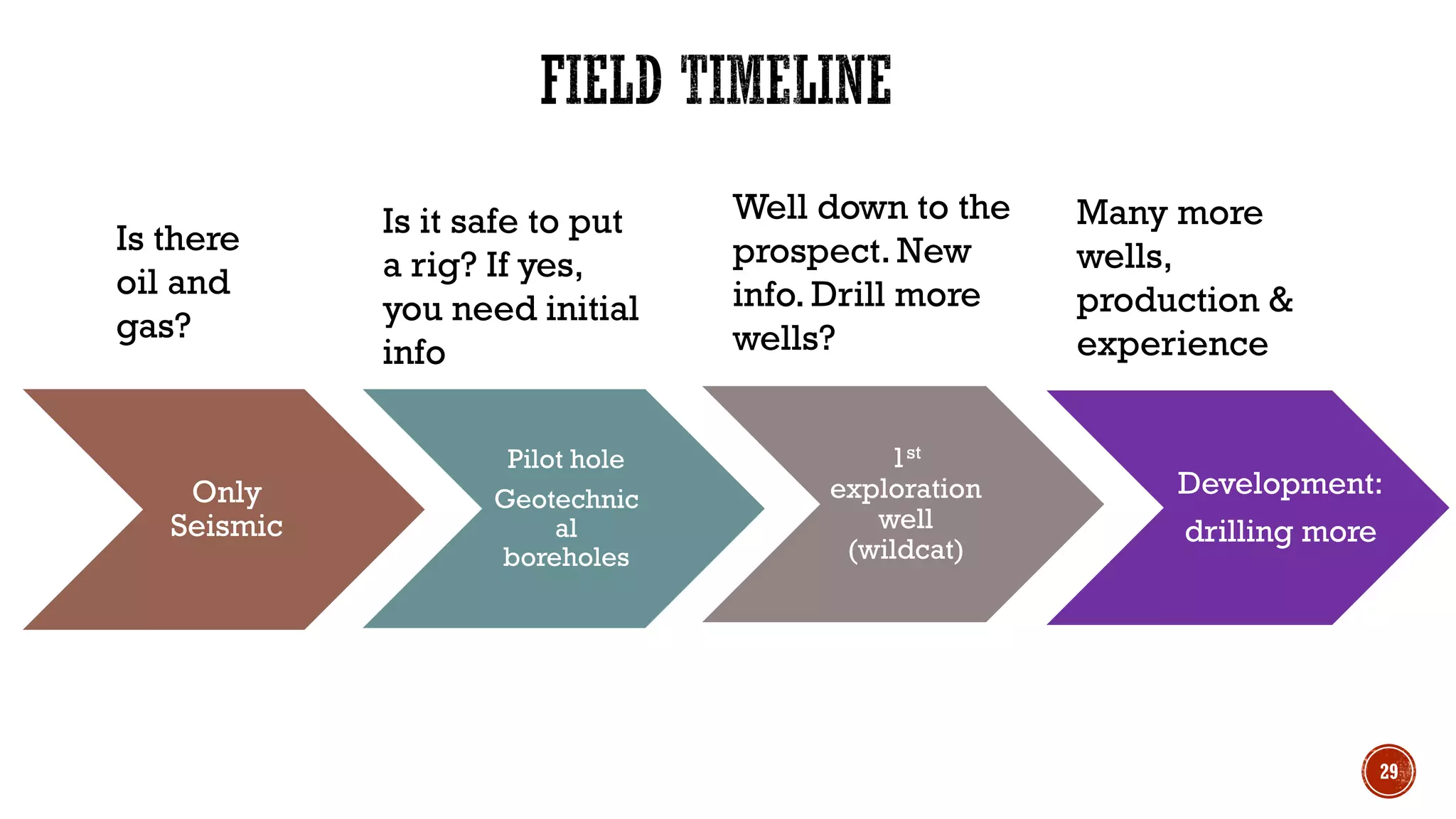

Farida Ismayilova has over 3 years of experience working for BP in drilling geohazards and PPFG specialization. She has a Bachelor's and Master's degree in Petroleum Engineering from Azerbaijan State Oil and Industry University. The presentation provides an overview of PPFG terms and principles, and the role of PPFG in well planning. It discusses basics like pore pressure, fracture gradient, and the PPFG window. It also explains how a PPFG specialist incorporates data from nearby wells to estimate high, base, and low cases for safe well design and mud weight selection.