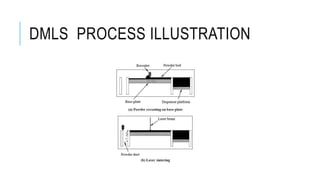

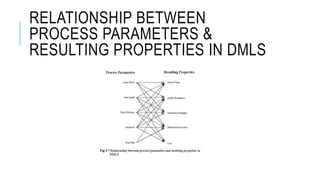

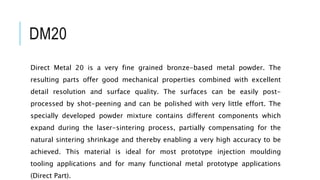

Direct Metal Laser Sintering (DMLS) is a rapid tooling and manufacturing process that creates metal parts layer-by-layer using a high-power laser to sinter metal powders. The process involves creating a 3D CAD model, converting it to .stl format, and then layer slicing for construction on a DMLS machine. DMLS is applicable across various industries, producing complex parts with high accuracy and mechanical properties, particularly using a fine-grained bronze-based powder known as DM20.