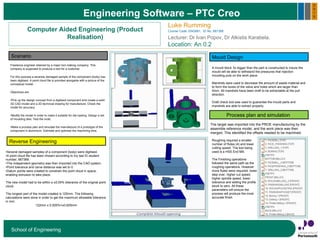

A freelance engineer was retained by a major tool making company to create tools for a customer. The engineer was provided with digitized samples and point cloud data of a severely damaged component to create a 3D CAD model and technical drawing for manufacturing. The engineer then modified the model to make it suitable for die casting and designed moulding dies. Finally, the engineer created a process plan and simulated machining a prototype of the component in aluminum to optimize machining time.